|

Fracture Toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions and thick components having plane strain conditions. Plane strain conditions give the lowest fracture toughness value which is a material property. The critical value of stress intensity factor in mode I loading measured under plane strain conditions is known as the plane strain fracture toughness, denoted K_\text. When a test fails to meet the thickness and other test requirements that are in place to ensure plane strain conditions, the fracture toughness value produced is given the designation K_\text. Fracture toughness is a quantitative way of expressing a material's resistance to crack propagation and standard values for a given material are generally available. Slow self-sust ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Toughness Thickness Dependence

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band or dislocation. Brittle fractures occur with no apparent deformation before fracture. Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen fails via fracture. This is usually determined for a given specimen by a tensile test, which charts the stress–strain cur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soda-lime Glass

Soda lime is a mixture of NaOH and CaO chemicals, used in granular form in closed breathing environments, such as general anaesthesia, submarines, rebreathers and recompression chambers, to remove carbon dioxide from breathing gases to prevent CO2 retention and carbon dioxide poisoning. It is made by treating slaked lime with concentrated sodium hydroxide solution. Chemical components The main components of soda lime are * Calcium oxide, CaO (about 75%) * Water, H2O (about 20%) * Sodium hydroxide, NaOH (about 3%) * Potassium hydroxide, KOH (about 0.1%). Anaesthetic use During the administration of general anaesthesia, the gases expired by a patient, which contain carbon dioxide, are passed through an anaesthetic machine breathing circuit filled with soda lime granules. Medical-grade soda lime includes an indicating dye that changes color when the soda lime reaches its carbon dioxide absorbing capacity. To ensure that a soda lime canister (CO2 absorber) is functioning pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

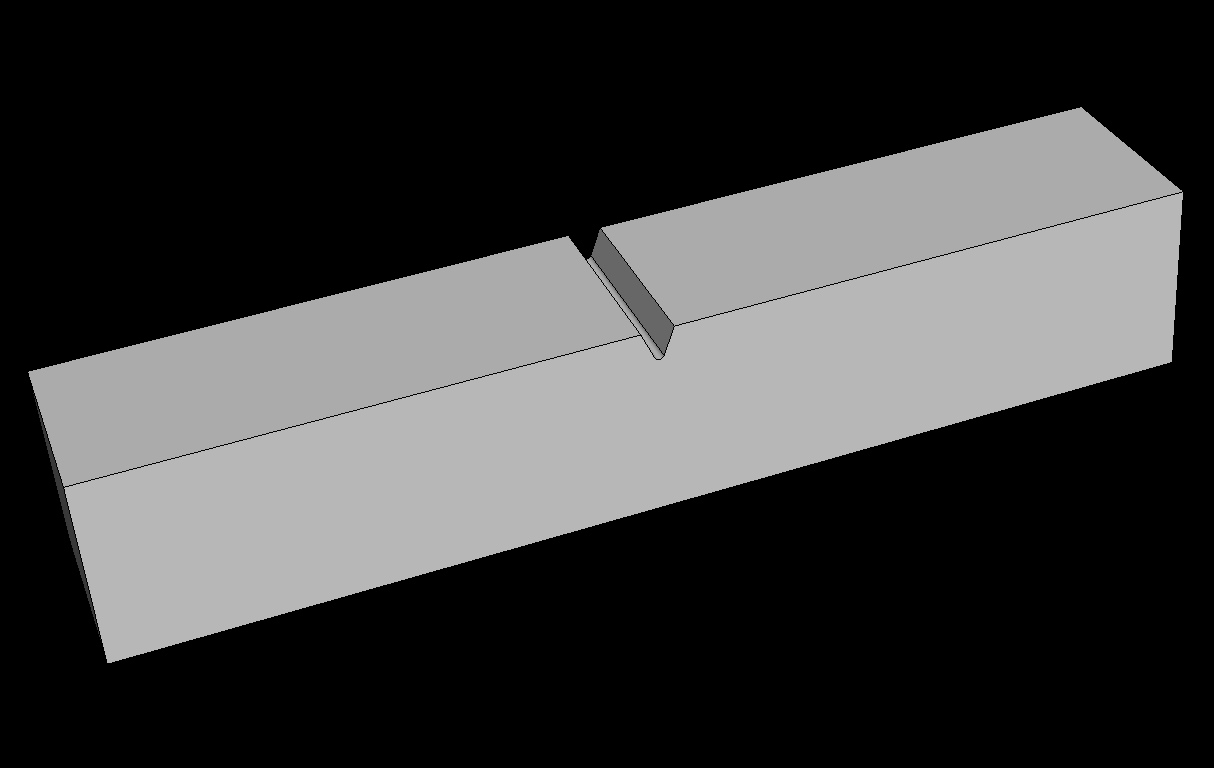

Notch (engineering)

In mechanical engineering and materials science, a notch refers to a V-shaped, U-shaped, or semi-circular defect deliberately introduced into a planar material. In structural components, a notch causes a stress concentration which can result in the initiation and growth of fatigue cracks. Notches are used in materials characterization to determine fracture mechanics related properties such as fracture toughness and rates of fatigue crack growth. Notches are commonly used in material impact tests where a morphological crack of a controlled origin is necessary to achieve standardized characterization of fracture resistance of the material. The most common is the Charpy impact test, which uses a pendulum hammer (striker) to strike a horizontal notched specimen. The height of its subsequent swing-through is used to determine the energy absorbed during fracture. The Izod impact strength test uses a circular notched vertical specimen in a cantilever configuration. Charpy testing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crack Growth Resistance Curve

In materials modeled by linear elastic fracture mechanics (LEFM), crack extension occurs when the applied energy release rate G exceeds G_R, where G_R is the material's resistance to crack extension. Conceptually G can be thought of as the energetic ''gain'' associated with an additional infinitesimal increment of crack extension, while G_R can be thought of as the energetic ''penalty'' of an additional infinitesimal increment of crack extension. At any moment in time, if G \geq G_R then crack extension is energetically favorable. A complication to this process is that in some materials, G_R is not a constant value during the crack extension process. A plot of crack growth resistance G_R versus crack extension \Delta a is called a crack growth resistance curve, or R-curve. A plot of energy release rate G versus crack extension \Delta a for a particular loading configuration is called the driving force curve. The nature of the applied driving force curve relative to the material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elastic Modulus

An elastic modulus (also known as modulus of elasticity) is the unit of measurement of an object's or substance's resistance to being deformed elastically (i.e., non-permanently) when a stress is applied to it. The elastic modulus of an object is defined as the slope of its stress–strain curve in the elastic deformation region: A stiffer material will have a higher elastic modulus. An elastic modulus has the form: :\delta \ \stackrel\ \frac where stress is the force causing the deformation divided by the area to which the force is applied and strain is the ratio of the change in some parameter caused by the deformation to the original value of the parameter. Since strain is a dimensionless quantity, the units of \delta will be the same as the units of stress. Specifying how stress and strain are to be measured, including directions, allows for many types of elastic moduli to be defined. The three primary ones are: # ''Young's modulus'' (E) describes tensile and compressive ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yttria-stabilized Zirconia

Yttria-stabilized zirconia (YSZ) is a ceramic in which the cubic crystal structure of zirconium dioxide is made stable at room temperature by an addition of yttrium oxide. These oxides are commonly called "zirconia" ( Zr O2) and "yttria" ( Y2 O3), hence the name. Stabilization Pure zirconium dioxide undergoes a phase transformation from monoclinic (stable at room temperature) to tetragonal (at about 1173 °C) and then to cubic (at about 2370 °C), according to the scheme : monoclinic (1173 °C) ↔ tetragonal (2370 °C) ↔ cubic (2690 °C) ↔ melt. Obtaining stable sintered zirconia ceramic products is difficult because of the large volume change, about 5%, accompanying the transition from tetragonal to monoclinic. Stabilization of the cubic polymorph of zirconia over wider range of temperatures is accomplished by substitution of some of the Zr4+ ions (ionic radius of 0.82 Å, too small for ideal lattice of fluorite characteristic for the cubi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Martensitic Transformation

A diffusionless transformation is a phase change that occurs without the long-range diffusion of atoms but rather by some form of cooperative, homogenous movement of many atoms that results in a change in the crystal structure. These movements are small, usually less than the interatomic distances, and the neighbors of an atom remain close. The systematic movement of large numbers of atoms led to some to refer to these as ''military'' transformations in contrast to ''civilian'' diffusion-based phase changes, initially by Frederick Charles Frank and John Wyrill Christian. The most commonly encountered transformation of this type is the martensitic transformation which, while probably the most studied, is only one subset of non-diffusional transformations. The martensitic transformation in steel represents the most economically significant example of this category of phase transformations, but an increasing number of alternatives, such as shape memory alloys, are becoming more impor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductility

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microstructure

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure. A microstructure’s influence on the mechanical and physical properties of a material is primarily governed by the different defects present or absent of the structure. These defects can tak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toughening

In materials science, toughening refers to the process of making a material more resistant to the propagation of cracks. When a crack propagates, the associated irreversible work in different materials classes is different. Thus, the most effective toughening mechanisms differ among different materials classes. The crack tip plasticity is important in toughening of metals and long-chain polymers. Ceramics have limited crack tip plasticity and primarily rely on different toughening mechanisms. Toughening in metals For the case of a ductile material such as a metal, this toughness is typically proportional to the fracture stress and strain as well as the gauge length of the crack. The plane strain toughness in a metal is given by:Courtney, T. H. (2005). Mechanical Behavior of Materials. United States: Waveland Press, Inc. :G_ = B\sigma_\epsilon_\rho where G_ is the plane strain toughness, B is a constant that incorporates the stress state, \sigma_ is the tensile flow stress at fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aerogel

Aerogels are a class of synthetic porous ultralight material derived from a gel, in which the liquid component for the gel has been replaced with a gas, without significant collapse of the gel structure. The result is a solid with extremely low density and extremely low thermal conductivity. Aerogels can be made from a variety of chemical compounds. Silica aerogels feel like fragile expanded polystyrene to the touch, while some polymer-based aerogels feel like rigid foams. The first documented example of an aerogel was created by Samuel Stephens Kistler in 1931, as a result of a bet with Charles Learned over who could replace the liquid in "jellies" with gas without causing shrinkage. Aerogels are produced by extracting the liquid component of a gel through supercritical drying or freeze-drying. This allows the liquid to be slowly dried off without causing the solid matrix in the gel to collapse from capillary action, as would happen with conventional evaporation. The first aer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mullite

Mullite or porcelainite is a rare silicate mineral formed during contact metamorphism of clay minerals. It can form two stoichiometric forms: 3 Al2 O32 SiO2 or 2Al2O3 SiO2. Unusually, mullite has no charge-balancing cations present. As a result, there are three different aluminium sites: two distorted tetrahedral and one octahedral. Mullite was first described in 1924 for an occurrence on the Isle of Mull, Scotland. It occurs as argillaceous inclusions in volcanic rocks in the Isle of Mull, inclusions in sillimanite within a tonalite at Val Sissone, Italy and with emerylike rocks in Argyllshire, Scotland. Porcellanite Mullite (porcelainite) can be found as a constituent mineral in a type of thermally-metamorphosed rock called porcellanite. Use in porcelain Mullite is present in the form of needles in porcelain. It is produced during various melting and firing processes, and is used as a refractory material,H. Schneider & S. Komarneni (2005) Mullite. Wiley, VCH, 509 pp, becau ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_diagram.jpg)