Pulped 1983–1992 on:

[Wikipedia]

[Google]

[Amazon]

Pulp is a

Pulp is a

'Charles Fenerty and his Paper Invention''. Toronto: Peter Burger, 2007. pp.25–30 Chemical processes quickly followed, first with

The timber resources used to make wood pulp are referred to as

The timber resources used to make wood pulp are referred to as

Thermomechanical pulp is pulp produced by processing Woodchips, wood chips using heat (thus "wikt:thermo-, thermo-") and a mechanical refining movement (thus "-mechanical"). It is a two-stage process where the logs are first stripped of their

Thermomechanical pulp is pulp produced by processing Woodchips, wood chips using heat (thus "wikt:thermo-, thermo-") and a mechanical refining movement (thus "-mechanical"). It is a two-stage process where the logs are first stripped of their

Chemical pulp is produced by combining wood chips and chemicals in large vessels called digesters. There, heat and chemicals break down lignin, which binds cellulose fibres together, without seriously degrading the cellulose fibres. Chemical pulp is used for materials that need to be stronger or combined with mechanical pulps to give a product different characteristics. The kraft process is the dominant chemical pulping method, with the sulfite process second. Historically soda pulping was the first successful chemical pulping method.

Chemical pulp is produced by combining wood chips and chemicals in large vessels called digesters. There, heat and chemicals break down lignin, which binds cellulose fibres together, without seriously degrading the cellulose fibres. Chemical pulp is used for materials that need to be stronger or combined with mechanical pulps to give a product different characteristics. The kraft process is the dominant chemical pulping method, with the sulfite process second. Historically soda pulping was the first successful chemical pulping method.

Versuche und Muster ohne alle Lumpen oder doch mit enem geringen Zusatze derselben Papier zu machen

' by Jacob Christian Schäffer on Google Books * Johan Richter (inventor), Johan Richter, developer of the process for continuous cooking of pulp * World Forestry Congress

Pulp is a

Pulp is a lignocellulosic

Lignocellulose refers to plant dry matter (biomass), so called lignocellulosic biomass. It is the most abundantly available raw material on the Earth for the production of biofuels. It is composed of two kinds of carbohydrate polymers, cellulose a ...

fibrous material prepared by chemically or mechanically separating cellulose fibers from wood, fiber crop

Fiber crops are field crops grown for their fibers, which are traditionally used to make paper, cloth, or rope.

Fiber crops are characterized by having a large concentration of cellulose, which is what gives them their strength. The fibers may b ...

s, waste paper, or rags. Mixed with water and other chemical or plant-based additives, pulp is the major raw material used in papermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a speciali ...

and the industrial production of other paper products.

History

Before the widely acknowledged invention ofpapermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a speciali ...

by Cai Lun

Cai Lun (; courtesy name: Jingzhong (); – 121 CE), formerly romanized as Ts'ai Lun, was a Chinese eunuch court official of the Eastern Han dynasty. He is traditionally regarded as the inventor of paper and the modern papermaking process ...

in China around 105 AD, paper-like writing materials such as papyrus and amate were produced by ancient civilizations using plant materials which were largely unprocessed. Strips of bark

Bark may refer to:

* Bark (botany), an outer layer of a woody plant such as a tree or stick

* Bark (sound), a vocalization of some animals (which is commonly the dog)

Places

* Bark, Germany

* Bark, Warmian-Masurian Voivodeship, Poland

Arts, ...

or bast material were woven together, beaten into rough sheets, dried, and polished by hand. Pulp used in modern and traditional papermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a speciali ...

is distinguished by the process which produces a finer, more regular slurry of cellulose fibers which are pulled out of solution by a screen and dried to form sheets or rolls. The earliest paper produced in China consisted of bast fibers from the paper mulberry (kozo) plant along with hemp

Hemp, or industrial hemp, is a botanical class of ''Cannabis sativa'' cultivars grown specifically for industrial or medicinal use. It can be used to make a wide range of products. Along with bamboo, hemp is among the fastest growing plants o ...

rag and net scraps. By the 6th century, the mulberry tree was domesticated by farmers in China specifically for the purpose of producing pulp to be used in the papermaking process. In addition to mulberry, pulp was also made from bamboo, hibiscus bark, blue sandalwood, straw

Straw is an agricultural byproduct consisting of the dry stalks of cereal plants after the grain and chaff have been removed. It makes up about half of the yield of cereal crops such as barley, oats, rice, rye and wheat. It has a number ...

, and cotton. Papermaking using pulp made from hemp and linen

Linen () is a textile made from the fibers of the flax plant.

Linen is very strong, absorbent, and dries faster than cotton. Because of these properties, linen is comfortable to wear in hot weather and is valued for use in garments. It also ...

fibers from tattered clothing, fishing nets and fabric bags spread to Europe in the 13th century, with an ever-increasing use of rags being central to the manufacture and affordability of rag paper, a factor in the development of printing. By the 1800s, production demands on the newly industrialized papermaking and printing industries led to a shift in raw materials, most notably the use of pulpwood

Pulpwood is timber with the principal use of making wood pulp for paper production.

Applications

* Trees raised specifically for pulp production account for 15% of world pulp production, old growth forests 9% and second- and third- and more gener ...

and other tree products which today make up more than 95% of global pulp production.

The use of wood pulp and the invention of automatic paper machines in the late 18th- and early 19th-century contributed to paper's status as an inexpensive commodity in modern times. While some of the earliest examples of paper made from wood pulp include works published by Jacob Christian Schäffer in 1765 and Matthias Koops in 1800, large-scale wood paper production began in the 1840s with unique, simultaneous developments in mechanical pulping made by Friedrich Gottlob Keller in Germany and by Charles Fenerty in Nova Scotia.Burger, Peter'Charles Fenerty and his Paper Invention''. Toronto: Peter Burger, 2007. pp.25–30 Chemical processes quickly followed, first with

J. Roth

''J. The Jewish News of Northern California'', formerly known as ''Jweekly'', is a weekly print newspaper in Northern California, with its online edition updated daily. It is owned and operated by San Francisco Jewish Community Publications In ...

's use of sulfurous acid

Sulfurous acid (also sulfuric(IV) acid, sulphurous acid (UK), sulphuric(IV) acid (UK)) is the chemical compound with the formula . There is no evidence that sulfurous acid exists in solution, but the molecule has been detected in the gas phase. ...

to treat wood, then by Benjamin Tilghman

Benjamin Chew Tilghman (18211901) was an American soldier and inventor. He is best known as the inventor of the process of sandblasting.

Early life

He was born in Philadelphia, Pennsylvania, on October 26, 1821, the third child of Benjamin and An ...

's U.S. patent

Under United States law, a patent is a right granted to the inventor of a (1) process, machine, article of manufacture, or composition of matter, (2) that is new, useful, and non-obvious. A patent is the right to exclude others, for a limited ...

on the use of calcium bisulfite, Ca(HSO3)2, to pulp wood in 1867. Almost a decade later, the first commercial sulfite pulp mill was built, in Sweden. It used magnesium as the counter ion and was based on work by Carl Daniel Ekman

Carl Daniel Ekman (March 17, 1845 – November 3, 1904) was a Swedish chemical engineer who invented the form of the sulfite process of wood pulp manufacturing which was first established on a firm commercial basis, helping to replace rags as the ...

. By 1900, sulfite pulping had become the dominant means of producing wood pulp, surpassing mechanical pulping methods. The competing chemical pulping process, the sulfate, or kraft

The second incarnation of Kraft Foods is an American food manufacturing and processing conglomerate, split from Kraft Foods Inc. in 2012 and headquartered in Chicago, Illinois. It became part of Kraft Heinz in 2015.

A merger with Heinz, arra ...

, process, was developed by Carl F. Dahl in 1879; the first kraft mill started, in Sweden, in 1890. The invention of the recovery boiler Recovery boiler is the part of kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usual ...

, by G.H. Tomlinson

GH, Gh, gh, or .gh may refer to:

* gh (digraph), a digraph found in many languages

* Gästrike-Hälsinge nation, a student association at Uppsala University, Sweden

* ''General Hospital'', an American daytime medical drama

* Ghana (ISO 3166-1 alph ...

in the early 1930s, allowed kraft mills to recycle almost all of their pulping chemicals. This, along with the ability of the kraft process to accept a wider variety of types of wood and to produce stronger fibres, made the kraft process the dominant pulping process, starting in the 1940s.

Global production of wood pulp in 2006 was 175 million tons (160 million tonnes). In the previous year, 63 million tons (57 million tonnes) of market pulp (not made into paper in the same facility) was sold, with Canada being the largest source at 21 percent of the total, followed by the United States at 16 percent. The wood fiber sources required for pulping are "45% sawmill residue, 21% logs and chips, and 34% recycled paper" (Canada, 2014). Chemical pulp made up 93% of market pulp.

Wood pulp

The timber resources used to make wood pulp are referred to as

The timber resources used to make wood pulp are referred to as pulpwood

Pulpwood is timber with the principal use of making wood pulp for paper production.

Applications

* Trees raised specifically for pulp production account for 15% of world pulp production, old growth forests 9% and second- and third- and more gener ...

. While in theory any tree can be used for pulp-making, coniferous trees are preferred because the cellulose fibers in the pulp of these species are longer, and therefore make stronger paper.

Some of the most commonly used softwood

file:Pinus sylvestris wood ray section 1 beentree.jpg, Scots Pine, a typical and well-known softwood

Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main diff ...

trees for paper making include spruce

A spruce is a tree of the genus ''Picea'' (), a genus of about 35 species of coniferous evergreen trees in the family Pinaceae, found in the northern temperate and boreal (taiga) regions of the Earth. ''Picea'' is the sole genus in the subfami ...

, pine, fir

Firs (''Abies'') are a genus of 48–56 species of evergreen coniferous trees in the family (biology), family Pinaceae. They are found on mountains throughout much of North America, North and Central America, Europe, Asia, and North Africa. The ...

, larch and Tsuga, hemlock, and hardwoods such as eucalyptus, aspen and birch. There is also increasing interest in Genetically modified tree, genetically modified tree species (such as GM eucalyptus and GM Populus, poplar) because of several major benefits these can provide, such as increased ease of breaking down lignin and increased growth rate.

A pulp mill is a manufacturing facility that converts wood chips or other plant fibre source into a thick fiberboard which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical or fully chemical methods (kraft and sulfite processes). The finished product may be either Bleaching of wood pulp, bleached or non-bleached, depending on the customer requirements.

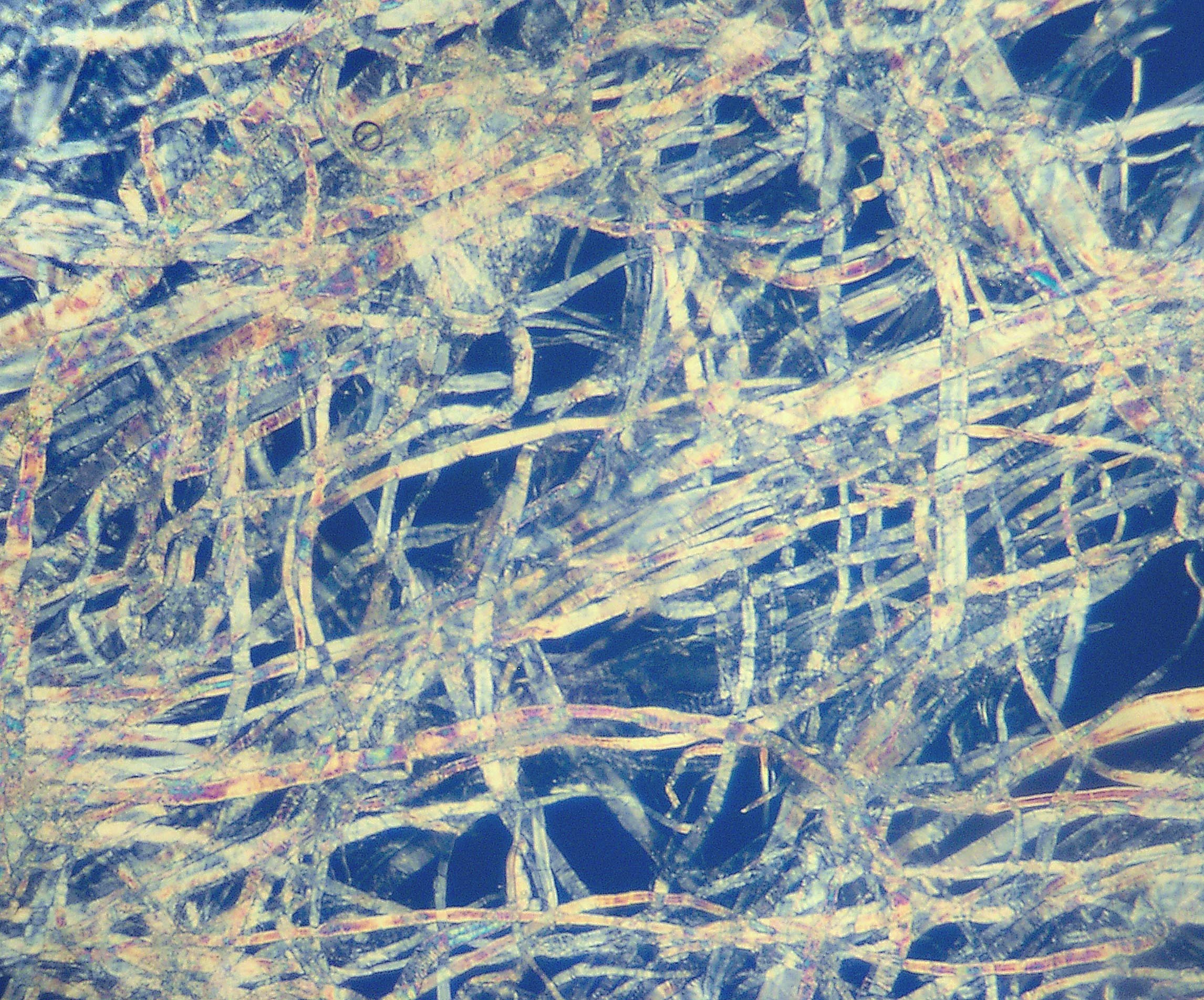

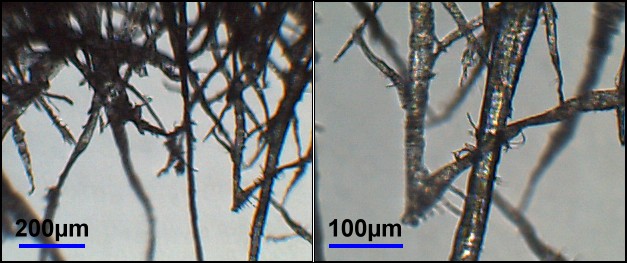

Wood and other plant materials used to make pulp contain three main components (apart from water): cellulose fibers (desired for papermaking), lignin (a three-dimensional polymer that binds the cellulose fibres together) and hemicelluloses (shorter branched carbohydrate polymers). The aim of pulping is to break down the bulk structure of the fibre source, be it chips, stems or other plant parts, into the constituent fibres.

Chemical pulping achieves this by degrading the lignin and hemicellulose into small, water-soluble molecules which can be washed away from the cellulose fibres without Depolymerization, depolymerizing the cellulose fibres (chemically depolymerizing the cellulose weakens the fibres). The various mechanical pulping methods, such as groundwood (GW) and refiner mechanical pulping (RMP), physically tear the cellulose fibres one from another. Much of the lignin remains adhering to the fibres. Strength is impaired because the fibres may be cut. There are a number of related hybrid pulping methods that use a combination of chemical and thermal treatment to begin an abbreviated chemical pulping process, followed immediately by a mechanical treatment to separate the fibres. These hybrid methods include thermomechanical pulping, also known as TMP, and chemithermomechanical pulping, also known as CTMP. The chemical and thermal treatments reduce the amount of energy subsequently required by the mechanical treatment, and also reduce the amount of strength loss suffered by the fibres.

Harvesting trees

Most pulp mills use good forest management practices in harvesting trees to ensure that they have a sustainable source of raw materials. One of the major complaints about harvesting wood for pulp mills is that it reduces the biodiversity of the harvested forest. Pulp tree plantations account for 16 percent of world pulp production, old-growth forests 9 percent, and second- and third- and more generation forests account for the rest. Reforestation is practiced in most areas, so trees are a renewable resource. The FSC (Forest Stewardship Council), SFI (Sustainable Forestry Initiative), PEFC (Programme for the Endorsement of Forest Certification), and other bodies certify paper made from trees harvested according to guidelines meant to ensure good forestry practices. The number of trees consumed depends on whether mechanical processes or chemical processes are used. It has been estimated that based on a mixture ofsoftwood

file:Pinus sylvestris wood ray section 1 beentree.jpg, Scots Pine, a typical and well-known softwood

Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main diff ...

s and hardwoods 12 metres (40 ft) tall and 15–20 centimetres (6–8 in) in diameter, it would take an average of 24 trees to produce 0.9 tonne (1 ton) of printing and writing paper, using the kraft process (chemical pulping). Mechanical pulping is about twice as efficient in using trees, since almost all of the wood is used to make fibre, therefore it takes about 12 trees to make 0.9 tonne (1 ton) of mechanical pulp or newsprint.

There are roughly two short tons in a Cord (unit), cord of wood.

Preparation for pulping

Wood chipping is the act and industry of chipping wood for pulp, but also for other Wood processing, processed wood products and mulch. Only the heartwood and sapwood (wood), sapwood are useful for making pulp. Bark (botany), Bark contains relatively few useful fibers and is removed and used as fuel to provide steam for use in the pulp mill. Most pulping processes require that the wood be chipped and screened to provide uniform sized chips.Pulping

There are a number of different processes which can be used to separate the wood fiber:Mechanical pulp

Manufactured grindstones with embedded silicon carbide or aluminum oxide can be used to grind small wood logs called "bolts" to make stone pulp (SGW). If the wood is steamed prior to grinding it is known as pressure ground wood pulp (PGW). Most modern mills use chips rather than logs and ridged metal discs called refiner plates instead of grindstones. If the chips are just ground up with the plates, the pulp is called refiner mechanical pulp (RMP) and if the chips are steamed while being refined the pulp is called thermomechanical pulp (TMP). Steam treatment significantly reduces the total energy needed to make the pulp and decreases the damage (cutting) to fibres. Mechanical pulps are used for products that require less strength, such as newsprint and paperboards.Thermomechanical pulp

Thermomechanical pulp is pulp produced by processing Woodchips, wood chips using heat (thus "wikt:thermo-, thermo-") and a mechanical refining movement (thus "-mechanical"). It is a two-stage process where the logs are first stripped of their

Thermomechanical pulp is pulp produced by processing Woodchips, wood chips using heat (thus "wikt:thermo-, thermo-") and a mechanical refining movement (thus "-mechanical"). It is a two-stage process where the logs are first stripped of their bark

Bark may refer to:

* Bark (botany), an outer layer of a woody plant such as a tree or stick

* Bark (sound), a vocalization of some animals (which is commonly the dog)

Places

* Bark, Germany

* Bark, Warmian-Masurian Voivodeship, Poland

Arts, ...

and converted into small chips. These chips have a moisture content of around 25–30 percent. A mechanical force is applied to the wood chips in a crushing or grinding action which generates heat and water vapour and softens the lignin thus separating the individual fibres. The pulp is then screened and cleaned, any clumps of fibre are reprocessed. This process gives a high yield of fibre from the timber (around 95 percent) and as the lignin has not been removed, the fibres are hard and rigid.

Chemi-thermomechanical pulp

Wood chips can be pre-treated with sodium carbonate, sodium hydroxide, sodium sulfate and other chemicals prior to refining with equipment similar to a mechanical mill. The conditions of the chemical treatment are much less vigorous (lower temperature, shorter time, less extreme pH) than in a chemical pulping process since the goal is to make the fibers easier to refine, not to remove lignin as in a fully chemical process. Pulps made using these hybrid processes are known as chemi-thermomechanical pulps (CTMP).Chemical pulp

Chemical pulp is produced by combining wood chips and chemicals in large vessels called digesters. There, heat and chemicals break down lignin, which binds cellulose fibres together, without seriously degrading the cellulose fibres. Chemical pulp is used for materials that need to be stronger or combined with mechanical pulps to give a product different characteristics. The kraft process is the dominant chemical pulping method, with the sulfite process second. Historically soda pulping was the first successful chemical pulping method.

Chemical pulp is produced by combining wood chips and chemicals in large vessels called digesters. There, heat and chemicals break down lignin, which binds cellulose fibres together, without seriously degrading the cellulose fibres. Chemical pulp is used for materials that need to be stronger or combined with mechanical pulps to give a product different characteristics. The kraft process is the dominant chemical pulping method, with the sulfite process second. Historically soda pulping was the first successful chemical pulping method.

Recycled pulp

Recycled pulp is also called deinked pulp (DIP). DIP is paper recycling, recycled paper which has been processed by chemicals, thus removing printing inks and other unwanted elements and freed the paper fibres. The process is called deinking. DIP is used as raw material inpapermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a speciali ...

. Many newsprint, toilet paper and facial tissue grades commonly contain 100 percent deinked pulp and in many other grades, such as lightweight coated for offset and printing and writing papers for office and home use, DIP makes up a substantial proportion of the furnish.

Organosolv pulping

Organosolv pulping uses organic solvents at temperatures above 140 °C to break down lignin and hemicellulose into soluble fragments. The pulping liquor is easily recovered by distillation. The reason for using a solvent is to make the lignin more soluble in the cooking liquor. Most common used solvents are methanol, ethanol, formic acid and acetic acid often in combination with water.Alternative pulping methods

Research is under way to develop biopulping (biological pulping), similar to chemical pulping but using certain species of fungus, fungi that are able to break down the unwanted lignin, but not the cellulose fibres. In the biopulping process, the fungal enzyme lignin peroxidase selectively digests lignin to leave remaining cellulose fibres. This could have major Environmentally friendly, environmental benefits in reducing the pollution associated with chemical pulping. The pulp is bleached using chlorine dioxide stage followed by neutralization and calcium hypochlorite. The oxidizing agent in either case oxidizes and destroys the dyes formed from the tannins of the wood and accentuated (reinforced) by sulfides present in it. Steam exploded fiber, Steam exploded fibre is a pulping and extraction technique that has been applied to wood and other fibrous organic material.Bleaching

The pulp produced up to this point in the process can be bleaching of wood pulp, bleached to produce a white paper product. The chemicals used to bleach pulp have been a source of environmental concern, and recently the pulp industry has been using alternatives to chlorine, such as chlorine dioxide, oxygen, ozone and hydrogen peroxide.Alternatives to wood pulp

Pulp made from non-wood plant sources or Textile recycling, recycled textiles is manufactured today largely as a speciality product for fine-printing and art purposes. Modern machine- and hand-made art papers made with cotton, linen, hemp, abaca, Japanese tissue, kozo, and other fibers are often valued for their longer, stronger fibers and their lower lignin content. Lignin, present in virtually all plant materials, contributes to the acidification and eventual breakdown of paper products, often characterized by the browning and embrittling of paper with a high lignin content such as newsprint. 100% cotton or a combination of cotton and linen pulp is widely used to produce documents intended for long-term use, such as certificates, currency, and passports. Today, some groups advocate using field crop fibre or agricultural residues instead of wood fibre as a more sustainability, sustainable means of production. There is enoughstraw

Straw is an agricultural byproduct consisting of the dry stalks of cereal plants after the grain and chaff have been removed. It makes up about half of the yield of cereal crops such as barley, oats, rice, rye and wheat. It has a number ...

to meet much of North America's book, magazine, catalogue and copy paper needs. Agricultural-based paper does not come from tree farms. Some agricultural residue pulps take less time to cook than wood pulps. That means agricultural-based paper uses less energy, less water and fewer chemicals. Pulp made from wheat and flax straw has half the ecological footprint of pulp made from forests.

Hemp paper is a possible replacement, but processing infrastructure, storage costs and the low usability percentage of the plant means it is not a ready substitute.

However, wood is also a renewable resource, with about 90 percent of pulp coming from plantations or reforested areas. Non-wood fibre sources account for about 5–10 percent of global pulp production, for a variety of reasons, including seasonal availability, problems with chemical recovery, brightness of the pulp etc. In China, as of 2009, a higher proportion of non-wood pulp processing increased use of water and energy.

Nonwovens are in some applications alternatives to paper made from wood pulp, like filter paper or tea bags.

Market pulp

Market pulp is any variety of pulp that is produced in one location, dried and shipped to another location for further processing. Important quality parameters for pulp not directly related to the fibres are brightness, dirt levels, viscosity and ash content. In 2004 it accounted for about 55 million metric tons of market pulp. Air dry pulp is the most common form to sell pulp. This is pulp dried to about 10 percent moisture content. It is normally delivered as sheeted bales of 250 kg. The reason to leave 10 percent moisture in the pulp is that this minimizes the fibre to fibre bonding and makes it easier to disperse the pulp in water for further processing to paper. Roll pulp or ''reel pulp'' is the most common delivery form of pulp to non traditional pulp markets. Fluff pulp is normally shipped on rolls (reels). This pulp is dried to 5–6 percent moisture content. At the customer this is going to a comminution process to prepare for further processing. Some pulps are flash dried. This is done by pressing the pulp to about 50 percent moisture content and then let it fall through silos that are 15–17 m high. Gas fired hot air is the normal heat source. The temperature is well above the charring, char point of cellulose, but large amount of moisture in the cell wall, fibre wall and lumen (anatomy), lumen prevents the fibres from being incinerated. It is often not dried down to 10 percent moisture (air dry). The bales are not as densely packed as air dry pulp.Environmental concerns

The major environmental impacts of producing wood pulp come from its impact on forest sources and from its waste products.Forest resources

The impact of logging to provide the raw material for wood pulp is an area of intense debate. Modern logging practices, using forest management seek to provide a reliable, renewable source of raw materials for pulp mills. The practice of clear cutting is a particularly sensitive issue since it is a very visible effect of logging. Reforestation, the planting of tree seedlings on logged areas, has also been criticized for decreasing biodiversity because reforested areas are monocultures. Logging of old growth forests accounts for less than 10 percent of wood pulp, but is one of the most controversial issues.Effluents from pulp mills

The process effluents are treated in a biological Industrial wastewater treatment, effluent treatment plant, which guarantees that the effluents are not toxic in the recipient. Mechanical pulp is not a major cause for environmental concern since most of the organic material is retained in the pulp, and the chemicals used (hydrogen peroxide and sodium dithionite) produce benign byproducts (water and sodium sulfate (finally), respectively). Chemical pulp mills, especially kraft mills, are energy self-sufficient and very nearly closed cycle with respect to inorganic chemicals. Bleaching of wood pulp, Bleaching with chlorine produces large amounts of organochlorine compounds, including polychlorinated dibenzo-p-dioxins, polychlorinated dibenzofurans (PCDD/Fs). Many mills have adopted alternatives to chlorinated bleaching agents thereby reducing emissions of organochlorine pollution.Odor problems

The kraft pulping reaction in particular releases foul-smelling compounds. The hydrogen sulfide reagent that degrades lignin structure also causes some demethylation to produce methanethiol, dimethyl sulfide and dimethyl disulfide. These same compounds are released during many forms of microbial decay, including the internal microbial action in Camembert cheese, although the kraft process is a chemical one and does not involve any microbial degradation. These compounds have extremely low odor thresholds and disagreeable smells.Applications

The main applications for pulp are paper and Paperboard, board production. The furnish of pulps used depends on the quality on the finished paper. Important quality parameters are Pulpwood, wood furnish, Bleaching of wood pulp, brightness, viscosity, extractives, dirt count and strength. Chemical pulps are used for making nanocellulose. Speciality pulp grades have many other applications. Dissolving pulp is used in making Viscose, regenerated cellulose that is used Rayon, textile and cellophane production. It is also used to make cellulose derivatives. Fluff pulp is used in diapers, feminine hygiene products and Nonwoven fabric, nonwovens.Paper production

The Fourdrinier Machine is the basis for most modernpapermaking

Papermaking is the manufacture of paper and cardboard, which are used widely for printing, writing, and packaging, among many other purposes. Today almost all paper is made using industrial machinery, while handmade paper survives as a speciali ...

, and it has been used in some variation since its conception. It accomplishes all the steps needed to transform pulp into a final paper product.

Economics

In 2009, NBSK pulp sold for $650/ton in the United States. The price had dropped due to falling demand when newspapers reduced their size, in part, as a result of the recession.See also

* Nanocellulose * Paper chemicals * Pulp mill * Pulpwood *Versuche und Muster ohne alle Lumpen oder doch mit enem geringen Zusatze derselben Papier zu machen

' by Jacob Christian Schäffer on Google Books * Johan Richter (inventor), Johan Richter, developer of the process for continuous cooking of pulp * World Forestry Congress

References

Bibliography

* . {{DEFAULTSORT:Pulp (Paper) Wood products Papermaking Cellulose