|

Multiaxis Machining

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This type of machining was originally performed mechanically on large complex machines. These machines operated on 4, 5, 6, and even 12 axes which were controlled individually via levers that rested on cam plates. The cam plates offered the ability to control the tooling device, the table in which the part is secured, as well as rotating the tooling or part within the machine. Due to the machines size and complexity it took extensive amounts of time to set them up for production. Once computer numerically controlled machining was introduced it provided a faster, more efficient method for machining complex parts. Typical CNC tools support translation in 3 axis; multiaxis machines also support rotation around one or multiple axis. 5-axis machin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Double Rotary Table

A double is a look-alike or doppelgänger; one person or being that resembles another. Double, The Double or Dubble may also refer to: Film and television * Double (filmmaking), someone who substitutes for the credited actor of a character * ''The Double'' (1934 film), a German crime comedy film * ''The Double'' (1971 film), an Italian film * ''The Double'' (2011 film), a spy thriller film * ''The Double'' (2013 film), a film based on the Dostoevsky novella * ''Kamen Rider Double'', a 2009–10 Japanese television series ** Kamen Rider Double (character), the protagonist in a Japanese television series of the same name Food and drink * Doppio, a double shot of espresso * Dubbel, a strong Belgian Trappist beer or, more generally, a strong brown ale * A drink order of two shots of hard liquor in one glass * A "double decker", a hamburger with two patties in a single bun Games * Double, action in games whereby a competitor raises the stakes ** , in contract bridge ** Doubl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

CNC Pocket Milling

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integrat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be print ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or "freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

G-code

G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants. G-code instructions are provided to a machine controller (industrial computer) that tells the motors where to move, how fast to move, and what path to follow. The two most common situations are that, within a machine tool such as a lathe or mill, a cutting tool is moved according to these instructions through a toolpath cutting away material to leave only the finished workpiece and/or an unfinished workpiece is precisely positioned in any of up to nine axes around the three dimensions relative to a toolpath and, either or both can move relative to each other. The same concept also extends to noncutting tools such as forming or burnishing tools, photoplotting, additive methods such as 3D printing, and measuring instruments. Implementations The first implementation of a numer ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finish

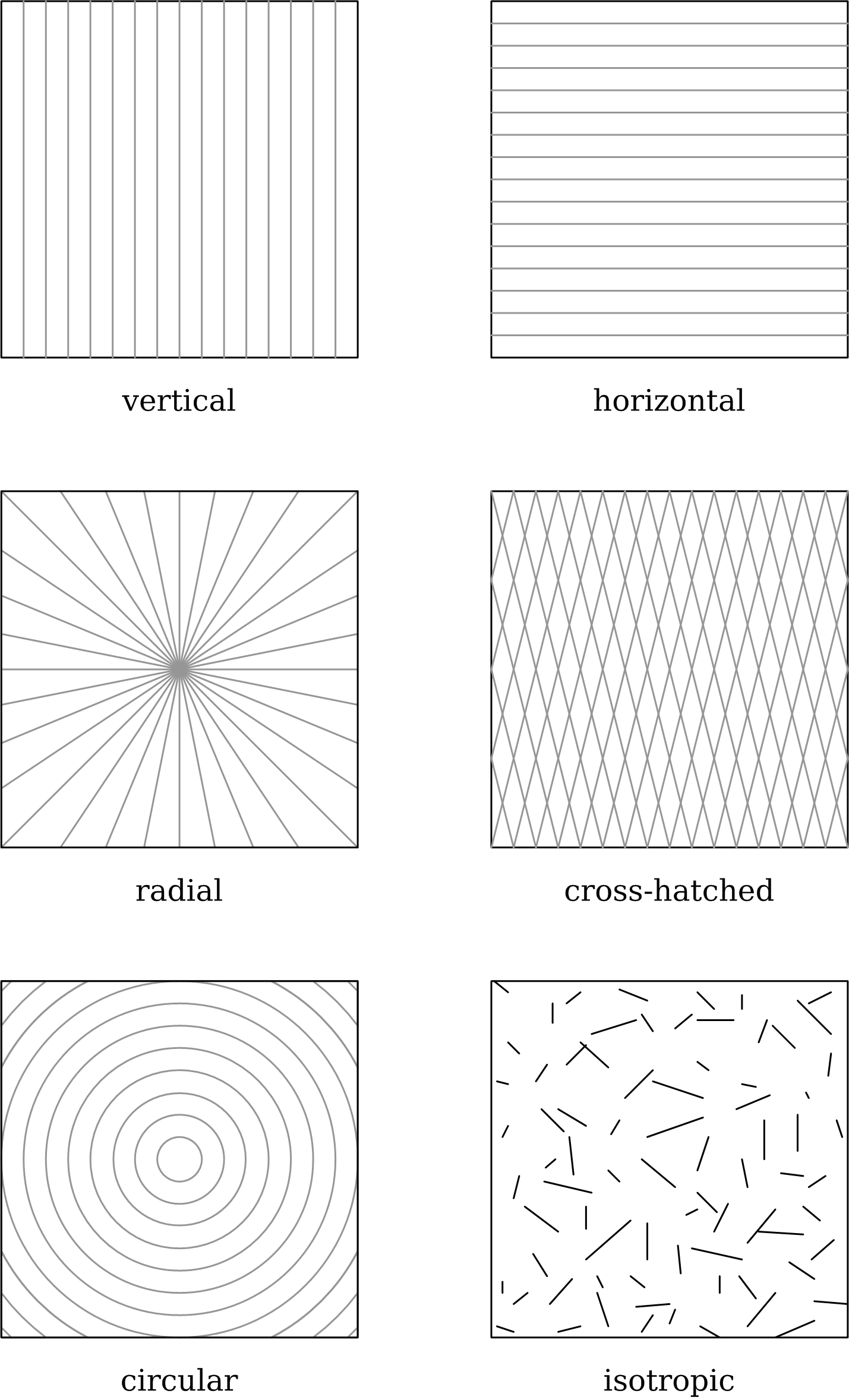

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), pol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Router (woodworking)

The router is a power tool with a flat base and a rotating blade extending past the base. The spindle may be driven by an electric motor or by a pneumatic motor. It routs (hollows out) an area in hard material, such as wood or plastic. Routers are used most often in woodworking, especially cabinetry. They may be handheld or affixed to router tables. Some woodworkers consider the router one of the most versatile power tools. There is also a traditional hand tool known as a router plane, a form of hand plane with a broad base and a narrow blade projecting well beyond the base plate. CNC wood routers add the advantages of computer numerical control (CNC). The laminate trimmer is a smaller, lighter version of the router. Although it is designed for trimming laminates, it can also be used for smaller general routing work. Rotary tools can also be used similarly to routers with the right bits and accessories (such as plastic router bases). History Before power routers exist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Table And Table Trunnion

Rotary may refer to: General * Rotary motion Engineering and technology * Rotary dial, a rotating telephone dial * Rotary engine (other), multiple types of engines called "rotary" * Rotary latch * Rotary milking shed, a type of milking shed used in the dairy industry * Rotary snowplow, one type of railroad snowplow used especially for deep snow removal * Rotary system, a type of pre-electronic telephone switch * Rotary table (drilling rig), a device used to apply directional force to a drill string * Rotary tiller, a motorised cultivator * Rotary woofer, a type of loudspeaker capable of producing very low frequency sound * Rotary wing aircraft Arts and entertainment * "The Rotary", a song by Andy Partridge from ''Take Away / The Lure of Salvage'' Organisations and enterprises * Rotary International, or Rotary Club, an international service organization founded in the United States ** Rotary Foundation, non-profit foundation of Rotary International ** Rotary Scholarsh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Double Pivot Head

A double is a look-alike or doppelgänger; one person or being that resembles another. Double, The Double or Dubble may also refer to: Film and television * Double (filmmaking), someone who substitutes for the credited actor of a character * ''The Double'' (1934 film), a German crime comedy film * ''The Double'' (1971 film), an Italian film * ''The Double'' (2011 film), a spy thriller film * ''The Double'' (2013 film), a film based on the Dostoevsky novella * ''Kamen Rider Double'', a 2009–10 Japanese television series ** Kamen Rider Double (character), the protagonist in a Japanese television series of the same name Food and drink * Doppio, a double shot of espresso * Dubbel, a strong Belgian Trappist beer or, more generally, a strong brown ale * A drink order of two shots of hard liquor in one glass * A "double decker", a hamburger with two patties in a single bun Games * Double, action in games whereby a competitor raises the stakes ** , in contract bridge ** Doubl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pivot Head And Rotary Table

Pivot may refer to: *Pivot, the point of rotation in a lever system *More generally, the center point of any rotational system *Pivot joint, a kind of joint between bones in the body *Pivot turn, a dance move Companies *Incitec Pivot, an Australian chemicals and explosives manufacturer * Pivot Legal Society, a legal advocacy organization based in Vancouver, British Columbia * Pivot Wireless, a cell phone service, created by a joint venture between Sprint and multiple cable companies Computing *Apache Pivot, an open-source platform for building applications in Java *Microsoft Live Labs Pivot, a data search application *Morrow Pivot and Morrow Pivot II, early laptop computers *Pivot, an element of the quicksort algorithm *Pivot, now PivotX, a content management system designed for bloggers *Pivot display, a display which can change orientation *Pivot Stickfigure Animator, stick-figure animation software *Pivot table, a data summarization tool in spreadsheets * Pivotal Games, a for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |