metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

techniques involving very large strains typically involving a complex stress state or high shear, resulting in a high defect density and equiaxed "ultrafine" grain

A grain is a small, hard, dry fruit ( caryopsis) – with or without an attached hull layer – harvested for human or animal consumption. A grain crop is a grain-producing plant. The two main types of commercial grain crops are cereals and legu ...

(UFG) size ( d < 500 nm) or nanocrystalline

A nanocrystalline (NC) material is a polycrystalline material with a crystallite size of only a few nanometers. These materials fill the gap between amorphous materials without any long range order and conventional coarse-grained materials. Def ...

(NC) structure (d < 100 nm).

History

The significance of SPD was known from the ancient times, at least during the transition from the Bronze Age to the Iron Age, when repeated hammering and folding was employed for processing strategic tools such as swords. The development of the principles underlying SPD techniques goes back to the pioneering work of P.W. Bridgman atHarvard University

Harvard University is a private Ivy League research university in Cambridge, Massachusetts. Founded in 1636 as Harvard College and named for its first benefactor, the Puritan clergyman John Harvard, it is the oldest institution of high ...

in the 1930s. This work concerned the effects on solids of combining large hydrostatic pressures with concurrent shear deformation and it led to the award of the Nobel Prize

The Nobel Prizes ( ; sv, Nobelpriset ; no, Nobelprisen ) are five separate prizes that, according to Alfred Nobel's will of 1895, are awarded to "those who, during the preceding year, have conferred the greatest benefit to humankind." Alfre ...

in Physics in 1946. Very successful early implementations of these principles, described in more detail below, are the processes of equal-channel angular pressing (ECAP) developed by V.M. Segal and co-workers in Minsk in the 1970s and high-pressure torsion, derived from Bridgman's work, but not widely developed until the 1980s at the Russian Institute of Metals Physics in modern-day Yekaterinburg

Yekaterinburg ( ; rus, Екатеринбург, p=jɪkətʲɪrʲɪnˈburk), alternatively romanized as Ekaterinburg and formerly known as Sverdlovsk ( rus, Свердло́вск, , svʲɪrˈdlofsk, 1924–1991), is a city and the administrat ...

.

Some definitions of SPD describe it as a process in which high strain is applied without any significant change in the dimensions of the workpiece, resulting in a large hydrostatic pressure

Fluid statics or hydrostatics is the branch of fluid mechanics that studies the condition of the equilibrium of a floating body and submerged body " fluids at hydrostatic equilibrium and the pressure in a fluid, or exerted by a fluid, on an i ...

component. However, the mechanisms that lead to grain refinement in SPD are the same as those originally developed for mechanical alloying, a powder process that has been characterized as "severe plastic deformation" by authors as early as 1983. Additionally, some more recent processes such as asymmetric rolling, do result in a change in the dimensions of the workpiece, while still producing an ultrafine grain structure. The principles behind SPD have even been applied to surface treatments.

Methods

Equal channel angular extrusion

Equal channel angular extrusion (ECAE, sometimes called Equal channel angular pressing, ECAP) was developed in the 1970s. In this process, a metal billet is pressed through an angled (typically 90 degrees) channel. To achieve optimal results, the process may be repeated several times, changing the orientation of the billet with each pass. This produces a uniform shear throughout the bulk of the material.

Equal channel angular extrusion (ECAE, sometimes called Equal channel angular pressing, ECAP) was developed in the 1970s. In this process, a metal billet is pressed through an angled (typically 90 degrees) channel. To achieve optimal results, the process may be repeated several times, changing the orientation of the billet with each pass. This produces a uniform shear throughout the bulk of the material.

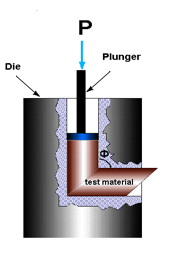

High pressure torsion

High pressure torsion (HPT) can be traced back to the experiments that won

High pressure torsion (HPT) can be traced back to the experiments that won Percy Bridgman

Percy Williams Bridgman (April 21, 1882 – August 20, 1961) was an American physicist who received the 1946 Nobel Prize in Physics for his work on the physics of high pressures. He also wrote extensively on the scientific method and on other as ...

the 1946 Nobel Prize in Physics

)

, image = Nobel Prize.png

, alt = A golden medallion with an embossed image of a bearded man facing left in profile. To the left of the man is the text "ALFR•" then "NOBEL", and on the right, the text (smaller) "NAT•" then " ...

, though its use in metal processing is considerably more recent. In this method, a disk of the material to be strained is placed between 2 anvils. A large compressive stress (typically several gigapascal

The pascal (symbol: Pa) is the unit of pressure in the International System of Units (SI), and is also used to quantify internal pressure, stress, Young's modulus, and ultimate tensile strength. The unit, named after Blaise Pascal, is defined ...

s) is applied, while one anvil is rotated to create a torsion force. HPT can be performed unconstrained, in which the material is free to flow outward, fully constrained, or to some degree between in which outward flow is allowed, but limited.

Accumulative roll bonding

In accumulative roll bonding (ARB), 2 sheets of the same material are stacked, heated (to below the recrystallization temperature), and rolled, bonding the 2 sheets together. This sheet is cut in half, the 2 halves are stacked, and the process is repeated several times. Compared to other SPD processes, ARB has the benefit that it does not require specialized equipment or tooling, only a conventional rolling mill. However, the surfaces to be joined must be well-cleaned before rolling to ensure good bonding.Repetitive corrugation and straightening

Repetitive corrugation and straightening (RCS) is a severe plastic deformation technique used to process sheet metals. In RCS, a sheet is pressed between two corrugated dies followed by pressing between two flat dies. RCS has gained wide popularity to produce fine grained sheet metals. Endeavors to improve this technique lead to introduce Repetitive Corrugation and Straightening by Rolling (RCSR), a novel SPD method. Applicability of this new method approved in the various materials.Asymmetric rolling

In asymmetric rolling (ASR), a rolling mill is modified such that one roll has a higher velocity than the other. This is typically done with either independent speed control or by using rolls of different size. This creates a region in which the frictional forces on the top and bottom of the sheet being rolled are opposite, creating shear stresses throughout the material in addition to the normal compressive stress from rolling. Unlike other SPD processes, ASR does not maintain the same net shape, but the effect on the microstructure of the material is similar.Mechanical alloying

Mechanical alloying/milling (MA/MM) performed in a high-energyball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done ...

such as a shaker mill or planetary mill will also induce severe plastic deformation in metals. During milling, particles are fractured and cold welded together, resulting in large deformations. The end product is generally a powder that must then be consolidated in some way (often using other SPD processes), but some alloys have the ability to consolidate ''in-situ'' during milling. Mechanical alloying also allows powders of different metals to be alloyed together during processing.

Surface treatments

More recently, the principles behind SPD have been used to develop surface treatments that create a nanocrystalline layer on the surface of a material. In the surface mechanical attrition treatment (SMAT), an ultrasonic horn is connected to an ultrasonic (20 kHz) transducer), with small balls on top of the horn. The workpiece is mounted a small distance above the horn. The high frequency results in a large number of collisions between the balls and the surface, creating astrain rate

In materials science, strain rate is the change in strain ( deformation) of a material with respect to time.

The strain rate at some point within the material measures the rate at which the distances of adjacent parcels of the material change ...

on the order of 102–103 s−1. The NC surface layer developed can be on the order of 50 μm thick. The process is similar to shot peening

Shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites. It entails striking a surface with shot (round metallic, glass, or ceramic particles) with ...

, but the kinetic energy of the balls is much higher in SMAT.

An ultrasonic nanocrystalline surface modification (UNSM) technique is also one of the newly developed surface modification technique. In the UNSM process, not only the static load, but also the dynamic load are exerted. The processing is conducted striking a workpiece surface up to 20K or more times per second with shots of an attached ball to the horn in the range of 1K-100K per square millimeter. The strikes, which can be described as cold-forging, introduce SPD to produce a NC surface layer by refining the coarse grains until nanometer scale without changing the chemical composition of a material which render the high strength and high ductility. This UNSM technique does not only improve the mechanical and tribological properties of a material, but also produces a corrugated structure having numerous of desired dimples on the treated surface.

Applications

Most research into SPD has focused on grain refinement, which has obvious applications in the development of high-strength materials as a result of the Hall-Petch relation. Conventionally processed industrial metals typically have a grain size from 10–100 μm. Reducing the grain size from 10 μm to 1 μm can increase the yield strength of metals by more than 100%. Techniques that use bulk materials such as ECAE can provide reliable and relatively inexpensive ways of producing ultrafine grain materials compared to rapid solidification techniques such asmelt spinning

Melt spinning is a metal forming technique that is typically used to form thin ribbons of metal or alloys with a particular atomic structure.

Some important commercial applications of melt spun metals include high-efficiency transformers ( Amor ...

.

However, other effects of SPD, such as texture

Texture may refer to:

Science and technology

* Surface texture, the texture means smoothness, roughness, or bumpiness of the surface of an object

* Texture (roads), road surface characteristics with waves shorter than road roughness

* Texture ...

modification also have potential industrial applications as properties such as the Lankford coefficient

The Lankford coefficient (also called Lankford value, R-value, or plastic strain ratio) is a measure of the plastic anisotropy of a rolled sheet metal. This scalar quantity is used extensively as an indicator of the formability of recrystallize ...

(important for deep drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "dee ...

processes) and magnetic properties of electrical steel

Electrical steel (E-steel, lamination steel, silicon electrical steel, silicon steel, relay steel, transformer steel) is an iron alloy tailored to produce specific magnetic properties: small hysteresis area resulting in low power loss per cycle ...

are highly dependent on texture.

Processes such as ECAE and HPT have also been used to consolidate metal powders and composites without the need for the high temperatures used in conventional consolidation processes such as hot isostatic pressing

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material's mechanical properties and workability.

The process can be used to pro ...

, allowing desirable characteristics such as nanocrystalline grain sizes or amorphous structures to be retained.

Some known commercial application of SPD processes are in the production of Sputtering

In physics, sputtering is a phenomenon in which microscopic particles of a solid material are ejected from its surface, after the material is itself bombarded by energetic particles of a plasma or gas. It occurs naturally in outer space, and ...

targets by Honeywell

Honeywell International Inc. is an American publicly traded, multinational conglomerate corporation headquartered in Charlotte, North Carolina. It primarily operates in four areas of business: aerospace, building technologies, performance ma ...

and UFG titanium for medical implants.

Grain refinement mechanism

The presence of a high hydrostatic pressure, in combination with large shear strains, is essential for producing high densities of crystal lattice defects, particularlydislocations

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to s ...

, which can result in a significant refining of the grains. Grain refinement in SPD processes occurs by a multi-step process:

#Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to ...

s, which are initially distributed throughout the grains, rearrange and group together into dislocation "cells" to reduce the total strain energy.

#As deformation continues and more dislocations are generated, misorientation develops between the cells, forming "subgrains"

#The process repeats within the subgrains until the size becomes sufficiently small such that the subgrains can rotate

#Additional deformation causes the subgrains to rotate into high-angle grain boundaries, typically with an equiaxed shape.

The mechanism by which the subgrains rotate is less understood. Wu ''et al.'' describe a process in which dislocation motion becomes restricted due to the small subgrain size and grain rotation becomes more energetically favorable. Mishra ''et al.'' propose a slightly different explanation, in which the rotation is aided by diffusion

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical p ...

along the grain boundaries (which is much faster than through the bulk).

F.A. Mohamad has proposed a model for the minimum grain size achievable using mechanical milling. The model is based on the concept that the grain size is dependent on the rates at which dislocations are generated and annihilated. The full model is given by

*On the left side of the equation: dmin is the minimum grain size and b is the Burgers vector

In materials science, the Burgers vector, named after Dutch physicist Jan Burgers, is a vector, often denoted as , that represents the magnitude and direction of the lattice distortion resulting from a dislocation in a crystal lattice.

The vec ...

.

*A3 is a constant.

*β=Qp−Qm/Q (Qp is the activation energy for pipe diffusion along dislocations, Qm is the activation energy for vacancy migration, and Q is the activation energy for self-diffusion), βQ represents the activation energy for recovery, R is the gas constant, and T is the processing temperature.

*Dp0 is the temperature-independent component of the pipe diffusion coefficient

Diffusivity, mass diffusivity or diffusion coefficient is a proportionality constant between the molar flux due to molecular diffusion and the gradient in the concentration of the species (or the driving force for diffusion). Diffusivity is enco ...

, G is the shear modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain:

:G \ \stack ...

, ν0 is the dislocation velocity, k is the Boltzmann constant

The Boltzmann constant ( or ) is the proportionality factor that relates the average relative kinetic energy of particles in a gas with the thermodynamic temperature of the gas. It occurs in the definitions of the kelvin and the gas consta ...

, γ is the stacking fault energy The stacking-fault energy (SFE) is a materials property on a very small scale. It is noted as γSFE in units of energy per area.

A stacking fault is an interruption of the normal stacking sequence of atomic planes in a close-packed crystal structu ...

, and H is the hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion (mechanical), abrasion. In general, different materials differ in their hardn ...

.

While the model was developed specifically for mechanical milling, it has also been successfully applied to other SPD processes. Frequently only a portion of the model is used (typically the term involving the stacking fault energy) as the other terms are often unknown and difficult to measure. This is still useful as it implies that all other things remaining equal, reducing the stacking fault energy, a property that is a function of the alloying elements, will allow for better grain refinement. A few studies, however, suggested that despite the significance of stacking fault energy on the grain refinement at the early stages of straining, the steady-state grain size at large strains is mainly controlled by the homologous temperature in pure metals and by the interaction of solute atoms and dislocations in single-phase alloys.

References

{{reflist Deformation (mechanics) Metal forming Materials science