house-built engine on:

[Wikipedia]

[Google]

[Amazon]

A house-built engine is a

A house-built engine is a

Most house-built engines were early

Most house-built engines were early

Small vertical engines were also house-built. An engine of this type, from Sunnybank Mill, has been preserved near

Small vertical engines were also house-built. An engine of this type, from Sunnybank Mill, has been preserved near

The ''girder bed engine'' avoided some of this dependency by providing the engine with a single long bed casting that spanned the crankshaft and trunk guide. The bed was connected to its plinth by a number of short pillars. Although this bed still required care during erection to avoid twisting by clamping it down too firmly to a misaligned foundation, it did simplify engine alignment and also reduced effects if the foundation settled in service.

Where

The ''girder bed engine'' avoided some of this dependency by providing the engine with a single long bed casting that spanned the crankshaft and trunk guide. The bed was connected to its plinth by a number of short pillars. Although this bed still required care during erection to avoid twisting by clamping it down too firmly to a misaligned foundation, it did simplify engine alignment and also reduced effects if the foundation settled in service.

Where

House building for beam engines continued into the 20th century.

One of the largest sets of engines installed in a single engine house were the six engines for pumping the completed

House building for beam engines continued into the 20th century.

One of the largest sets of engines installed in a single engine house were the six engines for pumping the completed

A house-built engine is a

A house-built engine is a stationary steam engine

Stationary steam engines are fixed steam engines used for pumping or driving mills and factories, and for power generation. They are distinct from locomotive engines used on railways, traction engines for heavy steam haulage on roads, steam cars ...

that is built into an engine house

__NOTOC__

An engine house is a building or other structure that holds one or more engines. It is often practical to bring engines together for common maintenance, as when train locomotives are brought together.

Types of engine houses include:

* m ...

, such that it uses the masonry

Masonry is the building of structures from individual units, which are often laid in and bound together by mortar; the term ''masonry'' can also refer to the units themselves. The common materials of masonry construction are bricks, building ...

of the engine house as an integral part of the support of the engine.

Beam engines

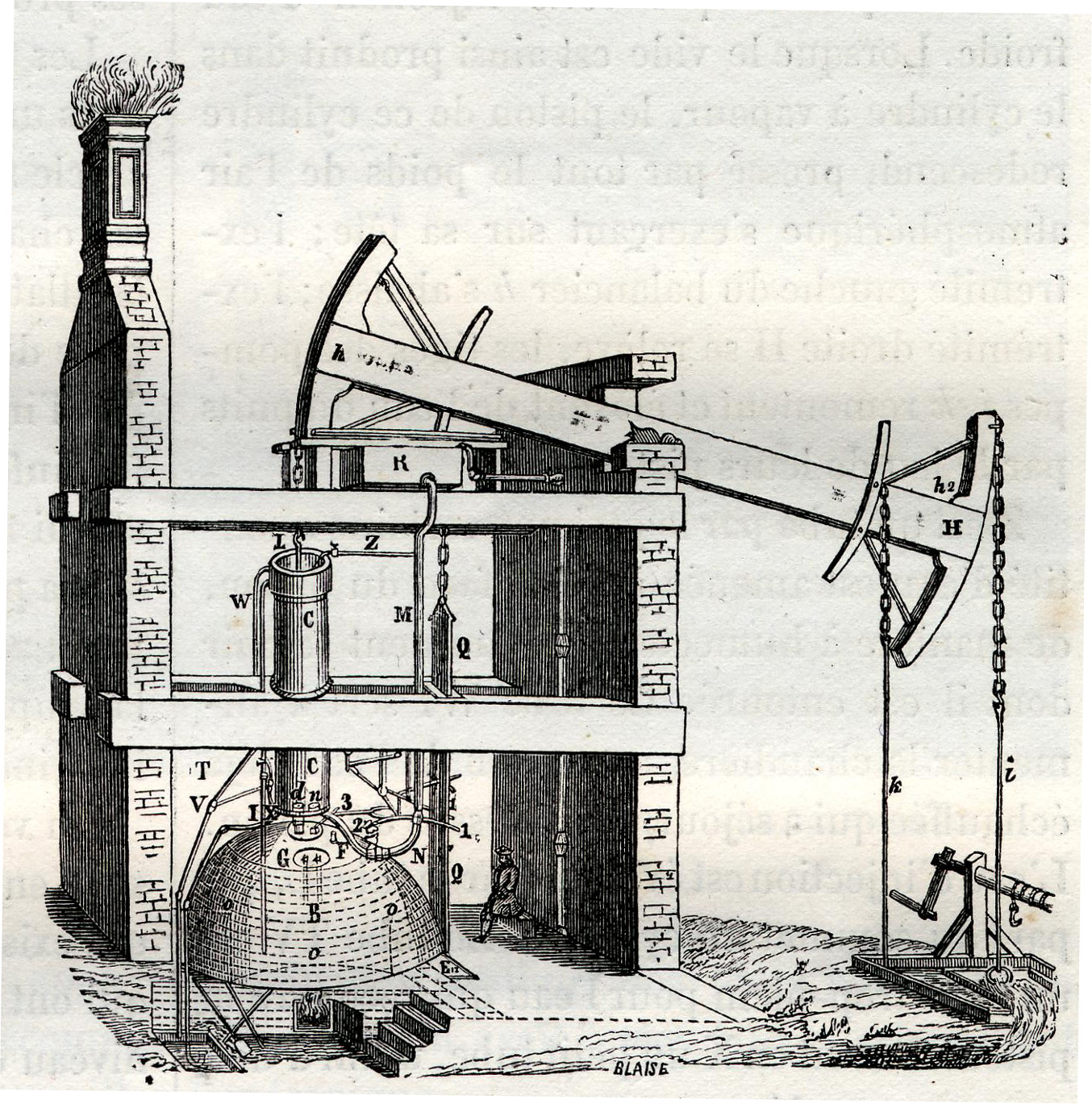

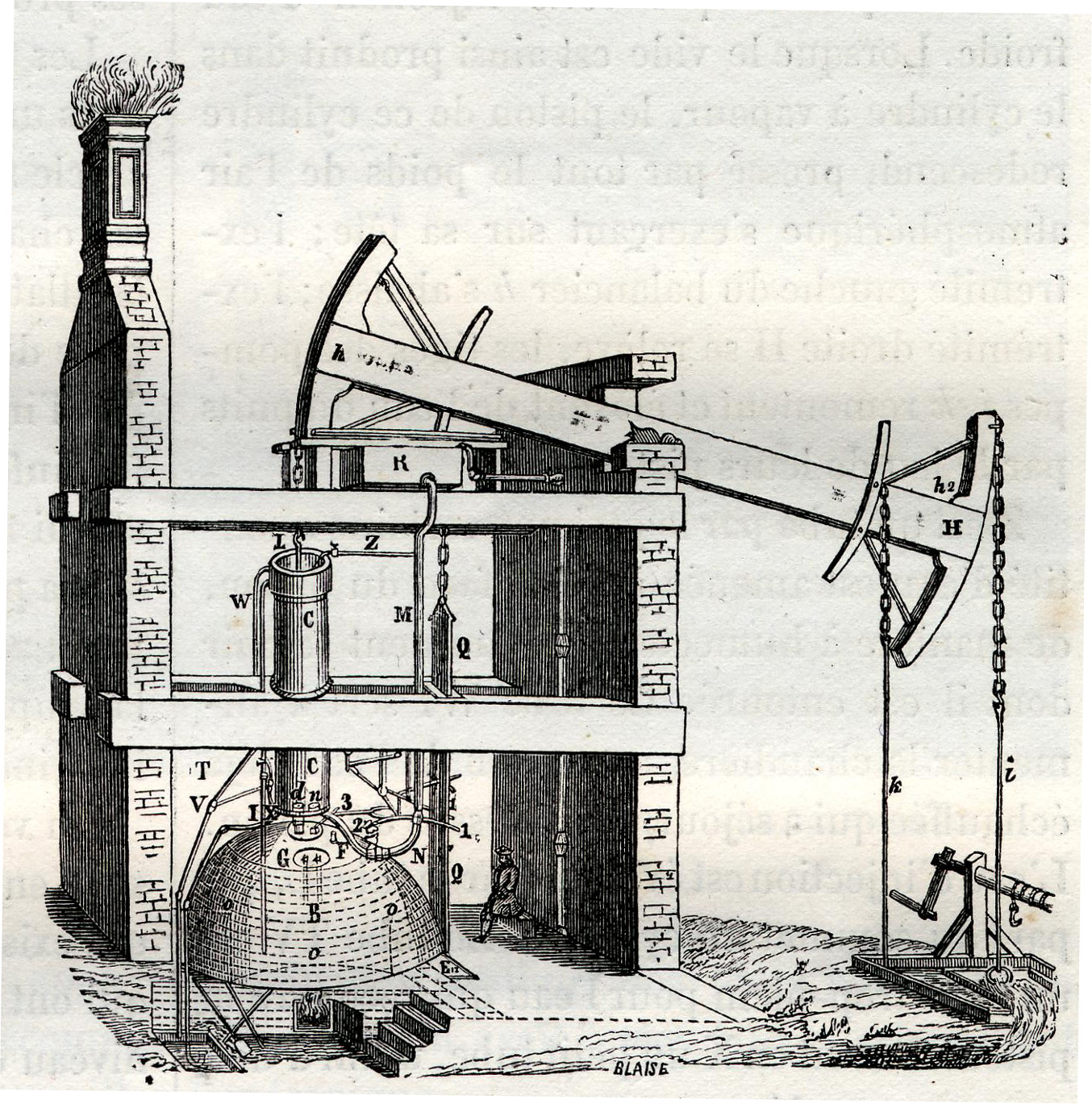

Most house-built engines were early

Most house-built engines were early beam engine

A beam engine is a type of steam engine where a pivoted overhead beam is used to apply the force from a vertical piston to a vertical connecting rod. This configuration, with the engine directly driving a pump, was first used by Thomas Newco ...

s. A 'bob wall' in the engine house supported the pivot axle of the beam

Beam may refer to:

Streams of particles or energy

*Light beam, or beam of light, a directional projection of light energy

**Laser beam

*Particle beam, a stream of charged or neutral particles

**Charged particle beam, a spatially localized grou ...

or 'bob'. This wall could be an internal wall, with both ends of the beam inside the house, but it was commonly the end wall of the house and so the beam projected to the outside. For a heavy beam, the bob wall was required to be extremely substantial. Early engines were used for pumping mines or wells, so as well as the weight of the beam, the house had to also support the weight of the long pump rod, reaching down to the depths of the mine.

Beam engines appeared during the 18th century. The only technologies at this time that could support the weight of an engine's beam were masonry and timber-framing

Timber framing (german: Holzfachwerk) and "post-and-beam" construction are traditional methods of building with heavy timbers, creating structures using squared-off and carefully fitted and joined timbers with joints secured by large wooden ...

, as the work of either shipwright

Shipbuilding is the construction of ships and other floating vessels. It normally takes place in a specialized facility known as a shipyard. Shipbuilders, also called shipwrights, follow a specialized occupation that traces its roots to befor ...

s or millwright

A millwright is a craftsperson or skilled tradesperson who installs, dismantles, maintains, repairs, reassembles, and moves machinery in factories, power plants, and construction sites.

The term ''millwright'' (also known as ''industrial mecha ...

s. Cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

was not yet a structural material, or capable of being worked at this scale. Wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a ...

was too expensive to be used in such sizes.

After the early beam engines, where the cylinder was mounted directly atop the boiler, the space inside the house of later beam engines was divided by floors. The 'bottom chamber' contained the base of the cylinder, the lower valves and the valvegear. This was the main working chamber and was where the engine driver would spend most of their time. Above this, a floor or partial floor and the 'top chamber' provided a working space for access to the valves or 'nozzles' at the top of the cylinder. This was used mostly for intermittent access to lubricate bearings etc. Often the floor did not span the full length of the house and formed a gallery above the bottom chamber. These floors and stairways were often fitted with woodwork and banisters of the highest quality. Similarly the 'beam chamber' at the top of the house provided access to the beam's bearings. Where the beam extended through the end wall of the house, two small outdoor platforms on either side of the beam gave access from the beam chamber to each side of the beam and the bearings for the pump shaft. A final chamber was beneath the floor of the bottom chamber. This contained the air pump

An air pump is a pump for pushing air. Examples include a bicycle pump, pumps that are used to aerate an aquarium or a pond via an airstone; a gas compressor used to power a pneumatic tool, air horn or pipe organ; a bellows used to encourage ...

and regulating cataract

A cataract is a cloudy area in the lens of the eye that leads to a decrease in vision. Cataracts often develop slowly and can affect one or both eyes. Symptoms may include faded colors, blurry or double vision, halos around light, trouble w ...

. It was so rarely visited that access was only by means of a trapdoor.

House-built vertical engines

Small vertical engines were also house-built. An engine of this type, from Sunnybank Mill, has been preserved near

Small vertical engines were also house-built. An engine of this type, from Sunnybank Mill, has been preserved near Darwen

Darwen is a market town and civil parish in the Blackburn with Darwen borough in Lancashire, England. The residents of the town are known as "Darreners".

The A666 road passes through Darwen towards Blackburn to the north, Bolton to the sout ...

.

Table engines

One of the first engines to ''avoid'' the need for house-building was thetable engine

A table engine is a variety of stationary steam engine where the cylinder is placed on top of a table-shaped base, the legs of which stand on the baseplate which locates the crankshaft bearings. The piston rod protrudes from the top of the cylinder ...

, from around 1800. This vertical engine placed the cylinder above the crankshaft and the crosshead above that, with a return connecting rod. Although Sadler's first table engine was house-built, Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an ...

's patent table engine sat the cylinder upon a cast iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impuriti ...

table, giving the engine its name. This table was independent of the engine house. Provided that the floor was strong enough to support the weight of the engine and was reasonably level, these engines could be placed anywhere, without needing special houses to be built for them.

Such construction was also quicker to build on-site, as a pre-manufactured engine could be supplied by the engine maker in almost completed form. Skilled engine erectors were a rare resource, especially in remote mining areas, and the need to have them working on-site for long periods whilst a large house was constructed around the engine was often a cause of delays to an engine being completed. Even with adequate labour, masonry construction is a slower process than delivery of machinery alone. Where brick foundations were constructed, it was recommended that at least fifteen days were allowed before the weight of the engine was placed onto them.

Horizontal engines

With the development of the horizontal stationary engine in the mid 19th century, the requirements were no longer to support a single heavy beam but now to provide accurate alignment between the cylinders and crankshaft of a medium-speed engine. These foundations were substantial, going down perhaps three-dozen courses of brickwork below the engine bed. Deep iron anchors were provided within the brickwork for the engine to be bolted down. Rough local stone was no longer rigid enough and so foundations were constructed of many layers of hardengineering brick

Engineering bricks are a type of brick used where strength, low water porosity or acid (flue gas) resistance are needed. Engineering bricks can be used for damp-proof courses.

Clay engineering bricks are defined in ''§ 6.4.51'' of ''British Sta ...

, as this was cheaper and more easily available than a cut ashlar

Ashlar () is finely dressed (cut, worked) stone, either an individual stone that has been worked until squared, or a structure built from such stones. Ashlar is the finest stone masonry unit, generally rectangular cuboid, mentioned by Vitruv ...

stone of equal rigidity. As these engine ran at faster speeds than the beam engines, their vibration could also be higher requiring a foundation that could withstand such. Alignment between slideways and crankshaft depended upon the original care with which the foundation had been built.

The ''girder bed engine'' avoided some of this dependency by providing the engine with a single long bed casting that spanned the crankshaft and trunk guide. The bed was connected to its plinth by a number of short pillars. Although this bed still required care during erection to avoid twisting by clamping it down too firmly to a misaligned foundation, it did simplify engine alignment and also reduced effects if the foundation settled in service.

Where

The ''girder bed engine'' avoided some of this dependency by providing the engine with a single long bed casting that spanned the crankshaft and trunk guide. The bed was connected to its plinth by a number of short pillars. Although this bed still required care during erection to avoid twisting by clamping it down too firmly to a misaligned foundation, it did simplify engine alignment and also reduced effects if the foundation settled in service.

Where high-speed steam engine

High-speed steam engines were one of the final developments of the stationary steam engine. They ran at a high speed, of several hundred rpm,, 400 to 1,200 rpm which was needed by tasks such as electricity generation.

Defining characteristics

...

s were used, these small engines usually incorporated a single-piece cast iron bed. This could be supported by a single brickwork pier, without needed careful alignment by its masons. Some engine makers, such as Robey & Co. of Lincoln

Lincoln most commonly refers to:

* Abraham Lincoln (1809–1865), the sixteenth president of the United States

* Lincoln, England, cathedral city and county town of Lincolnshire, England

* Lincoln, Nebraska, the capital of Nebraska, U.S.

* Lincol ...

, developed a distinctive form of cantilevered cast iron bed for their large medium speed engines that formed both the crosshead trunk guide and the crank bearings, thus permitting a similar single plinth foundation.

Late beam engines

House building for beam engines continued into the 20th century.

One of the largest sets of engines installed in a single engine house were the six engines for pumping the completed

House building for beam engines continued into the 20th century.

One of the largest sets of engines installed in a single engine house were the six engines for pumping the completed Severn Tunnel

The Severn Tunnel ( cy, Twnnel Hafren) is a railway tunnel in the United Kingdom, linking South Gloucestershire in the west of England to Monmouthshire in south Wales under the estuary of the River Severn. It was constructed by the Great Western ...

in 1886. These had six beams, arranged radially around the tunnel shaft, and passing in two groups of three through a pair of internal walls, just above ground level.

The last Cornish engine

A Cornish engine is a type of steam engine developed in Cornwall, England, mainly for pumping water from a mine. It is a form of beam engine that uses steam at a higher pressure than the earlier Watt steam engine, engines designed by James Wat ...

built, at Dorothea Quarry

Dorothea quarry is a disused slate quarry in the Nantlle Valley area in North Wales. It covers a large area near the village of Talysarn and contains three flooded deep lakes.

History Turner family

The quarry commenced working in the earl ...

in 1905, has a through-wall beam supported on a wall 5 ft 6in thick.

See also

*Semi-portable engine

A semi-portable engine is a form of stationary steam engine. They were built in a factory as a single unit including the boiler, so that they could be rapidly installed on site and brought into service.

Although the earliest examples can be dated ...

References

{{steam engine configurations, state=collapsed Stationary steam engines Beam engines Steam engines by layout