Purdue Enterprise Reference Architecture on:

[Wikipedia]

[Google]

[Amazon]

Purdue Enterprise Reference Architecture (PERA), or the Purdue model, is a 1990s

Purdue Enterprise Reference Architecture (PERA), or the Purdue model, is a 1990s

PERA has been further developed, and according to Gary Rathwell, PERA nowadays consists of the following components:

:* ''The PERA Enterprise Life-cycle Framework or Model or Architecture...''

:* ''Concepts of maximum and minimum lines of automation...''

:* ''Concepts explaining the effect of recycle and time delays on the design and operation of facilities.''

:* ''The PERA Master Planning Methodology''

:*''Concepts for dividing Enterprise Systems into Physical and Logical Architectures.''

:*''Purdue Reference Model for CIM including Generic Reference Data Flow Models.''

:*''Example Logical System Architectures from various industries...''

:*''Physical Systems Architecture Concepts including "Levels" and the "4Rs".''

:*''Example Physical architectures from various industries ...''

:*''Mapping of hardware and software products within the PERA Framework''

Later in the 1990s combined insights from PERA, and other reference architectures such as GRAI Integrated Methodology, CIM-OSA, and TOVE has led to the development of the Generic Enterprise Reference Architecture and Methodology

PERA has been further developed, and according to Gary Rathwell, PERA nowadays consists of the following components:

:* ''The PERA Enterprise Life-cycle Framework or Model or Architecture...''

:* ''Concepts of maximum and minimum lines of automation...''

:* ''Concepts explaining the effect of recycle and time delays on the design and operation of facilities.''

:* ''The PERA Master Planning Methodology''

:*''Concepts for dividing Enterprise Systems into Physical and Logical Architectures.''

:*''Purdue Reference Model for CIM including Generic Reference Data Flow Models.''

:*''Example Logical System Architectures from various industries...''

:*''Physical Systems Architecture Concepts including "Levels" and the "4Rs".''

:*''Example Physical architectures from various industries ...''

:*''Mapping of hardware and software products within the PERA Framework''

Later in the 1990s combined insights from PERA, and other reference architectures such as GRAI Integrated Methodology, CIM-OSA, and TOVE has led to the development of the Generic Enterprise Reference Architecture and Methodology

A framework to define a generic enterprise reference architecture and methodology

" ''Computer Integrated Manufacturing Systems'' Vol 9 (3). p. 179-191. * David Chen,

PERA Enterprise Integration Web SiteMES Center AssociationMES system as an integration tool

Enterprise architecture frameworks Reference models

Purdue Enterprise Reference Architecture (PERA), or the Purdue model, is a 1990s

Purdue Enterprise Reference Architecture (PERA), or the Purdue model, is a 1990s reference model A reference model—in systems engineering, systems, enterprise engineering, enterprise, and software engineering—is an abstract framework or domain-specific ontology (information science), ontology consisting of an interlinked set of clearly defi ...

for enterprise architecture

Enterprise architecture (EA) is a business function concerned with the structures and behaviours of a business, especially business roles and processes that create and use business data. The international definition according to the Federation of ...

, developed by Theodore J. Williams Theodore Joseph Williams (1923 – April 27, 2013) was an American engineer and Professor of Engineering at Purdue University, known for the development of the Purdue Enterprise Reference Architecture.

Biography

Williams received his B.S., M.S., ...

and members of the Industry-Purdue University Consortium for Computer Integrated Manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster a ...

.

Overview

PERA is a reference architecture that can model the enterprise in multiple layers and in multiple stages of the architectural life cycle. Initially PERA was part of the PERA methodology, which consisted of three main building blocks: * Purdue Enterprise Reference Architecture, * Purdue Reference Model, and * Purdue implementation procedures manual PERA has been further developed, and according to Gary Rathwell, PERA nowadays consists of the following components:

:* ''The PERA Enterprise Life-cycle Framework or Model or Architecture...''

:* ''Concepts of maximum and minimum lines of automation...''

:* ''Concepts explaining the effect of recycle and time delays on the design and operation of facilities.''

:* ''The PERA Master Planning Methodology''

:*''Concepts for dividing Enterprise Systems into Physical and Logical Architectures.''

:*''Purdue Reference Model for CIM including Generic Reference Data Flow Models.''

:*''Example Logical System Architectures from various industries...''

:*''Physical Systems Architecture Concepts including "Levels" and the "4Rs".''

:*''Example Physical architectures from various industries ...''

:*''Mapping of hardware and software products within the PERA Framework''

Later in the 1990s combined insights from PERA, and other reference architectures such as GRAI Integrated Methodology, CIM-OSA, and TOVE has led to the development of the Generic Enterprise Reference Architecture and Methodology

PERA has been further developed, and according to Gary Rathwell, PERA nowadays consists of the following components:

:* ''The PERA Enterprise Life-cycle Framework or Model or Architecture...''

:* ''Concepts of maximum and minimum lines of automation...''

:* ''Concepts explaining the effect of recycle and time delays on the design and operation of facilities.''

:* ''The PERA Master Planning Methodology''

:*''Concepts for dividing Enterprise Systems into Physical and Logical Architectures.''

:*''Purdue Reference Model for CIM including Generic Reference Data Flow Models.''

:*''Example Logical System Architectures from various industries...''

:*''Physical Systems Architecture Concepts including "Levels" and the "4Rs".''

:*''Example Physical architectures from various industries ...''

:*''Mapping of hardware and software products within the PERA Framework''

Later in the 1990s combined insights from PERA, and other reference architectures such as GRAI Integrated Methodology, CIM-OSA, and TOVE has led to the development of the Generic Enterprise Reference Architecture and Methodology

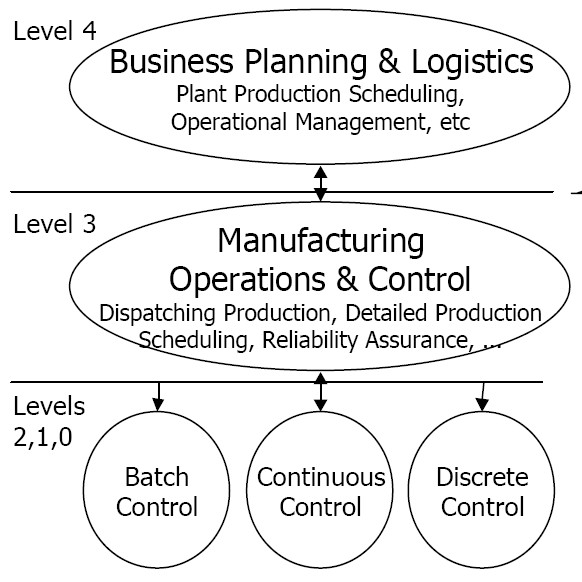

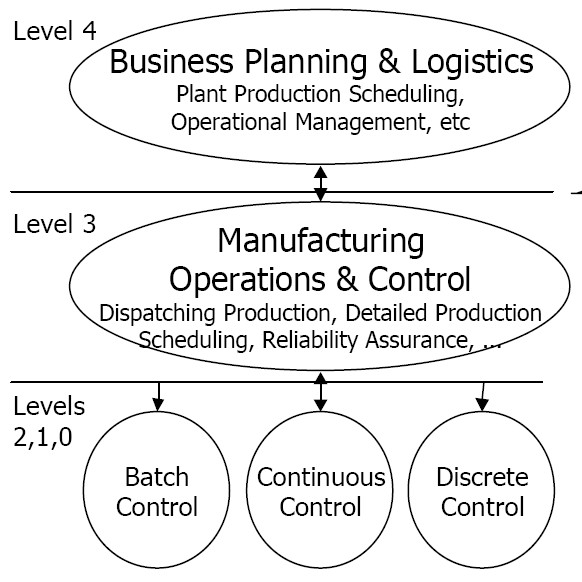

Levels for enterprise integration

Purdue Reference Model, “95” provides a model forenterprise control Enterprise control is the ability to combine control, intelligence and process management to enable business optimization that is inclusive of business and production operations. It combines the strength of both business processes and production op ...

, which end users, integrators and vendors can share in integrating applications at keyControl Global Magazine layers in the enterprise:

*Level 0 — The physical process — Defines the actual physical processes.

*Level 1 — Intelligent devices — Sensing and manipulating the physical processes. Process sensors, analyzers, actuators and related instrumentation.

*Level 2 — Control systems — Supervising, monitoring and controlling the physical processes. Real-time controls and software; DCS, human-machine interface (HMI); supervisory control and data acquisition (SCADA) software.

*Level 3 — Manufacturing operations systems — Managing production work flow to produce the desired products. Batch management; manufacturing execution/operations management systems (MES/MOMS); laboratory, maintenance and plant performance management systems; data historians and related middleware. Time frame: shifts, hours, minutes, seconds.

*Level 4 — Business logistics systems — Managing the business-related activities of the manufacturing operation. ERP is the primary system; establishes the basic plant production schedule, material use, shipping and inventory levels. Time frame: months, weeks, days, shifts.

See also

*ANSI/ISA-95

ANSI/ISA-95, or ISA-95 as it is more commonly referred, is an international standard from the International Society of Automation for developing an automated interface between enterprise and control systems. This standard has been developed for gl ...

* Enterprise integration

Enterprise integration is a technical field of enterprise architecture, which is focused on the study of topics such as system interconnection, electronic data interchange, product data exchange and distributed computing environments.

It is a con ...

* Manufacturing execution system

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision-makers understand how curr ...

* TOVE Project

The TOVE project ("Toronto Virtual Enterprise") is a project to develop an ontology (information science), ontological framework for enterprise integration (EI) based on and suited for enterprise modeling.Terje Totland (1997)5.2.3 Toronto Virtual ...

Publications

*Peter Bernus

Peter Bernus (born 1949) is a Hungarian Australian scientist and Associate Professor of Enterprise Architecture at the School of Information and Communication Technology, Griffith University, Brisbane, Australia.

and Laszlo Nemes (1996)A framework to define a generic enterprise reference architecture and methodology

" ''Computer Integrated Manufacturing Systems'' Vol 9 (3). p. 179-191. * David Chen,

Bruno Vallespir Bruno Vallespir (born 1960) is a French engineer, and Professor of Enterprise Modelling at the University of Bordeaux, working in the fields of production management, performance evaluation and enterprise modeling.Ejub Kajan eds. (2011) ''Electroni ...

, and Guy Doumeingts Guy Doumeingts (born 1938) is a French engineer, Emeritus professor at the University of Bordeaux 1 and former Director of "Laboratoire d’Automatique, Productique Signal et Image" control theory, known for the development of the GRAI method and ...

(1997). "GRAI integrated methodology and its mapping onto generic enterprise reference architecture and methodology." ''Computers in industry'' Vol 33 (2). p. 387-394.

* Theodore J. Williams Theodore Joseph Williams (1923 – April 27, 2013) was an American engineer and Professor of Engineering at Purdue University, known for the development of the Purdue Enterprise Reference Architecture.

Biography

Williams received his B.S., M.S., ...

(1992) ''The Purdue enterprise reference architecture: a technical guide for CIM planning and implementation''. Research Triangle Park, NC: Instrument Society of America.

* Theodore J. Williams (1993) "The Purdue enterprise reference architecture." ''Proceedings of the JSPE/IFIP TC5/WG5. 3 Workshop on the Design of Information Infrastructure Systems for Manufacturing''. North-Holland Publishing Co.

* Theodore J. Williams (1994) "The Purdue enterprise reference architecture." ''Computers in industry'' Vol 24 (2). p. 141-158.

References

External links

{{Commons category, Purdue Enterprise Reference ArchitecturePERA Enterprise Integration Web Site

Enterprise architecture frameworks Reference models