|

Grinding Dresser

A grinding dresser or wheel dresser is a tool to dress (slightly trim) the surface of a grinding wheel. Grinding dressers are used to return a wheel to its original round shape (to true it up), to expose fresh grains for renewed cutting action (including cleaning away clogged areas), or to make a different profile (cross-sectional shape) on the wheel's edge. Utilizing pre-determined dressing parameters will allow the wheel to be conditioned for optimum grinding performance while truing and restoring the form simultaneously. Purpose The objective of ''dressing the wheel'' is to: * True the wheel by knocking abrasive particles from the wheel's surface and making the wheel concentric. This minimizes vibration and improves surface finish, eliminating the vibration of the out-of-balance wheel across the workpiece's surface. It is not unusual for grinding wheels to become out of round with use. This is partially from loaded (clogged) areas of the wheel wearing at different rates from les ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Wheel

Grinding wheels contains abrasive compounds for grinding and abrasive machining operations. Such wheels are also used in grinding machines. The wheels are generally made with composite material . This consists of coarse-particle aggregate pressed and bonded together by a cementing matrix (called the ''bond'' in grinding wheel terminology) to form a solid, circular shape. Various profiles and cross sections are available depending on the intended usage for the wheel. They may also be made from a solid steel or aluminium disc with particles bonded to the surface. Today most grinding wheels are artificial composites made with artificial aggregates, but the history of grinding wheels began with natural composite stones, such as those used for millstones. The manufacture of these wheels is a precise and tightly controlled process, due not only to the inherent safety risks of a spinning disc, but also the composition and uniformity required to prevent that disc from exploding due to t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concentric

In geometry, two or more objects are said to be concentric, coaxal, or coaxial when they share the same center or axis. Circles, regular polygons and regular polyhedra, and spheres may be concentric to one another (sharing the same center point), as may cylinders (sharing the same central axis). Geometric properties In the Euclidean plane, two circles that are concentric necessarily have different radii from each other.. However, circles in three-dimensional space may be concentric, and have the same radius as each other, but nevertheless be different circles. For example, two different meridians of a terrestrial globe are concentric with each other and with the globe of the earth (approximated as a sphere). More generally, every two great circles on a sphere are concentric with each other and with the sphere. By Euler's theorem in geometry on the distance between the circumcenter and incenter of a triangle, two concentric circles (with that distance being zero) are the cir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roundness (object)

Roundness is the measure of how closely the shape of an object approaches that of a mathematically perfect circle. Roundness applies in two dimensions, such as the cross sectional circles along a cylindrical object such as a shaft or a cylindrical roller for a bearing. In geometric dimensioning and tolerancing, control of a cylinder can also include its fidelity to the longitudinal axis, yielding cylindricity. The analogue of roundness in three dimensions (that is, for spheres) is sphericity. Roundness is dominated by the shape's gross features rather than the definition of its edges and corners, or the surface roughness of a manufactured object. A smooth ellipse can have low roundness, if its eccentricity is large. Regular polygons increase their roundness with increasing numbers of sides, even though they are still sharp-edged. In geology and the study of sediments (where three-dimensional particles are most important), roundness is considered to be the measurement of surfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bench Grinder

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding. Depending on the bond and grade of the grinding wheel, it may be used for sharpening cutting tools such as tool bits, drill bits, chisels, and gouges. Alternatively, it may be used to roughly shape metal prior to welding or fitting. A wire brush wheel or buffing wheels can be interchanged with the grinding wheels in order to clean or polish workpieces. Stiff buffing wheels can also be used when deburring is the task at hand. Some buffing machines (buffers) are built on the same concept as bench grinders except for longer housings and arbors with buffing wheels instead of grinding wheels. Bench grinders are standard equipment in met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond Tool

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide. History In '' Natural History'', Pliny wrote "When an '' adamas'' is successfully broken it disintegrates into splinters so small as to be scarcely visible. These are much sought after by engravers of gems and are inserted by them into iron tools because they make hollows in the hardest materials without difficulty." Advantages Diamond is one of the hardest natural materials on earth; much harder than corundum and silicon carbide. Diamond also has high strength, good wear resistance, and a low friction coefficient. So when used as an abrasive, it has many obvious advantages over many other common abrasives. Advantages of diamond grinding tools Diamond can be used to make grinding tools, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tungsten Carbide

Tungsten carbide (chemical formula: WC) is a chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes through sintering for use in industrial machinery, cutting tools, chisels, abrasives, armor-piercing shells and jewelry. Tungsten carbide is approximately twice as stiff as steel, with a Young's modulus of approximately 530–700 GPa, and is double the density of steel—nearly midway between that of lead and gold. It is comparable with corundum (α-) in hardness and can be polished and finished only with abrasives of superior hardness such as cubic boron nitride and diamond powder, wheels and compounds. Naming Historically referred to as Wolfram, ''Wolf Rahm'', wolframite ore was then later carburized and cemented with a binder creating a composite now called "tungsten carbide". Tungsten is Swedish for "heavy stone". Col ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gymbal

A gimbal is a pivoted support that permits rotation of an object about an axis. A set of three gimbals, one mounted on the other with orthogonal pivot axes, may be used to allow an object mounted on the innermost gimbal to remain independent of the rotation of its support (e.g. vertical in the first animation). For example, on a ship, the gyroscopes, shipboard compasses, stoves, and even drink holders typically use gimbals to keep them upright with respect to the horizon despite the ship's pitching and rolling. The gimbal suspension used for mounting compasses and the like is sometimes called a Cardan suspension after Italian mathematician and physicist Gerolamo Cardano (1501–1576) who described it in detail. However, Cardano did not invent the gimbal, nor did he claim to. The device has been known since antiquity, first described in the 3rd c. BC by Philo of Byzantium, although some modern authors support the view that it may not have a single identifiable inventor. Histo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ice Skate

Ice skates are metal blades attached underfoot and used to propel the bearer across a sheet of ice while ice skating. The first ice skates were made from leg bones of horse, ox or deer, and were attached to feet with leather straps. These skates required a pole with a sharp metal spike that was used for pushing the skater forward, unlike modern bladed skates. Modern skates come in many different varieties, which are chosen depending on the nature of the requirements needed for the skating activity. They are worn recreationally in ice rinks or on frozen bodies of water across the globe and are used as footwear in many sports, including figure skating, bandy, ice hockey, ringette, rink bandy, rinkball, speed skating and tour skating. History According to a study done by Federico Formenti, University of Oxford, and Alberto Minetti, University of Milan, Finns were the first to develop ice skates some 5,000 years ago from animal bones. This was important for the Finnish populations ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

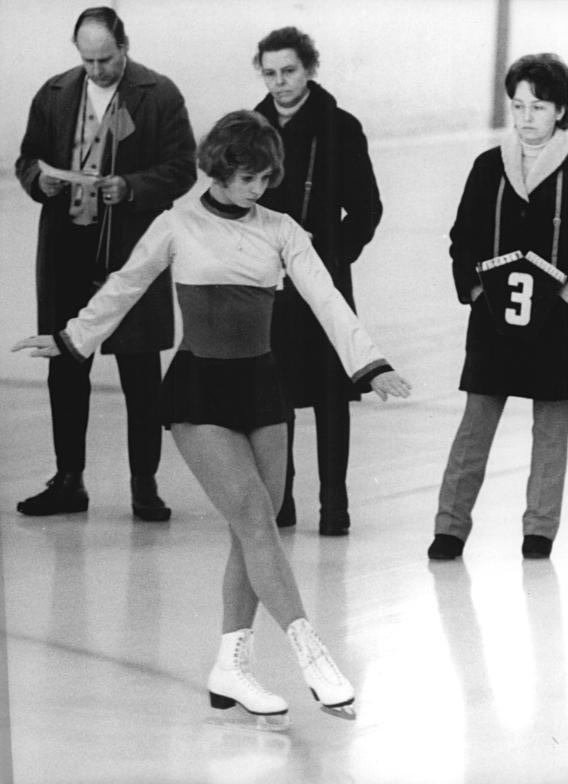

Compulsory Figures

Compulsory figures or school figures were formerly a segment of figure skating, and gave the sport its name. They are the "circular patterns which skaters trace on the ice to demonstrate skill in placing clean turns evenly on round circles". For approximately the first 50 years of figure skating as a sport, until 1947, compulsory figures made up 60 percent of the total score at most competitions around the world. These figures continued to dominate the sport, although they steadily declined in importance, until the International Skating Union (ISU) voted to discontinue them as a part of competitions in 1990. Learning and training in compulsory figures instilled discipline and control; some in the figure skating community considered them necessary to teach skaters basic skills. Skaters would train for hours to learn and execute them well, and competing and judging figures would often take up to eight hours during competitions. Skaters traced compulsory figures, and were judged acco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |