Computer-aided Manufacturing on:

[Wikipedia]

[Google]

[Amazon]

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of

Traditionally, CAM has been considered a numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in

Traditionally, CAM has been considered a numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in

CADSite.ru

CAD Models

Cimatron Brazil

about Software CAD/CAM CimatronE

Dragomatz and Mann

reviewed toolpath algorithms in 1997.

by Martin Held

Purdue Research and Education Centre for Information Systems in Engineering

How to evaluate a CAM system

Sheetmetalworld.com article {{DEFAULTSORT:Computer-Aided Manufacturing Information technology management Product lifecycle management

software

Software is a set of computer programs and associated documentation and data. This is in contrast to hardware, from which the system is built and which actually performs the work.

At the lowest programming level, executable code consists ...

to control machine tools in the manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a r ...

of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant

A factory, manufacturing plant or a production plant is an Industry (manufacturing), industrial facility, often a complex consisting of several buildings filled with Outline of industrial machinery, machinery, where workers manufacturing, manuf ...

, including planning, management

Management (or managing) is the administration of an organization, whether it is a business, a nonprofit organization, or a government body. It is the art and science of managing resources of the business.

Management includes the activities o ...

, transportation and storage. Its primary purpose is to create a faster production process

Industrial processes are procedures involving chemical, physical, electrical or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy in ...

and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption.

CAM is now a system used in schools and lower educational purposes.

CAM is a subsequent computer-aided process after computer-aided design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve c ...

(CAD) and sometimes computer-aided engineering

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes , , , durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) ...

(CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside computer-aided design (CAD) to create objects.

Overview

Traditionally, CAM has been considered a numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in

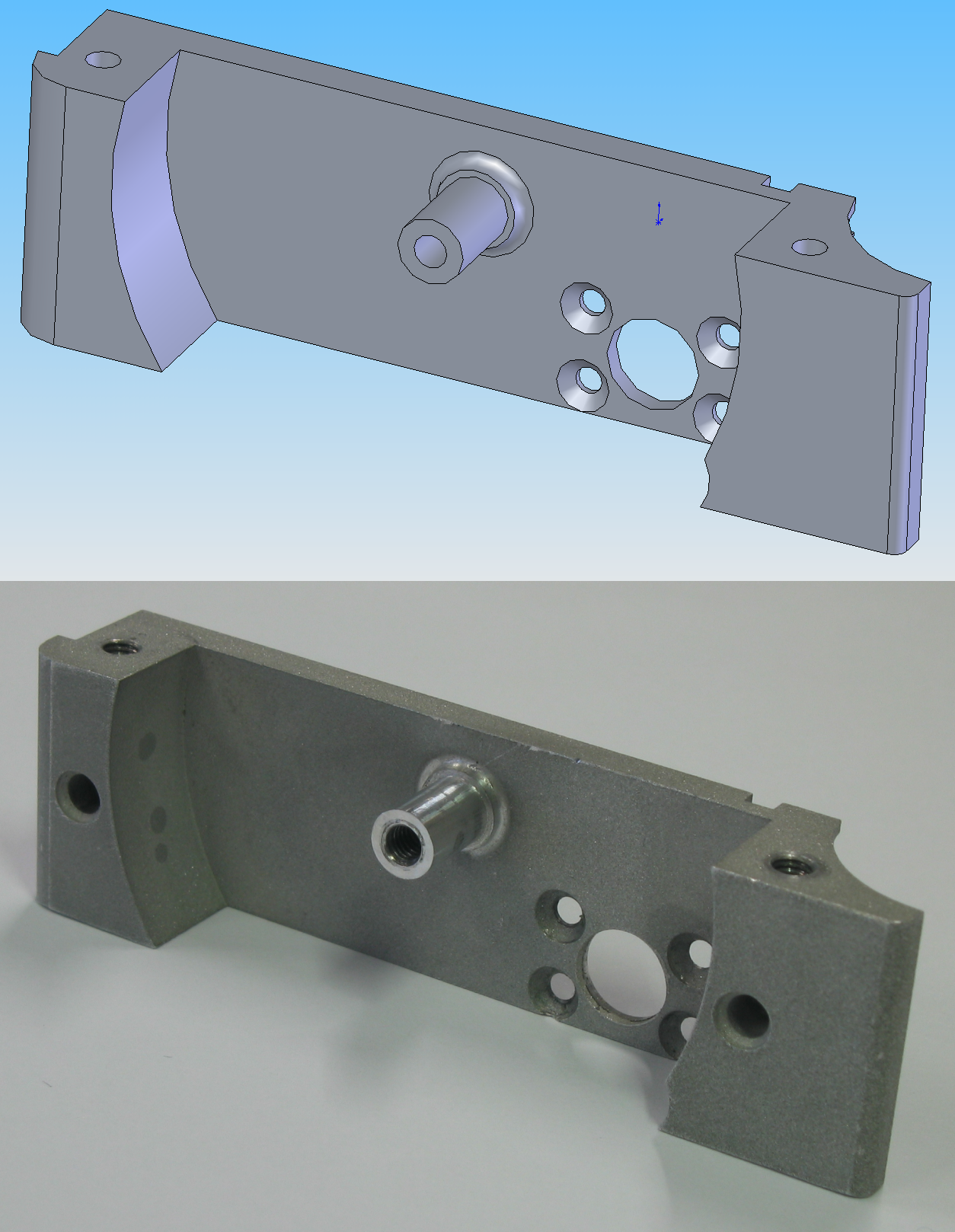

Traditionally, CAM has been considered a numerical control (NC) programming tool, wherein two-dimensional (2-D) or three-dimensional (3-D) models of components are generated in CAD

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve co ...

. As with other "computer-aided" technologies, CAM does not eliminate the need for skilled professionals such as manufacturing engineer

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering.

Manufa ...

s, NC programmers, or machinists. CAM leverages both the value of the most skilled manufacturing professionals through advanced productivity tools, while building the skills of new professionals through visualization, simulation and optimization tools.

A CAM tool generally converts a model to a language the target machine in question understands, typically G-Code

G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants.

G-code instructions are provided to ...

. The numerical control can be applied to machining tools, or more recently to 3D printers.

History

Early commercial applications of CAM were in large companies in the automotive and aerospace industries; for example,Pierre Bézier

Pierre Étienne Bézier (1 September 1910 – 25 November 1999; ) was a French engineer and one of the founders of the fields of solid, geometric and physical modelling as well as in the field of representing curves, especially in computer-a ...

s work developing the CAD/CAM application UNISURF UNISURF was a pioneering surface CAD/ CAM system, designed to assist with car body design and tooling. It was developed by French engineer Pierre Bézier for Renault

Groupe Renault ( , , , also known as the Renault Group in English; legal ...

in the 1960s for car body design and tooling at Renault

Groupe Renault ( , , , also known as the Renault Group in English; legally Renault S.A.) is a French multinational automobile manufacturer established in 1899. The company produces a range of cars and vans, and in the past has manufactured ...

. Alexander Hammer at DeLaval Steam Turbine Company invented a technique to progressively drill turbine blades out of a solid metal block of metal with the drill controlled by a punch card reader in 1950.

Historically, CAM software was seen to have several shortcomings that necessitated an overly high level of involvement by skilled CNC

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a p ...

machinists. Fallows created the first CAD software but this had severe shortcomings and was promptly taken back into the developing stage. CAM software would output code for the least capable machine, as each machine tool control added on to the standard G-code

G-code (also RS-274) is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants.

G-code instructions are provided to ...

set for increased flexibility. In some cases, such as improperly set up CAM software or specific tools, the CNC machine required manual editing before the program will run properly. None of these issues were so insurmountable that a thoughtful engineer or skilled machine operator could not overcome for prototyping or small production runs; G-Code is a simple language. In high production or high precision shops, a different set of problems were encountered where an experienced CNC machinist must both hand-code programs and run CAM software.

The integration of CAD with other components of CAD/CAM/CAE Product lifecycle management

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PL ...

(PLM) environment requires an effective CAD data exchange

CAD data exchange is a method of Engineering drawing, drawing data exchange used to translate between different Computer-aided design (Computer-aided design, CAD) authoring systems or between CAD and other downstream CAx systems.

Many companies us ...

. Usually it had been necessary to force the CAD operator to export the data in one of the common data formats, such as IGES

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. It's an ASCII-based textual format.

The official title of IGES is ''D ...

or STL or Parasolid

Parasolid is a geometric modeling kernel originally developed by Shape Data Limited, now owned and developed by Siemens Digital Industries Software. It can be licensed by other companies for use in their 3D computer graphics software products. ...

formats that are supported by a wide variety of software.

The output from the CAM software is usually a simple text file of G-code/M-codes, sometimes many thousands of commands long, that is then transferred to a machine tool using a direct numerical control

Direct numerical control (DNC), also known as distributed numerical control (also DNC), is a common manufacturing term for networking CNC machine tools. On some CNC machine controllers, the available memory is too small to contain the machining p ...

(DNC) program or in modern Controllers using a common USB

Universal Serial Bus (USB) is an industry standard that establishes specifications for cables, connectors and protocols for connection, communication and power supply (interfacing) between computers, peripherals and other computers. A broad ...

Storage Device.

CAM packages could not, and still cannot, reason as a machinist can. They could not optimize toolpaths to the extent required of mass production

Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch ...

. Users would select the type of tool, machining process and paths to be used. While an engineer may have a working knowledge of G-code programming, small optimization and wear issues compound over time. Mass-produced items that require machining are often initially created through casting or some other non-machine method. This enables hand-written, short, and highly optimized G-code that could not be produced in a CAM package.

At least in the United States, there is a shortage of young, skilled machinists entering the workforce able to perform at the extremes of manufacturing; high precision and mass production. As CAM software and machines become more complicated, the skills required of a machinist or machine operator advance to approach that of a computer programmer and engineer rather than eliminating the CNC machinist from the workforce.

;Typical areas of concern

* High-Speed Machining, including streamlining of tool paths

* Multi-function Machining

* 5 Axis Machining

* Feature recognition

The term "feature" implies different meanings in different engineering disciplines. This has resulted in many ambiguous definitions for feature. A feature, in computer-aided design (CAD), usually refers to a region of a part with some interesting ...

and machining

* Automation of Machining processes

* Ease of Use

Overcoming historical shortcomings

Over time, the historical shortcomings of CAM are being attenuated, both by providers of niche solutions and by providers of high-end solutions. This is occurring primarily in three arenas: # Ease of usage # Manufacturing complexity # Integration with PLM and the extended enterprise ;Ease in use :For the user who is just getting started as a CAM user, out-of-the-box capabilities providing Process Wizards, templates, libraries, machine tool kits, automated feature based machining and job function specific tailorable user interfaces build user confidence and speed the learning curve. :User confidence is further built on 3D visualization through a closer integration with the 3D CAD environment, including error-avoiding simulations and optimizations. ;Manufacturing complexity :The manufacturing environment is increasingly complex. The need for CAM and PLM tools by the manufacturing engineer, NC programmer or machinist is similar to the need for computer assistance by the pilot of modern aircraft systems. The modern machinery cannot be properly used without this assistance. :Today's CAM systems support the full range of machine tools including:turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates.

Usually the term "turning" is reserved for the generation ...

, 5 axis machining, waterjet, laser

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word "laser" is an acronym for "light amplification by stimulated emission of radiation". The fir ...

/ plasma cutting

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other c ...

, and wire EDM. Today’s CAM user can easily generate streamlined tool paths, optimized tool axis tilt for higher feed rates, better tool life and surface finish, and ideal cutting depth. In addition to programming cutting operations, modern CAM softwares can additionally drive non-cutting operations such as machine tool probing.

;Integration with PLM and the extended enterpriseLM to integrate manufacturing with enterprise operations from concept through field support of the finished product.

:To ensure ease of use appropriate to user objectives, modern CAM solutions are scalable from a stand-alone CAM system to a fully integrated multi-CAD 3D solution-set. These solutions are created to meet the full needs of manufacturing personnel including part planning, shop documentation, resource management and data management and exchange. To prevent these solutions from detailed tool specific information a dedicated tool management

Tool management is needed in Manufacturing, metalworking so that the information regarding the tools on hand can be uniformly organized and integrated. The information is stored in a database and is registered and applied using tool management. T ...

Machining process

Most machining progresses through many stages, each of which is implemented by a variety of basic and sophisticated strategies, depending on the part design, material, and software available. ;Roughing : This process usually begins with raw stock, known asbillet

A billet is a living-quarters to which a soldier is assigned to sleep. Historically, a billet was a private dwelling that was required to accept the soldier.

Soldiers are generally billeted in barracks or garrisons when not on combat duty, alth ...

, or a rough casting which a CNC machine cuts roughly to shape of the final model, ignoring the fine details. In milling, the result often gives the appearance of terraces or steps, because the strategy has taken multiple "steps" down the part as it removes material. This takes the best advantage of the machine's ability by cutting material horizontally. Common strategies are zig-zag clearing, offset clearing, plunge roughing, rest-roughing, and trochoidal milling (adaptive clearing). The goal at this stage is to remove the most material in the least time, without much concern for overall dimensional accuracy. When roughing a part, a small amount of extra material is purposely left behind to be removed in subsequent finishing operation(s).

;Semi-finishing

: This process begins with a roughed part that unevenly approximates the model and cuts to within a fixed offset distance from the model. The semi-finishing pass must leave a small amount of material (called the scallop) so the tool can cut accurately, but not so little that the tool and material deflect away from the cutting surfaces. Common strategies are raster passes, waterline passes, constant step-over passes, pencil milling.

;Finishing

: Finishing involves many light passes across the material in fine steps to produce the finished part. When finishing a part, the steps between passes is minimal to prevent tool deflection and material spring back. In order to reduce the lateral tool load, tool engagement is reduced, while feed rates and spindle speeds are generally increased in order to maintain a target surface speed (SFM). A light chip load at high feed and RPM is often referred to as High Speed Machining (HSM), and can provide quick machining times with high quality results. The result of these lighter passes is a highly accurate part, with a uniformly high surface finish. In addition to modifying speeds and feeds, machinists will often have finishing specific endmills, which never used as roughing endmills. This is done to protect the endmill from developing chips and flaws in the cutting surface, which would leave streaks and blemishes on the final part.

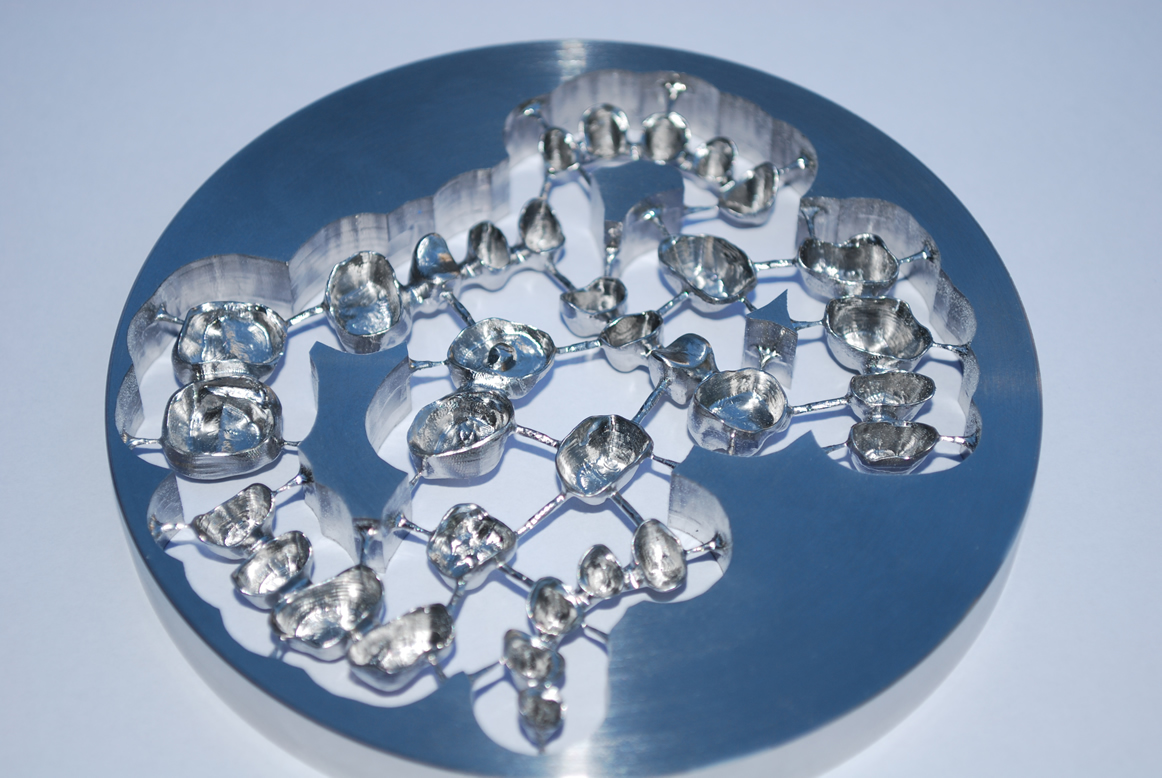

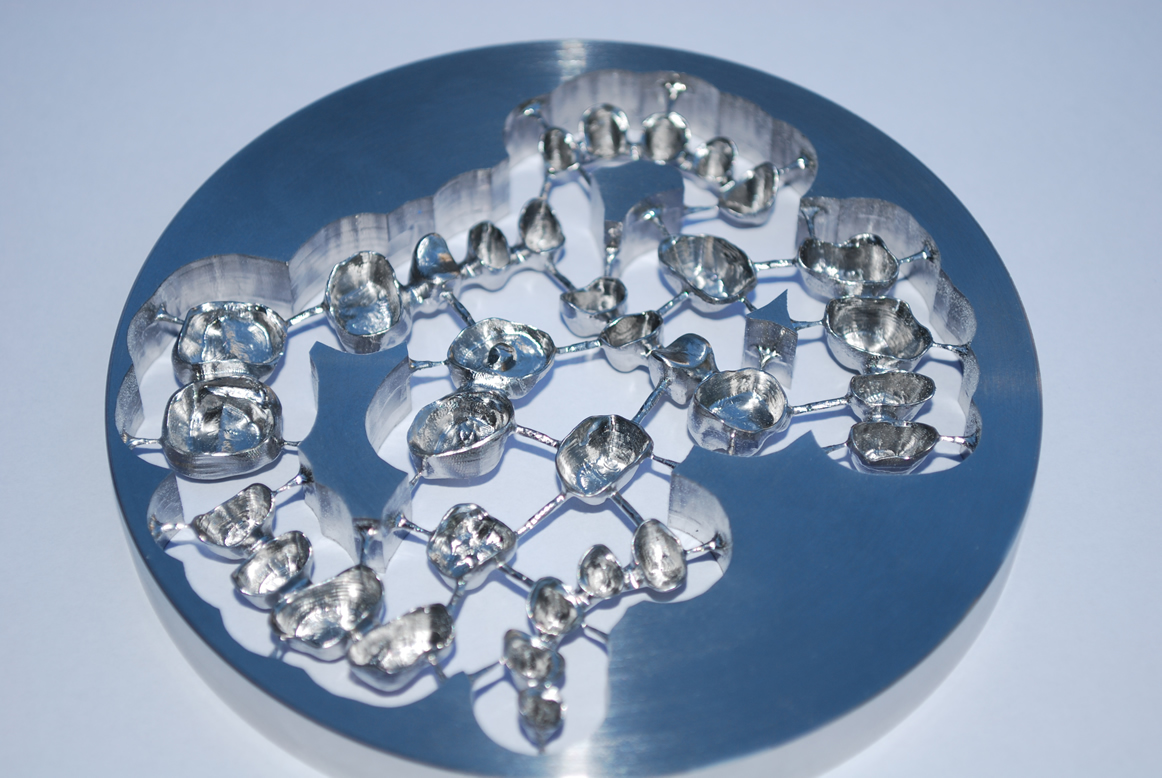

;Contour milling

: In milling applications on hardware with rotary table and/or rotary head axes, a separate finishing process called contouring can be performed. Instead of stepping down in fine-grained increments to approximate a surface, the work piece or tool is rotated to make the cutting surfaces of the tool tangent to the ideal part features. This produces an excellent surface finish with high dimensional accuracy. This process is commonly used to machine complex organic shapes such as turbine and impeller blades, which due to their complex curves and overlapping geometry, are impossible to machine with only three axis machines.

Software: large vendors

See also

*Computer-integrated manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster ...

(CIM)

* Digital modeling and fabrication Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufa ...

* Direct numerical control

Direct numerical control (DNC), also known as distributed numerical control (also DNC), is a common manufacturing term for networking CNC machine tools. On some CNC machine controllers, the available memory is too small to contain the machining p ...

(DNC)

* Flexible manufacturing system

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted.

This flexibility is generally considered to fall ...

(FMS)

* Integrated Computer-Aided Manufacturing

Integrated Computer-Aided Manufacturing (ICAM) is a US Air Force program that develops tools, techniques, and processes to support manufacturing integration. It influenced the computer-integrated manufacturing (CIM) and computer-aided manufacturin ...

(ICAM)

* Manufacturing process management

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing ...

(MPM)

* STEP-NC

* Rapid prototyping

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design (CAD) data.

Construction of the part or assembly is usually done using 3D printin ...

and rapid manufacturing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer ...

– solid freeform fabrication direct from CAD models

* CNC pocket milling

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of d ...

References

Further reading

* *https://patents.google.com/patent/US5933353A/en *External links

CADSite.ru

CAD Models

Cimatron Brazil

about Software CAD/CAM CimatronE

Dragomatz and Mann

reviewed toolpath algorithms in 1997.

by Martin Held

Purdue Research and Education Centre for Information Systems in Engineering

How to evaluate a CAM system

Sheetmetalworld.com article {{DEFAULTSORT:Computer-Aided Manufacturing Information technology management Product lifecycle management