Spark Testing on:

[Wikipedia]

[Google]

[Amazon]

Spark testing is a method of determining the general

Spark testing is a method of determining the general

;Wrought iron:

;Wrought iron:

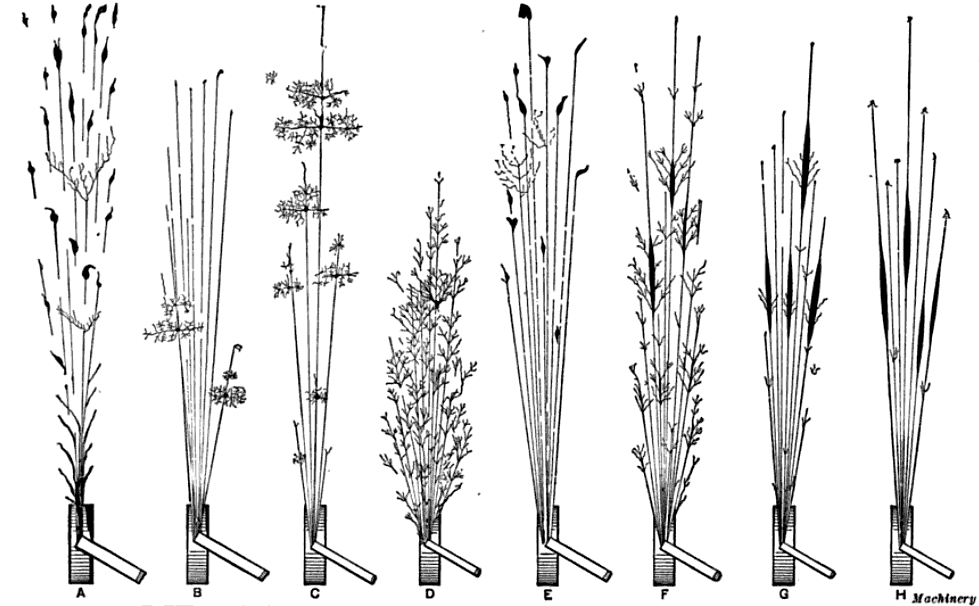

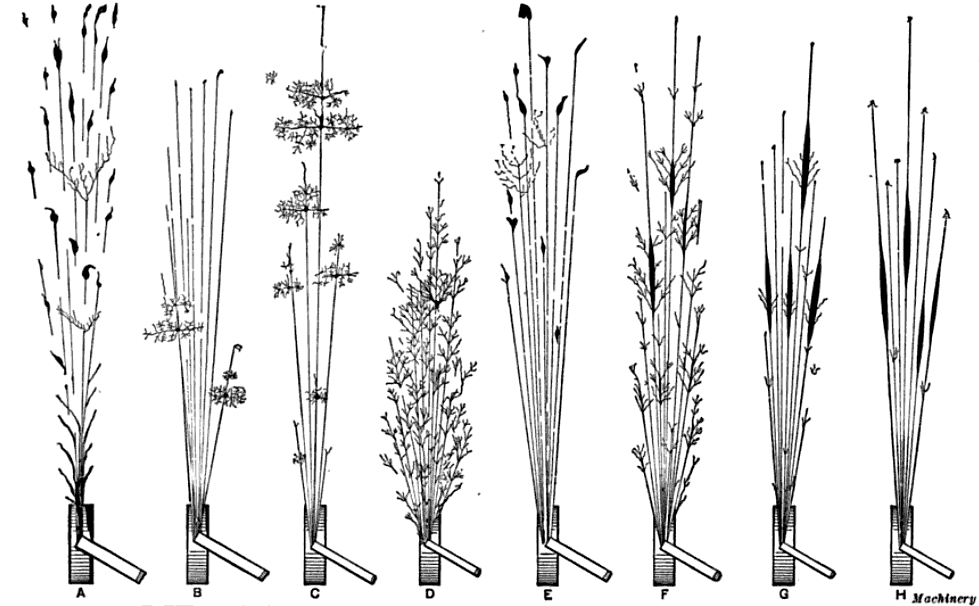

Spark test pictures of various materials

{{Metalworking navbox Ferrous alloys Metalworking

Spark testing is a method of determining the general

Spark testing is a method of determining the general classification Classification is a process related to categorization, the process in which ideas and objects are recognized, differentiated and understood.

Classification is the grouping of related facts into classes.

It may also refer to:

Business, organizat ...

of ferrous

In chemistry, the adjective Ferrous indicates a compound that contains iron(II), meaning iron in its +2 oxidation state, possibly as the divalent cation Fe2+. It is opposed to "ferric" or iron(III), meaning iron in its +3 oxidation state, such a ...

materials. It normally entails taking a piece of metal, usually scrap, and applying it to a grinding wheel

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines.

The wheels are generally made with composite material . This consists of coarse-particle aggregate press ...

in order to observe the sparks emitted.. These sparks can be compared to a chart or to sparks from a known test sample to determine the classification. Spark testing also can be used to sort ferrous materials, establishing the difference from one another by noting whether the spark is the same or different.

Spark testing is used because it is quick, easy, and inexpensive. Moreover, test samples do not have to be prepared in any way, so, often, a piece of scrap is used. The main disadvantage to spark testing is its inability to identify a material positively; if positive identification is required, chemical analysis

Analytical chemistry studies and uses instruments and methods to separate, identify, and quantify matter. In practice, separation, identification or quantification may constitute the entire analysis or be combined with another method. Separati ...

must be used. The spark comparison method also damages the material being tested, at least slightly.

Spark testing most often is used in tool room

Tool and die makers are highly skilled crafters working in the manufacturing, manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, Moldmaker, mold maker, moldmaker or tool jig and die-maker depending ...

s, machine shop

A machine shop or engineering workshop (UK) is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plast ...

s, heat treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also ...

shops, and foundries

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals pr ...

.

Process

Abench grinder

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These t ...

is usually used to create the sparks, but sometimes this is not convenient, so a portable grinder is used. In either case, the grinding wheel must have adequate surface velocity, at least 23 m/s (4500 surface feet per minute

Surface feet per minute (SFPM or SFM) is the combination of a physical quantity (''surface speed'') and an imperial and American customary unit (''feet per minute'' or ''FPM''). It is defined as the number of linear feet that a location on a rota ...

(sfpm)), but should be between 38 and 58 m/s (7500–11,500 sfpm). The wheel should be coarse and hard, therefore aluminium oxide or carborundum

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder and crystal sin ...

often are employed. The test area should be in an area where there is no bright light shining directly into the observer's eyes. Moreover, the grinding wheel and surrounding area should be dark so that the sparks can be observed clearly. The test sample is then touched lightly to the grinding wheel to produce the sparks..

The important spark characteristics are color, volume, nature of the spark, and length. Note that the length is dependent on the amount of pressure applied to the grinding wheel, so this can be a poor comparison tool if the pressure is not exactly the same for the samples. Also, the grinding wheel must be dressed frequently to remove metallic build-up.

Compressed air method

Another less common method for creating sparks is heating up the sample tored heat

The practice of using colours to determine the temperature of a piece of (usually) ferrous metal comes from blacksmithing. Long before thermometers were widely available it was necessary to know what state the metal was in for heat treating it an ...

and then applying compressed air to the sample. The compressed air supplies enough oxygen to ignite the sample and give off sparks. This method is more accurate than using a grinder because it will always give off sparks of the same length for the same sample. The compressed air applies in essence the same "pressure" each time. This makes observations of the spark length a much more reliable characteristic for comparison.

Automated spark testing

Automated spark testing has been developed to remove the reliance upon operator skill and experience, thereby increasing reliability. The system relies uponspectroscopy

Spectroscopy is the field of study that measures and interprets the electromagnetic spectra that result from the interaction between electromagnetic radiation and matter as a function of the wavelength or frequency of the radiation. Matter wa ...

, spectrometry, and other methods to "observe" the spark pattern. It has been found that this system can determine the difference between two materials that give off sparks that are indistinguishable to the human eye.

Spark characteristics

;Wrought iron:

;Wrought iron: Wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

sparks flow out in straight lines. The tails of the sparks widen out near the end, similar to a leaf

A leaf ( : leaves) is any of the principal appendages of a vascular plant stem, usually borne laterally aboveground and specialized for photosynthesis. Leaves are collectively called foliage, as in "autumn foliage", while the leaves, ste ...

..

;Mild steel: Mild steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states:

* no minimum content is specified or required for chromium, cobalt ...

sparks are similar to wrought iron's, except they will have tiny forks and their lengths will vary more. The sparks will be white in color.

;Medium-carbon steel: This steel has more forking than mild steel and a wide variety of spark lengths, with more near the grinding wheel.

;High-carbon steel: High-carbon steel has a bushy spark pattern (much forking) that starts at the grinding wheel. The sparks are not as bright as the medium-carbon steel ones.

;Manganese steel: Manganese

Manganese is a chemical element with the symbol Mn and atomic number 25. It is a hard, brittle, silvery metal, often found in minerals in combination with iron. Manganese is a transition metal with a multifaceted array of industrial alloy use ...

steel has medium length sparks that fork twice before ending.

;High-speed steel: High-speed steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material.

It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that ...

has a faint red spark that sparks at the tip.

;300-series stainless steel: These sparks are not so dense as the carbon steel sparks, do not fork, and are orange to straw in color.

;310-series stainless steel: These sparks are much shorter and thinner than the 300-series sparks. They are red to orange in color and do not fork.

;400-series stainless steel: 400-series sparks are similar to 300-series sparks, but are slightly longer and have forks at the ends of the sparks.

;Cast iron: Cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

has very short sparks that begin at the grinding wheel.

;Nickel and cobalt high-temperature alloys: These sparks are thin and very short, they are dark-red in color, and do not fork.

;Cemented carbide: Cemented carbide

Cemented carbides are a class of hard materials used extensively for cutting tools, as well as in other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use ...

has sparks under 3 inches, which are dark-red in color and do not fork.

;Titanium: Although titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in ...

is a non-ferrous metal, it gives off a great deal of sparks. These sparks are easily distinguishable from ferrous metals, as they are a very brilliant, blinding, white color.

History

In 1909, Max Bermann, an engineer inBudapest

Budapest (, ; ) is the capital and most populous city of Hungary. It is the ninth-largest city in the European Union by population within city limits and the second-largest city on the Danube river; the city has an estimated population ...

, was the first to discover that spark testing can be used reliably to classify ferrous material. He originally claimed to be able to distinguish different types of ferrous materials based on percent carbon and principal alloying elements. Moreover, he claimed to achieve an accuracy of 0.01% carbon content..

Tschorn . produced an exhaustive treatment of spark testing. His book, Spark Atlas of Steels, along with Spark Testing by Gladwin represent the two most comprehensive texts on the subject .

As of the late 1980s, the industrial use of spark testing is not as common as it used to be.. In the early 21st century the availability of portable X-ray fluorescence

X-ray fluorescence (XRF) is the emission of characteristic "secondary" (or fluorescent) X-rays from a material that has been excited by being bombarded with high-energy X-rays or gamma rays. The phenomenon is widely used for elemental analysis ...

equipment largely superseded it in laboratory practice.

See also

*Flame test

A flame test is an analytical procedure used in chemistry to detect the presence of certain elements, primarily metal ions, based on each element's characteristic flame emission spectrum (which may be affected by the presence of chloride ion ...

* Emission spectrum

The emission spectrum of a chemical element or chemical compound is the spectrum of frequencies of electromagnetic radiation emitted due to an electron making a atomic electron transition, transition from a high energy state to a lower energy st ...

References

Bibliography

*. *. *. *. *. *. *. *. *. *.External links

Spark test pictures of various materials

{{Metalworking navbox Ferrous alloys Metalworking