Pipe Ramming on:

[Wikipedia]

[Google]

[Amazon]

Pipe ramming (sometimes also called pipe jacking) is a

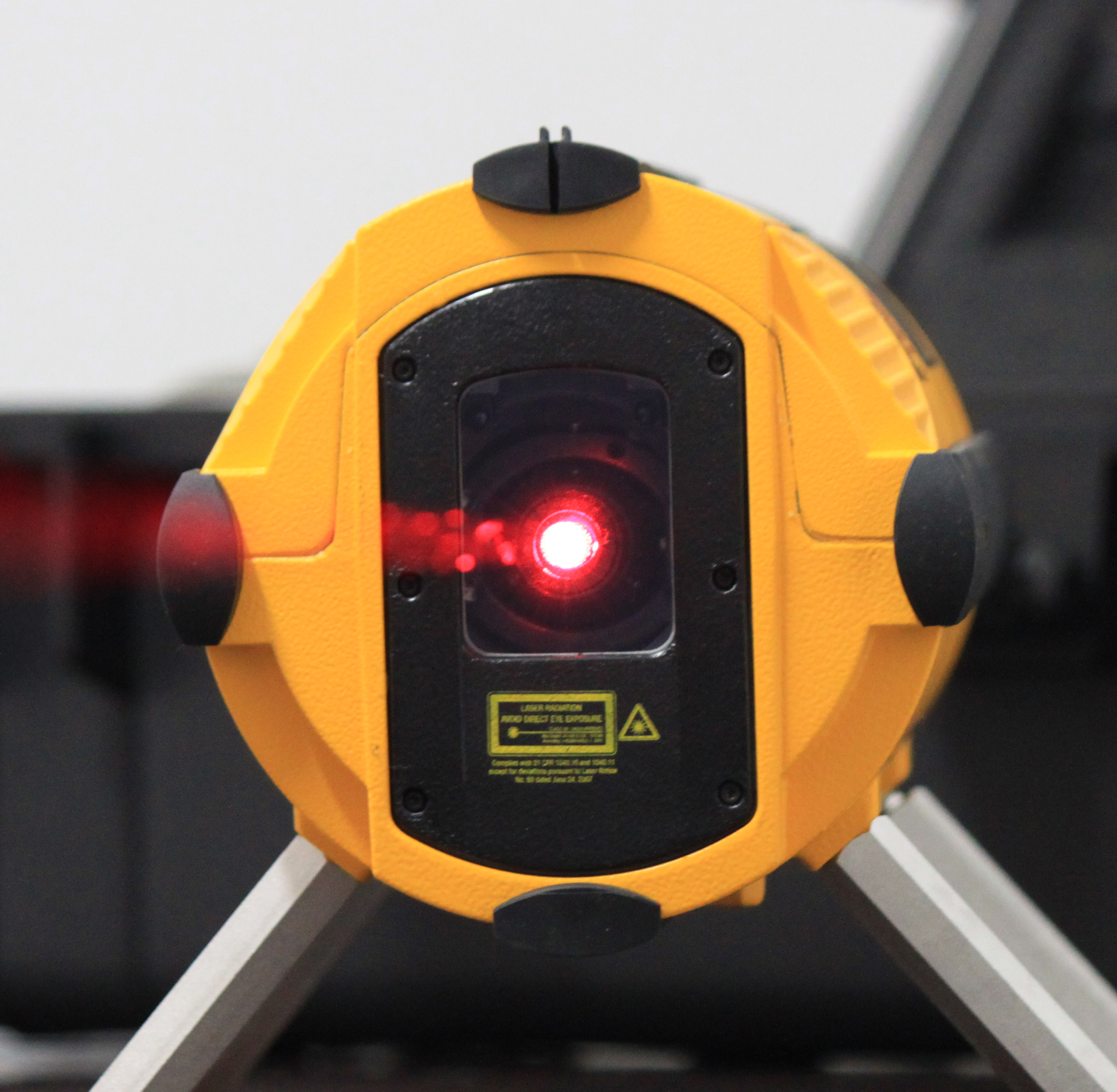

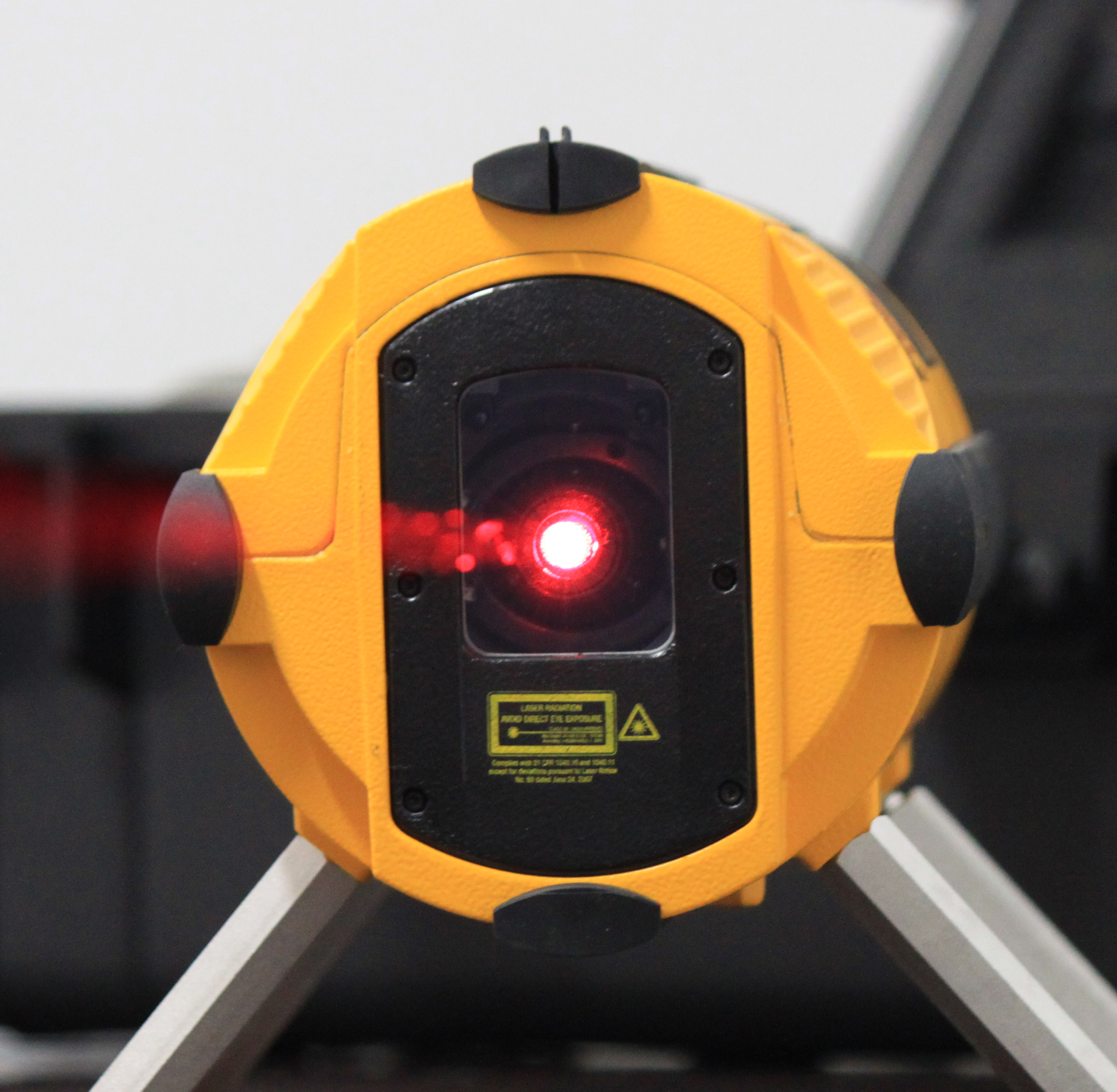

The alignment is controlled using a laser beam from the launch shaft, which guides the machine through the tunnel axis. The laser is the basic control device and it works with inclinometers and gyroscopes. The laser beam is directed to the machine cutter head and its position is controlled in real time by a navigation system at the surface.

The alignment is controlled using a laser beam from the launch shaft, which guides the machine through the tunnel axis. The laser is the basic control device and it works with inclinometers and gyroscopes. The laser beam is directed to the machine cutter head and its position is controlled in real time by a navigation system at the surface.

OSU Pipe Ramming Research

TTC.latech.edu

{{Authority control Trenchless technology Subterranean excavating equipment companies

trenchless

Trenchless technology is a type of subsurface construction work that requires few trenches or no continuous trenches. It is a rapidly growing sector of the construction and civil engineering industry. It can be defined as "a family of methods, mate ...

method for installation of steel pipe

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It ...

s and casings. Distances of 30 m (150 feet) or more and over 500 mm (20 inches) in diameter are common, although the method can be used for much longer and larger installations.

The method is useful for pipe and casing installations under railway line

Rail terminology is a form of technical terminology. The difference between the American term ''railroad'' and the international term ''railway'' (used by the International Union of Railways and English-speaking countries outside the United Sta ...

s and road

A road is a linear way for the conveyance of traffic that mostly has an improved surface for use by vehicles (motorized and non-motorized) and pedestrians. Unlike streets, the main function of roads is transportation.

There are many types of ...

s, where other trenchless methods could cause subsidence

Subsidence is a general term for downward vertical movement of the Earth's surface, which can be caused by both natural processes and human activities. Subsidence involves little or no horizontal movement, which distinguishes it from slope move ...

or heaving. The majority of installations are horizontal, although the method can be used for vertical installations.

The main differences between pipe ramming and pipe jacking are that pipe ramming uses percussion and does not have a navigation system, while pipe jacking uses hydraulic jacks and does have an active navigation system. Pipe ramming is preferable for shorter distances and applications that do not require tight directional control, such as cable installations.

The method uses pneumatic percussive blows to drive the pipe through the ground. The leading edge of the pipe is almost always open, and is typically closed only when smaller pipes are being installed. The shape allows a small overcut (to reduce friction between the pipe and soil and improve load conditions on the pipe), and directs the soil into the pipe interior instead of compacting it outside the pipe. These objectives are usually achieved by attaching a soil-cutting shoe or special bands to the pipe.

Further reduction of friction is typically achieved with lubrication, and different types of bentonite

Bentonite () is an absorbent swelling clay consisting mostly of montmorillonite (a type of smectite) which can either be Na-montmorillonite or Ca-montmorillonite. Na-montmorillonite has a considerably greater swelling capacity than Ca-mon ...

and/or polymers

A polymer (; Greek '' poly-'', "many" + ''-mer'', "part")

is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic an ...

can be used (as in horizontal directional boring

Directional boring, also referred to as horizontal directional drilling (HDD), is a minimal impact trenchless method of installing underground utilities such as pipe, conduit, or cables in a relatively shallow arc or radius along a prescribed unde ...

) for this purpose.

Spoil

Spoil or spoils:

*Plunder taken from an enemy or victim

*Material (such as rock, earth or other overburden) removed during:

**excavation

**mining

**dredging

Dredging is the excavation of material from a water environment. Possible reasons f ...

removal from the pipe can be performed after the entire pipe is in place (shorter installations). If the pipe containing the spoil becomes too heavy before the installation is complete, the ramming can be interrupted and the pipe cleaned (longer installations). Spoil can be removed by auger, compressed air or water jetting.

Research on instrumented pipe ramming installations has allowed the development of pipe ramming-specific models for static soil resistance and dynamic model parameters for simulating drivability of rammed pipes. These procedures can be used to estimate the feasibility of pipe ramming installations.

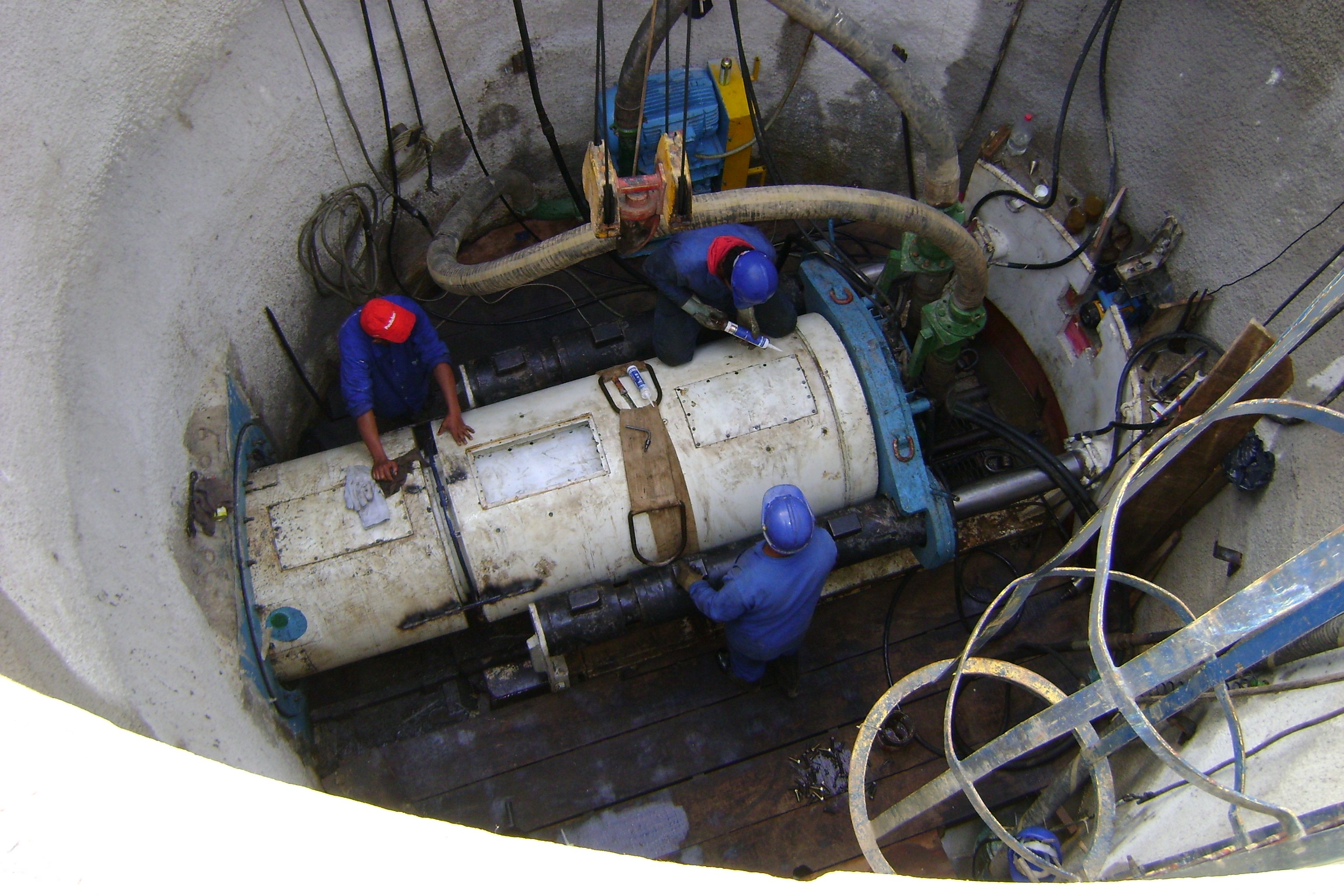

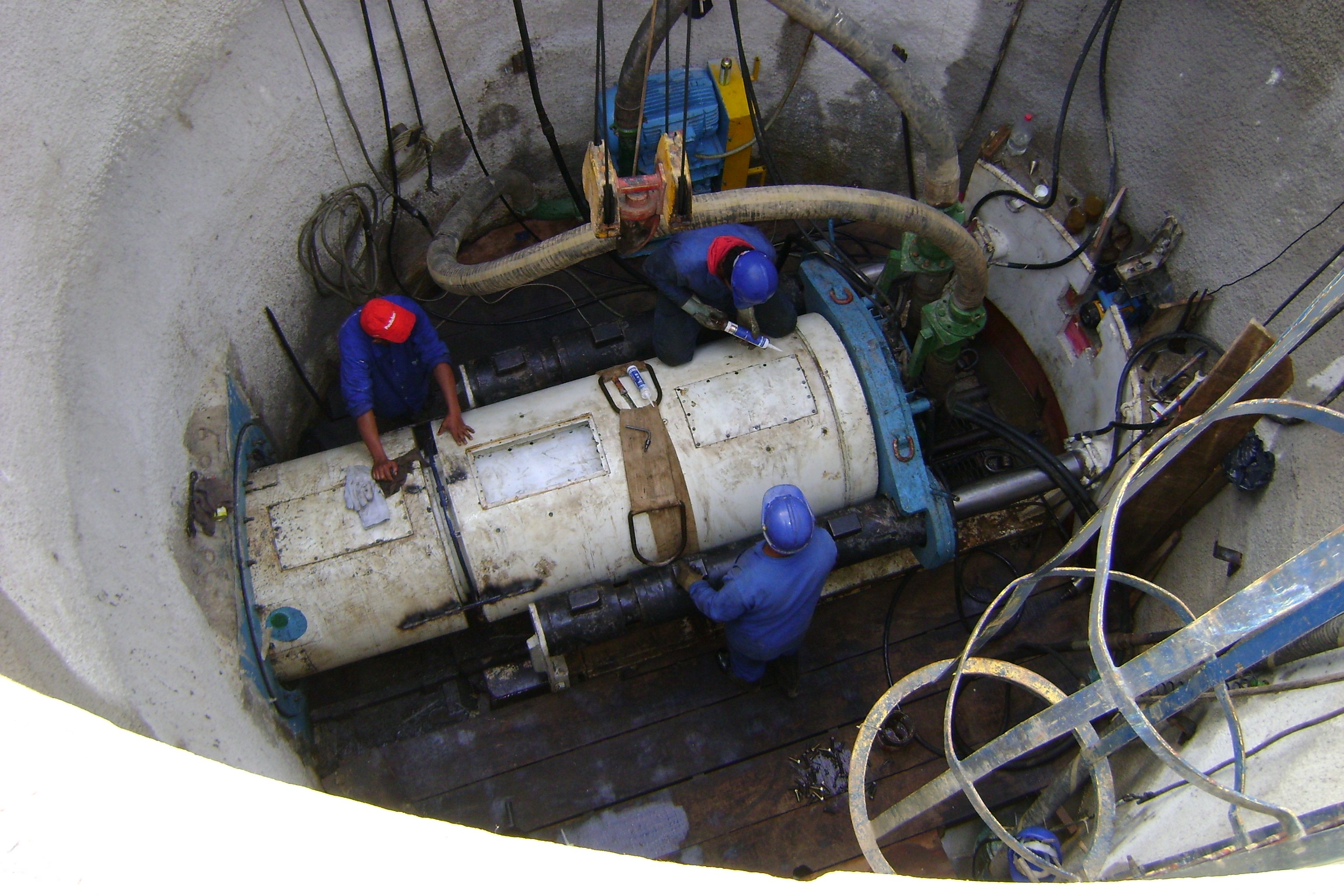

Pipe jacking

The pipe jacking method consists on the principle of driving the tunnel from a launch shaft in the direction of a target (or reception) shaft. The alignment is controlled using a laser beam from the launch shaft, which guides the machine through the tunnel axis. The laser is the basic control device and it works with inclinometers and gyroscopes. The laser beam is directed to the machine cutter head and its position is controlled in real time by a navigation system at the surface.

The alignment is controlled using a laser beam from the launch shaft, which guides the machine through the tunnel axis. The laser is the basic control device and it works with inclinometers and gyroscopes. The laser beam is directed to the machine cutter head and its position is controlled in real time by a navigation system at the surface.

References

External links

OSU Pipe Ramming Research

TTC.latech.edu

{{Authority control Trenchless technology Subterranean excavating equipment companies