ISO 216 on:

[Wikipedia]

[Google]

[Amazon]

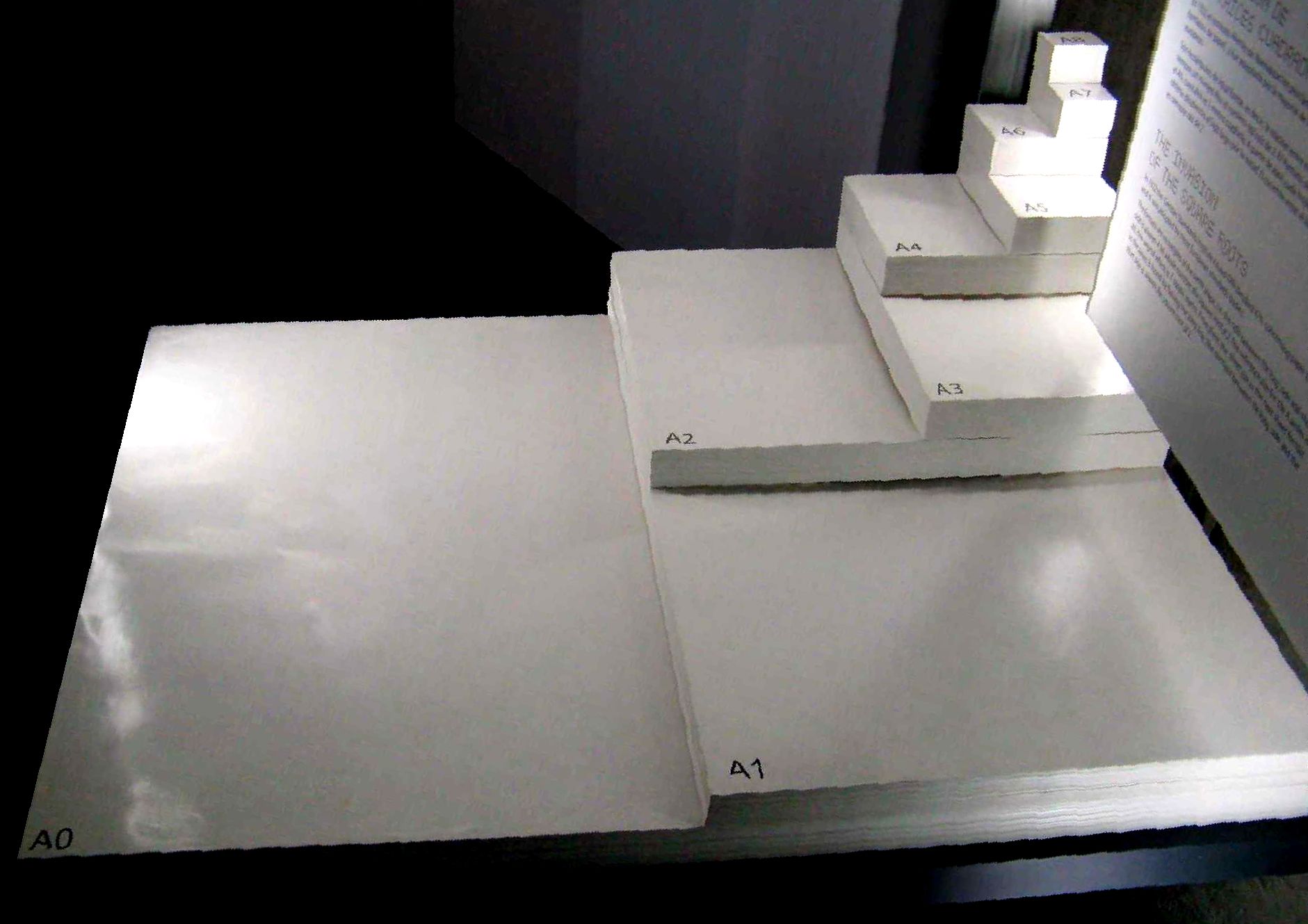

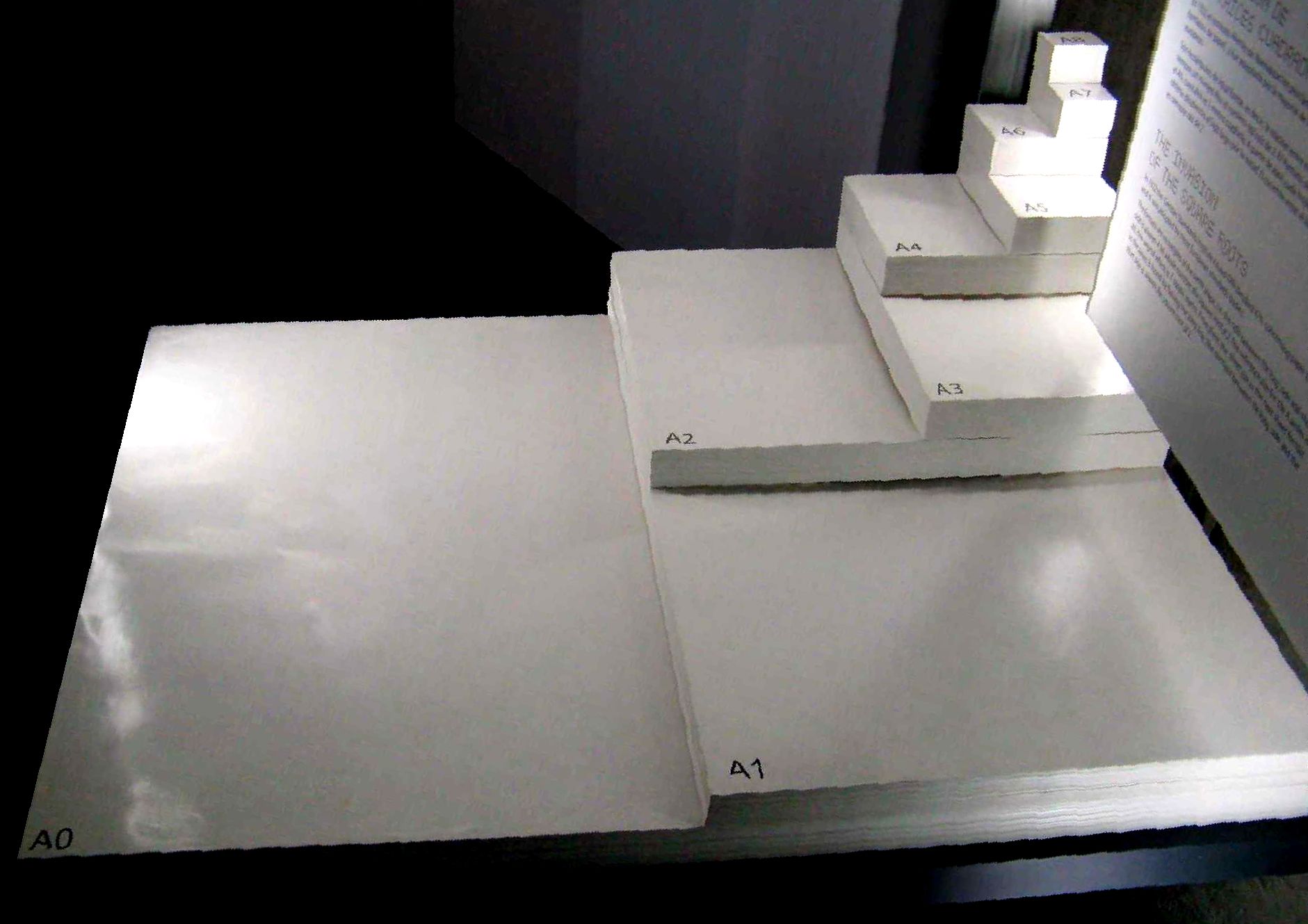

ISO 216 is an international standard for paper sizes, used around the world except in North America and parts of Latin America. The standard defines the "A", "B" and "C" series of paper sizes, including A4, the most commonly available paper size worldwide. Two supplementary standards, ISO 217 and ISO 269, define related paper sizes; the ISO 269 "C" series is commonly listed alongside the A and B sizes.

All ISO 216, ISO 217 and ISO 269 paper sizes (except some envelopes) have the same aspect ratio, , within rounding to millimetres. This ratio has the unique property that when cut or folded in half widthways, the halves also have the same aspect ratio. Each ISO paper size is one half of the area of the next larger size in the same series.

ISO 216 is an international standard for paper sizes, used around the world except in North America and parts of Latin America. The standard defines the "A", "B" and "C" series of paper sizes, including A4, the most commonly available paper size worldwide. Two supplementary standards, ISO 217 and ISO 269, define related paper sizes; the ISO 269 "C" series is commonly listed alongside the A and B sizes.

All ISO 216, ISO 217 and ISO 269 paper sizes (except some envelopes) have the same aspect ratio, , within rounding to millimetres. This ratio has the unique property that when cut or folded in half widthways, the halves also have the same aspect ratio. Each ISO paper size is one half of the area of the next larger size in the same series.

An adjunct to the ISO paper sizes, particularly the A series, are the technical drawing line widths specified in ISO 128. For example, line type A ("Continuous - thick", used for "visible outlines") has a standard thickness of 0.7 mm on an A0-sized sheet, 0.5 mm on an A1 sheet, and 0.35 mm on A2, A3, or A4.

The matching technical pen widths are 0.13, 0.18, 0.25, 0.35, 0.5, 0.7, 1.0, 1.40, and 2.0 mm, as specified in ISO 9175-1. Colour codes are assigned to each size to facilitate easy recognition by the drafter. These sizes again increase by a factor of , so that particular pens can be used on particular sizes of paper, and then the next smaller or larger size can be used to continue the drawing after it has been reduced or enlarged, respectively.

:

An adjunct to the ISO paper sizes, particularly the A series, are the technical drawing line widths specified in ISO 128. For example, line type A ("Continuous - thick", used for "visible outlines") has a standard thickness of 0.7 mm on an A0-sized sheet, 0.5 mm on an A1 sheet, and 0.35 mm on A2, A3, or A4.

The matching technical pen widths are 0.13, 0.18, 0.25, 0.35, 0.5, 0.7, 1.0, 1.40, and 2.0 mm, as specified in ISO 9175-1. Colour codes are assigned to each size to facilitate easy recognition by the drafter. These sizes again increase by a factor of , so that particular pens can be used on particular sizes of paper, and then the next smaller or larger size can be used to continue the drawing after it has been reduced or enlarged, respectively.

:

The earlier DIN 6775 standard upon which ISO 9175-1 is based also specified a term and symbol for easy identification of pens and drawing templates compatible with the standard, called ''Micronorm'', which may still be found on some technical drafting equipment.

The earlier DIN 6775 standard upon which ISO 9175-1 is based also specified a term and symbol for easy identification of pens and drawing templates compatible with the standard, called ''Micronorm'', which may still be found on some technical drafting equipment.

International standard paper sizes

ISO 216 details and rationale

ISO 216 at iso.org

Articles by Wilhelm Ostwald referencing Lichtenberg's letter, and W. Porstmann specifying a metric system of norms for formats for lengths, surfaces (planes), and volumes, laying the ground for the DIN-Series, in German

{{DEFAULTSORT:Iso 216 #00216 Stationery Metrication Technical specifications

ISO 216 is an international standard for paper sizes, used around the world except in North America and parts of Latin America. The standard defines the "A", "B" and "C" series of paper sizes, including A4, the most commonly available paper size worldwide. Two supplementary standards, ISO 217 and ISO 269, define related paper sizes; the ISO 269 "C" series is commonly listed alongside the A and B sizes.

All ISO 216, ISO 217 and ISO 269 paper sizes (except some envelopes) have the same aspect ratio, , within rounding to millimetres. This ratio has the unique property that when cut or folded in half widthways, the halves also have the same aspect ratio. Each ISO paper size is one half of the area of the next larger size in the same series.

ISO 216 is an international standard for paper sizes, used around the world except in North America and parts of Latin America. The standard defines the "A", "B" and "C" series of paper sizes, including A4, the most commonly available paper size worldwide. Two supplementary standards, ISO 217 and ISO 269, define related paper sizes; the ISO 269 "C" series is commonly listed alongside the A and B sizes.

All ISO 216, ISO 217 and ISO 269 paper sizes (except some envelopes) have the same aspect ratio, , within rounding to millimetres. This ratio has the unique property that when cut or folded in half widthways, the halves also have the same aspect ratio. Each ISO paper size is one half of the area of the next larger size in the same series.

Dimensions of A, B and C series

History

The oldest known mention of the advantages of basing a paper size on an aspect ratio of is found in a letter written on 25 October 1786 by the German scientist Georg Christoph Lichtenberg to Johann Beckmann. Published in The formats that became ISO paper sizes A2, A3, B3, B4, and B5 were developed in France. They were listed in a 1798 law on taxation of publications that was based in part on page sizes. Kuhn includes copies of pages from the journal article that announced the law: Searching for a standard system of paper formats on a scientific basis by the association Die Brücke – Internationales Institut zur Organisierung der geistigen Arbeit (The Bridge – International institute to organise intellectual work), as a replacement for the vast variety of other paper formats that had been used before, in order to make paper stocking and document reproduction cheaper and more efficient, Wilhelm Ostwald proposed in 1911, over a hundred years after the “Loi sur le timbre”, a ''Weltformat'' (world format) for paper sizes based on the ratio 1:, referring to the argument advanced by Lichtenberg's 1786 letter, and linking this to the metric system by using 1 centimetre as the width of the base format. W. Porstmann argued in a long article published in 1918, that a firm basis for the system of paper formats, which deal with surfaces, could not be the length, but the surface, i.e. linking the system of paper formats to the metric system of measures by the square metre, using the two formulae of ''x'' / ''y'' = 1: and ''x'' × ''y'' = 1. Porstmann also argued that formats for ''containers'' of paper like envelopes should be 10% larger than the paper format itself. In 1921, after a long discussion and another intervention by W. Porstmann, the ''Normenausschuß der deutschen Industrie'' (NADI, "Standardisation Committee of German Industry", todayDeutsches Institut für Normung

' (DIN; in English, the German Institute for Standardisation Registered Association) is the German national organization for standardization and is the German ISO member body. DIN is a German Registered Association ('' e.V.'') headquartered ...

or short DIN) published German standard ''DI Norm 476'' the specification of 4 series of paper formats with ratio 1:, with series A as the always preferred formats and basis for the other series. All measures are rounded to the nearest millimetre. A0 has a surface area of 1 square metre up to a rounding error

A roundoff error, also called rounding error, is the difference between the result produced by a given algorithm using exact arithmetic and the result produced by the same algorithm using finite-precision, rounded arithmetic. Rounding errors are ...

, with a width of 841 mm and height of 1189 mm, so an actual area of 0.999949 m2, and A4 recommended as standard paper size for business, administrative and government correspondence and A6 for postcards. Series B is based on B0 with width of 1 metre, C0 is 917 mm × 1297 mm, and D0 771 mm × 1090 mm. Series C is the basis for envelope formats.

The DIN paper-format concept was soon introduced as a national standard in many other countries, for example, Belgium (1924), Netherlands (1925), Norway (1926), Switzerland (1929), Sweden (1930), Soviet Union (1934), Hungary (1938), Italy (1939), Finland (1942), Uruguay (1942), Argentina (1943), Brazil (1943), Spain (1947), Austria (1948), Romania (1949), Japan (1951), Denmark (1953), Czechoslovakia (1953), Israel (1954), Portugal (1954), Yugoslavia (1956), India (1957), Poland (1957), United Kingdom (1959), Venezuela (1962), New Zealand (1963), Iceland (1964), Mexico (1965), South Africa (1966), France (1967), Peru (1967), Turkey (1967), Chile (1968), Greece (1970), Zimbabwe (1970), Singapore (1970), Bangladesh (1972), Thailand (1973), Barbados (1973), Australia (1974), Ecuador (1974), Colombia (1975) and Kuwait (1975).

It finally became both an international standard ( ISO 216) as well as the official United Nations document format in 1975, and it is today used in almost all countries in the world, with the exception of USA, Canada, Mexico, Peru, Colombia, and the Dominican Republic.

In 1977, a large German car manufacturer performed a study of the paper formats found in their incoming mail and concluded that out of 148 examined countries, 88 already used the A series formats.

Advantages

The main advantage of this system is its scaling. Rectangular paper with an aspect ratio of has the unique property that, when cut or folded in half midway between its longer sides, each half has the same aspect ratio as the whole sheet before it was divided. Equivalently, if one lays two same-sized sheets of paper with an aspect ratio of side by side along their longer side, they form a larger rectangle with the aspect ratio of and double the area of each individual sheet. The ISO system of paper sizes exploits these properties of the aspect ratio. In each series of sizes (for example, series A), the largest size is numbered 0 (for example, A0), and each successive size (for example, A1, A2, etc.) has half the area of the preceding sheet and can be cut by halving the length of the preceding size sheet. The new measurement is rounded down to the nearest millimetre. A foldedbrochure

A brochure is originally an informative paper document (often also used for advertising) that can be folded into a template, pamphlet, or leaflet. A brochure can also be a set of related unfolded papers put into a pocket folder or packet or can ...

can be made by using a sheet of the next larger size (for example, an A4 sheet is folded in half to make a brochure with size A5 pages. An office photocopier

A photocopier (also called copier or copy machine, and formerly Xerox machine, the generic trademark) is a machine that makes copies of documents and other visual images onto paper or plastic film quickly and cheaply. Most modern photocopiers u ...

or printer can be designed to reduce a page from A4 to A5 or to enlarge a page from A4 to A3. Similarly, two sheets of A4 can be scaled down to fit one A4 sheet without excess empty paper.

This system also simplifies calculating the weight of paper. Under ISO 536, paper's grammage is defined as a sheet's mass in gram

The gram (originally gramme; SI unit symbol g) is a unit of mass in the International System of Units (SI) equal to one one thousandth of a kilogram.

Originally defined as of 1795 as "the absolute weight of a volume of pure water equal to ...

s (g) per area in square metres (unit symbol g/m2; the nonstandard abbreviation "gsm" is also used). One can derive the grammage of other sizes by arithmetic division in . A standard A4 sheet made from } paper weighs , as it is (four halvings, ignoring rounding) of an A0 page. Thus the weight, and the associated postage rate, can be easily approximated by counting the number of sheets used.

ISO 216 and its related standards were first published between 1975 and 1995:

* ISO 216:2007, defining the A and B series of paper sizes

* ISO 269:1985, defining the C series for envelopes

* ISO 217:2013, defining the RA and SRA series of raw ("untrimmed") paper sizes

Properties

A series

Paper in the A series format has an aspect ratio of (≈ 1.414, when rounded). A0 is defined so that it has an area of 1 m before rounding to the nearest millimetre. Successive paper sizes in the series (A1, A2, A3, etc.) are defined by halving the area of the preceding paper size and rounding down, so that the long side of is the same length as the short side of A''n''. Hence, each next size is nearly exactly half of the prior size. So, an A1 page can fit two A2 pages inside the same area. The most used of this series is the size A4, which is and thus almost exactly in area. For comparison, the letter paper size commonly used in North America () is about () wider and () shorter than A4. Then, the size of A5 paper is half of A4, as × ( × ). The geometric rationale for using the square root of 2 is to maintain the aspect ratio of each subsequent rectangle after cutting or folding an A-series sheet in half, perpendicular to the larger side. Given a rectangle with a longer side, ''x'', and a shorter side, ''y'', ensuring that its aspect ratio, , will be the same as that of a rectangle half its size, , which means that , which reduces to ; in other words, an aspect ratio of .B series

The B series is defined in the standard as follows: "A subsidiary series of sizes is obtained by placing the geometrical means between adjacent sizes of the A series in sequence." The use of the geometric mean makes each step in size: B0, A0, B1, A1, B2 ... smaller than the previous one by the same factor. As with the A series, the lengths of the B series have the ratio , and folding one in half (and rounding down to the nearest millimetre) gives the next in the series. The shorter side of B0 is exactly 1 metre. There is also an incompatible Japanese B series which the JIS defines to have 1.5 times the area of the corresponding JIS A series (which is identical to the ISO A series). Thus, the lengths of JIS B series paper are ≈ 1.22 times those of A-series paper. By comparison, the lengths of ISO B series paper are ≈ 1.19 times those of A-series paper.C series

The C series formats are geometric means between the B series and A series formats with the same number (e.g., C2 is the geometric mean between B2 and A2). The width to height ratio is as in the A and B series. The C series formats are used mainly forenvelope

An envelope is a common packaging item, usually made of thin, flat material. It is designed to contain a flat object, such as a letter or card.

Traditional envelopes are made from sheets of paper cut to one of three shapes: a rhombus, a ...

s. An unfolded A4 page will fit into a C4 envelope. C series envelopes follow the same ratio principle as the A series pages. For example, if an A4 page is folded in half so that it is A5 in size, it will fit into a C5 envelope (which will be the same size as a C4 envelope folded in half). The lengths of ISO C series paper are therefore ≈ 1.09 times those of A-series paper.

A, B, and C paper fit together as part of a geometric progression, with ratio of successive side lengths of , though there is no size half-way between B''n'' and : A4, C4, B4, "D4", A3, ...; there is such a D-series in the Swedish extensions to the system.

Tolerances

The tolerances specified in the standard are: * ±1.5 mm for dimensions up to 150 mm, * ±2.0 mm for dimensions in the range 150 to 600 mm, and * ±3.0 mm for dimensions above 600 mm. These are related to comparison between series A, B and C.Application

The ISO 216 formats are organized around the ratio 1:; two sheets next to each other together have the same ratio, sideways. In scaled photocopying, for example, two A4 sheets reduced to A5 size fit exactly onto one A4 sheet, and an A4 sheet in magnified size onto an A3 sheet; in each case, there is neither waste nor want. The principal countries not generally using the ISO paper sizes are the United States and Canada, which use North American paper sizes. Although they have also officially adopted the ISO 216 paper format, Mexico, Panama, Peru, Colombia, the Philippines, and Chile also use mostly U.S. paper sizes. Rectangular sheets of paper with the ratio 1: are popular in paper folding, such as origami, where they are sometimes called "A4 rectangles" or "silver rectangles". In other contexts, the term "silver rectangle" can also refer to a rectangle in the proportion 1:(1 + ), known as the silver ratio.Matching technical pen widths

See also

* ANSI/ASME Y14.1 * International standard envelope sizes * Paper densityReferences

External links

International standard paper sizes

ISO 216 details and rationale

ISO 216 at iso.org

Articles by Wilhelm Ostwald referencing Lichtenberg's letter, and W. Porstmann specifying a metric system of norms for formats for lengths, surfaces (planes), and volumes, laying the ground for the DIN-Series, in German

{{DEFAULTSORT:Iso 216 #00216 Stationery Metrication Technical specifications