Contact Protection on:

[Wikipedia]

[Google]

[Amazon]

Contact protection methods are designed to mitigate the wear and degradation occurring during the normal use of contacts within an electromechanical

Every time the contacts of an

Every time the contacts of an

switch

In electrical engineering, a switch is an electrical component that can disconnect or connect the conducting path in an electrical circuit, interrupting the electric current or diverting it from one conductor to another. The most common type ...

, relay

A relay

Electromechanical relay schematic showing a control coil, four pairs of normally open and one pair of normally closed contacts

An automotive-style miniature relay with the dust cover taken off

A relay is an electrically operated swit ...

or contactor and thus avoid an excessive increase in contact resistance or switch failure.

Contact wear

Every time the contacts of an

Every time the contacts of an electromechanical

In engineering, electromechanics combines processes and procedures drawn from electrical engineering and mechanical engineering. Electromechanics focuses on the interaction of electrical and mechanical systems as a whole and how the two system ...

switch, relay or contactor are opened or closed, there is a certain amount of contact wear. The sources of the wear are high current densities in microscopic areas, and the electric arc

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The electric current, current through a normally Electrical conductance, nonconductive medium such as air produces a plasma (p ...

. Contact wear includes material transfer between contacts, loss of contact material due to splattering and evaporation, and oxidation or corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

of the contacts due to high temperatures and atmospheric influences.

While a pair of contacts is closed, only a small part of the contacts are in intimate contact due to asperities and low-conductivity films. Because of the constriction of the current to a very small area, the current density

In electromagnetism, current density is the amount of charge per unit time that flows through a unit area of a chosen cross section. The current density vector is defined as a vector whose magnitude is the electric current per cross-sectional a ...

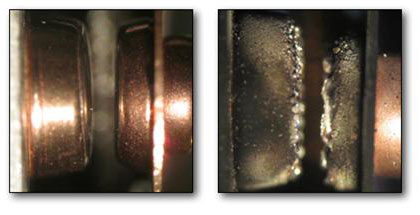

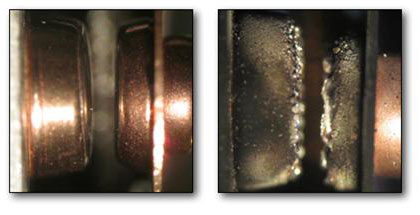

frequently becomes so high that it melts a microscopic portion of the contact. During the close-to-open (break) transition, a microscopic molten bridge forms and eventually ruptures asymmetrically, transferring contact material between contacts and increasing the surface roughness. This can also occur during the open-to-close (make) transition due to contact bounce.

The electric arc

An electric arc, or arc discharge, is an electrical breakdown of a gas that produces a prolonged electrical discharge. The electric current, current through a normally Electrical conductance, nonconductive medium such as air produces a plasma (p ...

occurs between the contact points (electrodes) both during the transition from closed to open (break) and from open to closed (make) when the contact gap is small and the voltage is high enough. Heating due to arcing and high current density can melt the contact surface temporarily. If some of the melting material solidifies while the contacts are closed, the contact may stick closed due to a micro-weld, similar to spot welding

A spot welder

Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistanc ...

.

The arc caused during the contact break (break arc) is similar to arc welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding po ...

, as the break arc is typically more energetic and more destructive. The arc can cause material transfer between contacts. The arc may also be hot enough to evaporate metal from the contact surface.

The high temperatures can also cause the contact metals to more rapidly oxidize and corrode.

Contacts reach end of life for one of two reasons. Either the contacts fail to break because they are stuck (welded) closed, or the contacts fail to make (high resistance) because of contact corrosion or because excessive material is lost from one or both contacts. These conditions are the result of cumulative material transfer during successive switching operations, and of material loss due to evaporation and splattering.

There are additional mechanisms for stuck closed failures, such as mechanical interlocking of rough contact surfaces due to contact wear.

Protection

The degradation of the contacts can be limited by including various contact protection methods. One method is to add electronic components such as:capacitor

A capacitor is a device that stores electrical energy in an electric field by virtue of accumulating electric charges on two close surfaces insulated from each other. It is a passive electronic component with two terminals.

The effect of a ...

s, snubbers, diodes, Zener diode

A Zener diode is a special type of diode designed to reliably allow current to flow "backwards" (inverted polarity) when a certain set reverse voltage, known as the ''Zener voltage'', is reached.

Zener diodes are manufactured with a great var ...

s, transient voltage suppressors (TVS), resistor

A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias activ ...

s, varistors or in-rush current limiters ( PTC and NTC resistors). However, this is the least effective method as these neither significantly influence the creation of nor suppress the arc between the contacts of electromechanical power switches, relays and contactors.

A slightly more effective method is to make the contacts themselves larger, i.e., a contactor.

A similar method to increasing contact size is to make the contacts out of more durable metals or metal alloys such as tungsten.

The most effective methods are to employ arc suppression Arc suppression is the reduction of sparks formed when current-carrying contacts are separated. The spark is a luminous discharge of highly energized electrons and ions, and is an electric arc.

Uses

There are several possible areas of use of arc ...

circuitry including arc suppressors, solid state relays, hybrid power relays, mercury displacement relays and hybrid power contactors.

See also

*Arc suppression Arc suppression is the reduction of sparks formed when current-carrying contacts are separated. The spark is a luminous discharge of highly energized electrons and ions, and is an electric arc.

Uses

There are several possible areas of use of arc ...

* Contact resistance

* Wetting current

* Wetting voltage

In electrical and electronics engineering, wetting current is the minimum electric current needing to flow through a contact to break through the surface film resistance at a contact. It is typically far below the contact's nominal maximum curre ...

References

{{Switches Switches Power engineering Electric arcs