Freeform Surface Machining on:

[Wikipedia]

[Google]

[Amazon]

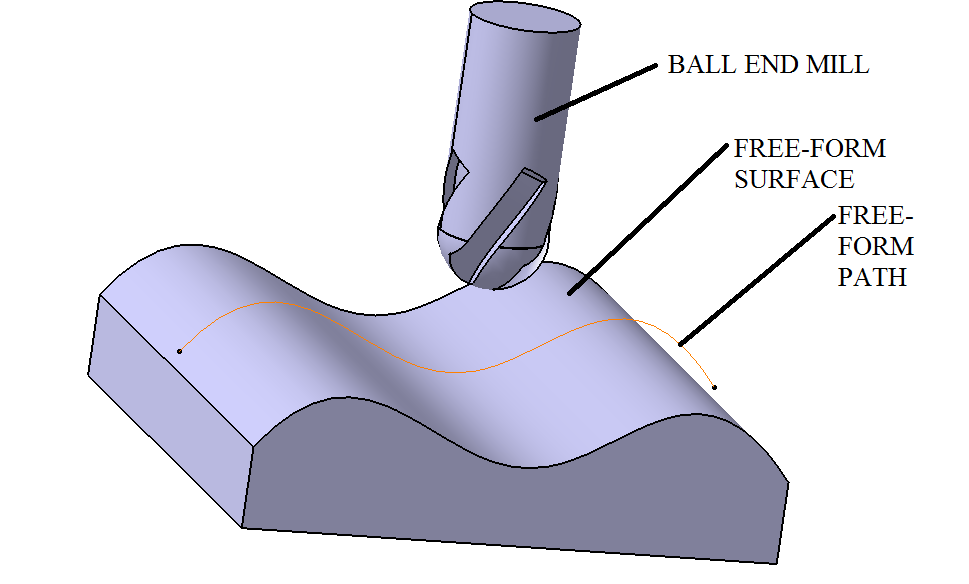

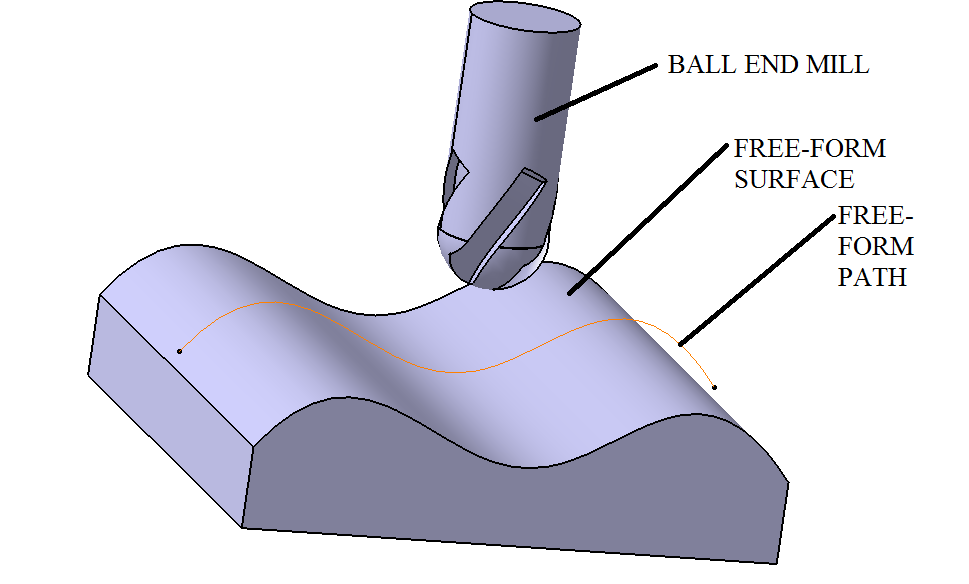

Freeform surface or complex surfaces are widely manufactured nowadays. The industries which most often manufactures free-form surfaces are basically

Freeform surface or complex surfaces are widely manufactured nowadays. The industries which most often manufactures free-form surfaces are basically

Freeform surface or complex surfaces are widely manufactured nowadays. The industries which most often manufactures free-form surfaces are basically

Freeform surface or complex surfaces are widely manufactured nowadays. The industries which most often manufactures free-form surfaces are basically aerospace

Aerospace is a term used to collectively refer to the atmosphere and outer space. Aerospace activity is very diverse, with a multitude of commercial, industrial and military applications. Aerospace engineering consists of aeronautics and astrona ...

, automotive, die mold industries, bio medical and power sector for turbine

A turbine ( or ) (from the Greek , ''tyrbē'', or Latin ''turbo'', meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. The work produced by a turbine can be used for generating ...

blades manufacturing. Generally 3 or 5 axis CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pie ...

milling machine is used for this purpose. The manufacturing process of free form surface is not an easy job as the tool path generation in present CAM

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bin ...

technology is generally based on geometric computation so tool path are not optimum. The geometry can also be not described explicitly so errors and discontinuities occurrence in the solid structure cannot be avoided. Free-form surfaces are machined with the help of different tool path generation method like adaptive iso-planar tool path generation, constant scallop tool path generation, adaptive iso-parametric method, iso-curvature, isophote and by other methods. The different methods are chosen based on the parameters which is needed to be optimized.

Different tool path generation methods

# Iso-planar tool path method: This is the most common and robust method used to machine free-form surface. In this process tool path generation is done by intersection of surfaces with parallel plane in Cartesian space. # Adaptive iso-planar tool path method: In this process the surface are partitioned into different regions according to their slope with the intersection planes by applying the concept ofisophote

In geometry, an isophote is a curve on an illuminated surface that connects points of equal brightness. One supposes that the illumination is done by parallel light and the brightness is measured by the following scalar product:

:b(P)= \vec n(P) ...

.

# Iso-scallop method: Scallop generated between two adjacent machining path is constant.

Optimization of free-form surface machining

CAM

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bin ...

software generally creates a tool path without considering any mechanics process. These causes risk of tool damage, tool deflection and errors on surface finish. By minimizing the forces we can increase tool life. Different optimization method can be used considering process parameters like feed rate, spindle speed, steps, tool diameter, magnitude and preset maximum force. The optimization can be done for minimum machining time, minimum tool travel, minimum production cost or for good surface finish. Efficiency of surface machined is also considered by maximum scallop height and by gouging. Gouging are the main reason for discrepancies of surface accuracy and texture specification. It also causes damage to part,s surface and machine tool. Scallop height tolerance help us in measuring the quality of free-form surface. Selection of proper topology result in minimum path length. In CAM

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the bin ...

software choosing NURBS

Non-uniform rational basis spline (NURBS) is a mathematical model using basis splines (B-splines) that is commonly used in computer graphics for representing curves and surfaces. It offers great flexibility and precision for handling both analy ...

to create surface is considered to be good method for presenting surface as it is accepted by both IGES

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. It's an ASCII-based textual format.

The official title of IGES is ''Di ...

and STEP files of CAM software.

See also

*Freeform surface modelling

Freeform surface modelling is a technique for engineering freeform surfaces with a CAD or CAID system.

The technology has encompassed two main fields. Either creating aesthetic surfaces ( class A surfaces) that also perform a function; for ex ...

* CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a pie ...

* G-code

G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants.

G-code instructions are provided to ...

* Multiaxis machining

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This ...

* NURBS

Non-uniform rational basis spline (NURBS) is a mathematical model using basis splines (B-splines) that is commonly used in computer graphics for representing curves and surfaces. It offers great flexibility and precision for handling both analy ...

References

{{reflist Computer-aided manufacturing