Rubber Toughening on:

[Wikipedia]

[Google]

[Amazon]

Rubber toughening is a process in which

Different theories describe how a dispersed rubber phase toughens a polymeric substance; most employ methods of dissipating energy throughout the matrix. These theories include: microcrack theory, shear-yielding theory, multiple-crazing theory, shear band and crazing interaction theory, and more recently those including the effects of critical ligament thickness, critical plastic area, voiding and cavitation, damage competition and others.

Different theories describe how a dispersed rubber phase toughens a polymeric substance; most employ methods of dissipating energy throughout the matrix. These theories include: microcrack theory, shear-yielding theory, multiple-crazing theory, shear band and crazing interaction theory, and more recently those including the effects of critical ligament thickness, critical plastic area, voiding and cavitation, damage competition and others.

Increasing the rubber concentration in a nanocomposite decreases the modulus and tensile strength. In one study, looking at PA6-EPDM blend, increasing the concentration of rubber up to 30 percent showed a negative linear relationship with the brittle-tough transition temperature, after which the toughness decreased. This suggests that the toughening effect of adding rubber particles is limited to a critical concentration. This is examined further in a study on PMMA from 1998; using

Increasing the rubber concentration in a nanocomposite decreases the modulus and tensile strength. In one study, looking at PA6-EPDM blend, increasing the concentration of rubber up to 30 percent showed a negative linear relationship with the brittle-tough transition temperature, after which the toughness decreased. This suggests that the toughening effect of adding rubber particles is limited to a critical concentration. This is examined further in a study on PMMA from 1998; using

rubber

Rubber, also called India rubber, latex, Amazonian rubber, ''caucho'', or ''caoutchouc'', as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, and ...

nanoparticles are interspersed within a polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

matrix to increase the mechanical robustness, or toughness

In materials science and metallurgy, toughness is the ability of a material to absorb energy and plastically deform without fracturing.polymer

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic a ...

it is meant that the ability of the polymeric substance to absorb energy and plastically deform without fracture is increased. Considering the significant advantages in mechanical properties that rubber toughening offers, most major thermoplastic

A thermoplastic, or thermosoft plastic, is any plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

Most thermoplastics have a high molecular weight. The polymer chains associate ...

s are available in rubber-toughened versions; for many engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad rang ...

applications, material toughness is a deciding factor in final material selection.

The effects of disperse rubber nanoparticles

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 1 ...

are complex and differ across amorphous and partly crystalline polymeric systems. Rubber particles toughen a system by a variety of mechanisms such as when particulates concentrate stress causing cavitation or initiation of dissipating crazes. However the effects are not one-sided; excess rubber content or debonding between the rubber and polymer can reduce toughness. It is difficult to state the specific effects of a given particle size or interfacial adhesion parameter due to numerous other confounding variables.

The presence of a given failure mechanism is determined by many factors: those intrinsic to the continuous polymer phase, and those that are extrinsic, pertaining to the stress, loading speed, and ambient conditions. The action of a given mechanism in a toughened polymer can be studied with microscopy. The addition of rubbery domains occurs via processes such as melt blending in a Rheomix mixer and atom-transfer radical-polymerization.

Current research focuses on how optimizing the secondary phase composition and dispersion affects mechanical properties of the blend. Questions of interest include those to do with fracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a c ...

, tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials t ...

, and glass transition temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rubb ...

.

Toughening mechanisms

Different theories describe how a dispersed rubber phase toughens a polymeric substance; most employ methods of dissipating energy throughout the matrix. These theories include: microcrack theory, shear-yielding theory, multiple-crazing theory, shear band and crazing interaction theory, and more recently those including the effects of critical ligament thickness, critical plastic area, voiding and cavitation, damage competition and others.

Different theories describe how a dispersed rubber phase toughens a polymeric substance; most employ methods of dissipating energy throughout the matrix. These theories include: microcrack theory, shear-yielding theory, multiple-crazing theory, shear band and crazing interaction theory, and more recently those including the effects of critical ligament thickness, critical plastic area, voiding and cavitation, damage competition and others.

Microcrack theory

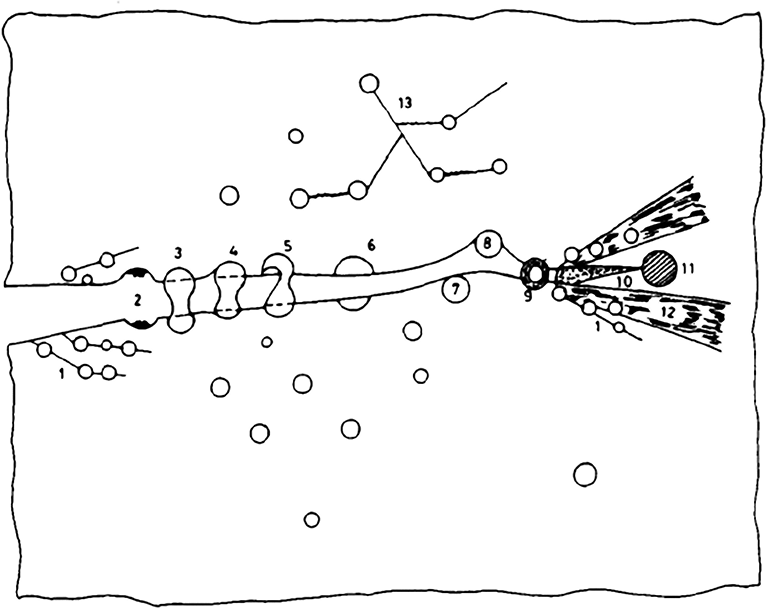

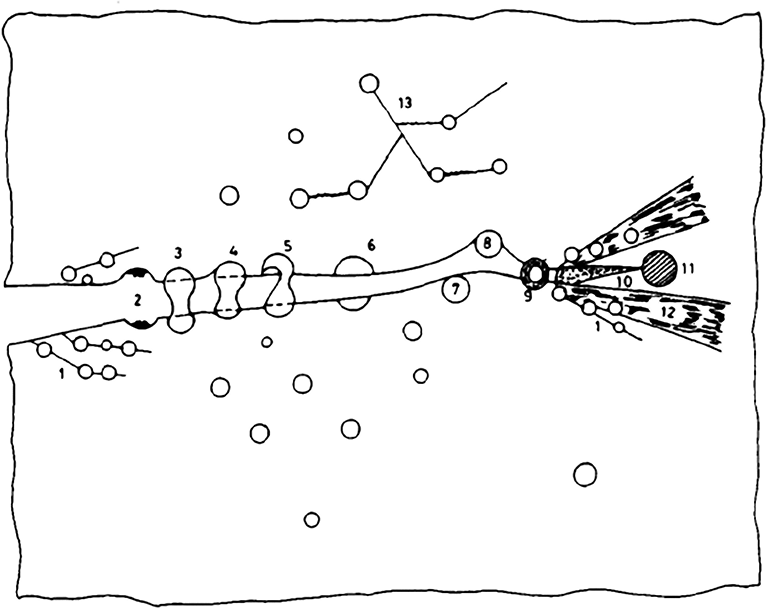

In 1956, the microcrack theory became the first to explain the toughening effect of a dispersed rubber phase in a polymer. Two key observations that went into the initial theory and subsequent expansion were as follows: (1) microcracks form voids over which styrene-butadiene copolymer fibrils form to prevent propagation, and (2) energy stored during elongation of toughened epoxies is released upon breaking of rubber particles. The theory concluded that the combined energy to initiate microcracks and the energy to break rubber particles could account for the increased energy absorption of toughened polymers. This theory was limited, only accounting for a small fraction of the observed increase in fracture energy.Matrix crazing

The matrixcrazing

Crazing is the phenomenon that produces a network of fine cracks on the surface of a material, for example in a glaze layer. Crazing frequently precedes fracture in some glassy thermoplastic polymers. As it only takes place under tensile stress, ...

theory focuses on explaining the toughening effects of crazing. Crazes start at the equator where principal strain

Strain may refer to:

Science and technology

* Strain (biology), variants of plants, viruses or bacteria; or an inbred animal used for experimental purposes

* Strain (chemistry), a chemical stress of a molecule

* Strain (injury), an injury to a mu ...

is highest, propagate perpendicular to the stress, and end when they meet another particle. Crazes with perpendicular fibrils

Fibrils (from the Latin ''fibra'') are structural biological materials found in nearly all living organisms. Not to be confused with fibers or filaments, fibrils tend to have diameters ranging from 10-100 nanometers (whereas fibers are micro ...

can eventually become a crack if the fibrils break. The volume expansion associated with small crazes distributed through a large volume compared to the small volume of a few large cracks in untoughened polymer accounts for a large fraction of the increase in fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displa ...

energy.

Interaction between rubber particles and crazes puts elongation pressures onto the particles in the direction of stress. If this force overcomes the surface adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another).

The forces that cause adhesion and cohesion can be ...

between the rubber and polymer, debonding will occur, thereby diminishing the toughening effect associated with crazing. If the particle is harder, it will be less able to deform, and thus debonding occurs under less stress. This is one reason why dispersed rubbers, below their own glass transition temperature, do not toughen plastics effectively.

Shear yielding

Shear yielding theory is one that, like matrixcrazing

Crazing is the phenomenon that produces a network of fine cracks on the surface of a material, for example in a glaze layer. Crazing frequently precedes fracture in some glassy thermoplastic polymers. As it only takes place under tensile stress, ...

, can account for a large fraction of the increase in energy absorption of a toughened polymer. Evidence of shear yielding in a toughened polymer can be seen where there is " necking, drawing or orientation hardening." Shear yielding will result if rubber particles act as stress concentrators and initiate volume-expansion through crazing, debonding and cavitation, to halt the formation of cracks. Overlapping stress fields from one particle to its neighbor will contribute to a growing shear-yielding region. The closer the particles are the more overlap and the larger shear-yielding region. Shear yielding is an energy absorbing process in itself, but furthermore initiation of shear band A shear band (or, more generally, a 'strain localization') is a narrow zone of intense shearing strain, usually of plastic nature, developing during severe deformation of ductile materials.

As an example, a soil (overconsolidated silty-clay) specime ...

s also aids in craze arrest. The occurrence of cavitation is important to shear yielding theory because it acts to lower the yield stress. Cavitation precedes shear yielding, however shear yielding accounts for a much larger increase in toughness than does the cavitation itself.

Cavitation

Cavitation

Cavitation is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, cal ...

is common in epoxy resins and other craze resistant toughened polymers, and is prerequisite to shearing in Izod impact strength testing. During the deformation and fracture of a toughened polymer, cavitation of the strained rubber particles occurs in crazing-prone and non-crazing-prone plastics, including, ABS, PVC, nylon, high impact polystyrene, and CTBN toughened epoxies. Engineers use an energy-balance approach to model how particle size and rubber modulus factors influence material toughness. Both particle size and modulus show positive correlation with brittle-tough transition temperatures. They are both shown to affect the cavitation process occurring at the crack tip process zone early in deformation, preceding large-scale crazing and shear yielding.

In order to show increased toughness under strain, the volumetric strain must overcome the energy of void formation as modeled by the equation:

"where and are the shear modulus and bulk modulus of the rubber, is the volume strain in the rubber particle, is the surface energy of the rubber phase, and the function is dependent on the failure strain of the rubber under biaxial stretching conditions."

The energy-balancing model applies the physical properties of the whole material to describe the microscopic behavior during triaxial stress. The volume stress and particle radius conditions for cavitation can be calculated, giving the theoretical minimum particle radius for cavitation, useful for practical applications in rubber toughening. Typically cavitation will occur when the average stress on the rubber particles is between 10 and 20 megapascal. The volume strain on the particle is relieved and voiding occurs. The energy absorption due to this increase in volume is theoretically negligible. Instead, it is the consequent shear band formation that accounts for increased toughness. Before debonding, as the strain increases, the rubber phases is forced to stretch further strengthening the matrix. Debonding between the matrix and the rubber reduces the toughness, creating the need for strong adhesion between the polymer and rubber phases.

Damage competition theory

The damage competition theory models the relative contributions of shear yielding and craze failure, when both are present. there are two main assumptions: crazing, microcracks, and cavitation dominate in brittle systems, and shearing dominates in the ductile systems. Systems that are in between brittle and ductile will show a combination of these. The damage competition theory defines the brittle-ductile transition as the point at which the opposite mechanism (shear or yield damage) appears in a system dominated by the other mechanism.Characterization of failure

The dominant failure mechanism can usually be observed directly usingTEM Tem or TEM may refer to:

Acronyms

* Threat and error management, an aviation safety management model.

* Telecom Expense Management

* Telecom Equipment Manufacturer

* TEM (currency), local to Volos, Greece

* TEM (nuclear propulsion), a Russian ...

, SEM and light microscopy

Microscopy is the technical field of using microscopes to view objects and areas of objects that cannot be seen with the naked eye (objects that are not within the resolution range of the normal eye). There are three well-known branches of micr ...

. If cavitation or crazing is dominant, tensile dilatometry (''see dilatometer

A dilatometer is a scientific instrument that measures volume changes caused by a physical or chemical process. A familiar application of a dilatometer is the mercury-in-glass thermometer, in which the change in volume of the liquid column is ...

'') can be used to measure the extent of the mechanism by measuring volume strain. However, if multiple dilatational mechanisms are present, it is difficult to measure the separate contributions. Shear yielding is a constant volume process and cannot be measured with tensile dilatometry. Voiding can be seen with optical microscopy, however one of two methods, using polarized light or low angle light scattering are necessary to observe the connection between cavitation and shear bands.

Characteristics of the continuous phase relevant to toughening theory

In order to gauge the toughening effects of a dispersed secondary phase, it is important to understand the relevant characteristics of the continuous polymer phase. The mechanical failure characteristics of the pure polymeric continuous phase will strongly influence how rubber toughened polymer failure occurs. When a polymer usually fails due to crazing, rubber toughening particles will act as craze initiators. When it fails by shear yielding, the rubber particles will initiate shear bands. It is also possible to having multiple mechanisms come into play if the polymer is prone to failing by multiple stresses equally.Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

and styrene-acrylonitrile Styrene acrylonitrile resin is a copolymer plastic consisting of styrene and acrylonitrile. It is also known as SAN. It is widely used in place of polystyrene owing to its greater thermal resistance. The chains of between 70 and 80% by weight styren ...

are brittle materials that are prone to craze failure while polycarbonate, polyamides, and polyethylene terephthalate (PET) are prone to shear yield failure.

Glass transition temperature

Amorphous plastics are used below their glass transition temperature (). They are brittle and notch sensitive but creep resistant. Molecules are immobile and the plastic responds to rapidly applied stress by fracturing. Partly crystalline thermoplastics are used for application in temperature conditions between and (melting temperature). Partly crystalline thermoplastics are tough and creep-prone because the amorphous regions surrounding the rigid crystals are afforded some mobility. Often they are brittle at room temperature because they have high glass transition temperatures. Polyethylene is tough at room temperature because its is lower than room temperature. Polyamide 66 and polyvinylchloride have secondary transitions below their that allows for some energy absorbing molecule mobility.Chemical structure

There are some general guidelines to follow when trying to determine a plastic's toughness from its chemical structure. Vinyl polymers like polystyrene and styrene-acrylonitrile tend to fail by crazing. They have low crack initiation and propagation energies. Polymers with aromatic backbones, such as polyethylene terephthalate and polycarbonate, tend to fail by shear yielding with high crack initiation energy but low propagation energy. Other polymers, including poly(methyl methacrylate) and polyacetal(polyoxymethylene), are not as brittle as "brittle polymers" and are also not as ductile as "ductile polymers".Entanglement density and flexibility of unperturbed real chain

The following equations relate the entanglement density and a measure of the flexibility of the unperturbed real chain () of a given plastic to its fracture mechanics: Where is the mass density of the amorphous polymer, and is the average molecular weight per statistical unit. Crazing stress is related to the entanglement density by: The normalized stress yield is related to by is a constant. The ratio of the crazing stress to the normalized stress yield is used to determine whether a polymer fails due to crazing or yield: When the ratio is higher, the matrix is prone to yielding; when the ratio is lower, the matrix is prone to failure by crazing. These formulas form the base of crazing theory, shear-yielding theory, and damage competition theory.Relationship between the secondary phase properties and toughening effect

Rubber selection and miscibility with continuous phase

In material selection it is important to look at the interaction between the matrix and the secondary phase. For example, crosslinking within the rubber phase promotes high strength fibril formation that toughens the rubber, preventing particle fracture. Carboxyl-terminated butadiene-acrylonitrile (CTBN) is often used to toughen epoxies, but using CTBN alone increases the toughness at the cost of stiffness and heat resistance. Amine-terminated butadiene acrylonitrile (ATBN) is also used. Using ultra-fine full-vulcanized powdered rubber (UFPR) researchers have been able to improve all three, toughness, stiffness, and heat resistance simultaneously, resetting the stage for rubber toughening with particles smaller than previously thought to be effective. In applications where high optical transparency is necessary, examples beingpoly(methyl methacrylate)

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastics. It is a transparent thermoplastic. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, ...

and polycarbonate

Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily work ...

it is important to find a secondary phase that does not scatter light. To do so it is important to match refractive indices of both phases. Traditional rubber particles do not offer this quality. Modifying the surface of nanoparticles with polymers of comparable refractive indices is an interest of current research.

Secondary phase concentration

Increasing the rubber concentration in a nanocomposite decreases the modulus and tensile strength. In one study, looking at PA6-EPDM blend, increasing the concentration of rubber up to 30 percent showed a negative linear relationship with the brittle-tough transition temperature, after which the toughness decreased. This suggests that the toughening effect of adding rubber particles is limited to a critical concentration. This is examined further in a study on PMMA from 1998; using

Increasing the rubber concentration in a nanocomposite decreases the modulus and tensile strength. In one study, looking at PA6-EPDM blend, increasing the concentration of rubber up to 30 percent showed a negative linear relationship with the brittle-tough transition temperature, after which the toughness decreased. This suggests that the toughening effect of adding rubber particles is limited to a critical concentration. This is examined further in a study on PMMA from 1998; using SAXS

Small-angle X-ray scattering (SAXS) is a small-angle scattering technique by which nanoscale density differences in a sample can be quantified. This means that it can determine nanoparticle size distributions, resolve the size and shape of (monodis ...

to analyze crazing density, it was found that crazing density increases and yield stress decreases until the critical point when the relationship flips.

Rubber particle size

A material that is expected to fail by crazing is more likely to benefit from larger particles than a shear prone material, which would benefit from a smaller particle. In materials where crazing and yielding are comparable, a bimodal distribution of particle size may be useful for toughening. At fixed rubber concentrations, one can find that an optimal particle size is a function of the entanglement density of the polymer matrix. The neat polymer entanglement densities of PS, SAN, and PMMA are 0.056, 0.093, and 0.127 respectively. As entanglement density increases, the optimum particle size decreases linearly, ranging between 0.1 and 3 micrometers. The effect of particle size on toughening is dependent on the type of test performed. This can be explained because for different test conditions, the failure mechanism changes. For impact strength testing on PMMA where failure occurs by shear-yielding, the optimum size of filler PBA-core PMMA-shell particle was shown in one case to be 250 nm. In the three-point bend test, where failure is due to crazing, 2000 nm particles had the most significant toughening effect.Temperature effects

Temperature has a direct effect on thefracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics t ...

. At low temperatures, below the glass transition temperature of the rubber, the dispersed phase behaves like a glass rather than like a rubber that toughens the polymer. As a result, the continuous phase fails by mechanisms characteristic of the pure polymer, as if the rubber was not present. As temperature increases past the glass transition temperature, the rubber phase increases the crack initiation energy. At this point the crack self-propagates due to the stored elastic energy in the material. As temperature rises further past the glass transition of the rubber phase, the impact strength of a rubber-polymer composite still dramatically increases as crack propagation requires additional energy input.

Sample applications

Epoxy resins

Epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also coll ...

resins are a highly useful class of materials used in engineering applications. Some of these include use for adhesives, fiber-reinforced composites, and electronics coatings. Their rigidity and low crack propagation resistance makes epoxies a candidate of interest for rubber toughening research to fine-tune the toughening processes.

Some of the factors affecting the toughness of epoxy nanocomposites include the chemical identity of the epoxy curing agent, entanglement density, and interfacial adhesion. Curing epoxy 618 with piperidine

Piperidine is an organic compound with the molecular formula (CH2)5NH. This heterocyclic compound, heterocyclic amine consists of a six-membered ring containing five methylene bridges (–CH2–) and one amine bridge (–NH–). It is a colorless ...

, for example, produces tougher epoxies than when boron trifluoride-ethylamine is used. Low entanglement density increases the toughness. Bisphenol A

Bisphenol A (BPA) is a chemical compound primarily used in the manufacturing of various plastics. It is a colourless solid which is soluble in most common organic solvents, but has very poor solubility in water. BPA is produced on an industrial s ...

can be added to lower the crosslinking density of epoxy 618, thereby increasing the fracture toughness. Bisphenol A and a rubber filler increase toughness synergistically.

In textbooks and literature before 2002 it was assumed that there is a lower limit for rubber-toughening particle diameter at 200 nm; it was then discovered that ultra-fine full-vulcanized powdered rubber particles with diameter of 90 nm show significant toughening of rubber epoxies. This finding underlines how this field is constantly growing and more work can be done to better model the rubber toughening effect.

ABS

Acrylonitrile butadiene styrene

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)''x''·(C4H6)''y''·(C3H3N)''z'' is a common thermoplastic polymer. Its glass transition temperature is approximately . ABS is amorphous and therefore has no true melting point.

A ...

(ABS) polymer is an application of rubber toughening. The properties of this polymer come mainly from rubber toughening. The polybutadiene rubber domains in the main styrene-acrylonitrile matrix act as a stop to crack propagation.

Optically transparent plastics

PMMA PMMA may refer to:

* para-Methoxymethamphetamine, a stimulant drug

* Philippine Merchant Marine Academy

The Philippine Merchant Marine Academy ( fil, Akademiya sa Bapor Pangkalakalan ng Pilipinas) also referred to by its acronym PMMA) is a ma ...

’s high optical transparency, low cost, and compressibility make it a viable option for practical applications in architecture and car manufacturing as a substitute for glass when high transparency is necessary. Incorporating a rubber filler phase increases the toughness. Such fillers need to form strong interfacial bonds with the PMMA matrix. In applications where optical transparency is important, measures must be taken to limit light scattering.

It is common in toughening PMMA, and in other composites, to synthesize core-shell particles via atom-transfer radical-polymerization Atom transfer radical polymerization (ATRP) is an example of a reversible-deactivation radical polymerization. Like its counterpart, ATRA, or atom transfer radical addition, ATRP is a means of forming a carbon-carbon bond with a transition metal ca ...

that have an outer polymer layer that has properties similar to those of the primary phase that increases the particle’s adhesion to the matrix. Developing PMMA compatible core-shell particles with low glass transition temperature while maintaining optical transparency is of interest to architects and car companies.

For optimal transparency the disperse rubber phase needs the following:

* Small average particle radius

* Narrow particle size distribution

* Refractive index matching that of matrix across range of temperatures and wavelengths

* Strong adhesion to matrix

* Similar viscosity

The viscosity of a fluid is a measure of its resistance to deformation at a given rate. For liquids, it corresponds to the informal concept of "thickness": for example, syrup has a higher viscosity than water.

Viscosity quantifies the inte ...

to matrix at processing temperature

Cyclic olefin copolymer, an optically transparent plastic with low moisture uptake and solvent resistance among other useful properties, can be toughened effectively with a styrene-butadiene-styrene rubber with the above properties. The Notched-Izod strength more than doubled from 21 J/m to 57 J/m with an optical haze of 5%.

Improving polystyrene

Polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

generally has stiffness

Stiffness is the extent to which an object resists deformation in response to an applied force.

The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is.

Calculations

The stiffness, k, of a b ...

, transparency, processibility, and dielectric

In electromagnetism, a dielectric (or dielectric medium) is an electrical insulator that can be polarised by an applied electric field. When a dielectric material is placed in an electric field, electric charges do not flow through the mate ...

qualities that make it useful. However, its low impact resistance at low temperatures makes catastrophic fracture failure when cold more likely. The most widely used version of toughened polystyrene is called high impact polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

or HIPS. Being cheap and easy to thermoform (see ''thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. The sheet, or "film" when referring to thinner gauges and cert ...

''), it is utilized for many everyday uses. HIPS

In vertebrate anatomy, hip (or "coxa"Latin ''coxa'' was used by Celsus in the sense "hip", but by Pliny the Elder in the sense "hip bone" (Diab, p 77) in medical terminology) refers to either an anatomical region or a joint.

The hip region is ...

is made by polymerizing styrene in a polybutadiene rubber solution. After the polymerization reaction begins, the polystyrene and rubber phases separate. When phase separation begins, the two phases compete for volume until phase inversion occurs and the rubber can distribute throughout the matrix. The alternative emulsion polymerization with styrene-butadiene-styrene or styrene-butadiene copolymers allows fine-tuned manipulation of particle size distribution. This method makes use of the core-shell architecture.

In order to study the fracture microstructure of HIPS in a transmission electron microscope it is necessary to stain one of the phases with a heavy metal, Osmium tetroxide for example. This produces substantially different electron density between phases. Given a constant particle size, it is the cross-linking density that determines the toughness of a HIPS material. This can be measured by exploiting the negative relationship between the cis-polybutadiene content of the rubber and the crosslink density that can be measured with the swelling index. Lower crosslink density leads to increased toughness.

The generation of vast quantities of waste rubber from car tires has sparked interest in finding uses for this discarded rubber. The rubber can be turned into a fine powder, which can then be used as a toughening agent for polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

. However, poor miscibility

Miscibility () is the property of two substances to mix in all proportions (that is, to fully dissolve in each other at any concentration), forming a homogeneous mixture (a solution). The term is most often applied to liquids but also applies ...

between the waste rubber and polystyrene weakens the material. This problem requires the use of a compatibilizer (see '' compatibilization'') in order to reduce interfacial tension and ultimately make rubber toughening of polystyrene effective. A polystyrene

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. Polystyrene can be solid or foamed. General-purpose polystyrene is clear, hard, and brittle. It is an inexpensive resin per unit weight. It is a ...

/styrene-butadiene

Styrene-butadiene or styrene-butadiene rubber (SBR) describe families of synthetic rubbers derived from styrene and butadiene (the version developed by Goodyear is called Neolite). These materials have good abrasion resistance and good aging st ...

copolymer

In polymer chemistry, a copolymer is a polymer derived from more than one species of monomer. The polymerization of monomers into copolymers is called copolymerization. Copolymers obtained from the copolymerization of two monomer species are some ...

acts to increase the adhesion

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another ( cohesion refers to the tendency of similar or identical particles/surfaces to cling to one another).

The forces that cause adhesion and cohesion can be ...

between the dispersed and continuous phases.

References

{{Reflist Plastics Polymers Materials science