|

Thermal Oxidizer

A thermal oxidizer (also known as thermal oxidiser, or thermal incinerator) is a process unit for air pollution control in many chemical plants that decomposes hazardous gases at a high temperature and releases them into the atmosphere. Principle Thermal oxidizers are typically used to destroy hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) from industrial air streams. These pollutants are generally hydrocarbon based and when destroyed via thermal combustion they are chemically oxidized to form CO2 and H2O. Three main factors in designing the effective thermal oxidizers are temperature, residence time, and turbulence. The temperature needs to be high enough to ignite the waste gas. Most organic compounds ignite at the temperature between and . To ensure near destruction of hazardous gases, most basic oxidizers are operated at much higher temperature levels. When catalyst is used, the operating temperature range may be lower. Residence time is to ensure tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Operating Temperature

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the maximum operating temperature (or peak operating temperature). Outside this range of safe operating temperatures the device may fail. It is one component of reliability engineering. Similarly, biological systems have a viable temperature range, which might be referred to as an "operating temperature". Ranges Most devices are manufactured in several temperature grades. Broadly accepted grades are: *Commercial: 0 ° to 70 °C *Industrial: −40 ° to 85 °C *Military: −55 ° to 125 °C Nevertheless, each manufacturer defines its own temperature grades so designers must pay close attention to actual datasheet spe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sintering

Clinker nodules produced by sintering Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The atoms in the materials diffuse across the boundaries of the particles, fusing the particles together and creating one solid piece. Because the sintering temperature does not have to reach the melting point of the material, sintering is often chosen as the shaping process for materials with extremely high melting points such as tungsten and molybdenum. The study of sintering in metallurgical powder-related processes is known as powder metallurgy. An example of sintering can be observed when ice cubes in a glass of water adhere to each other, which is driven by the temperature difference between the water and the ice. Examples of pressure-driven sintering are the compact ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

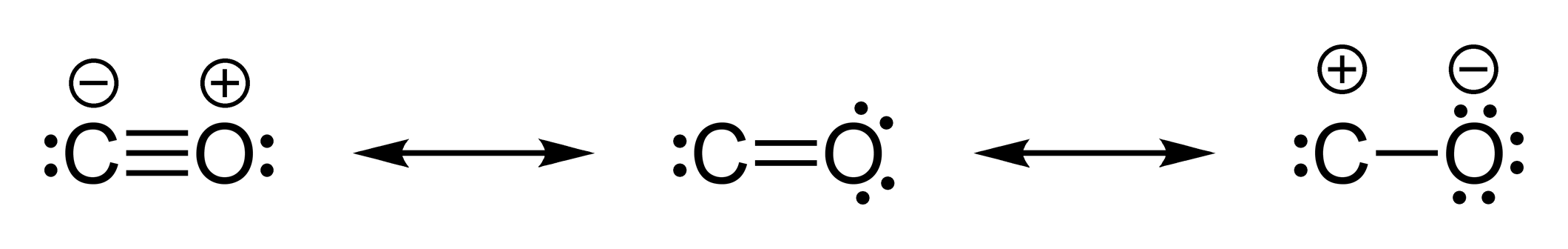

Carbon Monoxide

Carbon monoxide (chemical formula CO) is a colorless, poisonous, odorless, tasteless, flammable gas that is slightly less dense than air. Carbon monoxide consists of one carbon atom and one oxygen atom connected by a triple bond. It is the simplest molecule of the oxocarbon family. In coordination complexes the carbon monoxide ligand is called carbonyl. It is a key ingredient in many processes in industrial chemistry. The most common source of carbon monoxide is the partial combustion of carbon-containing compounds, when insufficient oxygen or heat is present to produce carbon dioxide. There are also numerous environmental and biological sources that generate and emit a significant amount of carbon monoxide. It is important in the production of many compounds, including drugs, fragrances, and fuels. Upon emission into the atmosphere, carbon monoxide affects several processes that contribute to climate change. Carbon monoxide has important biological roles across phylogenetic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalysis

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Schematic Of Recuperative Catalytic Oxidizer

A schematic, or schematic diagram, is a designed representation of the elements of a system using abstract, graphic symbols rather than realistic pictures. A schematic usually omits all details that are not relevant to the key information the schematic is intended to convey, and may include oversimplified elements in order to make this essential meaning easier to grasp, as well as additional organization of the information. For example, a subway map intended for passengers may represent a subway station with a dot. The dot is not intended to resemble the actual station at all but aims to give the viewer information without unnecessary visual clutter. A schematic diagram of a chemical process uses symbols in place of detailed representations of the vessels, piping, valves, pumps, and other equipment that compose the system, thus emphasizing the functions of the individual elements and the interconnections among them and suppresses their physical details. In an electronic circuit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluidized Bed Concentrator

A fluidized bed concentrator (FBC) is an industrial process for the treatment of exhaust air. The system uses a bed of activated carbon beads to adsorb volatile organic compounds (VOCs) from the exhaust gas. Evolving from the previous fixed-bed and carbon rotor concentrators, the FBC system forces the VOC-laden air through several perforated steel trays, increasing the velocity of the air and allowing the sub-millimeter carbon beads to fluidize, or behave as if suspended in a liquid. This increases the surface area of the carbon-gas interaction, making it more effective at capturing VOCs. Components The fluidized bed concentrator consists of five primary components: *Adsorption tower *Desorption tower *Thermal oxidizer *Carbon transport system *Process fans: inlet adsorber, inlet desorber, outlet oxidizer to stack How it works Industrial processes requiring ventilation, including paint booths, printing, and chemical production, exhaust the ventilated air to the fluidized bed co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Parts-per Notation

In science and engineering, the parts-per notation is a set of pseudo-units to describe small values of miscellaneous dimensionless quantities, e.g. mole fraction or mass fraction. Since these fractions are quantity-per-quantity measures, they are pure numbers with no associated units of measurement. Commonly used are parts-per-million (ppm, ), parts-per-billion (ppb, ), parts-per-trillion (ppt, ) and parts-per-quadrillion (ppq, ). This notation is not part of the International System of Units (SI) system and its meaning is ambiguous. Overview Parts-per notation is often used describing dilute solutions in chemistry, for instance, the relative abundance of dissolved minerals or pollutants in water. The quantity "1 ppm" can be used for a mass fraction if a water-borne pollutant is present at one-millionth of a gram per gram of sample solution. When working with aqueous solutions, it is common to assume that the density of water is 1.00 g/mL. Therefore, it is common to equat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

New Hampshire

New Hampshire is a U.S. state, state in the New England region of the northeastern United States. It is bordered by Massachusetts to the south, Vermont to the west, Maine and the Gulf of Maine to the east, and the Canadian province of Quebec to the north. Of the 50 U.S. states, New Hampshire is the List of U.S. states and territories by area, fifth smallest by area and the List of U.S. states and territories by population, tenth least populous, with slightly more than 1.3 million residents. Concord, New Hampshire, Concord is the state capital, while Manchester, New Hampshire, Manchester is the largest city. New Hampshire's List of U.S. state mottos, motto, "Live Free or Die", reflects its role in the American Revolutionary War; its state nickname, nickname, "The Granite State", refers to its extensive granite formations and quarries. It is well known nationwide for holding New Hampshire primary, the first primary (after the Iowa caucus) in the United States presidential election ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasification

Gasification is a process that converts biomass- or fossil fuel-based carbonaceous materials into gases, including as the largest fractions: nitrogen (N2), carbon monoxide (CO), hydrogen (H2), and carbon dioxide (). This is achieved by reacting the feedstock material at high temperatures (typically >700 °C), without combustion, via controlling the amount of oxygen and/or steam present in the reaction. The resulting gas mixture is called syngas (from synthesis gas) or producer gas and is itself a fuel due to the flammability of the H2 and CO of which the gas is largely composed. Power can be derived from the subsequent combustion of the resultant gas, and is considered to be a source of renewable energy if the gasified compounds were obtained from biomass feedstock. An advantage of gasification is that syngas can be more efficient than direct combustion of the original feedstock material because it can be combusted at higher temperatures so that the thermodynamic upper li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biomass

Biomass is plant-based material used as a fuel for heat or electricity production. It can be in the form of wood, wood residues, energy crops, agricultural residues, and waste from industry, farms, and households. Some people use the terms biomass and biofuel interchangeably, while others consider biofuel to be a ''liquid'' or ''gaseous'' fuel used for transportation, as defined by government authorities in the US and EU. The European Union's Joint Research Centre defines solid biofuel as raw or processed organic matter of biological origin used for energy, such as firewood, wood chips, and wood pellets. In 2019, biomass was used to produce 57 EJ (exajoules) of energy, compared to 190 EJ from crude oil, 168 EJ from coal, 144 EJ from natural gas, 30 EJ from nuclear, 15 EJ from hydro and 13 EJ from wind, solar and geothermal combined. Approximately 86% of modern bioenergy is used for heating applications, with 9% used for transport and 5% for electricity. Most of the global b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plate Heat Exchanger

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Plate heat exchangers are now common and very small brazed versions are used in the hot-water sections of millions of combination boilers. The high heat transfer efficiency for such a small physical size has increased the domestic hot water (DHW) flowrate of combination boilers. The small plate heat exchanger has made a great impact in domestic heating and hot-water. Larger commercial versions use gaskets between the plates, whereas smaller versions tend to be brazed. The concept behind a heat exchanger is the use of pipes or other containment vessels to heat or cool one fluid by transferring heat betwe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_at_Honda_Alabama.png)

.jpg)