Activated sludge on:

[Wikipedia]

[Google]

[Amazon]

The activated sludge process is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using

The activated sludge process is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using

The activated sludge process is a biological process used to

The activated sludge process is a biological process used to

"Package Plants."

Wastewater Technology Fact Sheet. Document no. EPA 832-F-00-016. Package plants may be referred to as ''high charged'' or ''low charged''. This refers to the way the biological load is processed. In high charged systems, the biological stage is presented with a high organic load and the combined floc and organic material is then oxygenated for a few hours before being charged again with a new load. In the low charged system the biological stage contains a low organic load and is combined with

The basins may range in depth from and utilize motor-driven aerators floating on the surface of the wastewater. In an aerated basin system, the aerators provide two functions: they transfer air into the basins required by the biological oxidation reactions, and they provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater and microbes). Typically, the floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kilograms O2/ kWh (4.0 to 6.0 lb O2/kWh). However, they do not provide as good mixing as is normally achieved in activated sludge systems and therefore aerated basins do not achieve the same performance level as activated sludge units. Biological oxidation processes are sensitive to temperature and, between , the rate of biological reactions increase with temperature. Most surface aerated vessels operate at between .

Sewage liquor is run into deep tanks with

Sewage liquor is run into deep tanks with

Vertically mounted tubes of up to diameter extending from just above the base of a deep concrete tank to just below the surface of the sewage liquor. A typical shaft might be high. At the surface end, the tube is formed into a cone with helical vanes attached to the inner surface. When the tube is rotated, the vanes spin liquor up and out of the cones drawing new sewage liquor from the base of the tank. In many works, each cone is located in a separate cell that can be isolated from the remaining cells if required for maintenance. Some works may have two cones to a cell and some large works may have 4 cones per cell.

Vertically mounted tubes of up to diameter extending from just above the base of a deep concrete tank to just below the surface of the sewage liquor. A typical shaft might be high. At the surface end, the tube is formed into a cone with helical vanes attached to the inner surface. When the tube is rotated, the vanes spin liquor up and out of the cones drawing new sewage liquor from the base of the tank. In many works, each cone is located in a separate cell that can be isolated from the remaining cells if required for maintenance. Some works may have two cones to a cell and some large works may have 4 cones per cell.

The activated sludge process was discovered in 1913 in the

The activated sludge process was discovered in 1913 in the

The activated sludge process is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using

The activated sludge process is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration

Aeration (also called aerification or aeriation) is the process by which air is circulated through, mixed with or dissolved in a liquid or other substances that act as a fluid (such as soil). Aeration processes create additional surface area in ...

and a biological floc composed of bacteria and protozoa. It uses air (or oxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

) and microorganism

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in olde ...

s to biologically oxidize organic pollutants, producing a waste sludge (or floc) containing the oxidized material.

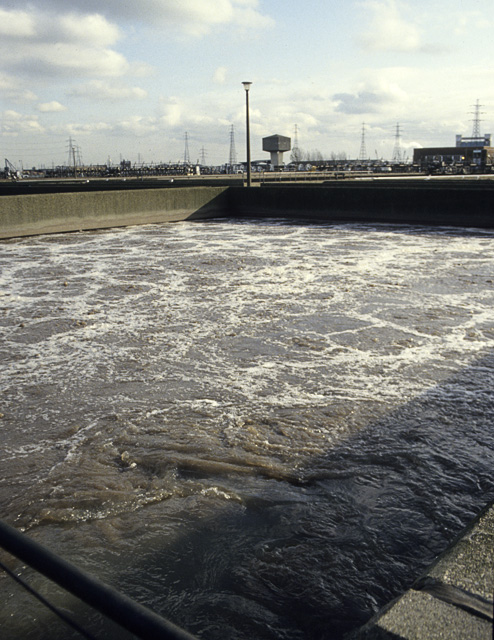

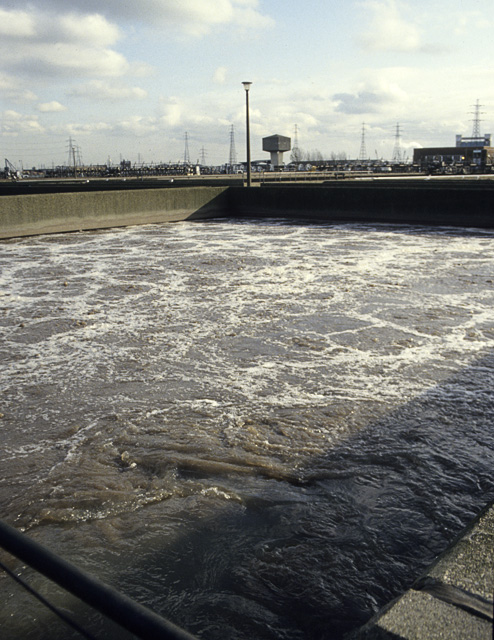

The activated sludge process for removing carbonaceous pollution begins with an aeration tank where air (or oxygen) is injected into the waste water. This is followed by a settling tank to allow the biological flocs (the sludge blanket) to settle, thus separating the biological sludge from the clear treated water. Part of the waste sludge is recycled to the aeration tank and the remaining waste sludge is removed for further treatment and ultimate disposal.

Plant types include package plants, oxidation ditch, deep shaft/vertical treatment, surface-aerated basins, sequencing batch reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatmen ...

s (SBRs). Aeration methods include diffused aeration, surface aerators (cones) or, rarely, pure oxygen aeration.

Sludge bulking can occur which makes activated sludge difficult to settle and frequently has an adverse impact on final effluent quality. Treating sludge bulking and managing the plant to avoid a recurrence requires skilled management and may require full-time staffing of a works to allow immediate intervention. A new development of the activated sludge process is the Nereda

Nereda is a wastewater treatment technology invented by Mark van Loosdrecht of the Delft University of Technology in the Netherlands. The technology is based on aerobic granulation and is a modification of the activated sludge process.

Aerobic g ...

process which produces a granular sludge that settles very well.

Purpose

The activated sludge process is a biological process used to

The activated sludge process is a biological process used to oxidise

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a d ...

carbonaceous biological matter, oxidising nitrogenous matter (mainly ammonium and nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

) in biological matter, and removing nutrients

A nutrient is a substance used by an organism to survive, grow, and reproduce. The requirement for dietary nutrient intake applies to animals, plants, fungi, and protists. Nutrients can be incorporated into cells for metabolic purposes or excre ...

(nitrogen and phosphorus).

Process description

The process takes advantage ofaerobic

Aerobic means "requiring air," in which "air" usually means oxygen.

Aerobic may also refer to

* Aerobic exercise, prolonged exercise of moderate intensity

* Aerobics, a form of aerobic exercise

* Aerobic respiration, the aerobic process of cel ...

micro-organisms that can digest organic matter in sewage, and clump together by flocculation

Flocculation, in the field of chemistry, is a process by which colloidal particles come out of suspension to sediment under the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from ...

entrapping fine particulate matter as they do so. It thereby produces a liquid that is relatively free from suspended solids and organic material, and flocculated particles that will readily settle out and can be removed.

The general arrangement of an activated sludge process for removing carbonaceous pollution includes the following items:

* Aeration tank where air (or oxygen) is injected in the mixed liquor.

* Settling tank (usually referred to as "final clarifier" or "secondary settling tank") to allow the biological flocs (the sludge blanket) to settle, thus separating the biological sludge from the clear treated water.

Treatment of nitrogenous matter or phosphate involves additional steps where the processes are managed to generate an anoxic zone so that phosphates can be solubilised in the reducing environment and oxides of nitrogen can be reduced to ammonium ion.

Bioreactor and final clarifier

The process involves air oroxygen

Oxygen is the chemical element with the symbol O and atomic number 8. It is a member of the chalcogen group in the periodic table, a highly reactive nonmetal, and an oxidizing agent that readily forms oxides with most elements as ...

being introduced into a mixture of screened, and primary treated sewage or industrial wastewater (wastewater

Wastewater is water generated after the use of freshwater, raw water, drinking water or saline water in a variety of deliberate applications or processes. Another definition of wastewater is "Used water from any combination of domestic, industrial ...

) combined with organisms to develop a biological floc which reduces the organic content of the sewage. This material, which in healthy sludge is a brown floc, is largely composed of Saprotrophic bacteria

Saprotrophic bacteria are bacteria that are typically soil-dwelling and utilize saprotrophic nutrition as their primary energy source. They are often associated with soil fungi that also use saprotrophic nutrition and both are classified as saprot ...

but also has an important protozoan flora component mainly composed of amoeba

An amoeba (; less commonly spelled ameba or amœba; plural ''am(o)ebas'' or ''am(o)ebae'' ), often called an amoeboid, is a type of cell or unicellular organism with the ability to alter its shape, primarily by extending and retracting pseudop ...

e, Spirotrich

The spirotrichs are a large and diverse group of ciliate protozoa. They typically have prominent oral cilia in the form of a series of polykinetids, called the adoral zone of membranelles, beginning anterior to the oral cavity and running down ...

s, Peritrich

The peritrichs (Latin: Peritrichia) are a large and distinctive group of ciliates.

The peritrichs were first defined by Friedrich von Stein in 1859. Initially they were considered spirotrichs, then treated as a separate category, before receivi ...

s including Vorticellids and a range of other filter-feeding species. Other important constituents include motile and sedentary Rotifers. In poorly managed activated sludge, a range of mucilaginous

Mucilage is a thick, gluey substance produced by nearly all plants and some microorganisms. These microorganisms include protists which use it for their locomotion. The direction of their movement is always opposite to that of the secretion of ...

filamentous bacteria can develop - including '' Sphaerotilus natans'', '' Gordonia'', and other microorganisms - which produces a sludge that is difficult to settle and can result in the sludge blanket decanting over the weirs in the settlement tank to severely contaminate the final effluent quality. This material is often described as sewage fungus but true fungal communities are relatively uncommon.

The combination of wastewater and biological mass is commonly known as ''mixed liquor''. In all activated sludge plants, once the wastewater has received sufficient treatment, excess mixed liquor is discharged into settling tanks and the treated supernatant

In an aqueous solution, precipitation is the process of transforming a dissolved substance into an insoluble solid from a super-saturated solution. The solid formed is called the precipitate. In case of an inorganic chemical reaction leading ...

is run off to undergo further treatment before discharge. Part of the settled material, the sludge

Sludge is a semi-solid slurry that can be produced from a range of industrial processes, from water treatment, wastewater treatment or on-site sanitation systems. For example, it can be produced as a settled suspension obtained from conventional ...

, is returned to the head of the aeration

Aeration (also called aerification or aeriation) is the process by which air is circulated through, mixed with or dissolved in a liquid or other substances that act as a fluid (such as soil). Aeration processes create additional surface area in ...

system to re-seed the new wastewater entering the tank. This fraction of the floc is called ''return activated sludge'' (R.A.S.).

The space required for a sewage treatment plant can be reduced by using a membrane bioreactor

Membrane bioreactor (MBR) is a combination of membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater ...

to remove some wastewater from the mixed liquor prior to treatment. This results in a more concentrated waste product that can then be treated using the activated sludge process.

Many sewage treatment plants use axial flow pump

An axial-flow pump, or AFP, is a common type of pump that essentially consists of a propeller (an axial impeller) in a pipe. The propeller can be driven directly by a sealed motor in the pipe or by electric motor or petrol/diesel engines mounted ...

s to transfer nitrified mixed liquor from the aeration zone to the anoxic zone for denitrification. These pumps are often referred to as internal mixed liquor recycle pumps (IMLR pumps). The raw sewage, the RAS, and the nitrified mixed liquor are mixed by submersible mixers in the anoxic zones in order to achieve denitrification.

Sludge production

Activated sludge is also the name given to the active biological material produced by activated sludge plants. Excess sludge is called "surplus activated sludge" or "waste activated sludge" and is removed from the treatment process to keep the ratio of biomass to food supplied in the wastewater in balance. Thissewage sludge

Sewage sludge is the residual, semi-solid material that is produced as a by-product during sewage treatment of industrial or municipal wastewater. The term " septage" also refers to sludge from simple wastewater treatment but is connected to s ...

is usually mixed with primary sludge from the primary clarifiers and undergoes further sludge treatment for example by anaerobic digestion

Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to Waste management, manage waste or to produce fuels. Mu ...

, followed by thickening, dewatering, composting

Compost is a mixture of ingredients used as plant fertilizer and to improve soil's physical, chemical and biological properties. It is commonly prepared by decomposing plant, food waste, recycling organic materials and manure. The resulting m ...

and land application.

The amount of sewage sludge produced from the activated sludge process is directly proportional to the amount of wastewater treated. The total sludge production consists of the sum of primary sludge from the primary sedimentation tanks as well as waste activated sludge from the bioreactors. The activated sludge process produces about of waste activated sludge (that is grams of dry solids produced per cubic metre of wastewater treated). is regarded as being typical. In addition, about of primary sludge is produced in the primary sedimentation tanks which most - but not all - of the activated sludge process configurations use.

Process control

The general process control method is to monitor sludge blanket level, SVI (Sludge Volume Index), MCRT (Mean Cell Residence Time), F/M (Food to Microorganism), as well as the biota of the activated sludge and the major nutrients DO (Dissolved oxygen

Oxygen saturation (symbol SO2) is a relative measure of the concentration of oxygen that is dissolved or carried in a given medium as a proportion of the maximal concentration that can be dissolved in that medium at the given temperature. It ca ...

), nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at se ...

, phosphate

In chemistry, a phosphate is an anion, salt, functional group or ester derived from a phosphoric acid. It most commonly means orthophosphate, a derivative of orthophosphoric acid .

The phosphate or orthophosphate ion is derived from phosph ...

, BOD (Biochemical oxygen demand

Biochemical oxygen demand (BOD) is the amount of dissolved oxygen (DO) needed (i.e. demanded) by aerobic biological organisms to break down organic material present in a given water sample at a certain temperature over a specific time period. ...

), and COD (Chemical oxygen demand

In environmental chemistry, the chemical oxygen demand (COD) is an indicative measure of the amount of oxygen that can be consumed by reactions in a measured solution. It is commonly expressed in mass of oxygen consumed over volume of solution whic ...

). In the reactor/aerator and clarifier system, the sludge blanket is measured from the bottom of the clarifier to the level of settled solids in the clarifier's water column; this, in large plants, can be done up to three times a day.

The SVI is the volume of settled sludge occupied by a given mass of dry sludge solids. It is calculated by dividing the volume of settled sludge in a mixed liquor sample, measured in milliliters per liter of sample (after 30 minutes of settling), by the MLSS (Mixed Liquor Suspended Solids), measured in grams per liter. The MCRT is the total mass (in kilograms or pounds) of mixed liquor suspended solids in the aerator and clarifier divided by the mass flow rate (in kilograms/pounds per day) of mixed liquor suspended solids leaving as WAS and final effluent. The F/M is the ratio of food fed to the microorganisms each day to the mass of microorganisms held under aeration. Specifically, it is the amount of BOD fed to the aerator (in kilograms/pounds per day) divided by the amount (in kilograms or pounds) of Mixed Liquor Volatile Suspended Solids (MLVSS) under aeration. Note: Some references use MLSS (Mixed Liquor Suspended Solids) for expedience, but MLVSS is considered more accurate for the measure of microorganisms. Again, due to expedience, COD is generally used, in lieu of BOD, as BOD takes five days for results.

Based on these control methods, the amount of settled solids in the mixed liquor can be varied by wasting activated sludge (WAS) or returning activated sludge (RAS).

Plant types

There are a variety of types of activated sludge plants. These include:Package plants

There are a wide range of types of package plants, often serving small communities or industrial plants that may use hybrid treatment processes often involving the use of aerobic sludge to treat the incoming sewage. In such plants the primary settlement stage of treatment may be omitted. In these plants, a biotic floc is created which provides the required substrate. Package plants are designed and fabricated by specialty engineering firms in dimensions that allow for their transportation to the job site in public highways, typically width and height of . Length varies with capacity with larger plants being fabricated in pieces and welded on site. Steel is preferred over synthetic materials (e.g., plastic) for its durability. Package plants are commonly variants ofextended aeration Extended aeration is a method of sewage treatment using modified activated sludge procedures. It is preferred for relatively small waste loads, where lower operating efficiency is offset by mechanical simplicity.Steel & McGhee (1979) p.501

Convent ...

, to promote the "fit and forget" approach required for small communities without dedicated operational staff. There are various standards to assist with their design.

To use less space, treat difficult waste, and intermittent flows, a number of designs of hybrid treatment plants have been produced. Such plants often combine at least two stages of the three main treatment stages into one combined stage. In the UK, where a large number of wastewater treatment plants serve small populations, package plants are a viable alternative to building a large structure for each process stage. In the US, package plants are typically used in rural areas, highway rest stops and trailer parks.EPA. Washington, DC (2000)"Package Plants."

Wastewater Technology Fact Sheet. Document no. EPA 832-F-00-016. Package plants may be referred to as ''high charged'' or ''low charged''. This refers to the way the biological load is processed. In high charged systems, the biological stage is presented with a high organic load and the combined floc and organic material is then oxygenated for a few hours before being charged again with a new load. In the low charged system the biological stage contains a low organic load and is combined with

flocculate

Flocculation, in the field of chemistry, is a process by which colloidal particles come out of suspension to sediment under the form of floc or flake, either spontaneously or due to the addition of a clarifying agent. The action differs from p ...

for longer times.

Oxidation ditch

In some areas, where more land is available, sewage is treated in large round or oval ditches with one or more horizontal aerators typically called brush or disc aerators which drive the mixed liquor around the ditch and provide aeration. These are oxidation ditches, often referred to by manufacturer's trade names such as Pasveer, Orbal, or Carrousel. They have the advantage that they are relatively easy to maintain and are resilient to shock loads that often occur in smaller communities (i.e. at breakfast time and in the evening). Oxidation ditches are installed commonly as 'fit & forget' technology, with typical design parameters of a hydraulic retention time of 24 – 48 hours, and a sludge age of 12 – 20 days. This compares with nitrifying activated sludge plants having a retention time of 8 hours, and a sludge age of 8 – 12 days.Deep shaft / Vertical treatment

Where land is in short supply sewage may be treated by injection of oxygen into a pressured return sludge stream which is injected into the base of a deep columnar tank buried in the ground. Such shafts may be up to deep and are filled with sewage liquor. As the sewage rises the oxygen forced into solution by the pressure at the base of the shaft breaks out as molecular oxygen providing a highly efficient source of oxygen for the activated sludge biota. The rising oxygen and injected return sludge provide the physical mechanism for mixing of the sewage and sludge. Mixed sludge and sewage is decanted at the surface and separated into supernatant and sludge components. The efficiency of deep shaft treatment can be high. Surface aerators are commonly quoted as having an aeration efficiency of 0.5–1.5 kg O2/kWh (1.1–3.3 lb O2/kWh), diffused aeration as 1.5–2.5 kg O2/kWh (3.3–5.5 lb O2/kWh). Deep Shaft claims 5–8 kg O2/kWh (11–18 lb O2/kWh). However, the costs of construction are high. Deep Shaft has seen the greatest uptake in Japan, because of the land area issues. Deep Shaft was developed by ICI, as a spin-off from their Pruteen process. In the UK it is found at three sites: Tilbury, Anglian water, treating a wastewater with a high industrial contribution; Southport, United Utilities, because of land space issues; and Billingham, ICI, again treating industrial effluent, and built (after the Tilbury shafts) by ICI to help the agent sell more. DeepShaft is a patented, licensed, process. The licensee has changed several times and currently (2015) Noram Engineering sells it.Surface-aerated basins

Most biological oxidation processes for treating industrial wastewaters have in common the use of oxygen (or air) and microbial action. Surface-aerated basins achieve 80 to 90% removal of BOD with retention times of 1 to 10 days.Available at CSA Illumina websiteThe basins may range in depth from and utilize motor-driven aerators floating on the surface of the wastewater. In an aerated basin system, the aerators provide two functions: they transfer air into the basins required by the biological oxidation reactions, and they provide the mixing required for dispersing the air and for contacting the reactants (that is, oxygen, wastewater and microbes). Typically, the floating surface aerators are rated to deliver the amount of air equivalent to 1.8 to 2.7 kilograms O2/ kWh (4.0 to 6.0 lb O2/kWh). However, they do not provide as good mixing as is normally achieved in activated sludge systems and therefore aerated basins do not achieve the same performance level as activated sludge units. Biological oxidation processes are sensitive to temperature and, between , the rate of biological reactions increase with temperature. Most surface aerated vessels operate at between .

Sequencing batch reactors (SBRs)

Sequencing batch reactor

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatmen ...

s (SBRs) treat wastewater in batches within the same vessel. This means that the bioreactor and final clarifier are not separated in space but in a timed sequence. The installation consists of at least two identically equipped tanks with a common inlet, which can be alternated between them. While one tank is in settle/decant mode the other is aerating and filling.

Aeration methods

Diffused aeration

Sewage liquor is run into deep tanks with

Sewage liquor is run into deep tanks with diffuser

Diffuser may refer to:

Aerodynamics

* Diffuser (automotive), a shaped section of a car's underbody which improves the car's aerodynamic properties

* Part of a jet engine air intake, especially when operated at supersonic speeds

* The channel bet ...

grid aeration systems that are attached to the floor. These are like the diffused airstone An airstone, also called an aquarium bubbler, is a piece of aquarium furniture, traditionally a piece of limewood or porous stone, whose purpose is to gradually diffuse air into the tank, eliminating the noise and large bubbles of conventional air ...

used in tropical fish

Tropical fish are generally those fish found in aquatic tropical environments around the world. Fishkeepers often keep tropical fish in freshwater and saltwater aquariums. The term "tropical fish" is not a taxonomic group, but rather is a ge ...

tanks but on a much larger scale. Air is pumped through the blocks and the curtain of bubbles formed both oxygenates the liquor and also provides the necessary mixing action. Where capacity is limited or the sewage is unusually strong or difficult to treat, oxygen may be used instead of air. Typically, the air is generated by some type of air blower.

Surface aerators (cones)

Vertically mounted tubes of up to diameter extending from just above the base of a deep concrete tank to just below the surface of the sewage liquor. A typical shaft might be high. At the surface end, the tube is formed into a cone with helical vanes attached to the inner surface. When the tube is rotated, the vanes spin liquor up and out of the cones drawing new sewage liquor from the base of the tank. In many works, each cone is located in a separate cell that can be isolated from the remaining cells if required for maintenance. Some works may have two cones to a cell and some large works may have 4 cones per cell.

Vertically mounted tubes of up to diameter extending from just above the base of a deep concrete tank to just below the surface of the sewage liquor. A typical shaft might be high. At the surface end, the tube is formed into a cone with helical vanes attached to the inner surface. When the tube is rotated, the vanes spin liquor up and out of the cones drawing new sewage liquor from the base of the tank. In many works, each cone is located in a separate cell that can be isolated from the remaining cells if required for maintenance. Some works may have two cones to a cell and some large works may have 4 cones per cell.

Pure oxygen aeration

Pure oxygen activated sludge aeration systems are sealed-tank reactor vessels with surface aerator type impellers mounted within the tanks at the oxygen carbon liquor surface interface. The amount of oxygen entrainment, or DO (Dissolved Oxygen), can be controlled by a weir adjusted level control, and a vent gas oxygen controlled oxygen feed valve. Oxygen is generated on site by cryogenic distillation of air,pressure swing adsorption

Pressure swing adsorption (PSA) is a technique used to separate some gas species from a mixture of gases (typically air) under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at ne ...

, or other methods. These systems are used where wastewater plant space is at a premium and high sewage throughput is required as high energy costs are involved in purifying oxygen.

Recent developments

A new development of the activated sludge process is theNereda

Nereda is a wastewater treatment technology invented by Mark van Loosdrecht of the Delft University of Technology in the Netherlands. The technology is based on aerobic granulation and is a modification of the activated sludge process.

Aerobic g ...

process which produces a granular sludge that settles very well (the sludge volume index is reduced from ). A new process reactor system is created to take advantage of this quick settling sludge and is integrated into the aeration tank instead of having a separate unit outside. About 30 Nereda wastewater treatment plants worldwide are operational, under construction or under design, varying in size from 5,000 up to 858,000 person equivalent.

Issues

Process upsets

Sludge bulking can occur which makes activated sludge difficult to settle and frequently has an adverse impact on final effluent quality. Treating sludge bulking and managing the plant to avoid a recurrence requires skilled management and may require full-time staffing of a works to allow immediate intervention. The discharge of toxic industrialpollution

Pollution is the introduction of contaminants into the natural environment that cause adverse change. Pollution can take the form of any substance (solid, liquid, or gas) or energy (such as radioactivity, heat, sound, or light). Pollutants, the ...

to treatment plants designed primarily to treat domestic sewage can create process upsets.

Costs and technology choice

The activated sludge process is an example for a more high-tech, energy intensive or "mechanized" process that is relatively expensive compared to some other wastewater treatment systems. It can provide a very high level of treatment. Activated sludge plants are wholly dependent on an electrical supply to power the aerators to transfer settled solids back to the aeration tank inlet, and in many cases to pump waste sludge and final effluent. In some works untreated sewage is lifted by pumps to the head-works to provide sufficient fall through the works to enable a satisfactory discharge head for the final effluent. Alternative technologies such astrickling filter

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and c ...

treatment requires much less power and can operate on gravity alone.

History

The activated sludge process was discovered in 1913 in the

The activated sludge process was discovered in 1913 in the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Europe, off the north-western coast of the European mainland, continental mainland. It comprises England, Scotlan ...

by two engineers, Edward Ardern and W.T. Lockett, who were conducting research for the Manchester Corporation Rivers Department at Davyhulme Sewage Works. In 1912, Dr. Gilbert Fowler, a scientist at the University of Manchester

, mottoeng = Knowledge, Wisdom, Humanity

, established = 2004 – University of Manchester Predecessor institutions: 1956 – UMIST (as university college; university 1994) 1904 – Victoria University of Manchester 1880 – Victoria Univ ...

, observed experiments being conducted at the Lawrence Experiment Station at Massachusetts

Massachusetts (Massachusett: ''Muhsachuweesut Massachusett_writing_systems.html" ;"title="nowiki/> məhswatʃəwiːsət.html" ;"title="Massachusett writing systems">məhswatʃəwiːsət">Massachusett writing systems">məhswatʃəwiːsət'' En ...

involving the aeration of sewage in a bottle that had been coated with algae. Fowler's engineering colleagues, Ardern and Lockett, experimented on treating sewage in a draw-and-fill reactor, which produced a highly treated effluent. They aerated the waste-water continuously for about a month and were able to achieve a complete nitrification of the sample material. Believing that the sludge had been activated (in a similar manner to activated carbon) the process was named ''activated sludge''. Not until much later was it realized that what had actually occurred was a means to concentrate biological organisms, decoupling the liquid retention time (ideally, low, for a compact treatment system) from the solids retention time (ideally, fairly high, for an effluent low in BOD5 and ammonia.)

Their results were published in their seminal 1914 paper, and the first full-scale continuous-flow system was installed at Worcester

Worcester may refer to:

Places United Kingdom

* Worcester, England, a city and the county town of Worcestershire in England

** Worcester (UK Parliament constituency), an area represented by a Member of Parliament

* Worcester Park, London, Engla ...

two years later. In the aftermath of the First World War

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fightin ...

the new treatment method spread rapidly, especially to the US, Denmark

)

, song = ( en, "King Christian stood by the lofty mast")

, song_type = National and royal anthem

, image_map = EU-Denmark.svg

, map_caption =

, subdivision_type = Sovereign state

, subdivision_name = Kingdom of Denmark

, establish ...

, Germany

Germany,, officially the Federal Republic of Germany, is a country in Central Europe. It is the second most populous country in Europe after Russia, and the most populous member state of the European Union. Germany is situated betwe ...

and Canada

Canada is a country in North America. Its ten provinces and three territories extend from the Atlantic Ocean to the Pacific Ocean and northward into the Arctic Ocean, covering over , making it the world's second-largest country by tot ...

. By the late 1930s, the activated sludge treatment became a well-known biological wastewater treatment process in those countries where sewer systems and sewage treatment plant

Sewage treatment (or domestic wastewater treatment, municipal wastewater treatment) is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding en ...

s were common.

See also

*Activated sludge model

Activated sludge model is a generic name for a group of mathematical methods to model activated sludge systems. The research in this area is coordinated by a task group of the International Water Association (IWA). Activated sludge models are used ...

*Aerated lagoon

An aerated lagoon (or aerated pond) is a simple wastewater treatment system consisting of a pond with artificial aeration to promote the biological oxidation of wastewaters.

There are many other aerobic biological processes for treatment of waste ...

*Aerobic granulation

The biological treatment of wastewater in the sewage treatment plant is often accomplished using conventional activated sludge systems. These systems generally require large surface areas for treatment and biomass separation units due to the genera ...

* Aerobic granular reactor

*Aerobic treatment system

An aerobic treatment system (ATS), often called an aerobic septic system, is a small scale sewage treatment system similar to a septic tank system, but which uses an Cellular respiration, aerobic process for digestion rather than just the Fermentat ...

* Industrial wastewater treatment

*List of wastewater treatment technologies

This page consists of a list of wastewater treatment technologies:

See also

*Agricultural wastewater treatment

*Industrial wastewater treatment

*List of solid waste treatment technologies

* Waste treatment technologies

*Water purification

*Sewa ...

*Membrane bioreactor

Membrane bioreactor (MBR) is a combination of membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater ...

*Rotating biological contactor

A rotating biological contactor or RBC is a biological fixed-film treatment process used in the secondary treatment of wastewater following primary treatment. The primary treatment process involves removal of grit, sand and coarse suspended mate ...

* Sludge bulking

*Thermal hydrolysis

Thermal hydrolysis is a process used for treating industrial waste, municipal solid waste and sewage sludge.

Description

Thermal hydrolysis is a two-stage process combining high-pressure boiling of waste or sludge followed by a rapid decompressio ...

References

{{Authority control Sewerage Environmental engineering Chemical engineering