|

Computer Integrated Manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as ''flexible design and manufacturing''. Overview # Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. # The term "computer-integrated manufacturing" is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized. # In a CIM system functional areas such as design, analysis, planning, purchasing, cost accounting, inventory control, and distribution are linked through the computer with facto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

NIST Manufacturing Systems Integration Program

The National Institute of Standards and Technology (NIST) is an agency of the United States Department of Commerce whose mission is to promote American innovation and industrial competitiveness. NIST's activities are organized into physical science laboratory programs that include nanoscale science and technology, engineering, information technology, neutron research, material measurement, and physical measurement. From 1901 to 1988, the agency was named the National Bureau of Standards. History Background The Articles of Confederation, ratified by the colonies in 1781, provided: The United States in Congress assembled shall also have the sole and exclusive right and power of regulating the alloy and value of coin struck by their own authority, or by that of the respective states—fixing the standards of weights and measures throughout the United States. Article 1, section 8, of the Constitution of the United States, ratified in 1789, granted these powers to the new Cong ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Society Of Manufacturing Engineers

SME, also known as the Society of Manufacturing Engineers, is a non-profit A nonprofit organization (NPO), also known as a nonbusiness entity, nonprofit institution, not-for-profit organization, or simply a nonprofit, is a non-governmental (private) legal entity organized and operated for a collective, public, or so ... student and professional association for educating and advancing the manufacturing industry in North America. History SME was founded in January 1932 at the height of the Great Depression in the United States, Great Depression. Originally named the Society of Tool Engineers, and renamed the American Society of Tool Engineers one year later, it was formed by a group of 33 engineers and mechanics gathered at the Detroit College of Applied Science. By April of that year, just four months after its beginning, membership increased from the original 33 members to 200 members and continued to grow rapidly with new chapters popping up across the country. As the ec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, Industrial management, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Engineering

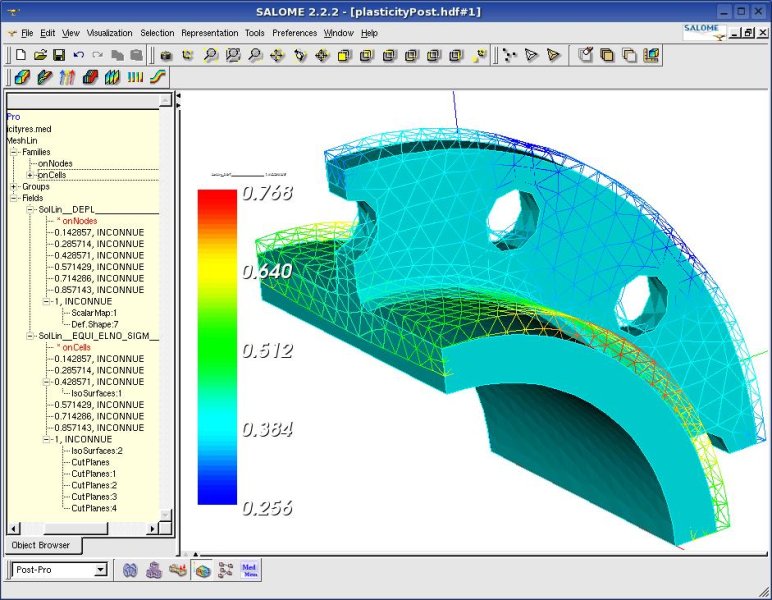

Computer-aided engineering (CAE) is the general usage of technology to aid in tasks related to engineering analysis. Any use of technology to solve or assist engineering issues falls under this umbrella. Overview Following alongside the consistent improvement in computer graphics and speed, computer aid assists engineers with once complicated and time consuming tasks with the input of information and a press of a button. It includes finite element method or analysis (FEA), computational fluid dynamics (CFD), multibody dynamics (MBD), durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) in a collective term and abbreviation computer-aided technologies (CAx). The term CAE has been used to describe the use of computer technology within engineering in a broader sense than just engineering analysis. It was in this context that the term was coined by Jason Lemon, founder of Structural Dynamics Research Corporation ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software help protect products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer-aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as ''electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics to depict t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Factory

A factory, manufacturing plant or production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. They are a critical part of modern economic production, with the majority of the world's goods being created or processed within factories. Factories arose with the introduction of machinery during the Industrial Revolution, when the capital and space requirements became too great for cottage industry or workshops. Early factories that contained small amounts of machinery, such as one or two spinning mules, and fewer than a dozen workers have been called "glorified workshops". Most modern factories have large warehouses or warehouse-like facilities that contain heavy equipment used for assembly line production. Large factories tend to be located with access to multiple modes of transportation, some having rail, highway and water load ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flexible Manufacturing System

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. This flexibility is generally considered to fall into two categories, which both contain numerous subcategories. * The first category is called routing flexibility, which covers the system's ability to be changed to produce new product types, and the ability to change the order of operations executed on a part. * The second category is called machine flexibility, which consists of the ability to use multiple machines to perform the same operation on a part, as well as the system's ability to absorb large-scale changes, such as in volume, capacity, or capability. Most flexible manufacturing systems consist of three main systems: # The work machines which are often automated CNC machines are connected by # A material handling system to optimize parts flow and # The central control compute ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lights Out (manufacturing)

Lights-out manufacturing or dark factory is the manufacturing methodology of fully automating the production of goods at factories and other industrial facilities, without requiring any human labour presence on-site. Many of these factories are considered to be able to run "with the lights off," but few run exclusively lights-out production. For example, in computer numerical control machining, the presence of human workers is typically required for removing completed parts and setting up tombstones that hold unfinished parts. As the technology necessary for total automation becomes increasingly available, many factories are beginning to use lights-out production between shifts (or as a separate shift) to meet increasing production demand or to save money on labor. An automatic factory is a place where raw materials enter, and finished products leave with little or no human intervention. One of the earliest descriptions of the automatic factory in fiction was the 1955 short sto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

Industrial process control (IPC) or simply process control is a system used in modern manufacturing which uses the principles of control theory and physical industrial control systems to monitor, control and optimize continuous Industrial processes, industrial production processes using control algorithms. This ensures that the industrial machines run smoothly and safely in factories and efficiently use energy to transform raw materials into high-quality finished products with reliable consistency while reducing Efficient energy use#Industry, energy waste and economic costs, something which could not be achieved purely by human manual control. In IPC, control theory provides the theoretical framework to understand system dynamics, predict outcomes and design control strategies to ensure predetermined objectives, utilizing concepts like feedback loops, stability analysis and controller design. On the other hand, the physical apparatus of IPC, based on automation technologies, cons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Data Integrity

Data integrity is the maintenance of, and the assurance of, data accuracy and consistency over its entire Information Lifecycle Management, life-cycle. It is a critical aspect to the design, implementation, and usage of any system that stores, processes, or retrieves data. The term is broad in scope and may have widely different meanings depending on the specific context even under the same general umbrella of computing. It is at times used as a proxy term for data quality, while data validation is a prerequisite for data integrity. Definition Data integrity is the opposite of data corruption. The overall intent of any data integrity technique is the same: ensure data is recorded exactly as intended (such as a database correctly rejecting mutually exclusive possibilities). Moreover, upon later Data retrieval, retrieval, ensure the data is the same as when it was originally recorded. In short, data integrity aims to prevent unintentional changes to information. Data integrity is no ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Guided Vehicle

An automated guided vehicle (AGV), different from an autonomous mobile robot (AMR), is a portable robot that follows along marked long lines or wires on the floor, or uses radio waves, vision cameras, magnets, or lasers for navigation. They are most often used in industrial applications to transport heavy materials around a large industrial building, such as a factory or warehouse. Application of the automatic guided vehicle broadened during the late 20th century. Introduction The AGV can tow objects behind them in trailers to which they can autonomously attach. The trailers can be used to move raw materials or finished products. The AGV can also store objects on a bed. The objects can be placed on a set of motorized rollers (conveyor) and then pushed off by reversing them. AGVs are employed in nearly every industry, including pulp, paper, metals, newspaper, and general manufacturing. Transporting materials such as food, linen or medicine in hospitals is also done. An AG ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Communications Protocols

A communication protocol is a system of rules that allows two or more entities of a communications system to transmit information via any variation of a physical quantity. The protocol defines the rules, syntax, semantics, and synchronization of communication and possible error recovery methods. Protocols may be implemented by hardware, software, or a combination of both. Communicating systems use well-defined formats for exchanging various messages. Each message has an exact meaning intended to elicit a response from a range of possible responses predetermined for that particular situation. The specified behavior is typically independent of how it is to be implemented. Communication protocols have to be agreed upon by the parties involved. To reach an agreement, a protocol may be developed into a technical standard. A programming language describes the same for computations, so there is a close analogy between protocols and programming languages: ''protocols are to communicat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |