Fluidized bed concentrator on:

[Wikipedia]

[Google]

[Amazon]

A fluidized bed concentrator (FBC) is an industrial process for the treatment of exhaust air. The system uses a bed of

A fluidized bed concentrator (FBC) is an industrial process for the treatment of exhaust air. The system uses a bed of

The fluidized bed concentrator consists of five primary components:

*

The fluidized bed concentrator consists of five primary components:

*

Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature. The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads. The 0.7 mm bead activated carbon (BAC) fluidizes in the trays and captures the VOCs as they intermix.

The saturated carbon beads are passed from the adsorber tower to the desorber tower, where the beads are heated to 350 °F and the VOCs are released. Typically the adsorber tower is many times larger than the desorber tower, leading to an air volume reduction and an increase in VOC concentration. The ratio of adsorber size to desorber size is called the concentration ratio, and ranges from 10:1 to 100:1.

The concentrated VOC gas stream is sent from the desorb tower to a thermal oxidizer, where the organic compounds are heated to 1400 °F and oxidized, or broken down into carbon dioxide (CO2), water (H2O), and by-products. In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NOX), and other gases are produced.

Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature. The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads. The 0.7 mm bead activated carbon (BAC) fluidizes in the trays and captures the VOCs as they intermix.

The saturated carbon beads are passed from the adsorber tower to the desorber tower, where the beads are heated to 350 °F and the VOCs are released. Typically the adsorber tower is many times larger than the desorber tower, leading to an air volume reduction and an increase in VOC concentration. The ratio of adsorber size to desorber size is called the concentration ratio, and ranges from 10:1 to 100:1.

The concentrated VOC gas stream is sent from the desorb tower to a thermal oxidizer, where the organic compounds are heated to 1400 °F and oxidized, or broken down into carbon dioxide (CO2), water (H2O), and by-products. In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NOX), and other gases are produced.

The primary advantage of the FBC over traditional rotor concentrators lies in its ability to achieve any concentration ratio up to the

The primary advantage of the FBC over traditional rotor concentrators lies in its ability to achieve any concentration ratio up to the

* Paint finishing

** Automotive

**

* Paint finishing

** Automotive

**

Clean Air Act

plus further links to relevant rules, reports, and programs.

Organic NESHAP

Air pollution control systems Pollution control technologies Air pollution in the United States Hazardous air pollutants United States Environmental Protection Agency Chemical safety Volatile organic compound abatement Industrial processes Fluidization

A fluidized bed concentrator (FBC) is an industrial process for the treatment of exhaust air. The system uses a bed of

A fluidized bed concentrator (FBC) is an industrial process for the treatment of exhaust air. The system uses a bed of activated carbon

Activated carbon, also called activated charcoal, is a form of carbon commonly used to filter contaminants from water and air, among many other uses. It is processed (activated) to have small, low-volume pores that increase the surface area avail ...

beads to adsorb volatile organic compound

Volatile organic compounds (VOCs) are organic compounds that have a high vapour pressure at room temperature. High vapor pressure correlates with a low boiling point, which relates to the number of the sample's molecules in the surrounding air, a ...

s (VOCs) from the exhaust gas

Exhaust gas or flue gas is emitted as a result of the combustion of fuels such as natural gas, gasoline (petrol), diesel fuel, fuel oil, biodiesel blends, or coal. According to the type of engine, it is discharged into the atmosphere through an ...

. Evolving from the previous fixed-bed and carbon rotor concentrators, the FBC system forces the VOC-laden air through several perforated steel trays, increasing the velocity of the air and allowing the sub-millimeter carbon beads to fluidize, or behave as if suspended in a liquid. This increases the surface area of the carbon-gas interaction, making it more effective at capturing VOCs.

Components

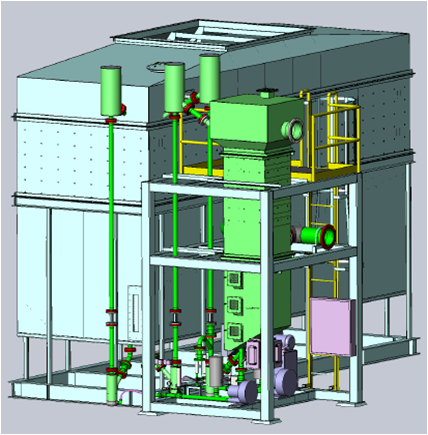

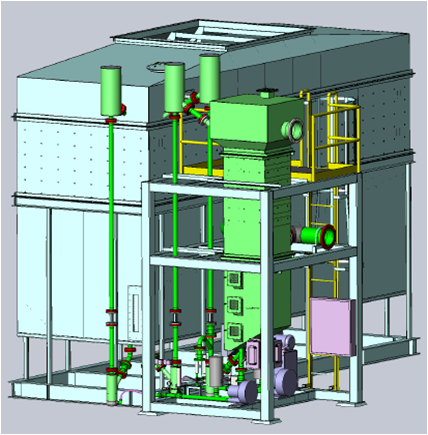

The fluidized bed concentrator consists of five primary components:

*

The fluidized bed concentrator consists of five primary components:

*Adsorption

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the ''adsorbate'' on the surface of the ''adsorbent''. This process differs from absorption, in which a f ...

tower

*Desorption

Desorption is the physical process where a previously adsorbed substance is released from a surface. This happens when a molecule gains enough energy to overcome the activation barrier of the bounding energy that keeps it in the surface.

There ...

tower

*Thermal oxidizer

A thermal oxidizer (also known as thermal oxidiser, or thermal incinerator) is a process unit for air pollution control in many chemical plants that decomposes hazardous gases at a high temperature and releases them into the atmosphere.

Principl ...

*Carbon transport system

*Process fans: inlet adsorber

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the ''adsorbate'' on the surface of the ''adsorbent''. This process differs from absorption, in which a ...

, inlet desorber, outlet oxidizer to stack

How it works

Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature. The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads. The 0.7 mm bead activated carbon (BAC) fluidizes in the trays and captures the VOCs as they intermix.

The saturated carbon beads are passed from the adsorber tower to the desorber tower, where the beads are heated to 350 °F and the VOCs are released. Typically the adsorber tower is many times larger than the desorber tower, leading to an air volume reduction and an increase in VOC concentration. The ratio of adsorber size to desorber size is called the concentration ratio, and ranges from 10:1 to 100:1.

The concentrated VOC gas stream is sent from the desorb tower to a thermal oxidizer, where the organic compounds are heated to 1400 °F and oxidized, or broken down into carbon dioxide (CO2), water (H2O), and by-products. In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NOX), and other gases are produced.

Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature. The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads. The 0.7 mm bead activated carbon (BAC) fluidizes in the trays and captures the VOCs as they intermix.

The saturated carbon beads are passed from the adsorber tower to the desorber tower, where the beads are heated to 350 °F and the VOCs are released. Typically the adsorber tower is many times larger than the desorber tower, leading to an air volume reduction and an increase in VOC concentration. The ratio of adsorber size to desorber size is called the concentration ratio, and ranges from 10:1 to 100:1.

The concentrated VOC gas stream is sent from the desorb tower to a thermal oxidizer, where the organic compounds are heated to 1400 °F and oxidized, or broken down into carbon dioxide (CO2), water (H2O), and by-products. In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NOX), and other gases are produced.

Emissions and energy usage

The primary advantage of the FBC over traditional rotor concentrators lies in its ability to achieve any concentration ratio up to the

The primary advantage of the FBC over traditional rotor concentrators lies in its ability to achieve any concentration ratio up to the lower explosive limit

Mixtures of dispersed combustible materials (such as gaseous or vaporised fuels, and some dusts) and oxygen in the air will burn only if the fuel concentration lies within well-defined lower and upper bounds determined experimentally, referred to a ...

(LEL). This allows Honda Alabama's paint shop to switch from oxidizing 100,000 CFM of VOCs in a regenerative thermal oxidizer (RTO), to oxidizing only 1,500 CFM of VOCs in a small thermal oxidizer, at a much higher concentration. Reducing the volume of air to be oxidized from 100,000 CFM to 1,500 CFM (66:1 concentration ratio), allows for a much lower energy usage and consequently, fewer CO2 and NOX emissions.

Industries served

* Paint finishing

** Automotive

**

* Paint finishing

** Automotive

**Aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astrona ...

**Heavy machinery

Heavy equipment or heavy machinery refers to heavy-duty vehicles specially designed to execute construction tasks, most frequently involving earthwork operations or other large construction tasks. ''Heavy equipment'' usually comprises five e ...

**Transportation

Transport (in British English), or transportation (in American English), is the intentional movement of humans, animals, and goods from one location to another. Modes of transport include air, land (rail and road), water, cable, pipeline, ...

*Printing

Printing is a process for mass reproducing text and images using a master form or template. The earliest non-paper products involving printing include cylinder seals and objects such as the Cyrus Cylinder and the Cylinders of Nabonidus. The ea ...

*Chemical production

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., wit ...

*Semiconductor

A semiconductor is a material which has an electrical resistivity and conductivity, electrical conductivity value falling between that of a electrical conductor, conductor, such as copper, and an insulator (electricity), insulator, such as glas ...

*Food processing

Food processing is the transformation of agricultural products into food, or of one form of food into other forms. Food processing includes many forms of processing foods, from grinding grain to make raw flour to home cooking to complex industr ...

See also

*Volatile organic compound

Volatile organic compounds (VOCs) are organic compounds that have a high vapour pressure at room temperature. High vapor pressure correlates with a low boiling point, which relates to the number of the sample's molecules in the surrounding air, a ...

*National Emissions Standards for Hazardous Air Pollutants

The National Emission Standards for Hazardous Air Pollutants (NESHAP) are air pollution standards issued by the United States Environmental Protection Agency (EPA). The standards, authorized by the Clean Air Act, are for pollutants not covered by ...

*Air pollution in the United States

Air pollution is the introduction of chemicals, particulate matter, or biological materials into the atmosphere, causing harm or discomfort to humans or other living organisms, or damaging ecosystems. Air pollution can cause health problems inc ...

*Activated carbon

Activated carbon, also called activated charcoal, is a form of carbon commonly used to filter contaminants from water and air, among many other uses. It is processed (activated) to have small, low-volume pores that increase the surface area avail ...

*Air pollution

Air pollution is the contamination of air due to the presence of substances in the atmosphere that are harmful to the health of humans and other living beings, or cause damage to the climate or to materials. There are many different types ...

References

{{ReflistExternal links

Clean Air Act

plus further links to relevant rules, reports, and programs.

Organic NESHAP

Air pollution control systems Pollution control technologies Air pollution in the United States Hazardous air pollutants United States Environmental Protection Agency Chemical safety Volatile organic compound abatement Industrial processes Fluidization