Fiberglass Sculptures In Oregon on:

[Wikipedia]

[Google]

[Amazon]

Fiberglass (

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strengths. If a bulk piece of glass were defect-free, it would be equally as strong as glass fibers; however, it is generally impractical to produce and maintain bulk material in a defect-free state outside of laboratory conditions.

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strengths. If a bulk piece of glass were defect-free, it would be equally as strong as glass fibers; however, it is generally impractical to produce and maintain bulk material in a defect-free state outside of laboratory conditions.

Fiberglass is an immensely versatile material due to its lightweight, inherent strength, weather-resistant finish and variety of surface textures.

The development of fiber-reinforced plastic for commercial use was extensively researched in the 1930s. It was of particular interest to the aviation industry. A means of mass production of glass strands was accidentally discovered in 1932 when a researcher at

Fiberglass is an immensely versatile material due to its lightweight, inherent strength, weather-resistant finish and variety of surface textures.

The development of fiber-reinforced plastic for commercial use was extensively researched in the 1930s. It was of particular interest to the aviation industry. A means of mass production of glass strands was accidentally discovered in 1932 when a researcher at

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

* DIY bows / youth recurve; longbows

* Pole vaulting poles

*Equipment handles(Hammers, axes, etc.)

* Traffic lights

* Ship hulls

* Rowing shells and oars

* Waterpipes

* Helicopter rotor blades

*

* DIY bows / youth recurve; longbows

* Pole vaulting poles

*Equipment handles(Hammers, axes, etc.)

* Traffic lights

* Ship hulls

* Rowing shells and oars

* Waterpipes

* Helicopter rotor blades

*

White Paper, Topic: "Clean Air in the Manufacture of Glass Fibre Reinforced Plastic (GRP) Parts"

GRP Technique & Service

American English

American English, sometimes called United States English or U.S. English, is the set of variety (linguistics), varieties of the English language native to the United States. English is the Languages of the United States, most widely spoken lan ...

) or fibreglass ( Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix

A thermoset polymer matrix is a synthetic polymer reinforcement where polymers act as binder or matrix to secure in place incorporated particulates, fibres or other reinforcements. They were first developed for structural applications, such as gla ...

—most often based on thermosetting polymers such as epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also coll ...

, polyester resin, or vinyl ester resin—or a thermoplastic.

Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, non-magnetic

Magnetism is the class of physical attributes that are mediated by a magnetic field, which refers to the capacity to induce attractive and repulsive phenomena in other entities. Electric currents and the magnetic moments of elementary particle ...

, non- conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboard

A surfboard is a narrow plank used in surfing. Surfboards are relatively light, but are strong enough to support an individual standing on them while riding an ocean wave. They were invented in ancient Hawaii, where they were known as ''papa he'e ...

s, and external door skins.

Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK (from ). Because glass fiber itself is sometimes referred to as "fiberglass", the composite is also called fiberglass-reinforced plastic (FRP). This article will adopt the convention that "fiberglass" refers to the complete fiber-reinforced composite material, rather than only to the glass fiber within it.

Carbon-fiber-reinforced polymers are a similar composite material in which the reinforcement are carbon fibers.

History

Glass fibers have been produced for centuries, but the earliest patent was awarded to the Prussian inventor Hermann Hammesfahr (1845–1914) in the U.S. in 1880.Mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch ...

of glass strands was accidentally discovered in 1932 when Games Slayter, a researcher at Owens-Illinois

O-I Glass, Inc. is an American company that specializes in container glass products. It is one of the world's leading manufacturers of packaging products, holding the position of largest manufacturer of glass containers in North America, South A ...

, directed a jet of compressed air at a stream of molten glass and produced fibers. A patent for this method of producing glass wool

Glass wool is an insulating material made from glass fiber arranged using a binder into a texture similar to wool. The process traps many small pockets of air between the glass, and these small air pockets result in high thermal insulation prop ...

was first applied for in 1933. Owens joined with the Corning company in 1935 and the method was adapted by Owens Corning

Owens Corning is an American company that develops and produces insulation, roofing, and fiberglass composites and related materials and products. It is the world's largest manufacturer of fiberglass composites. It was formed in 1935 as a partn ...

to produce its patented "Fiberglas" (spelled with one "s") in 1936. Originally, Fiberglas was a glass wool with fibers entrapping a great deal of gas, making it useful as an insulator, especially at high temperatures.

A suitable resin for combining the fiberglass with a plastic to produce a composite material was developed in 1936 by DuPont

DuPont de Nemours, Inc., commonly shortened to DuPont, is an American multinational chemical company first formed in 1802 by French-American chemist and industrialist Éleuthère Irénée du Pont de Nemours. The company played a major role in ...

. The first ancestor of modern polyester resins is Cyanamid's resin of 1942. Peroxide curing systems were used by then. With the combination of fiberglass and resin the gas content of the material was replaced by plastic. This reduced the insulation properties to values typical of the plastic, but now for the first time, the composite showed great strength and promise as a structural and building material. Many glass fiber composites continued to be called "fiberglass" (as a generic name) and the name was also used for the low-density glass wool product containing gas instead of plastic.

Ray Greene of Owens Corning is credited with producing the first composite boat in 1937 but did not proceed further at the time due to the brittle nature of the plastic used. In 1939 Russia was reported to have constructed a passenger boat of plastic materials, and the United States a fuselage and wings of an aircraft. The first car to have a fiber-glass body was a 1946 prototype of the Stout Scarab

The Stout Scarab is a streamlined 1930–1940s American car, designed by William Bushnell Stout and manufactured by Stout Engineering Laboratories and later by Stout Motor Car Company of Detroit, Michigan.

The Stout Scarab is credited by s ...

, but the model did not enter production.

Fiber

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strengths. If a bulk piece of glass were defect-free, it would be equally as strong as glass fibers; however, it is generally impractical to produce and maintain bulk material in a defect-free state outside of laboratory conditions.

Unlike glass fibers used for insulation, for the final structure to be strong, the fiber's surfaces must be almost entirely free of defects, as this permits the fibers to reach gigapascal tensile strengths. If a bulk piece of glass were defect-free, it would be equally as strong as glass fibers; however, it is generally impractical to produce and maintain bulk material in a defect-free state outside of laboratory conditions.

Production

The process of manufacturing fiberglass is called pultrusion. The manufacturing process for glass fibers suitable for reinforcement uses large furnaces to gradually melt the silica sand, limestone, kaolin clay,fluorspar

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF2. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

The Mohs scal ...

, colemanite

Colemanite (Ca2B6O11·5H2O) or (CaB3O4(OH)3·H2O) is a borate mineral found in evaporite deposits of alkaline lacustrine environments. Colemanite is a secondary mineral that forms by alteration of borax and ulexite.

It was first described in 18 ...

, dolomite Dolomite may refer to:

*Dolomite (mineral), a carbonate mineral

*Dolomite (rock), also known as dolostone, a sedimentary carbonate rock

*Dolomite, Alabama, United States, an unincorporated community

*Dolomite, California, United States, an unincor ...

and other minerals until a liquid forms. It is then extruded through bushings ( spinneret), which are bundles of very small orifices (typically 5–25 micrometres in diameter for E-Glass, 9 micrometres for S-Glass).

These filaments are then ''sized'' (coated) with a chemical solution. The individual filaments are now bundled in large numbers to provide a roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialised ...

. The diameter of the filaments, and the number of filaments in the roving, determine its ''weight'', typically expressed in one of two measurement systems:

*''yield'', or yards per pound (the number of yards of fiber in one pound of material; thus a smaller number means a heavier roving). Examples of standard yields are 225yield, 450yield, 675yield.

*''tex'', or grams per km (how many grams 1 km of roving weighs, inverted from yield; thus a smaller number means a lighter roving). Examples of standard tex are 750tex, 1100tex, 2200tex.

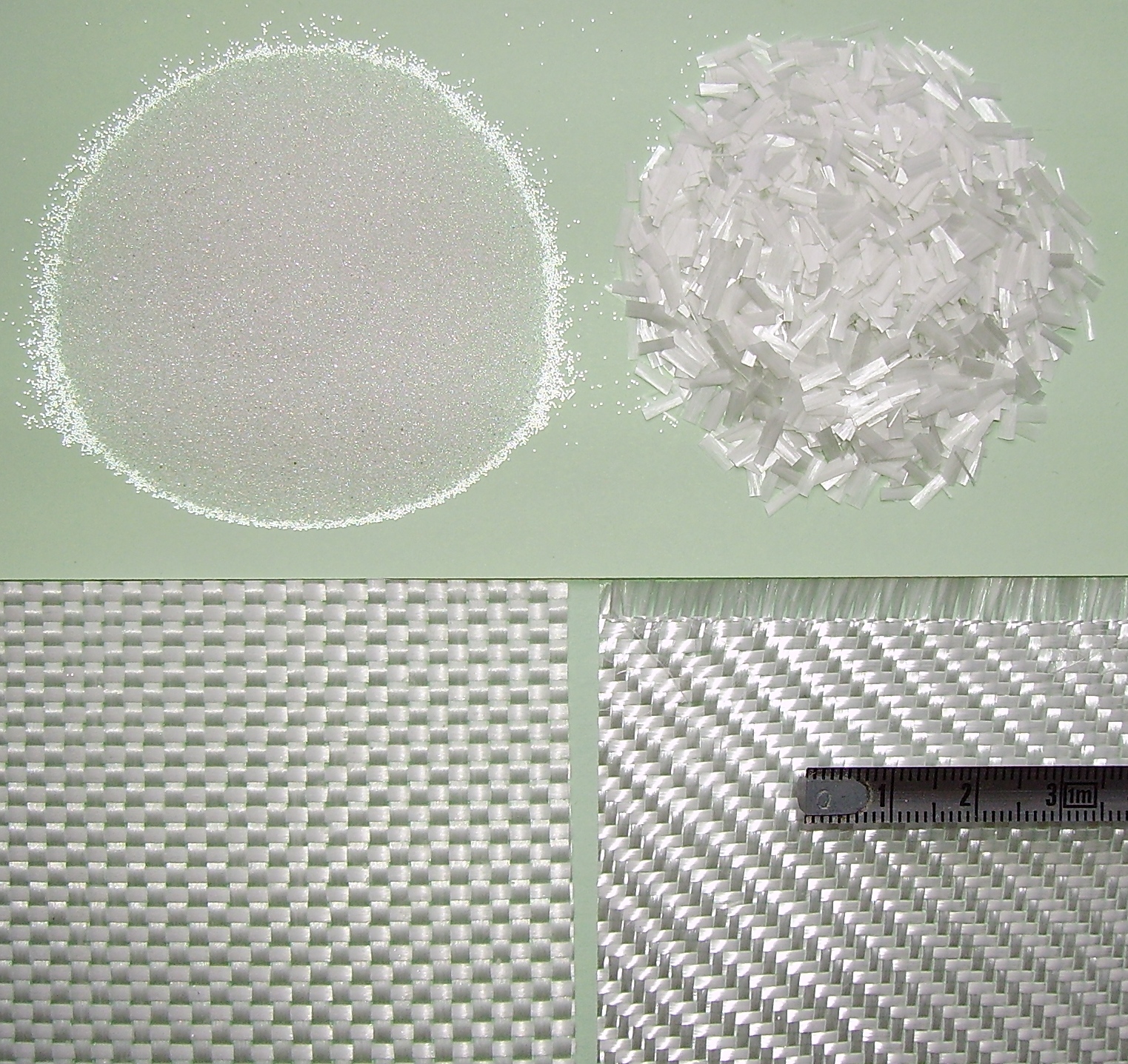

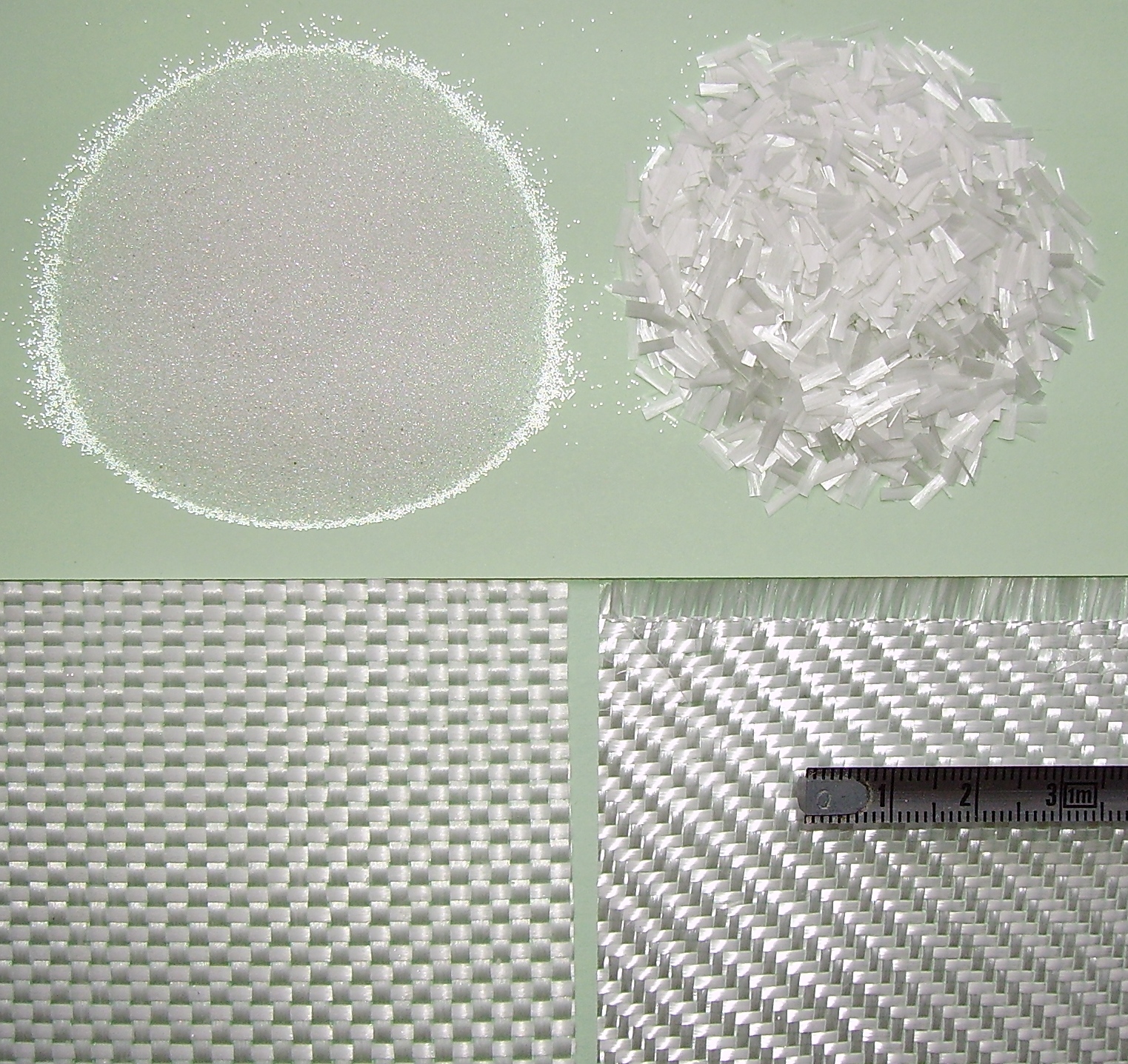

These rovings are then either used directly in a composite application such as pultrusion, filament winding (pipe), gun roving (where an automated gun chops the glass into short lengths and drops it into a jet of resin, projected onto the surface of a mold), or in an intermediary step, to manufacture fabrics such as ''chopped strand mat'' (CSM) (made of randomly oriented small cut lengths of fiber all bonded together), woven fabrics, knit fabrics or unidirectional fabrics.

Chopped strand mat

Chopped strand mat or CSM is a form of reinforcement used in fiberglass. It consists of glass fibers laid randomly across each other and held together by a binder. It is typically processed using the hand lay-up technique, where sheets of material are placed on a mold and brushed with resin. Because the binder dissolves in resin, the material easily conforms to different shapes when wetted out. After the resin cures, the hardened product can be taken from the mold and finished. Using chopped strand mat gives the fiberglassisotropic

Isotropy is uniformity in all orientations; it is derived . Precise definitions depend on the subject area. Exceptions, or inequalities, are frequently indicated by the prefix ' or ', hence ''anisotropy''. ''Anisotropy'' is also used to describe ...

in-plane material properties.

Sizing

A coating or primer is applied to the roving to: * help protect the glass filaments for processing and manipulation. * ensure proper bonding to the resin matrix, thus allowing for the transfer of shear loads from the glass fibers to the thermoset plastic. Without this bonding, the fibers can 'slip' in the matrix causing localized failure.Properties

An individual structural glass fiber is both stiff and strong in tension and compression—that is, ''along'' its axis. Although it might be assumed that the fiber is weak in compression, it is actually only the long aspect ratio of the fiber which makes it seem so; i.e., because a typical fiber is long and narrow, it buckles easily. On the other hand, the glass fiber is weak in shear—that is, ''across'' its axis. Therefore, if a collection of fibers can be arranged permanently in a preferred direction within a material, and if they can be prevented from buckling in compression, the material will be preferentially strong in that direction. Furthermore, by laying multiple layers of fiber on top of one another, with each layer oriented in various preferred directions, the material's overall stiffness and strength can be efficiently controlled. In fiberglass, it is the plastic matrix which permanently constrains the structural glass fibers to directions chosen by the designer. With chopped strand mat, this directionality is essentially an entire two-dimensional plane; with woven fabrics or unidirectional layers, directionality of stiffness and strength can be more precisely controlled within the plane. A fiberglass component is typically of a thin "shell" construction, sometimes filled on the inside with structural foam, as in the case of surfboards. The component may be of nearly arbitrary shape, limited only by the complexity and tolerances of the mold used for manufacturing the shell. The mechanical functionality of materials is heavily reliant on the combined performances of both the resin (AKA matrix) and fibers. For example, in severe temperature conditions (over 180 °C), the resin component of the composite may lose its functionality, partially due to bond deterioration of resin and fiber. However, GFRPs can still show significant residual strength after experiencing high temperatures (200 °C).Types of glass fiber used

The most common types of glass fiber used in fiberglass isE-glass

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

, which is alumino-borosilicate glass with less than 1% w/w alkali oxides, mainly used for glass-reinforced plastics. Other types of glass used are A-glass (Alkali-lime glass with little or no boron oxide), E-CR-glass (Electrical/Chemical Resistance; alumino-lime silicate with less than 1% w/w alkali oxides, with high acid resistance), C-glass (alkali-lime glass with high boron oxide content, used for glass staple fibers and insulation), D-glass (borosilicate glass, named for its low Dielectric constant), R-glass (alumino silicate glass without MgO and CaO with high mechanical requirements as Reinforcement), and S-glass (alumino silicate glass without CaO but with high MgO content with high tensile strength).

Pure silica (silicon dioxide), when cooled as fused quartz into a glass with no true melting point, can be used as a glass fiber for fiberglass but has the drawback that it must be worked at very high temperatures. In order to lower the necessary work temperature, other materials are introduced as "fluxing agents" (i.e., components to lower the melting point). Ordinary A-glass ("A" for "alkali-lime") or soda lime glass, crushed and ready to be remelted, as so-called cullet

Glass recycling is the processing of waste glass into usable products. Glass that is crushed or imploded and ready to be remelted is called cullet. There are two types of cullet: internal and external. Internal cullet is composed of defective p ...

glass, was the first type of glass used for fiberglass. E-glass ("E" because of initial Electrical application), is alkali-free and was the first glass formulation used for continuous filament formation. It now makes up most of the fiberglass production in the world, and also is the single largest consumer of boron

Boron is a chemical element with the symbol B and atomic number 5. In its crystalline form it is a brittle, dark, lustrous metalloid; in its amorphous form it is a brown powder. As the lightest element of the ''boron group'' it has th ...

minerals globally. It is susceptible to chloride ion attack and is a poor choice for marine applications. S-glass ("S" for "stiff") is used when tensile strength (high modulus) is important and is thus an important building and aircraft epoxy composite (it is called R-glass, "R" for "reinforcement" in Europe). C-glass ("C" for "chemical resistance") and T-glass ("T" is for "thermal insulator"—a North American variant of C-glass) are resistant to chemical attack; both are often found in insulation-grades of blown fiberglass.

Table of some common fiberglass types

Applications

Fiberglass is an immensely versatile material due to its lightweight, inherent strength, weather-resistant finish and variety of surface textures.

The development of fiber-reinforced plastic for commercial use was extensively researched in the 1930s. It was of particular interest to the aviation industry. A means of mass production of glass strands was accidentally discovered in 1932 when a researcher at

Fiberglass is an immensely versatile material due to its lightweight, inherent strength, weather-resistant finish and variety of surface textures.

The development of fiber-reinforced plastic for commercial use was extensively researched in the 1930s. It was of particular interest to the aviation industry. A means of mass production of glass strands was accidentally discovered in 1932 when a researcher at Owens-Illinois

O-I Glass, Inc. is an American company that specializes in container glass products. It is one of the world's leading manufacturers of packaging products, holding the position of largest manufacturer of glass containers in North America, South A ...

directed a jet of compressed air at a stream of molten glass and produced fibers. After Owens merged with the Corning company in 1935, Owens Corning

Owens Corning is an American company that develops and produces insulation, roofing, and fiberglass composites and related materials and products. It is the world's largest manufacturer of fiberglass composites. It was formed in 1935 as a partn ...

adapted the method to produce its patented "Fiberglas" (one "s"). A suitable resin for combining the "Fiberglas" with a plastic was developed in 1936 by DuPont

DuPont de Nemours, Inc., commonly shortened to DuPont, is an American multinational chemical company first formed in 1802 by French-American chemist and industrialist Éleuthère Irénée du Pont de Nemours. The company played a major role in ...

. The first ancestor of modern polyester resins is Cyanamid's of 1942. Peroxide curing systems were used by then.

During World War II, fiberglass was developed as a replacement for the molded plywood used in aircraft radomes (fiberglass being transparent to microwaves). Its first main civilian application was for the building of boats and sports car bodies, where it gained acceptance in the 1950s. Its use has broadened to the automotive and sport equipment sectors. In the production of some products, such as aircraft, carbon fiber is now used instead of fiberglass, which is stronger by volume and weight.

Advanced manufacturing techniques such as pre-pregs and fiber roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialised ...

s extend fiberglass's applications and the tensile strength possible with fiber-reinforced plastics.

Fiberglass is also used in the telecommunications industry for shrouding antennas, due to its RF permeability and low signal attenuation properties. It may also be used to conceal other equipment where no signal permeability is required, such as equipment cabinets and steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

support structures, due to the ease with which it can be molded and painted to blend with existing structures and surfaces. Other uses include sheet-form electrical insulators and structural components commonly found in power-industry products. Because of fiberglass's lightweight and durability, it is often used in protective equipment such as helmets. Many sports use fiberglass protective gear, such as goaltenders' and catchers' masks.

Storage tanks

Storage tank

Storage tanks are containers that hold liquids, compressed gases (gas tank; or in U.S.A "pressure vessel", which is not typically labeled or regulated as a storage tank) or mediums used for the short- or long-term storage of heat or cold. The t ...

s can be made of fiberglass with capacities up to about 300 tonnes. Smaller tanks can be made with chopped strand mat cast over a thermoplastic inner tank which acts as a preform

Preform may refer to:

* Preform, a piece of glass used to draw an optical fiber

* Preform, a piece of polyethylene terephthalate test tube shaped form blown into a completed bottle

* Preform, an incomplete and unused basic form of a stone tool ...

during construction. Much more reliable tanks are made using woven mat or filament wound fiber, with the fiber orientation at right angles to the hoop stress imposed in the sidewall by the contents. Such tanks tend to be used for chemical storage because the plastic liner (often polypropylene) is resistant to a wide range of corrosive chemicals. Fiberglass is also used for septic tanks.

House building

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

Glass-reinforced plastics are also used to produce house building components such as roofing laminate, door surrounds, over-door canopies, window canopies and dormers, chimneys, coping systems, and heads with keystones and sills. The material's reduced weight and easier handling, compared to wood or metal, allows faster installation. Mass-produced fiberglass brick-effect panels can be used in the construction of composite housing, and can include insulation to reduce heat loss.

Oil and gas artificial lift systems

In rod pumping applications, fiberglass rods are often used for their high tensile strength to weight ratio. Fiberglass rods provide an advantage over steel rods because they stretch more elastically (lower Young's modulus) than steel for a given weight, meaning more oil can be lifted from the hydrocarbon reservoir to the surface with each stroke, all while reducing the load on the pumping unit. Fiberglass rods must be kept in tension, however, as they frequently part if placed in even a small amount of compression. The buoyancy of the rods within a fluid amplifies this tendency.Piping

GRP and GRE pipe can be used in a variety of above- and below-ground systems, including those for: * desalination * water treatment * water distribution networks * chemical process plants * water used for firefighting * hot and cold water * drinking water * wastewater/sewage, Municipal waste * liquified petroleum gasExamples of fiberglass use

* DIY bows / youth recurve; longbows

* Pole vaulting poles

*Equipment handles(Hammers, axes, etc.)

* Traffic lights

* Ship hulls

* Rowing shells and oars

* Waterpipes

* Helicopter rotor blades

*

* DIY bows / youth recurve; longbows

* Pole vaulting poles

*Equipment handles(Hammers, axes, etc.)

* Traffic lights

* Ship hulls

* Rowing shells and oars

* Waterpipes

* Helicopter rotor blades

* Surfboard

A surfboard is a narrow plank used in surfing. Surfboards are relatively light, but are strong enough to support an individual standing on them while riding an ocean wave. They were invented in ancient Hawaii, where they were known as ''papa he'e ...

s, tent poles

* Gliders, kit cars, dune buggies, microcars, karts, bodyshells, kayak

A kayak is a small, narrow watercraft which is typically propelled by means of a double-bladed paddle. The word kayak originates from the Greenlandic word ''qajaq'' ().

The traditional kayak has a covered deck and one or more cockpits, each se ...

s, flat roofs, lorries

* Pods, domes and architectural features where a light weight is necessary

* Auto body parts, and entire auto bodies (e.g. Sabre Sprint

The Sabre Sprint was a product of the mini car company Sabre Cars, formed in 1984 in Wallsend, Newcastle upon Tyne. Steven Crabtree founded Sabre Cars in 1984 after years of producing fibreglass products such as canoes, boats, sunbeds and fibre ...

, Lotus Elan, Anadol

Anadol was Turkey's first domestic mass-production passenger vehicle company. Its first model, Anadol A1 (1966–1975) was the second Turkish car after the ill-fated Devrim sedan of 1961. Anadol cars and pick-ups were manufactured by Otosan Oto ...

, Reliant, Quantum Coupé, Saab Sonett, Chevrolet Corvette, Studebaker Avanti

The Studebaker Avanti is a personal luxury coupe manufactured and marketed by Studebaker Corporation between June 1962 and December 1963. A halo car for the maker, it was marketed as "America's only four-passenger high-performance personal car ...

, and DMC DeLorean

The DMC DeLorean is a rear-engine two-passenger sports car manufactured and marketed by John DeLorean's DeLorean Motor Company (DMC) for the American market from 1981 until 1983—ultimately the only car brought to market by the fledgling comp ...

underbody)

* Antenna covers and structures, such as radomes, UHF broadcasting antennas, and pipes used in hex beam antennas for amateur radio communications

* FRP tanks and vessels: FRP is used extensively to manufacture chemical equipment and tanks and vessels. BS4994 is a British standard related to this application.

* Most commercial velomobiles

* Most printed circuit board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in Electrical engineering, electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a L ...

s consist of alternating layers of copper and fiberglass FR-4

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (''self-extinguishing'').

"FR" stands fo ...

* Large commercial wind turbine blades

* RF coils used in MRI scanner

The physics of magnetic resonance imaging (MRI) concerns fundamental physical considerations of MRI techniques and technological aspects of MRI devices. MRI is a medical imaging technique mostly used in radiology and nuclear medicine in order t ...

s

* Drum Sets

* Sub-sea installation protection covers

* Reinforcement of asphalt pavement, as a fabric or mesh interlayer between lifts

* Helmets and other protective gear used in various sports

* Orthopedic casts

* Fiberglass grating is used for walkways on ships and oil rigs, and in factories

*Fiberglass Profiles for structural use

* Fiber-reinforced composite columns

* Water slide

A water slide (also referred to as a flume, or water chute) is a type of slide designed for warm-weather or indoor recreational use at water parks. Water slides differ in their riding method and therefore size. Some slides require riders to si ...

s

*sculpture making

*Fish ponds or lining cinder block fish ponds.

*Insulating sheds or summerhouses

Construction methods

Filament winding

Filament winding is a fabrication technique mainly used for manufacturing open (cylinders) or closed-end structures (pressure vessels or tanks). The process involves winding filaments under tension over a male mandrel. The mandrel rotates while a wind eye on a carriage moves horizontally, laying down fibers in the desired pattern. The most common filaments are carbon or glass fiber and are coated with synthetic resin as they are wound. Once the mandrel is completely covered to the desired thickness, the resin is cured; often the mandrel is placed in an oven to achieve this, though sometimes radiant heaters are used with the mandrel still turning in the machine. Once the resin has cured, the mandrel is removed, leaving the hollow final product. For some products such as gas bottles, the 'mandrel' is a permanent part of the finished product forming a liner to prevent gas leakage or as a barrier to protect the composite from the fluid to be stored. Filament winding is well suited to automation, and there are many applications, such as pipe and small pressure vessels that are wound and cured without any human intervention. The controlled variables for winding are fiber type, resin content, wind angle, tow or bandwidth and thickness of the fiber bundle. The angle at which the fiber has an effect on the properties of the final product. A high angle "hoop" will provide circumferential or "burst" strength, while lower angle patterns (polar or helical) will provide greater longitudinal tensile strength. Products currently being produced using this technique range from pipes, golf clubs, Reverse Osmosis Membrane Housings, oars, bicycle forks, bicycle rims, power and transmission poles, pressure vessels to missile casings, aircraft fuselages and lamp posts and yacht masts.Fiberglass hand lay-up operation

A release agent, usually in either wax or liquid form, is applied to the chosen mold to allow the finished product to be cleanly removed from the mold. Resin—typically a 2-part thermoset polyester, vinyl, or epoxy—is mixed with its hardener and applied to the surface. Sheets of fiberglass matting are laid into the mold, then more resin mixture is added using a brush or roller. The material must conform to the mold, and air must not be trapped between the fiberglass and the mold. Additional resin is applied and possibly additional sheets of fiberglass. Hand pressure, vacuum or rollers are used to be sure the resin saturates and fully wets all layers, and that any air pockets are removed. The work must be done quickly before the resin starts to cure unless high-temperature resins are used which will not cure until the part is warmed in an oven. In some cases, the work is covered with plastic sheets and vacuum is drawn on the work to remove air bubbles and press the fiberglass to the shape of the mold.Fiberglass spray lay-up operation

Thefiberglass spray lay-up process Spray-Up also known as chop method of creating fiberglass objects by spraying short strands of glass out of a pneumatic gun. This method is used often when one side of the finished product is not seen, or when large quantities of a product must be ...

is similar to the hand lay-up process but differs in the application of the fiber and resin to the mold. Spray-up is an open-molding composites fabrication process where resin and reinforcements are sprayed onto a mold. The resin and glass may be applied separately or simultaneously "chopped" in a combined stream from a chopper gun. Workers roll out the spray-up to compact the laminate. Wood, foam or other core material may then be added, and a secondary spray-up layer imbeds the core between the laminates. The part is then cured, cooled, and removed from the reusable mold.

Pultrusion operation

Pultrusion is a manufacturing method used to make strong, lightweight composite materials. In pultrusion, material is pulled through forming machinery using either a hand-over-hand method or a continuous-roller method (as opposed to extrusion, where the material is pushed through dies). In fiberglass pultrusion, fibers (the glass material) are pulled from spools through a device that coats them with a resin. They are then typically heat-treated and cut to length. Fiberglass produced this way can be made in a variety of shapes and cross-sections, such as W or S cross-sections.Warping

One notable feature of fiberglass is that the resins used are subject to contraction during the curing process. For polyester this contraction is often 5–6%; for epoxy, about 2%. Because the fibers do not contract, this differential can create changes in the shape of the part during curing. Distortions can appear hours, days, or weeks after the resin has set. While this distortion can be minimised by symmetric use of the fibers in the design, a certain amount of internal stress is created; and if it becomes too great, cracks form.Health hazards

In June 2011, the US National Toxicology Program (NTP) removed from its Report on Carcinogens all biosoluble glass wool used in home andbuilding insulation

Building insulation is any object in a building used as insulation for thermal management. While the majority of insulation in buildings is for thermal purposes, the term also applies to acoustic insulation, fire insulation, and impact insul ...

and for non-insulation products. However, NTP considers fibrous glass dust to be "reasonably anticipated sa human carcinogen (Certain Glass Wool Fibers (Inhalable))". Similarly, California's Office of Environmental Health Hazard Assessment ("OEHHA") published a November, 2011 modification to its Proposition 65 listing to include only "Glass wool fibers (inhalable and biopersistent)." The actions of U.S. NTP and California's OEHHA mean that a cancer warning label for biosoluble fiber glass home and building insulation is no longer required under federal or California law. All fiberglass wools commonly used for thermal and acoustical insulation were reclassified by the International Agency for Research on Cancer (IARC) in October 2001 as Not Classifiable as to carcinogenicity to humans (Group 3).

People can be exposed to fiberglass in the workplace by breathing it in, skin contact, or eye contact. The Occupational Safety and Health Administration (OSHA) has set the legal limit ( permissible exposure limit) for fiberglass exposure in the workplace as 15 mg/m3 total and 5 mg/m3 in respiratory exposure over an 8-hour workday. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit (REL) of 3 fibers/cm3 (less than 3.5 micrometers in diameter and greater than 10 micrometers in length) as a time-weighted average over an 8-hour workday, and a 5 mg/m3 total limit.

The European Union and Germany classify synthetic vitreous fibers as possibly or probably carcinogenic, but fibers can be exempt from this classification if they pass specific tests. Evidence for these classifications is primarily from studies on experimental animals and mechanisms of carcinogenesis. The glass wool epidemiology studies have been reviewed by a panel of international experts convened by the IARC. These experts concluded: "Epidemiologic studies published during the 15 years since the previous IARC monographs review of these fibers in 1988 provide no evidence of increased risks of lung cancer or mesothelioma (cancer of the lining of the body cavities) from occupational exposures during the manufacture of these materials, and inadequate evidence overall of any cancer risk." A 2012 health hazard review for the European Commission stated that inhalation of fiberglass at concentrations of 3, 16 and 30 mg/m3 "did not induce fibrosis nor tumours except transient lung inflammation that disappeared after a post-exposure recovery period." Similar reviews of the epidemiology studies have been conducted by the Agency for Toxic Substances and Disease Registry ("ATSDR"), the National Toxicology Program, the National Academy of Sciences and Harvard's Medical and Public Health Schools which reached the same conclusion as IARC that there is no evidence of increased risk from occupational exposure to glass wool fibers.

Fiberglass will irritate the eyes, skin, and the respiratory system. Potential symptoms include irritation of eyes, skin, nose, throat, dyspnea (breathing difficulty); sore throat, hoarseness and cough. Scientific evidence demonstrates that fiberglass is safe to manufacture, install and use when recommended work practices are followed to reduce temporary mechanical irritation. Unfortunately these work practices are not always followed, and fiberglass is often left exposed in basements that later become occupied. Fiberglass insulation should never be left exposed in an occupied area, according to the American Lung Association.

While the resins are cured, styrene vapors are released. These are irritating to mucous membranes and respiratory tract. Therefore, the Hazardous Substances Ordinance in Germany dictates a maximum occupational exposure limit of 86 mg/m3. In certain concentrations, a potentially explosive mixture may occur. Further manufacture of GRP components (grinding, cutting, sawing) creates fine dust and chips containing glass filaments, as well as tacky dust, in quantities high enough to affect health and the functionality of machines and equipment. The installation of effective extraction and filtration equipment is required to ensure safety and efficiency.Türschmann, V.; Jakschik, C.; Rother, H.-J. (March 2011White Paper, Topic: "Clean Air in the Manufacture of Glass Fibre Reinforced Plastic (GRP) Parts"

GRP Technique & Service

See also

*Bulk moulding compound Bulk moulding compound (BMC), bulk moulding composite, or dough moulding compound (DMC), is a ready-to-mold, glass-fiber reinforced thermoset polymer material primarily used in compression moulding, as well as in injection moulding and transfer mo ...

* Fiberglass sheet laminating

Fiberglass sheet laminating is the process of taking a thin fiberglass sheet and laminating it to another material in order to provide strength and support to that material.

Process characteristics

Fiberglass is composed of very fine strands of g ...

* G10 (material)

G-10 or garolite is a high-pressure fiberglass laminate, a type of composite material. It is created by stacking multiple layers of glass cloth, soaked in epoxy resin, then compressing the resulting material under heat until the epoxy cures. It is ...

* Glass fiber reinforced concrete

* Hobas

HOBAS is a manufacturer of centrifugal casting (industrial), centrifugally cast glassfiber reinforced (GRP) pipe systems made of unsaturated polyester resin with diameters ranging from 150 mm to 3600 mm. The company was founded in B ...

* Ignace Dubus-Bonnel Ignace Dubus-Bonnel (born 11.05.1794 in Lille, France) was a Parisian craftsman, who most notably was the first to get a patent for a method of creating and weaving glass threads, the predecessor of fiberglass

Fiberglass (American English) or ...

* Sheet moulding compound

References

External links

* {{DEFAULTSORT:Fiberglass American inventions Composite materials Fibre-reinforced polymers Glass applications