|

Computer-integrated Manufacturing

Computer-integrated manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each part. Manufacturing can be faster and less error-prone by the integration of computers. Typically CIM relies on closed-loop control processes based on real-time input from sensors. It is also known as ''flexible design and manufacturing''. Overview # Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. # The term "computer-integrated manufacturing" is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise are organized. # In a CIM system functional areas such as design, analysis, planning, purchasing, cost accounting, inventory control, and distribution are linked through the computer with facto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

NIST Manufacturing Systems Integration Program

The National Institute of Standards and Technology (NIST) is an agency of the United States Department of Commerce whose mission is to promote American innovation and industrial competitiveness. NIST's activities are organized into physical science laboratory programs that include nanoscale science and technology, engineering, information technology, neutron research, material measurement, and physical measurement. From 1901 to 1988, the agency was named the National Bureau of Standards. History Background The Articles of Confederation, ratified by the colonies in 1781, provided: The United States in Congress assembled shall also have the sole and exclusive right and power of regulating the alloy and value of coin struck by their own authority, or by that of the respective states—fixing the standards of weights and measures throughout the United States. Article 1, section 8, of the Constitution of the United States, ratified in 1789, granted these powers to the new Congr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Efficiency

Efficiency is the often measurable ability to avoid wasting materials, energy, efforts, money, and time in doing something or in producing a desired result. In a more general sense, it is the ability to do things well, successfully, and without waste. In more mathematical or scientific terms, it signifies the level of performance that uses the least amount of inputs to achieve the highest amount of output. It often specifically comprises the capability of a specific application of effort to produce a specific outcome with a minimum amount or quantity of waste, expense, or unnecessary effort. Efficiency refers to very different inputs and outputs in different fields and industries. In 2019, the European Commission said: "Resource efficiency means using the Earth's limited resources in a sustainable manner while minimising impacts on the environment. It allows us to create more with less and to deliver greater value with less input." Writer Deborah Stone notes that efficiency is " ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Process Planning

# Computer-aided process planning (CAPP) is the use of computer technology to aid in the process planning of a part or product, in manufacturing. # CAPP is the link between CAD and CAM in that it provides for the planning of the process to be used in producing a designed part. Computer-aided process planning # CAPP is a link between the CAD and CAM modules. # Process planning is concerned with determining the sequence of individual manufacturing operations needed to produce a given part or product. # The resulting operation sequence is documented on a form typically referred to as a " Route Sheet" (also called a process sheet/method sheet) containing a listing of the production operations and associated machine tools for a work part or assembly. # Process planning in manufacturing also refers to the planning of use of blanks, spare parts, packaging material, user instructions (manuals), etc. # As the term "computer-aided production planning" is used in different contexts on dif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

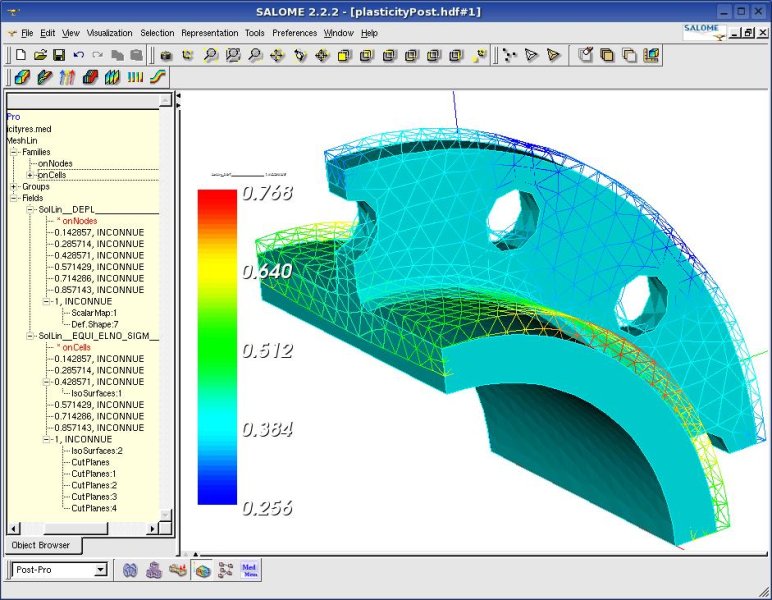

Computer-aided Engineering

Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes , , , durability and optimization. It is included with computer-aided design (CAD) and computer-aided manufacturing (CAM) in the collective abbreviation " CAx". Overview Computer-aided engineering primarily uses computer-aided design (CAD) software, which are sometimes called CAE tools. CAE tools are used, to analyze the robustness and performance of components and assemblies. CAE tools encompass simulation, validation, and optimization of products and manufacturing tools. CAE systems aim to be major providers of information to help support design teams in decision-making. Computer-aided engineering is used in various fields, like automotive, aviation, space, and shipbuilding industries. CAE systems can provide support to businesses. This is achieved by the use of reference architectures and their ability to place information views on the business proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Design

Computer-aided design (CAD) is the use of computers (or ) to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used. Its use in designing electronic systems is known as '' electronic design automation'' (''EDA''). In mechanical design it is known as ''mechanical design automation'' (''MDA''), which includes the process of creating a technical drawing with the use of computer software. CAD software for mechanical design uses either vector-based graphics ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Factory

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. They are a critical part of modern economic production, with the majority of the world's goods being created or processed within factories. Factories arose with the introduction of machinery during the Industrial Revolution, when the capital and space requirements became too great for cottage industry or workshops. Early factories that contained small amounts of machinery, such as one or two spinning mules, and fewer than a dozen workers have been called "glorified workshops". Most modern factories have large warehouses or warehouse-like facilities that contain heavy equipment used for assembly line production. Large factories tend to be located with access to multiple modes of transportation, some having rail, highway and water loading ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flexible Manufacturing System

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. This flexibility is generally considered to fall into two categories, which both contain numerous subcategories. The first category is called as ''Routing Flexibility'' which covers the system's ability to be changed to produce new product types, and ability to change the order of operations executed on a part. The second category is called ''Machine Flexibility'' which consists of the ability to use multiple machines to perform the same operation on a part, as well as the system's ability to absorb large-scale changes, such as in volume, capacity, or capability. Most FMS consist of three main systems: 1) The "Work Machines" which are often automated "CNC machines" are connected by 2) By a "Material handling" system to optimize parts flow and 3) The "Central Control Computer" which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lights Out (manufacturing)

Lights-out manufacturing is a manufacturing methodology (or philosophy), not a specific process. Factories that employ "lights-out manufacturing" are fully automated and require no human presence on-site. These factories are considered to be able to run "with the lights off." Many factories are capable of lights-out production, but few run exclusively lights-out. Typically, in computer numerical control (CNC) machining, workers are necessary to set up tombstones that hold parts to be manufactured and remove completed parts. As the technology necessary for total automation becomes increasingly available, many factories are beginning to use lights-out production between shifts (or as a separate shift) to meet increasing production demand or to save money on labor. Going forward this concept of automation will become more popular and can support human beings. An automatic factory is a place where raw materials enter, and finished products leave with little or no human intervention. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthrou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Data Integrity

Data integrity is the maintenance of, and the assurance of, data accuracy and consistency over its entire Information Lifecycle Management, life-cycle and is a critical aspect to the design, implementation, and usage of any system that stores, processes, or retrieves data. The term is broad in scope and may have widely different meanings depending on the specific context even under the same general umbrella of computing. It is at times used as a proxy term for data quality, while data validation is a prerequisite for data integrity. Data integrity is the opposite of data corruption. The overall intent of any data integrity technique is the same: ensure data is recorded exactly as intended (such as a database correctly rejecting mutually exclusive possibilities). Moreover, upon later Data retrieval, retrieval, ensure the data is the same as when it was originally recorded. In short, data integrity aims to prevent unintentional changes to information. Data integrity is not to be confus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |