machine-shop on:

[Wikipedia]

[Google]

[Amazon]

A machine shop or engineering workshop (UK) is a room, building, or company where

A machine shop or engineering workshop (UK) is a room, building, or company where

Further development early in the 19th century in

Further development early in the 19th century in

Professional management of the

Professional management of the

The standards followed, the industry served, quality control, and mainly the type of practices in the machine shop, will denote the utilization of precision inspection instruments, and the accuracy of metrology employed. This means that not all machine shops implement a periodic interval for calibrating measuring devices. Not all machine shops have the same type of measuring instruments, though it is common to find

The standards followed, the industry served, quality control, and mainly the type of practices in the machine shop, will denote the utilization of precision inspection instruments, and the accuracy of metrology employed. This means that not all machine shops implement a periodic interval for calibrating measuring devices. Not all machine shops have the same type of measuring instruments, though it is common to find

In a machine shop usually, there are numerous practices that are known in relation to working safely with machines. Some of the common practices include:

*Wear appropriate personal, protective equipment ( PPE) - such as

In a machine shop usually, there are numerous practices that are known in relation to working safely with machines. Some of the common practices include:

*Wear appropriate personal, protective equipment ( PPE) - such as

Handbook of Machine Shop Management

'' McGraw-Hill book Company, Incorporated, 1915. * James A. Harvey. ''Machine Shop Trade Secrets: A Guide to Manufacturing Machine Shop Practices.'' Industrial Press Inc., 1 jan. 2005. * Rex Miller, Mark Richard Miller. ''Audel Machine Shop Basics.'' 5th ed. John Wiley & Sons, 30 jan. 2004. * Oscar E. Perrigo.

Modern machine shop construction, equipment and management

'' 1905 *

Vol, 1Vol. 2Vol. 3Vol. 4

* Moltrecht, Karl Hans (1981)

''Machine Shop Practice, Volume 1'' (2nd ed.)

New York: Industrial Press, 1981. * Moltrecht, Karl Hans (1981)

''Machine Shop Practice, Volume 2'' (2nd ed.)

New York: Industrial Press, 1981. * Moltrecht, Karl Hans (1981)

Norwalk, CT: Industrial Press, 2015. *

Modern machine-shop practice: operation, construction, and principles of shop machinery, steam engines, and electrical machinery

'' Volume 1, Scribner's, 1887; 3rd ed. 1899 * Roy, Donald.

Quota restriction and goldbricking in a machine shop

" ''American journal of sociology'' (1952): 427-442. * Roy, Donald.

Efficiency and" the fix": Informal intergroup relations in a piecework machine shop

" ''American Journal of Sociology'' (1954): 255-266. * Harold Clifford Town. ''Technology of the machine shop.'' Longmans, Green, 1951. * Albert M. Wagener, Harlan R. Arthur (1941). ''Machine Shop: Theory and Practice.''

Machine shops in UAE

{{Authority control Machines Manufacturing buildings and structures Secondary sector of the economy

A machine shop or engineering workshop (UK) is a room, building, or company where

A machine shop or engineering workshop (UK) is a room, building, or company where machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

, a form of subtractive manufacturing, is done. In a machine shop, machinist

A machinist is a tradesperson or trained professional who not only operates machine tools, but also has the knowledge of tooling and materials required to create set ups on machine tools such as milling machines, grinders, lathes, and drilling ...

s use machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

s and cutting tools

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The majori ...

to make parts, usually of metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typicall ...

or plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

(but sometimes of other materials such as glass

Glass is a non-crystalline, often transparent, amorphous solid that has widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Glass is most often formed by rapid cooling (quenching) of ...

or wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin th ...

). A machine shop can be a small business

Small businesses are types of corporations, partnerships, or sole proprietorships which have fewer employees and/or less annual revenue than a regular-sized business or corporation. Businesses are defined as "small" in terms of being able to ap ...

(such as a job shop

Job shops are typically small manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs. Job shops typically move on to diffe ...

) or a portion of a factory

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. T ...

, whether a toolroom

Tool and die makers are highly skilled crafters working in the manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, mold maker, moldmaker or tool jig and die-maker depending on which area of concent ...

or a production area for manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a r ...

. The building construction and the layout of the place and equipment vary, and are specific to the shop; for instance, the flooring in one shop may be concrete, or even compacted dirt, and another shop may have asphalt floors. A shop may be air-conditioned or not; but in other shops it may be necessary to maintain a controlled climate. Each shop has its own tools and machinery which differ from other shops in quantity, capability and focus of expertise.

The parts produced can be the end product of the factory, to be sold to customers in the machine industry

The machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

This machine industry traditionally belongs to the heavy indust ...

, the car industry

The automotive industry comprises a wide range of companies and organizations involved in the design, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industries by revenue (from 16 % such ...

, the aircraft industry, or others. It may encompass the frequent machining of customized components. In other cases, companies in those fields have their own machine shops.

The production can consist of cutting

Cutting is the separation or opening of a physical object, into two or more portions, through the application of an acutely directed force.

Implements commonly used for wikt:cut, cutting are the knife and saw, or in medicine and science the scal ...

, shaping, drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at ra ...

, finishing, and other processes, frequently those related to metalworking

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale ...

. The machine tools typically include metal lathes, milling machines

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

, machining centers, multitasking machines, drill press

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to i ...

es, or grinding machine

A grinding machine, often shortened to grinder, is a power tool (or machine tool) used for grinding. It is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the ...

s, many controlled with computer numerical control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pie ...

(CNC). Other processes, such as heat treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also ...

, electroplating

Electroplating, also known as electrochemical deposition or electrodeposition, is a process for producing a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric current. The part to be ...

, or painting

Painting is the practice of applying paint, pigment, color or other medium to a solid surface (called the "matrix" or "support"). The medium is commonly applied to the base with a brush, but other implements, such as knives, sponges, and ...

of the parts before or after machining, are often done in a separate facility.

A machine shop can contain some raw material

A raw material, also known as a feedstock, unprocessed material, or primary commodity, is a basic material that is used to produce goods, finished goods, energy, or intermediate materials that are feedstock for future finished products. As feedst ...

s (such as bar stock

Bar stock, also (colloquially) known as blank, slug or billet, is a common form of raw purified metal, used by industry to manufacture metal parts and products. Bar stock is available in a variety of extrusion shapes and lengths. The most commo ...

for machining) and an inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

Inventory management is a discipline primarily about specifying the shap ...

of finished parts. These items are often stored in a warehouse

A warehouse is a building for storing goods. Warehouses are used by manufacturers, importers, exporters, wholesalers, transport businesses, customs, etc. They are usually large plain buildings in industrial parks on the outskirts of cities ...

. The control and traceability Traceability is the capability to trace something. In some cases, it is interpreted as the ability to verify the history, location, or application of an item by means of documented recorded identification.

Other common definitions include the capab ...

of the materials usually depend on the company's management and the industries that are served, standard certification of the establishment, and stewardship.

A machine shop can be a capital intensive

Capital intensity is the amount of fixed or real capital present in relation to other factors of production, especially labor. At the level of either a production process or the aggregate economy, it may be estimated by the capital to labor ratio, ...

business, because the purchase

Purchasing is the process a business or organization uses to acquire goods or services to accomplish its goals. Although there are several organizations that attempt to set standards in the purchasing process, processes can vary greatly between ...

of equipment can require large investment

Investment is the dedication of money to purchase of an asset to attain an increase in value over a period of time. Investment requires a sacrifice of some present asset, such as time, money, or effort.

In finance, the purpose of investing i ...

s. A machine shop can also be labour-intensive

Labor intensity is the relative proportion of labor (compared to capital) used in any given process. Its inverse is capital intensity.

Labor intensity has been declining since the onset of the Industrial Revolution in the late 1700s, while its inv ...

, especially if it is specialized in repairing machinery on a job production

Job production, sometimes called jobbing or one-off production, involves producing custom work, such as a one-off product for a specific customer or a small batch of work in quantities usually less than those of mass-market products. Job producti ...

basis, but production machining (both batch production

Batch production is a method of manufacturing where the products are made as specified groups or amounts, within a time frame. A batch can go through a series of steps in a large manufacturing process to make the final desired product. Batch prod ...

and mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch ...

) is much more automated

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

than it was before the development of CNC, programmable logic control

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity th ...

(PLC), microcomputer

A microcomputer is a small, relatively inexpensive computer having a central processing unit (CPU) made out of a microprocessor. The computer also includes memory and input/output (I/O) circuitry together mounted on a printed circuit board (PC ...

s, and robotics

Robotics is an interdisciplinary branch of computer science and engineering. Robotics involves design, construction, operation, and use of robots. The goal of robotics is to design machines that can help and assist humans. Robotics integrat ...

. It no longer requires masses of workers

The workforce or labour force is a concept referring to the pool of human beings either in employment or in unemployment. It is generally used to describe those working for a single company or industry, but can also apply to a geographic reg ...

, although the job

Work or labor (or labour in British English) is intentional activity people perform to support the needs and wants of themselves, others, or a wider community. In the context of economics, work can be viewed as the human activity that contr ...

s that remain tend to require high talent and skill

A skill is the learned ability to act with determined results with good execution often within a given amount of time, energy, or both. Skills can often be divided into domain-general and domain-specific skills. For example, in the domain of wo ...

. Training

Training is teaching, or developing in oneself or others, any skills and knowledge or Physical fitness, fitness that relate to specific practicality, useful Competence (human resources), competencies. Training has specific goals of improving on ...

and experience

Experience refers to conscious events in general, more specifically to perceptions, or to the practical knowledge and familiarity that is produced by these conscious processes. Understood as a conscious event in the widest sense, experience involv ...

in a machine shop can both be scarce and valuable.

Methodology, such as the practice of 5S, the level of compliance over safety practices and the use of personal protective equipment

Personal protective equipment (PPE) is protective clothing, helmets, goggles, or other garments or equipment designed to protect the wearer's body from injury or infection. The hazards addressed by protective equipment include physical, elec ...

by the personnel, as well as the frequency of maintenance to the machines and how stringent housekeeping is performed in a shop, may vary widely from one place to another business.

History

Until the 19th century

The first machine shops started to appear in the 19th century when theIndustrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

was already long underway. Before the industrial revolution parts and tools were produced in workshops in local villages and cities on small-scale often for a local market. The first machinery that made possible the Industrial Revolution were also developed in similar workshop

Beginning with the Industrial Revolution era, a workshop may be a room, rooms or building which provides both the area and tools (or machinery) that may be required for the manufacture or repair of manufactured goods. Workshops were the only ...

s.

The production machines in the first factories were built on site, where every part was still individually made to fit. After some time those factories started their own workshops, where parts of the existing machinery were repaired or modified. In those days textiles were the dominant industry, and these industries started to further develop their own machine tools.

19th century

Further development early in the 19th century in

Further development early in the 19th century in England

England is a country that is part of the United Kingdom. It shares land borders with Wales to its west and Scotland to its north. The Irish Sea lies northwest and the Celtic Sea to the southwest. It is separated from continental Europe b ...

, Germany

Germany,, officially the Federal Republic of Germany, is a country in Central Europe. It is the second most populous country in Europe after Russia, and the most populous member state of the European Union. Germany is situated betwe ...

and Scotland

Scotland (, ) is a country that is part of the United Kingdom. Covering the northern third of the island of Great Britain, mainland Scotland has a border with England to the southeast and is otherwise surrounded by the Atlantic Ocean to the ...

of machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

s and cheaper methods for the production of steel, such as the Bessemer steel

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is steelmaking, removal of impurities from the iron by ox ...

, triggered the Second Industrial Revolution

The Second Industrial Revolution, also known as the Technological Revolution, was a phase of rapid scientific discovery, standardization, mass production and industrialization from the late 19th century into the early 20th century. The Firs ...

, which culminated in early factory electrification, mass production and the production line. The machine shop emerged as Burghardt called, a "place in which metal parts are cut to the size required and put together to form mechanical units or machines, the machines so made to be used directly or indirectly in the production of the necessities and luxuries of civilization."

The rise of machine shops and their specific manufacturing and organizational problems triggered the early job shop

Job shops are typically small manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs. Job shops typically move on to diffe ...

management pioneers, whose theories became known as scientific management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineer ...

. One of the earliest publications in this field was Horace Lucian Arnold

Horace Lucian Arnold (June 25, 1837 – January 25, 1915Editorial comment

...

, who in 1896 wrote a first series of articles about "Modern Machine-Shop Economics." This work stretched out from production technology, production methods and factory lay out to time studies, ...

production planning

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.Farghe ...

, and machine shop management. A series of publications on these topics would follow. In 1899 Joshua Rose

Joshua Liam "Josh" Rose (born 16 December 1981) is an Australian professional football (soccer) player who plays as a left back for National Premier Leagues Northern NSW side Edgeworth. He previously featured in the A-League for New Zealand ...

published the book ''Modern machine-shop practice,'' about the operation, construction, and principles of shop machinery, steam engines, and electrical machinery.

20th century

In 1903 the ''Cyclopedia of Modern Shop Practice'' was published withHoward Monroe Raymond

Howard Monroe Raymond (October 25, 1872 – 1943) was an American physicist, Professor of Physics and President of the Armour Institute of Technology from 1892 to 1932, also known as editor of the early 20th century ''Cyclopedia of Modern Shop ...

as Editor-in-Chief, and in the same year Frederick Winslow Taylor

Frederick Winslow Taylor (March 20, 1856 – March 21, 1915) was an American mechanical engineer. He was widely known for his methods to improve industrial efficiency. He was one of the first management consultants. In 1909, Taylor summed up hi ...

published his ''Shop management; a paper read before the American society of mechanical engineers. New York.'' Taylor had started his workmanship as a machine-shop laborer at Midvale Steel Works in 1878, and worked his way up to machine shop foreman, research director, and finally chief engineer of the works. As an independent consulting engineer one of his first major assignments was in 1898 at Bethlehem Steel

The Bethlehem Steel Corporation was an American steelmaking company headquartered in Bethlehem, Pennsylvania. For most of the 20th century, it was one of the world's largest steel producing and shipbuilding companies. At the height of its succe ...

was to solve an expensive machine-shop capacity problem.

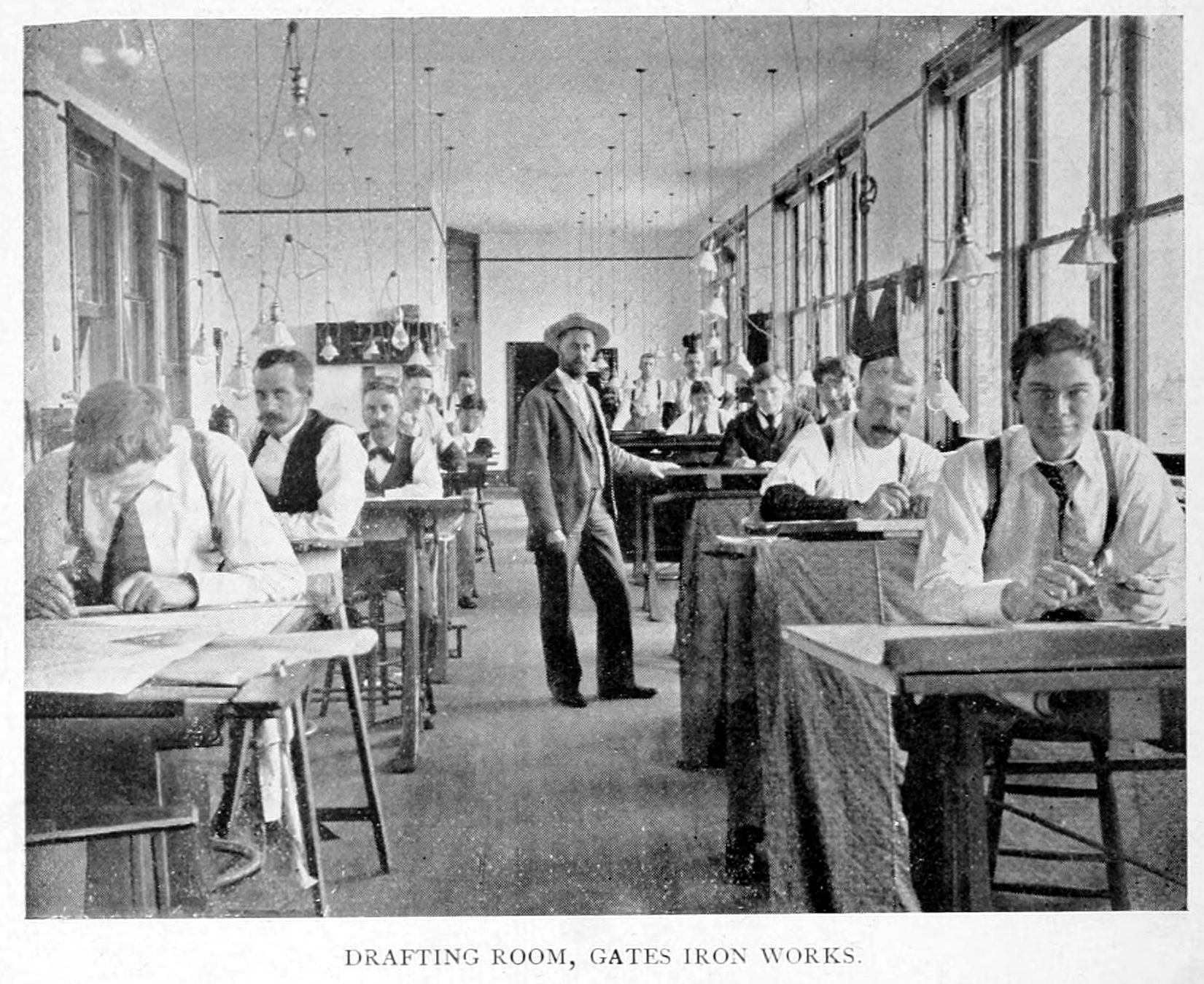

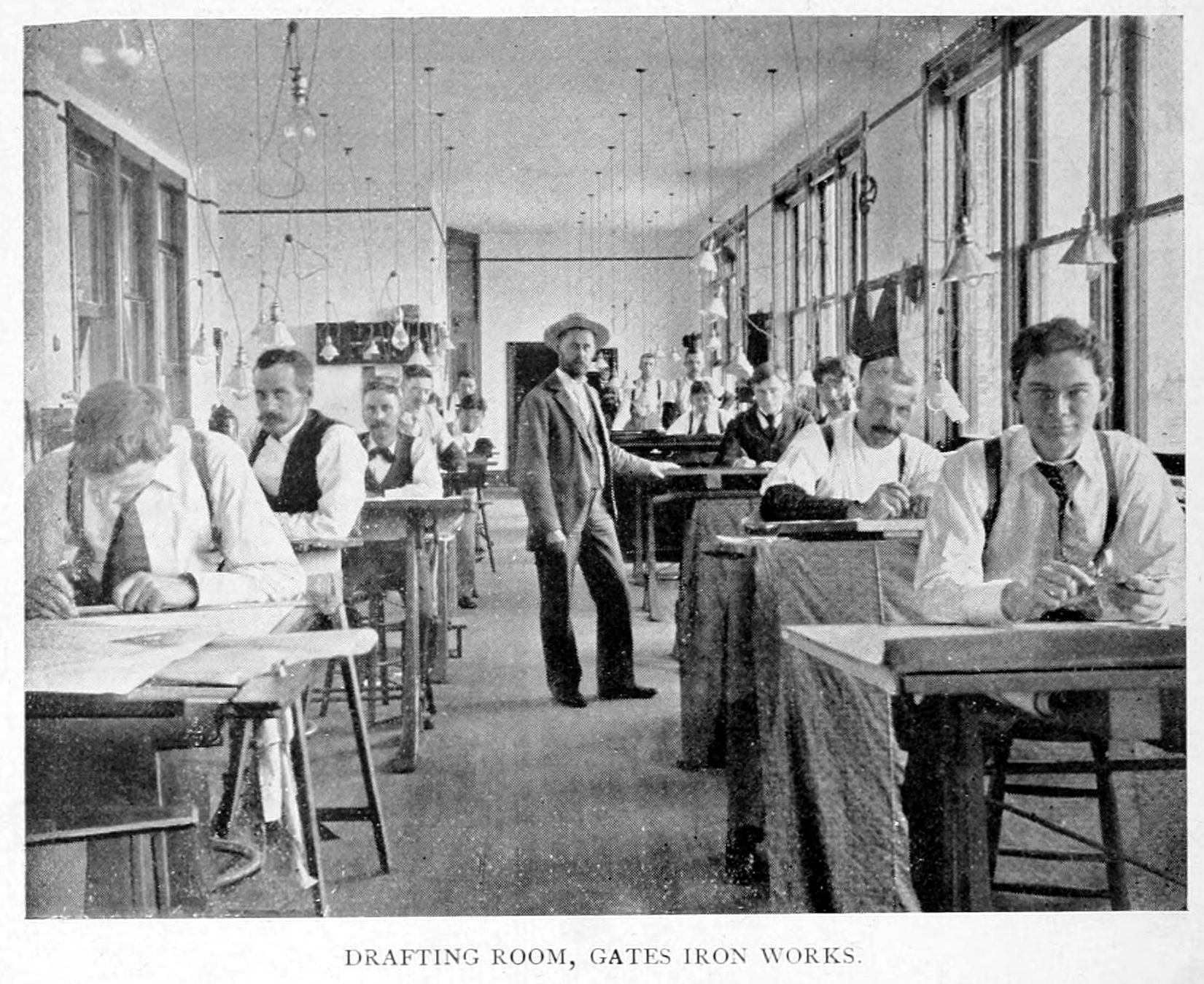

In 1906 Oscar E. Perrigo published the popular book ''Modern machine shop,'' construction the equipment and management of machine shops. The first part of ''Modern machine shop,'' Perrigo (1906) focussed on the physical construction of the building and presented a model machine shop. With this model machine shop, Perrigo explored the way the space in factories could be organized.Anna Vemer Andrzejewski (2008). ''Building Power: Architecture and Surveillance in Victorian America.'' p. 77 This was not uncommon in his days. Many industrial engineer

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information a ...

s, like Alexander Hamilton Church

Alexander Hamilton Church (28 May 1866 – 11 February 1936) was an English efficiency engineer, accountant and writer on accountancy and management, known for his seminal work of management and cost accounting.

Biography

Church was born in U ...

, J. Slater Lewis

Joseph Slater Lewis MICE FRSE (4 June 1852 – 27 July 1901) was a British engineer, inventor, business manager, and early author on management and accounting, known for his pioneering work on cost accounting.Chatfield (2014, p. 379).

Biograph ...

, Hugo Diemer

Hugo Diemer (November 18, 1870 – March 3, 1939)SAM, "Necrology Hugo Diemer, November 18, 1960 - March 3, 1939," in: ''The Society for the Advancement of Management Journal,'' Volume 4, Nr 1-4. 1939. p. 35/56 was an American engineer, management ...

etc., published plans for some new industrial complex.

These works among others cumulated in the scientific management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineer ...

movement on which Taylor in 1911 wrote his famous ''The Principles of Scientific Management

''The Principles of Scientific Management''1911 is a monograph published by Frederick Winslow Taylor. This laid out Taylor's views on principles of scientific management, or industrial era organization and decision theory. Taylor was an American ...

,'' a seminal text of modern organization and decision theory

Decision theory (or the theory of choice; not to be confused with choice theory) is a branch of applied probability theory concerned with the theory of making decisions based on assigning probabilities to various factors and assigning numerical ...

, with a significant part dedicated to the organization of machine shops. The introduction of new cutting materials as high-speed steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material.

It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in tha ...

, and better organization of the production by implementing new scientific management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineer ...

methods such as planning boards (see image), significantly improved machine shop productivity

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production proces ...

and efficiency

Efficiency is the often measurable ability to avoid wasting materials, energy, efforts, money, and time in doing something or in producing a desired result. In a more general sense, it is the ability to do things well, successfully, and without ...

of machine shops. In the course of the 20th century, these further increased with the further development of technology.

In the early 20th century, the power for the machine tools was still supplied by a mechanical belt, which was powered by a central steam engine. In the course of the 20th-century electric motors took over the power supply of the machine tools.

As materials and chemical substances, including cutting oil, become more sophisticated, the awareness of the impact on the environment slowly grew. In parallel to the acknowledgment of the ever-present reality of accidents and potential occupational injury, the sorting of scrap materials for recycling and the disposal of refuse evolved in an area related to the environment, safety, and health. In regulated machine shops this would turn into a constant practice supported by what would be a discipline known as EHS (for environment, health, and safety), or of a similar name, such as HQSE that would include quality assurance

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to ensure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design ...

.

In the second part of the 20th century, automation started with numerical control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pi ...

(NC) automation, and computer numerical control (CNC).

Digital instruments for quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach places ...

and inspection become widely available, and the utilization of lasers for precision measurements became more common for the larger shops that can afford the equipment.

Further integration of information technology into machine tools lead to the beginning of computer-integrated manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster a ...

. Production design and production became integrated into CAD/CAM

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). Both of these require powerful computers. ''CAD'' software helps designers and draftsmen; ''CAM'' "reduces manpower costs" in the manufactur ...

, and production control Within supply chain management and manufacturing, production control is the activity of monitoring and controlling any particular production or operation. Production control is often run from a specific control room or operations room. With invento ...

became integrated in enterprise resource planning

Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of Business management tools, business management ...

.

21st century

In the late of the 20th century, the introduction ofindustrial robot

An industrial robot is a robot system used for manufacturing. Industrial robots are automated, programmable and capable of movement on three or more axes.

Typical applications of robots include welding, painting, assembly, disassembly, pick a ...

s further increased factory automation. Typical applications of robots include welding, painting, assembly, pick and place (such as packaging, palletizing and SMT), product inspection, and testing. As a result of this introduction the machine shop also "has been modernized to the extent that robotics and electronic controls have been introduced into the operation and control of machines.Rex Miller, Mark Richard Miller (2004). ''AudelMachine Shop Tools and Operations.'' p. 389 For small machine shops, though, having robots is more of an exception.

Machine shop topics

Machines

Amachine

A machine is a physical system using Power (physics), power to apply Force, forces and control Motion, movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to na ...

is a tool

A tool is an object that can extend an individual's ability to modify features of the surrounding environment or help them accomplish a particular task. Although many animals use simple tools, only human beings, whose use of stone tools dates ba ...

containing one or more parts that uses energy

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of heat a ...

to perform an intended action. Machines are usually powered by mechanical, chemical, thermal, or electrical means, and are often motorized. Historically, a power tool

A power tool is a tool that is actuated by an additional power source and mechanism other than the solely manual labor used with hand tools. The most common types of power tools use electric motors. Internal combustion engines and compressed ...

also required moving parts to classify as a machine. However, the advent of electronics

The field of electronics is a branch of physics and electrical engineering that deals with the emission, behaviour and effects of electrons using electronic devices. Electronics uses active devices to control electron flow by amplification ...

has led to the development of power tools without moving parts that are considered machines.''The American Heritage Dictionary'', Second College Edition. Houghton Mifflin Co., 1985.

Machining

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

is any of the various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The many processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing. Exactly what the "controlled" part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools).

Though not all machine shops may have a CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a p ...

milling center, commonly, they may have access to a manual milling machine.

Machine tools

Amachine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All m ...

is a machine

A machine is a physical system using Power (physics), power to apply Force, forces and control Motion, movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to na ...

for shaping or machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

metal or other rigid materials, usually by cutting, boring, grinding

Grind is the cross-sectional shape of a blade.

Grind, grinds, or grinding may also refer to:

Grinding action

* Grinding (abrasive cutting), a method of crafting

* Grinding (dance), suggestive club dancing

* Grinding (video gaming), repetitive and ...

, shearing, or other forms of deformation. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools use some means of constraining the workpiece and provide a guided movement of the parts of the machine. Thus the relative movement between the workpiece and the cutting tool

In the context of machining, a cutting tool or cutter is typically a hardened metal tool that is used to cut, shape, and remove material from a workpiece by means of machining tools as well as abrasive tools by way of shear deformation. The major ...

is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand".

Cutting tools

Professional management of the

Professional management of the inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation.

Inventory management is a discipline primarily about specifying the shap ...

of cutting tools occurs mainly in larger operations. Smaller machine shops may have a more limited assortment of endmills, keyseat cutters, inserts, and other cutting tools. The choice in the sophistication of the design of the cutting tool, including material and finish, commonly depends on the job and the price of the cutting tool. In some instances, the cost of custom-made tools could be prohibitive for a small shop.

Depending on the industry and demands of the job, a cutting tool may only be used on a certain type of material, that is, a cutting tool may not contact another workpiece made of different chemical composition

A chemical composition specifies the identity, arrangement, and ratio of the elements making up a compound.

Chemical formulas can be used to describe the relative amounts of elements present in a compound. For example, the chemical formula for ...

.

Not all machine shops are equipped with a mill and not all machine shops are aimed to do milling work.

Housekeeping

Some machine shops are better organized than others, and some places are kept cleaner than other establishments. In some instances, the shop is swept minutes before the end of every shift, and in other cases, there’s no schedule or routine, or the cycle for sweeping and cleaning is more relaxed. When it comes to machines, in some places the care and maintenance of the equipment are paramount, and the swarf (commonly known as chips) produced after parts have been machined, are removed daily, and then the machine is air-blown and wiped clean; while in other machine shops, the chips are left in the machines until is an absolute necessity to remove them; the second instance is not advisable.Recycling

The remanent or residue of materials used, such as aluminum, steel, and oil, among others, can be gathered and recycled, and commonly, it may be sold. However, not all machine shops practicerecycling

Recycling is the process of converting waste materials into new materials and objects. The recovery of energy from waste materials is often included in this concept. The recyclability of a material depends on its ability to reacquire the p ...

, and not all have personnel dedicated to enforcing the habit of separating and keeping materials separated. In larger and organized operations, such responsibility may be delegated to the Health, Safety, Environment, and Quality (HSEQ) department.

Inspection

:''See :Metalworking measuring instruments''Quality assurance

Quality assurance (QA) is the term used in both manufacturing and service industries to describe the systematic efforts taken to ensure that the product(s) delivered to customer(s) meet with the contractual and other agreed upon performance, design ...

, quality control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements".

This approach places ...

and inspection

An inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity. ...

, are terms commonly used interchangeably. The accuracy and precision

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

to be attained depends on several determining factors. Since not all machines have the same level of reliability and capability to execute predictable finished results within certain tolerances, nor all manufacturing processes achieve the same range of exactness, the machine shop is then limited to its own dependability in delivering the desire outcomes. Subsequently, subject to the rigor declared by the customer, the machine shop may be required to undergo a verification and validation

Verification and validation (also abbreviated as V&V) are independent procedures that are used together for checking that a product, service, or system meets requirements and specifications and that it fulfills its intended purpose. These are ...

even prior to the issuance and acknowledgment of an order.

The machine shop may have a specific area established for measuring and inspecting the parts in order to confirm compliance, while other shops only rely on the inspections performed by the machinists and fabricators. For instance, in some shops, a granite, calibrated surface plate

A surface plate is a solid, flat plate used as the main horizontal reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, therefore ...

may be shared by different departments, and in other shops, the lathes, the mills, etc, may have their own, or may not have one at all.

Calibration

The standards followed, the industry served, quality control, and mainly the type of practices in the machine shop, will denote the utilization of precision inspection instruments, and the accuracy of metrology employed. This means that not all machine shops implement a periodic interval for calibrating measuring devices. Not all machine shops have the same type of measuring instruments, though it is common to find

The standards followed, the industry served, quality control, and mainly the type of practices in the machine shop, will denote the utilization of precision inspection instruments, and the accuracy of metrology employed. This means that not all machine shops implement a periodic interval for calibrating measuring devices. Not all machine shops have the same type of measuring instruments, though it is common to find micrometer Micrometer can mean:

* Micrometer (device), used for accurate measurements by means of a calibrated screw

* American spelling of micrometre

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; ...

s, Vernier calipers, granite surface plates, among others.

The frequency and precision for calibrating metrology instruments may vary and it may require hiring the services of a specialized third-party. Also, in some instances, maintaining all instruments existent in the shop calibrated may be a necessary requirement to not fall out of compliance.

Layout

The location and orientation of the machines are important. Preferably, some prior thought has been given in the positioning of the equipment; likely not as meticulously as in aplant layout study

A plant layout study is an engineering study used to analyze different physical configurations for a manufacturing plant.''Systematic Layout Planning'', Muther, Cahners, 1973 It is also known as Facilities Planning and Layout.

Overview

The ab ...

, the closeness of the machines, the types of machines, were the raw material are received and kept, as well as other factors, including ventilation, are taken in account to establish the initial layout of the machine shop. A routing diagram

A routing diagram or route diagram in the field of management engineering is a type of diagram, that shows a route through an accessible physical space. Routing diagrams are used in plant layout study, and manufacturing plant design.

Overview ...

and daily operations may dictate the need to rearrange.

Profitability is commonly a driving consideration in regards to maximizing production, and thus aligning the machines in an effective manner; however, other critical factors must be considered, such as the preventive maintenance

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure, and supporting utilities in industrial, business, and residential installa ...

of the equipment and safety in the workplace. For instance, allowing room for a technician to maneuver behind the machining center to inspect connections, and not placing the machine where it would block the emergency exit.

Storage rooms and tool cribs

Some shops have cages or rooms dedicated to keeping certain tools or supplies; for instance, a room may be dedicated to only welding supplies, gas tanks, etcetera; or where janitorial supplies or other consumables such as grinding disks are stored. Depending on the size of the operation, management, and controls, these areas may be restricted and locked, or these could be manned by an employee, as by a tool crib attendant; in other instances, the storage rooms or cages are accessible to all personnel. Not all shops have a tool crib or storage room(s) though, and in many cases, a large cabinet suffices.Hand tools

Also, the way hand tools are stored and are made available to the fabricator or operators depends on how the shop functions or is managed. In many cases, common hand tools are visible in the work area and at reach for anyone. In many cases, the workers do not need to provide their own tools since the daily tools are available and provided, but in many other cases, the workers bring their own tools and toolboxes to their workplaceSafety

Safety is a consideration that needs to be observed and enforced daily and constantly; however, a shop may vary from other shops in strictness and thoroughness when it comes to the actual practice, policies implemented and overall seriousness ascertained by the personnel and management. In an effort to standardize some common guidelines, in the United States, the Occupational Safety and Health Administration (OSHA

OSHA or Osha may refer to:

Work

* Occupational Safety and Health Administration, a federal agency of the United States that regulates workplace safety and health

* Occupational Safety and Health Act (United States) of 1970, a federal law in the Un ...

) issues didactic material and enforces precautions with the goal of preventing accidents.

In a machine shop usually, there are numerous practices that are known in relation to working safely with machines. Some of the common practices include:

*Wear appropriate personal, protective equipment ( PPE) - such as

In a machine shop usually, there are numerous practices that are known in relation to working safely with machines. Some of the common practices include:

*Wear appropriate personal, protective equipment ( PPE) - such as safety glasses

Glasses, also known as eyeglasses or spectacles, are vision eyewear, with lenses (clear or tinted) mounted in a frame that holds them in front of a person's eyes, typically utilizing a bridge over the nose and hinged arms (known as temples or ...

.

*Wear appropriate attire and shoes - like steel-toe shoes and short sleeves when working with machines that have a powered rotational feature such as a lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to c ...

.

*Do not wear jewelry, including rings.

*Do not sport unrestrained long hair.

*Consult operations and service manuals of machines

*Lock-out Tag-out ( LOTO).

*Correct use of fire extinguisher

A fire extinguisher is a handheld active fire protection device usually filled with a dry or wet chemical used to extinguish or control small fires, often in emergencies. It is not intended for use on an out-of-control fire, such as one which ha ...

; types of fires and regular inspections.

*Ergonomics

Human factors and ergonomics (commonly referred to as human factors) is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Four primary goals of human factors learnin ...

. Rubber floor mats for support at the workstations.

*Escape routes must be clear of obstacles and emergency exits must not be blocked.

*Other.

Safety precautions in a machine shop are aimed to avoid injuries and tragedies, for example, to eliminate the possibility of a worker being fatally harmed by being entangled in a lathe.

Many machines have safety measurements as built-in parts of their design; for example, an operator must press two buttons which are out of the way for a press or punch to function, and thus not pinch the operator’s hands.

See also

*Job shop

Job shops are typically small manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs. Job shops typically move on to diffe ...

* Forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to th ...

* Machine factory

A machine factory is a company, that produces machines. These companies traditionally belong to the heavy industry sector in comparison to a more consumer oriented and less capital intensive light industry. Today many companies make more sophistic ...

* Machine industry

The machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

This machine industry traditionally belongs to the heavy indust ...

* Machine tool builder A machine tool builder is a corporation or person that builds machine tools, usually for sale to manufacturers, who use them to manufacture products. A machine tool builder runs a machine factory, which is part of the machine industry.

The machin ...

References

Further reading

* Barnwell, George W. ''New encyclopedia of machine shop practice; a guide to the principles and practice of machine shop procedure.'' (1941). * Calvert, Monte A. ''The mechanical engineer in America, 1830-1910: Professional cultures in conflict.'' Baltimore, MD: Johns Hopkins Press, 1967. * Van Deventer, John Herbert.Handbook of Machine Shop Management

'' McGraw-Hill book Company, Incorporated, 1915. * James A. Harvey. ''Machine Shop Trade Secrets: A Guide to Manufacturing Machine Shop Practices.'' Industrial Press Inc., 1 jan. 2005. * Rex Miller, Mark Richard Miller. ''Audel Machine Shop Basics.'' 5th ed. John Wiley & Sons, 30 jan. 2004. * Oscar E. Perrigo.

Modern machine shop construction, equipment and management

'' 1905 *

Raymond, Howard Monroe

Howard Monroe Raymond (October 25, 1872 – 1943) was an American physicist, Professor of Physics and President of the Armour Institute of Technology from 1892 to 1932, also known as editor of the early 20th century ''Cyclopedia of Modern Shop ...

, ed. ''Cyclopedia of Modern Shop Practice.'' 1903/06/09Vol, 1

* Moltrecht, Karl Hans (1981)

''Machine Shop Practice, Volume 1'' (2nd ed.)

New York: Industrial Press, 1981. * Moltrecht, Karl Hans (1981)

''Machine Shop Practice, Volume 2'' (2nd ed.)

New York: Industrial Press, 1981. * Moltrecht, Karl Hans (1981)

Norwalk, CT: Industrial Press, 2015. *

Joshua Rose

Joshua Liam "Josh" Rose (born 16 December 1981) is an Australian professional football (soccer) player who plays as a left back for National Premier Leagues Northern NSW side Edgeworth. He previously featured in the A-League for New Zealand ...

. Modern machine-shop practice: operation, construction, and principles of shop machinery, steam engines, and electrical machinery

'' Volume 1, Scribner's, 1887; 3rd ed. 1899 * Roy, Donald.

Quota restriction and goldbricking in a machine shop

" ''American journal of sociology'' (1952): 427-442. * Roy, Donald.

Efficiency and" the fix": Informal intergroup relations in a piecework machine shop

" ''American Journal of Sociology'' (1954): 255-266. * Harold Clifford Town. ''Technology of the machine shop.'' Longmans, Green, 1951. * Albert M. Wagener, Harlan R. Arthur (1941). ''Machine Shop: Theory and Practice.''

External links

*Machine shops in UAE

{{Authority control Machines Manufacturing buildings and structures Secondary sector of the economy