|

Asperity (materials Science)

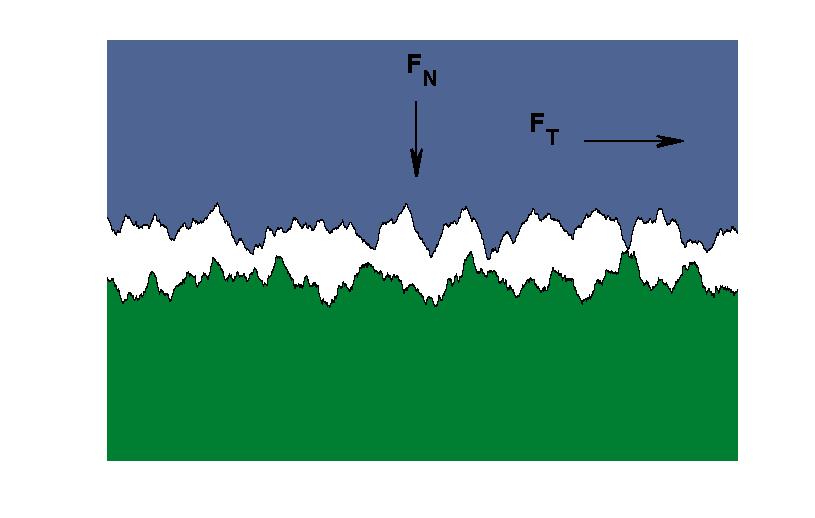

In materials science, asperity, defined as "unevenness of surface, roughness, ruggedness" (from the Latin ''asper''—"rough"), has implications (for example) in physics and seismology. Smooth surfaces, even those polished to a mirror finish, are not truly smooth on a microscopic scale. They are rough, with sharp, rough or rugged projections, termed "asperities". Surface asperities exist across multiple scales, often in a self affine or fractal geometry. The fractal dimension of these structures has been correlated with the contact mechanics exhibited at an interface in terms of friction and contact stiffness. When two macroscopically smooth surfaces come into contact, initially they only touch at a few of these asperity points. These cover only a very small portion of the surface area. Friction and wear originate at these points, and thus understanding their behavior becomes important when studying materials in contact. When the surfaces are subjected to a compressive load, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Normal Contact Stiffness

Normal contact stiffness is a physical quantity related to the generalized force displacement behavior of rough surfaces in contact with a rigid body or a second similar rough surface. Rough surfaces can be seen as consisting of large numbers of asperities. As two solid bodies of the same material approach one another, the asperities interact, and they transition from conditions of non-contact to homogeneous bulk behaviour. The varying values of stiffness and true contact area that is exhibited at an interface during this transition are dependent on the conditions of applied pressure and are of importance for the study of systems involving the physical interactions of multiple bodies including granular matter, electrode contacts, and thermal contacts, where the interface-localized structures govern overall system performance. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burnishing (metal)

Burnishing is the plastic deformation of a surface due to sliding contact with another object. It smooths the surface and makes it shinier. Burnishing may occur on any sliding surface if the contact stress locally exceeds the yield strength of the material. The phenomenon can occur both unintentionally as a failure mode, and intentionally as part of a manufacturing process. It is a squeezing operation under cold working. Mechanics The action of a hardened ball against a softer, flat plate illustrates the process of burnishing. If the ball is pushed directly into the plate, stresses develop in both objects around the area where they contact. As this normal force increases, both the ball and the plate's surfaces deform. The deformation caused by the hardened ball increases with the magnitude of the force pressing against it. If the force on it is small, when the force is released both the ball and plate's surface will return to their original, undeformed shape. In that case, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Roughness

Surface roughness, often shortened to roughness, is a component of surface finish (surface texture). It is quantified by the deviations in the direction of the normal vector of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small, the surface is smooth. In surface metrology, roughness is typically considered to be the high-frequency, short-wavelength component of a measured surface. However, in practice it is often necessary to know both the amplitude and frequency to ensure that a surface is fit for a purpose. Roughness plays an important role in determining how a real object will interact with its environment. In tribology, rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces. Roughness is often a good predictor of the performance of a mechanical component, since irregularities on the surface may form nucleation sites for cracks or corrosion. On the other hand, roughness ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Archard Equation

The Archard wear equation is a simple model used to describe sliding wear and is based on the theory of asperity contact. The Archard equation was developed much later than (sometimes also known as energy dissipative hypothesis), though both came to the same physical conclusions, that the volume of the removed debris due to wear is proportional to the work done by friction forces. Theodor Reye's model became popular in Europe and it is still taught in university courses of applied mechanics. Until recently, Reye's theory of 1860 has, however, been totally ignored in English and American literature where subsequent works by Ragnar Holm and John Frederick Archard are usually cited. In 1960, and Mikhail Alekseevich Babichev published a similar model as well. In modern literature, the relation is therefore also known as Reye–Archard–Khrushchov wear law. In 2022, the steady-state Archard wear equation was extended into the running-in regime using the bearing ratio curve repre ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology. Wear in machine elements, together with other processes such as fatigue and creep, causes functional surfaces to degrade, eventually leading to material failure or loss of functionality. Thus, wear has large economic relevance as first outlined in the Jost Report. Abrasive wear alone has been estimated to cost 1-4% of the gross national product of industrialized nations. Wear of metals occurs by plastic displacement of surface and near-surface material and by detachment of particles that form wear debris. The particle size may vary from millimeters to nanometers. This process may occur by contact with other metals, nonmetallic solids, flowing liquids, solid particles or liquid droplets entrained in flowing gasses. The wear rate is affected by f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding (motion), sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into ''static friction'' ("stiction") between non-moving surfaces, and ''kinetic friction'' between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as Asperity (materials science), asperities (see Figure 1). *Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other. *Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces. *Skin friction is a component of Drag (physics), drag, the force resisting the motion of a fluid across the surface of a body. *Internal friction is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interface (chemistry)

In the physical sciences, an interface is the boundary between two spatial regions occupied by different matter, or by matter in different physical states. The interface between matter and air, or matter and vacuum, is called a surface, and studied in surface science. In thermal equilibrium, the regions in contact are called phases, and the interface is called a phase boundary. An example for an interface out of equilibrium is the grain boundary in polycrystalline matter. The importance of the interface depends on the type of system: the bigger the quotient area/volume, the greater the effect the interface will have. Consequently, interfaces are very important in systems with large interface area-to-volume ratios, such as colloids. Interfaces can be flat or curved. For example, oil droplets in a salad dressing are spherical but the interface between water and air in a glass of water is mostly flat. Surface tension is the physical property which rules interface processes invol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Mechanics

Contact mechanics is the study of the deformation of solids that touch each other at one or more points.Johnson, K. L, 1985, Contact mechanics, Cambridge University Press.Popov, Valentin L., 2010, ''Contact Mechanics and Friction. Physical Principles and Applications'', Springer-Verlag, 362 p., . A central distinction in contact mechanics is between stresses acting perpendicular to the contacting bodies' surfaces (known as normal stress) and frictional stresses acting tangentially between the surfaces (shear stress). Normal contact mechanics or frictionless contact mechanics focuses on normal stresses caused by applied normal forces and by the adhesion present on surfaces in close contact, even if they are clean and dry. '' Frictional contact mechanics'' emphasizes the effect of friction forces. Contact mechanics is part of mechanical engineering. The physical and mathematical formulation of the subject is built upon the mechanics of materials and continuum mechanics and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |