Low Moor Iron Works on:

[Wikipedia]

[Google]

[Amazon]

The Low Moor Ironworks was a

Construction of the plant began in June 1790, including blast furnaces and casting shops.

The furnaces had square bases, tapering as they rose to about in height.

The two furnaces were blown in on 13 August 1791 and the first casting was made by the forgemen three days later.

At first the works produced domestic goods, but soon began producing industrial products including parts for steam engines.

In 1795 the company won contracts to provide guns, shot and shells to the government, which had been at war with

Construction of the plant began in June 1790, including blast furnaces and casting shops.

The furnaces had square bases, tapering as they rose to about in height.

The two furnaces were blown in on 13 August 1791 and the first casting was made by the forgemen three days later.

At first the works produced domestic goods, but soon began producing industrial products including parts for steam engines.

In 1795 the company won contracts to provide guns, shot and shells to the government, which had been at war with

The process to convert ore into

The process to convert ore into

Robert Wilson, Works Manager at

Robert Wilson, Works Manager at

The company began to run into difficulty in the late 1880s. Its mines were increasingly scattered and expensive. The rail network had a variety of gauges and used a mix of stationary engines and locomotives. Some of the plant was obsolete and operations were generally inefficient.

However, there was continued demand for "Best Yorkshire Iron" for applications where safety was critically important.

In 1888 Low Moor was converted to a limited liability company, although descendants of the founders retained control.

The directors planned two new blast furnaces at the New Works, each high, with capacities of 340 and 240 tons per week.

The first came into operation in 1892. In 1905 an electrical power station was built at the New Works, with boilers fired by gas from the blast furnaces. Apart from the heaviest machines, steam drives were replaced by electrical drives.

The outbreak of

The company began to run into difficulty in the late 1880s. Its mines were increasingly scattered and expensive. The rail network had a variety of gauges and used a mix of stationary engines and locomotives. Some of the plant was obsolete and operations were generally inefficient.

However, there was continued demand for "Best Yorkshire Iron" for applications where safety was critically important.

In 1888 Low Moor was converted to a limited liability company, although descendants of the founders retained control.

The directors planned two new blast furnaces at the New Works, each high, with capacities of 340 and 240 tons per week.

The first came into operation in 1892. In 1905 an electrical power station was built at the New Works, with boilers fired by gas from the blast furnaces. Apart from the heaviest machines, steam drives were replaced by electrical drives.

The outbreak of

wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

foundry established in 1791 in the village of Low Moor about south of Bradford

Bradford is a city and the administrative centre of the City of Bradford district in West Yorkshire, England. The city is in the Pennines' eastern foothills on the banks of the Bradford Beck. Bradford had a population of 349,561 at the 2011 ...

in Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

Background

The ironworks depended on the excellent resources of high-quality coal and iron ore found in the vicinity. The "better bed" coal came from a seam about thick resting on hard sandstone. This coal is particularly low in sulphur. About above this coal seam there is a layer of "black bed" coal. The ironstone lies above this layer, holding about 32% iron. The Halifax coal beds lie about below the better bed. At the time the ironworks were developed recent technological advances had made it practical to smelt iron using coal rather than charcoal and to use steam engines to power the steps in production of iron goods. Most of the land occupied by the iron works was part of the Royds Hall estate. Operation of a coal mine on the estate is mentioned in 1673. In 1744 the owner, Edward Rookes Leeds, began to actively develop the coal mines. About 1780 a wooden railway was built from the Low Moor mines to the coal yard in the centre of Bradford, from where the coal could be carried via theLeeds and Liverpool Canal

The Leeds and Liverpool Canal is a canal in Northern England, linking the cities of Leeds and Liverpool.

Over a distance of , crossing the Pennines, and including 91 locks on the main line. The Leeds and Liverpool Canal has several small branc ...

. Soon after, Leeds went bankrupt.

The property was twice offered for sale by auction, in December 1786 and October 1787, but no suitable offer was made.

Leeds committed suicide in 1787.

In 1788 the estate was sold to a partnership of Richard Hird, a country gentleman, John Preston and John Jarratt for £34,000.

After some sales of shares the partners were Richard Hird, Joseph Dawson,

a minister, and John Hardy, a solicitor. Dawson was interested in metallurgy and chemistry and was a close friend of Dr. Joseph Priestley

Joseph Priestley (; 24 March 1733 – 6 February 1804) was an English chemist, natural philosopher, separatist theologian, grammarian, multi-subject educator, and liberal political theorist. He published over 150 works, and conducted exp ...

.

He seems to have been the prime mover in the enterprise.

The partners planned to found an ironworks, and engaged an engineer from Wigan

Wigan ( ) is a large town in Greater Manchester, England, on the River Douglas, Lancashire, River Douglas. The town is midway between the two cities of Manchester, to the south-east, and Liverpool, to the south-west. Bolton lies to the nor ...

named Smalley to build the blast engine.

Smalley called on Thomas Woodcock to prepare plans for the furnaces, casting houses and other works.

Woodcock moved to Low Moor, and was to be architect and general manager until his death in 1833.

Expansion

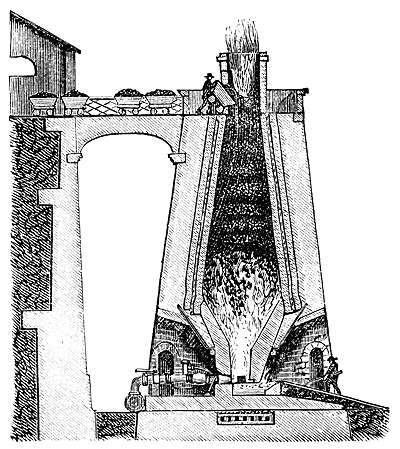

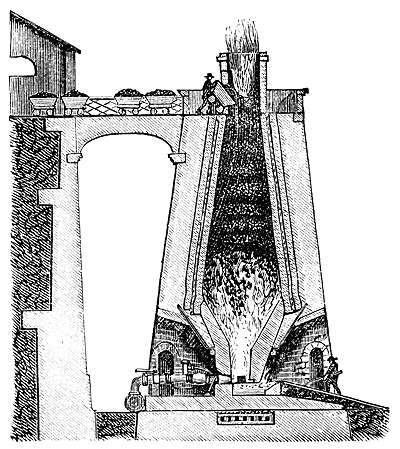

Construction of the plant began in June 1790, including blast furnaces and casting shops.

The furnaces had square bases, tapering as they rose to about in height.

The two furnaces were blown in on 13 August 1791 and the first casting was made by the forgemen three days later.

At first the works produced domestic goods, but soon began producing industrial products including parts for steam engines.

In 1795 the company won contracts to provide guns, shot and shells to the government, which had been at war with

Construction of the plant began in June 1790, including blast furnaces and casting shops.

The furnaces had square bases, tapering as they rose to about in height.

The two furnaces were blown in on 13 August 1791 and the first casting was made by the forgemen three days later.

At first the works produced domestic goods, but soon began producing industrial products including parts for steam engines.

In 1795 the company won contracts to provide guns, shot and shells to the government, which had been at war with revolutionary France

The French Revolution ( ) was a period of radical political and societal change in France that began with the Estates General of 1789 and ended with the formation of the French Consulate in November 1799. Many of its ideas are considere ...

since 1793. By 1799 the works were producing about 2,000 tons of pig iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silic ...

per year, from which iron goods were made that ranged from columns used in mill construction to garden furniture.

In 1800, the company opened the Barnby Furnace Colliery on land leased from Walter Spencer Stanhope. This mine worked the "Silkstone Seam". In 1802 the Low Moor Furnace Waggonway was constructed connecting the colliery to Barnby Basin on the Barnsley Canal

The Barnsley Canal is a canal that ran from Barnby Basin, through Barnsley, South Yorkshire, England to a junction with the Aire and Calder Navigation near Wakefield, West Yorkshire. It was built in the 1790s, to provide a transport link from c ...

. The colliery had closed by May 1807. The waggonway was replaced in 1809 by the Silkstone Waggonway

The Silkstone Waggonway was a narrow-gauge industrial wagonway serving the Barnsley Canal, in England, at Silkstone in South Yorkshire.

History The Barnsley Canal

The Barnsley Canal was built in the 1790s to carry coal from the mines near Bar ...

which ran over much of its trackbed, and operated until 1870.

The ironworks were owned by the families of the founders throughout the 19th century, with the addition of the Wickhams, who married into the Hirds.

The annually employed capital grew from £52,000 in 1793 to £250,000 in 1818.

The company started to produce wrought iron in 1801, at first using imported iron but by 1803 using Low Moor pig iron.

In 1803 a regiment of volunteers was formed at Low Moor ready to repel the expected French invasion.

The works were gradually mechanised.

By 1805 there was a self-tipping inclined railway to charge the furnaces, a nail slitting mill, two nose-helve hammers and a plate-rolling mill.

As the iron works grew, the company built workers' cottages in the district that took the name of North Brierley and a hostel for the boys who worked in the pits.

The boys were given free clothing and schooling. The company also ran several public houses.

By the end of the war with France in 1814 the works were producing 33 tons of pig iron weekly.

Prices fell for a while as demand slackened after the war, but demand for gas pipes and street lights began to pick up in 1822.

The Airedale

Airedale is a geographic area in Yorkshire, England, corresponding to the river valley or dale of the River Aire.

The valley stretches from the river's origin in Aire Head Springs, Malham which is in the Yorkshire Dales, down past Skipton on ...

poet John Nicholson wrote in 1829,

By 1835 the works were handling a growing volume of orders. There was no room to expand in the original site, which was crowded by industrial works, offices and workers houses. Construction started on a new site to the southeast, and in 1836 two oven-topped blast furnaces came into operation there.

In 1842 the company installed a new mill to roll iron plate for engine boilers. In 1843 four pairs of forge hammers were installed, driven by steam engines, and in 1844 the company decided to install one of James Nasmyth

James Hall Nasmyth (sometimes spelled Naesmyth, Nasmith, or Nesmyth) (19 August 1808 – 7 May 1890) was a Scottish engineer, philosopher, artist and inventor famous for his development of the steam hammer. He was the co-founder of Nasmyth, ...

's newly invented steam hammer

A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Typically the hammer is attached to a piston that slides within a fixed cylinder, but i ...

s.

Process

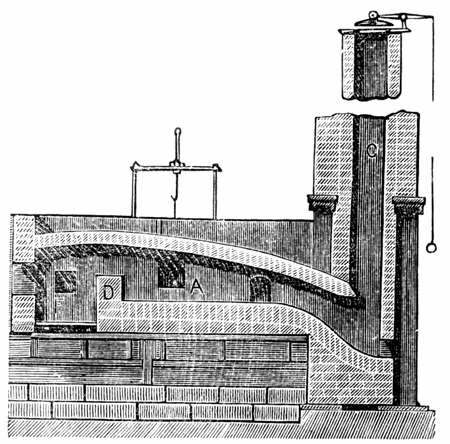

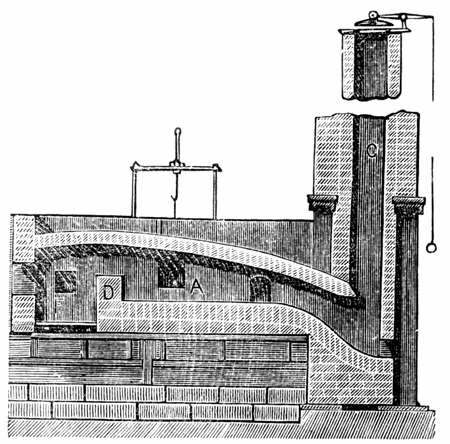

The process to convert ore into

The process to convert ore into pig iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silic ...

and then into wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

involved first converting the coal to coke to remove water and sulphur, a process that took 48 hours if done in piles in the yard, or 24 hours if done in ovens.

About 32% of the better bed coal would be lost in coking.

The ironstone was allowed to weather for some time to free it from shale. Limestone was brought from Skipton

Skipton (also known as Skipton-in-Craven) is a market town and civil parish in the Craven district of North Yorkshire, England. Historically in the East Division of Staincliffe Wapentake in the West Riding of Yorkshire, it is on the River Air ...

to help separate clay from the iron ore.

In 1832 it took of coal, of limestone and of ironstone to make of pig iron.

The ironstone was baked with coke and limestone in a kiln, then emptied into a furnace, from which it came out as ore.

This was cast into pigs with crystalline or granular structure, and then refined by cold blast, coming out flaky. There were four blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being "forced" or supplied above atmospheric ...

s, with the air delivered by powerful steam engines.

The iron was then puddled, becoming granular and malleable. The steam hammers forged the glowing iron into malleable slabs, which were rolled into wrought iron plates.

Large quantities of slag from the blast furnaces were sold for use in road-making.

Full production

Robert Wilson, Works Manager at

Robert Wilson, Works Manager at James Nasmyth

James Hall Nasmyth (sometimes spelled Naesmyth, Nasmith, or Nesmyth) (19 August 1808 – 7 May 1890) was a Scottish engineer, philosopher, artist and inventor famous for his development of the steam hammer. He was the co-founder of Nasmyth, ...

's Bridgewater foundry in Patricroft near Manchester, had improved Nasmyth's 1842 design for a steam hammer

A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Typically the hammer is attached to a piston that slides within a fixed cylinder, but i ...

, inventing the self-acting motion that made it possible to adjust the force of the blow delivered by the hammer – a critically important improvement.

Nasmyth's steam hammers could now vary the force of the blow across a wide range.

Nasmyth's first steam hammer was built for the Low Moor Works.

They rejected the machine, but on 18 August 1843 accepted an improved version with a self-acting gear.

From 1845 to 1856 Robert Wilson was employed by the Low Moor Ironworks.

While at Low Moor he improved the steam hammer with the "circular balanced valve".

In the Great Exhibition

The Great Exhibition of the Works of Industry of All Nations, also known as the Great Exhibition or the Crystal Palace Exhibition (in reference to the temporary structure in which it was held), was an international exhibition which took pl ...

of 1851 at the Crystal Palace

The Crystal Palace was a cast iron and plate glass structure, originally built in Hyde Park, London, Hyde Park, London, to house the Great Exhibition of 1851. The exhibition took place from 1 May to 15 October 1851, and more than 14,000 exhibit ...

in London the ironworks exhibited an enormous cannon.

The company also provided samples of ore, coal, pig iron and wrought iron, a smaller gun, a sugar cane mill, an olive mill and an elliptograph.

The Low Moor company bought the Bierley Ironworks in 1854.

By 1855 Low Moor was producing 21,840 tons of iron per year, and was the largest ironworks in Yorkshire.

The foundries at Low Moor produced quantities of guns, shells and shot for troops fighting in the Crimean War

The Crimean War, , was fought from October 1853 to February 1856 between Russia and an ultimately victorious alliance of the Ottoman Empire, France, the United Kingdom and Piedmont-Sardinia.

Geopolitical causes of the war included the de ...

(1853–56) and the Indian Mutiny

The Indian Rebellion of 1857 was a major uprising in India in 1857–58 against the rule of the British East India Company, which functioned as a sovereign power on behalf of the British Crown. The rebellion began on 10 May 1857 in the fo ...

(1857–58).

The arms business declined after this, as the government increasingly took charge of weapons production. The works turned to making weldless railway tyres, steam engine boilers, sugar pans for refineries in the West Indies, water pipes and heavy iron components for industrial purposes.

By 1863 there were 3,600 employees at the works including 1,993 miners, 420 furnacemen, 770 forgemen and 323 engineers.

In 1864 a second steam hammer with an 8-ton ram was installed for heavy forgings. In 1871 a third steam hammer of 7 tons was installed.

New rolling mills were also built to meet demand for iron plates in shipbuilding, supplied by slabs forged in the works.

By 1867 there were about 4,000 employees. A description of the works at that time said

In 1868 617,628 tons of Low Moor ironstone were raised, the peak production.

In 1876 about 2,000 coal miners were employed in pits ranging in depth from in the surrounding townships of North Bierley, Tong Tong may refer to:

Chinese

*Tang Dynasty, a dynasty in Chinese history when transliterated from Cantonese

*Tong (organization), a type of social organization found in Chinese immigrant communities

*''tong'', pronunciation of several Chinese char ...

, Bowling, Shelf, Wyke, Clifton

Clifton may refer to:

People

*Clifton (surname)

*Clifton (given name)

Places

Australia

* Clifton, Queensland, a town

**Shire of Clifton

*Clifton, New South Wales, a suburb of Wollongong

*Clifton, Western Australia

Canada

*Clifton, Nova Scotia ...

, Hipperholme

Hipperholme is a village in West Yorkshire, England, located between the towns of Halifax and Brighouse in the Hipperholme and Lightcliffe ward of the Metropolitan Borough of Calderdale. The population of this ward at the 2011 Census was 11,3 ...

and Cleckheaton

Cleckheaton is a town in the Metropolitan borough of Kirklees, in West Yorkshire, England. Historically part of the West Riding of Yorkshire, it is situated south of Bradford, east of Brighouse, west of Batley and south-west of Leeds. It is a ...

.

Thirteen pumping engines were used to drain water from the mines.

The company also employed about 800 miners in collieries to the east at Beeston, Churwell

Churwell is a suburb of Leeds, West Yorkshire, England, between Leeds city centre and Morley. It is southwest of Leeds city centre and away from the Leeds United Elland Road Football Ground.

Churwell still retains its semi-rural feel with ...

, Osmondthorpe

Osmondthorpe a district of east Leeds in West Yorkshire, England is considered part of the Halton Moor district.

It is situated in the LS9 Leeds postcode area, two miles (3 km) to the east of Leeds city centre between East End Park and H ...

and Potternewton

Potternewton (until recently also Potter Newton) is a suburb and parish between Chapeltown and Chapel Allerton in north-east Leeds, West Yorkshire, England. It is in the Chapel Allerton ward of Leeds City Council.

Potternewton is bounded by ...

, near Leeds

Leeds () is a city and the administrative centre of the City of Leeds district in West Yorkshire, England. It is built around the River Aire and is in the eastern foothills of the Pennines. It is also the third-largest settlement (by populati ...

.

Minerals were carried to the works by horse-drawn wagons or by wagons on tramways drawn by stationary engines.

The Low Moor mines produced about 60,000 tons of ore yearly by 1876. The iron was prized for its uniform and brilliant grain, commanding premium prices.

The quality seemed to be due in part to the nature of the ore and coal and in part to the manufacturing process.

Production came at the cost of aesthetics. An 1876 description said "the natural effect of the perpetual smoke-canopy under which the vegetation of the district exists is to give to it a dinginess not pleasant to look upon... The appearance created by the works themselves and their surroundings has been not inaptly likened to that in the vicinity of the crater of some volcano."

Decline

The company began to run into difficulty in the late 1880s. Its mines were increasingly scattered and expensive. The rail network had a variety of gauges and used a mix of stationary engines and locomotives. Some of the plant was obsolete and operations were generally inefficient.

However, there was continued demand for "Best Yorkshire Iron" for applications where safety was critically important.

In 1888 Low Moor was converted to a limited liability company, although descendants of the founders retained control.

The directors planned two new blast furnaces at the New Works, each high, with capacities of 340 and 240 tons per week.

The first came into operation in 1892. In 1905 an electrical power station was built at the New Works, with boilers fired by gas from the blast furnaces. Apart from the heaviest machines, steam drives were replaced by electrical drives.

The outbreak of

The company began to run into difficulty in the late 1880s. Its mines were increasingly scattered and expensive. The rail network had a variety of gauges and used a mix of stationary engines and locomotives. Some of the plant was obsolete and operations were generally inefficient.

However, there was continued demand for "Best Yorkshire Iron" for applications where safety was critically important.

In 1888 Low Moor was converted to a limited liability company, although descendants of the founders retained control.

The directors planned two new blast furnaces at the New Works, each high, with capacities of 340 and 240 tons per week.

The first came into operation in 1892. In 1905 an electrical power station was built at the New Works, with boilers fired by gas from the blast furnaces. Apart from the heaviest machines, steam drives were replaced by electrical drives.

The outbreak of World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fightin ...

(1914–1918) caused a temporary surge in demand for shell casings and drop forgings, including shoes for the tracks of the first tanks.

After the war it was clear that future demand for wrought iron was uncertain. The company was taken over by Robert Heath & Sons of Staffordshire

Staffordshire (; postal abbreviation Staffs.) is a landlocked county in the West Midlands region of England. It borders Cheshire to the northwest, Derbyshire and Leicestershire to the east, Warwickshire to the southeast, the West Midlands Cou ...

, creating a new company called Robert Heath And Low Moor Ltd. Efforts were made to reduce costs, although this affected quality.

Attempts to use high-sulphur coal created serious problems and destroyed the reputation of the works as a supplier of high quality iron, while a slump in heavy industry in the 1920s further reduced demand. The company poured money into attempts to diversify the operations, but did not succeed. In 1928 the company was declared bankrupt, and the Low Moor assets bought by Thos. W. Ward Ltd. Many of the mines, tracks and plant were closed or dismantled.

Some buildings were sold or leased to other companies, and some plant was modernised. Wrought iron production finally ended in 1957.

As of 1971 new owners were producing alloy steel, making about 350 tons per week.

References

Notes Citations Sources * * * * * * * * * * * * * * * * {{DEFAULTSORT:Low Moor Ironworks Industrial Revolution Buildings and structures in Bradford Manufacturing companies based in Bradford History of the City of Bradford