|

Trenchless

Trenchless technology is a type of subsurface construction work that requires few trenches or no continuous trenches. It is a rapidly growing sector of the construction and civil engineering industry. It can be defined as "a family of methods, materials, and equipment capable of being used for the installation of new or replacement or rehabilitation of existing underground infrastructure with minimal disruption to surface traffic, business, and other activities." Trenchless & construction Trenchless construction includes such construction methods as tunneling, microtunneling (MTM), horizontal directional drilling (HDD) also known as directional boring, pipe ramming (PR), pipe jacking (PJ), moling, horizontal auger boring (HAB) and other methods for the installation of pipelines and cables below the ground with minimal excavation. Large diameter tunnels such as those constructed by a tunnel boring machine (TBM), and drilling and blasting techniques are larger versions of subsurface ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trenchless Technology

Trenchless technology is a type of subsurface construction work that requires few trenches or no continuous trenches. It is a rapidly growing sector of the construction and civil engineering industry. It can be defined as "a family of methods, materials, and equipment capable of being used for the installation of new or replacement or rehabilitation of existing underground infrastructure with minimal disruption to surface traffic, business, and other activities." Trenchless & construction Trenchless construction includes such construction methods as tunneling, microtunneling (MTM), horizontal directional drilling (HDD) also known as directional boring, pipe ramming (PR), pipe jacking (PJ), moling, horizontal auger boring (HAB) and other methods for the installation of pipelines and cables below the ground with minimal excavation. Large diameter tunnels such as those constructed by a tunnel boring machine (TBM), and drilling and blasting techniques are larger versions of subsurfa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cured-in-place Pipe

A cured-in-place pipe (CIPP) is a trenchless rehabilitation method used to repair existing pipelines. It is a jointless, seamless pipe lining within an existing pipe. As one of the most widely used rehabilitation methods, CIPP has applications in sewer, water, gas, chemical and district heating pipelines ranging in diameter from 0.1 to 2.8 meters (2–110 inches). The process of CIPP involves inserting and running a felt lining into a preexisting pipe that is the subject of repair. Resin within the liner is then exposed to a curing element to make it attach to the inner walls of the pipe. Once fully cured, the lining now acts as a new pipeline. Process Installation Curing A resin impregnated felt tube made of polyester, fiberglass cloth, spread tow carbon fiber or another resin-impregnable substance, is inserted or pulled through a damaged pipe. It is usually done from the upstream access point (manhole or excavation). It is possible to insert the liner upstream (e.g. f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe Ramming

Pipe ramming (sometimes also called pipe jacking) is a trenchless method for installation of steel pipes and casings. Distances of 30 m (150 feet) or more and over 500 mm (20 inches) in diameter are common, although the method can be used for much longer and larger installations. The method is useful for pipe and casing installations under railway lines and roads, where other trenchless methods could cause subsidence or heaving. The majority of installations are horizontal, although the method can be used for vertical installations. The main differences between pipe ramming and pipe jacking are that pipe ramming uses percussion and does not have a navigation system, while pipe jacking uses hydraulic jacks and does have an active navigation system. Pipe ramming is preferable for shorter distances and applications that do not require tight directional control, such as cable installations. The method uses pneumatic percussive blows to drive the pipe through the ground. The leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe Jacking

Pipe ramming (sometimes also called pipe jacking) is a trenchless method for installation of steel pipes and casings. Distances of 30 m (150 feet) or more and over 500 mm (20 inches) in diameter are common, although the method can be used for much longer and larger installations. The method is useful for pipe and casing installations under railway lines and roads, where other trenchless methods could cause subsidence or heaving. The majority of installations are horizontal, although the method can be used for vertical installations. The main differences between pipe ramming and pipe jacking are that pipe ramming uses percussion and does not have a navigation system, while pipe jacking uses hydraulic jacks and does have an active navigation system. Pipe ramming is preferable for shorter distances and applications that do not require tight directional control, such as cable installations. The method uses pneumatic percussive blows to drive the pipe through the ground. The leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sliplining

Sliplining is a technique for repairing leaks or restoring structural stability to an existing pipeline. It involves installing a smaller, "carrier pipe" into a larger "host pipe", grouting the annular space between the two pipes, and sealing the ends. Sliplining has been used since the 1940s.Mohammed Najafi, PhD, PE and Sanjov Gokhale, PhD, PE, Trenchless Technology (New York: McGraw Hill, 2004), p. 295-311. Available from Water Environment Federation at http://www.e-wef.org/timssnet/static/OM/WPM404.htm The most common material used to slipline an existing pipe is high-density polyethylene (HDPE), but fiberglass-reinforced pipe (FRP) and PVC are also common. Sliplining can be used to stop infiltration and restore structural integrity to an existing pipe. The most common size is (8"-60"), but sliplining can occur in any size given appropriate access and a new pipe small or large enough to install. Installation methods There are two methods used to install a slipline: continuous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Directional Boring

Directional boring, also referred to as horizontal directional drilling (HDD), is a minimal impact trenchless method of installing underground utilities such as pipe, conduit, or cables in a relatively shallow arc or radius along a prescribed underground path using a surface-launched drilling rig. Directional boring offers significant environmental advantages over traditional cut and cover pipeline/utility installations. The technique is routinely used when conventional trenching or excavating is not practical or when minimal surface disturbance is required. Although often used interchangeably, the terms directional boring and horizontal directional drilling are distinct in that they convey a different sense of scale. The term "directional boring" or "bore" is generally reserved for mini/small sized drilling rigs, small diameter bores, and crossing lengths in terms of hundreds of feet. Generally, the term Horizontal Directional Drilling (HDD) is intended to describe large/maxi si ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microtunneling

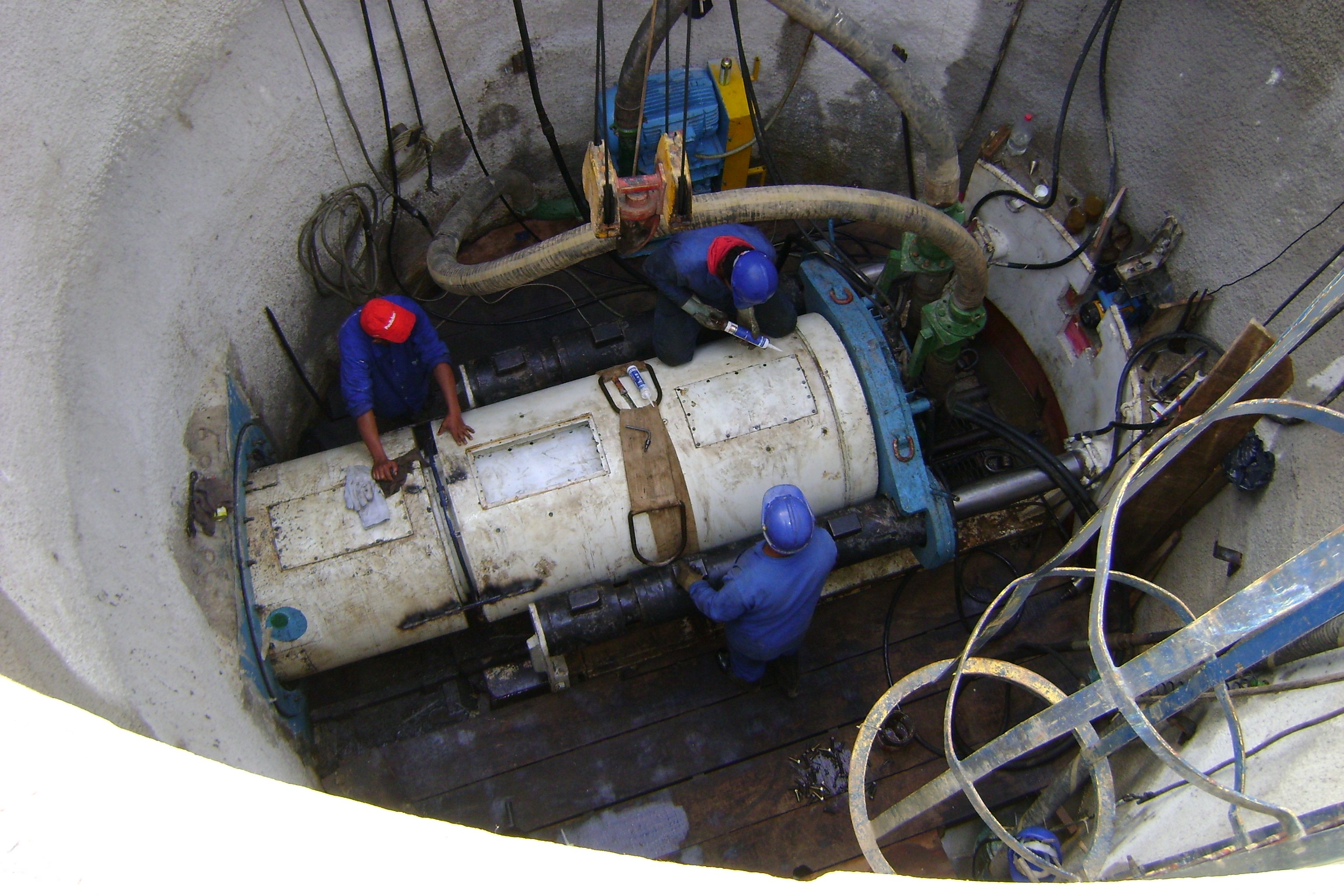

Microtunneling or microtunnelling is a tunnel construction technique used to construct utility tunnels from approximately in diameter. Because of their incredibly small diameter, it is not possible to have an operator driving the tunneling machine, so they have to be remotely operated. Microtunnel boring machines (MTBM) are similar to larger tunnel boring machines (TBMs). The MTBM and jacking frame are set up in a shaft at the required depth. The operator monitors the MTBM's location, orientation and hydraulic devices via a computer console, a CCTV camera or Gyro unit. Some systems use video cameras in the jacking shaft and at the separation plant. Gyro Control have generally replaced cameras for location and digital feedback. Operation In most microtunneling operations the machine is launched through an entry eye and pipes are pushed behind the machine. This pipe jacking process is repeated until the MTBM reaches the reception shaft at the far end. The speed of the advancing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

National Association Of Sewer Service Companies

The National Association of Sewer Service Companies or NASSCO is a not-for-profit North American trade organization, established in 1976 "to increase the awareness of aging underground infrastructure and to provide viable solutions through education, technical resources and industry advocacy". NASSCO's intent is to research, train and educate members and non-members on rehabilitation of underground utilities using trenchless technology Trenchless technology is a type of subsurface construction work that requires few trenches or no continuous trenches. It is a rapidly growing sector of the construction and civil engineering industry. It can be defined as "a family of methods, mate .... Ultimately, NASSCO is committed to set the "industry standards for the rehabilitation of underground pipelines, and to assure the continued acceptance and growth of trenchless technologies". Publications NASSCO has developed multiple publications covering varied topics. The following is the list of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tunnel Boring Machine

A tunnel boring machine (TBM), also known as a "mole", is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through hard rock, wet or dry soil, or sand. Tunnel diameters can range from (micro-TBMs) to to date. Tunnels of less than a metre or so in diameter are typically done using trenchless construction methods or horizontal directional drilling rather than TBMs. TBMs can be designed to excavate non-circular tunnels, including u-shaped, horseshoe, square or rectangular tunnels. Tunnel boring machines are used as an alternative to drilling and blasting (D&B) methods in rock and conventional "hand mining" in soil. TBMs have the advantages of limiting the disturbance to the surrounding ground and producing a smooth tunnel wall. This significantly reduces the cost of lining the tunnel, and makes them suitable to use in urban areas. The major disadvan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe Bursting

Pipe bursting is a trenchless method of replacing buried Pipeline transport, pipelines (such as sewer, water, or natural gas pipes) without the need for a traditional construction trench. "Launching and receiving pits" replace the trench needed by conventional pipe-laying. Equipment There are five key pieces of equipment used in a pipebursting operation: the expander head, pulling rods, a pulling machine, a retaining device, and a hydraulic power pack. Today's expander heads have a leading end much smaller in diameter than the trailing (bursting) end, small enough to fit through the pipe that will be replaced. The smaller leading end is designed to guide the expander head through the existing pipe; earlier models did not have this feature and lost course at times, resulting in incomplete pipe bursts and project failures. The transition from the leading end to the trailing end can include "fins" that make first contact with the existing pipe. Using these fins as the primary break ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipebursting

Pipe bursting is a trenchless method of replacing buried Pipeline transport, pipelines (such as sewer, water, or natural gas pipes) without the need for a traditional construction trench. "Launching and receiving pits" replace the trench needed by conventional pipe-laying. Equipment There are five key pieces of equipment used in a pipebursting operation: the expander head, pulling rods, a pulling machine, a retaining device, and a hydraulic power pack. Today's expander heads have a leading end much smaller in diameter than the trailing (bursting) end, small enough to fit through the pipe that will be replaced. The smaller leading end is designed to guide the expander head through the existing pipe; earlier models did not have this feature and lost course at times, resulting in incomplete pipe bursts and project failures. The transition from the leading end to the trailing end can include "fins" that make first contact with the existing pipe. Using these fins as the primary break ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Directional Drilling

Directional drilling (or slant drilling) is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling, directional boring (horizontal directional drilling - HDD), and surface in seam (SIS), which horizontally intersects a vertical bore target to extract coal bed methane. History Many prerequisites enabled this suite of technologies to become productive. Probably, the first requirement was the realization that oil wells, or water wells, do not necessarily need to be vertical. This realization was quite slow, and did not really grasp the attention of the oil industry until the late 1920s when there were several lawsuits alleging that wells drilled from a rig on one property had crossed the boundary and were penetrating a reservoir on an adjacent property. Initially, proxy evidence such as production changes in other wells was accepted, but such cases fueled the development of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |