API Oil–water Separator on:

[Wikipedia]

[Google]

[Amazon]

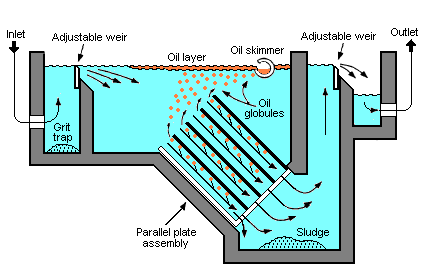

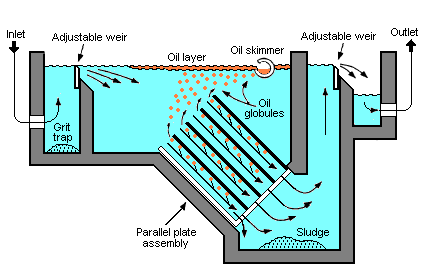

An API oil–water separator is a device designed to separate gross amounts of oil and suspended solids from

Plate separators, or Coalescing Plate Separators are similar to API separators, in that they are based on Stokes Law principles, but include inclined plate assemblies (also known as parallel packs). The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Coalescing plate separators may not be effective in situation where water chemicals or suspended solids restrict or prevent oil droplets coalesce. In operation it is intended that sediment will slide down the topside of each parallel plate, however in many practical situations the sediment can adhere to the plates requiring periodic removal and cleaning. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates can enhance the degree of oil-water separation for oil droplets above 50 micron in size. Alternatively parallel plate separators are added to the design of API Separators and require less space than a conventional API separator to achieve a similar degree of separation.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The parallel plates provide more surface for suspended oil droplets to coalesce into larger globules. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

Plate separators, or Coalescing Plate Separators are similar to API separators, in that they are based on Stokes Law principles, but include inclined plate assemblies (also known as parallel packs). The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Coalescing plate separators may not be effective in situation where water chemicals or suspended solids restrict or prevent oil droplets coalesce. In operation it is intended that sediment will slide down the topside of each parallel plate, however in many practical situations the sediment can adhere to the plates requiring periodic removal and cleaning. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates can enhance the degree of oil-water separation for oil droplets above 50 micron in size. Alternatively parallel plate separators are added to the design of API Separators and require less space than a conventional API separator to achieve a similar degree of separation.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The parallel plates provide more surface for suspended oil droplets to coalesce into larger globules. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

Evoqua

. The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in Philadelphia. Since that time, virtually all of the refineries worldwide have installed API separators as a first primary stage of their oily

Photographs, drawings and design discussion of gravimetric API Separators

Oil/Water Separators

Diagrams and description of separators using plastic parallel plate packing.

Oil-in-water Separation

Good discussion and explanation of

Monroe Environmental API Separators

Manufacturer, drawings, photographs, diagrams, case studies, and descriptions.

Oil Water Separators

Features, Case Studies, Technology, Photos

AFL Industries

Manufacturer. OWS descriptions and drawings {{DEFAULTSORT:API oil-water separator Oil refineries Liquid-liquid separation Waste treatment technology Chemical equipment

industrial wastewater

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a s ...

produced at oil refineries

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied pet ...

, petrochemical plants, chemical plant

A chemical plant is an industrial process plant that manufactures (or otherwise processes) chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transfor ...

s, natural gas processing plants and other industrial oily water sources. The API separator is a gravity separation device designed by using Stokes Law

In fluid dynamics, Stokes' law gives the frictional force – also called drag force – exerted on spherical objects moving at very small Reynolds numbers in a viscous fluid. It was derived by George Gabriel Stokes in 1851 by solving the S ...

to define the rise velocity of oil droplets based on their density

Density (volumetric mass density or specific mass) is the ratio of a substance's mass to its volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' (or ''d'') can also be u ...

and size. The design is based on the specific gravity

Relative density, also called specific gravity, is a dimensionless quantity defined as the ratio of the density (mass of a unit volume) of a substance to the density of a given reference material. Specific gravity for solids and liquids is nea ...

difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. The suspended solids settles to the bottom of the separator as a sediment layer, the oil rises to top of the separator and the cleansed wastewater is the middle layer between the oil layer and the solids.

The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute

The American Petroleum Institute (API) is the largest U.S. trade association for the oil and natural gas industry. It claims to represent nearly 600 corporations involved in extraction of petroleum, production, oil refinery, refinement, pipeline ...

(API).

Description of the design and operation

The API separator is a gravity separation device designed usingStokes' law

In fluid dynamics, Stokes' law gives the frictional force – also called drag force – exerted on spherical objects moving at very small Reynolds numbers in a viscous fluid. It was derived by George Gabriel Stokes in 1851 by solving the S ...

principles that define the rise velocity of oil droplets based on their density

Density (volumetric mass density or specific mass) is the ratio of a substance's mass to its volume. The symbol most often used for density is ''ρ'' (the lower case Greek letter rho), although the Latin letter ''D'' (or ''d'') can also be u ...

, size and water properties. The design of the separator is based on the specific gravity

Relative density, also called specific gravity, is a dimensionless quantity defined as the ratio of the density (mass of a unit volume) of a substance to the density of a given reference material. Specific gravity for solids and liquids is nea ...

difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom. The API Design Standards, when correctly applied, make adjustments to the geometry, design and size of the separator beyond simple Stokes Law principles. This includes allowances for water flow entrance and exit turbulence losses as well as other factors. API Specification 421 requires a minimum length to width ratio of 5:1 and minimum depth-to-width ratio of 0.3:0.5.”Schultz, Thomas. “Get the Most out of API Separators.” Chemical Engineering. July 2005.

Typically, the oil layer is skimmed off and subsequently re-processed or disposed of, and the bottom sediment layer is removed by a chain and flight scraper (or similar device) and a sludge pump. The water layer is sent to further treatment for additional removal of any residual oil and then to some type of biological treatment unit for removal of undesirable dissolved chemical compounds.

Many oils can be recovered from open water surfaces by skimming devices. Considered a dependable and cheap way to remove oil, grease and other hydrocarbons from water, oil skimmers can sometimes achieve the desired level of water purity. At other times, skimming is also a cost-efficient method to remove most of the oil before using membrane filters and chemical processes. Skimmers will prevent filters from blinding prematurely and keep chemical costs down because there is less oil to process.

Because grease skimming involves higher viscosity hydrocarbons, skimmers must be equipped with heaters powerful enough to keep grease fluid for discharge. If floating grease forms into solid clumps or mats, a spray bar, aerator or mechanical apparatus can be used to facilitate removal.

However, hydraulic oils and the majority of oils that have degraded to any extent will also have a soluble or emulsified component that will require further treatment to eliminate. Dissolving or emulsifying oil using surfactants or solvent

A solvent (from the Latin language, Latin ''wikt:solvo#Latin, solvō'', "loosen, untie, solve") is a substance that dissolves a solute, resulting in a Solution (chemistry), solution. A solvent is usually a liquid but can also be a solid, a gas ...

s usually exacerbates the problem rather than solving it, producing wastewater that is more difficult to treat.

Design Limitations

API design separators, and similar gravity tanks, are not intended to be effective when any of the following conditions apply to the feed conditions: * Mean Oil droplets size in the feed is less than 150 micron * Oil density is greater than 925 kg/m3 * Suspended solids are adhering to the oil meaning the 'effective' oil density is greater than 925 kg/m3 * Water temperature less than 5 °C * There are high levels of dissolved hydrocarbons According to Stokes' Law, heavier oils require more retention time. In many cases where refineries have switched to heavier crude slates, the API separator’s efficiency has declined.Further treatment of API water discharges

Because of performance limitations the water discharged from API type separators usually requires several further processing stages before the treated water can be discharged or reused. Further water treatment is designed to remove oil droplets smaller than 150 micron, dissolved materials and hydrocarbons, heavier oils or other contaminants not removed by the API. Secondary treatment technologies include dissolved air flotation (DAF), Anaerobic and Aerobic biological treatment, Parallel Plate Separators, Hydrocyclone, Walnut Shell Filters and Media filters.Alternative technologies

Plate separators, or Coalescing Plate Separators are similar to API separators, in that they are based on Stokes Law principles, but include inclined plate assemblies (also known as parallel packs). The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Coalescing plate separators may not be effective in situation where water chemicals or suspended solids restrict or prevent oil droplets coalesce. In operation it is intended that sediment will slide down the topside of each parallel plate, however in many practical situations the sediment can adhere to the plates requiring periodic removal and cleaning. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates can enhance the degree of oil-water separation for oil droplets above 50 micron in size. Alternatively parallel plate separators are added to the design of API Separators and require less space than a conventional API separator to achieve a similar degree of separation.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The parallel plates provide more surface for suspended oil droplets to coalesce into larger globules. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

Plate separators, or Coalescing Plate Separators are similar to API separators, in that they are based on Stokes Law principles, but include inclined plate assemblies (also known as parallel packs). The underside of each parallel plate provides more surface for suspended oil droplets to coalesce into larger globules. Coalescing plate separators may not be effective in situation where water chemicals or suspended solids restrict or prevent oil droplets coalesce. In operation it is intended that sediment will slide down the topside of each parallel plate, however in many practical situations the sediment can adhere to the plates requiring periodic removal and cleaning. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates can enhance the degree of oil-water separation for oil droplets above 50 micron in size. Alternatively parallel plate separators are added to the design of API Separators and require less space than a conventional API separator to achieve a similar degree of separation.

Parallel plate separators are similar to API separators but they include tilted parallel plate assemblies (also known as parallel packs). The parallel plates provide more surface for suspended oil droplets to coalesce into larger globules. Such separators still depend upon the specific gravity between the suspended oil and the water. However, the parallel plates enhance the degree of oil-water separation. The result is that a parallel plate separator requires significantly less space than a conventional API separator to achieve the same degree of separation.

History

The API separator was developed by the API and the Rex Chain Belt Company (noEvoqua

. The first API separator was installed in 1933 at the Atlantic Refining Company (ARCO) refinery in Philadelphia. Since that time, virtually all of the refineries worldwide have installed API separators as a first primary stage of their oily

wastewater treatment

Wastewater treatment is a process which removes and eliminates contaminants from wastewater. It thus converts it into an effluent that can be returned to the water cycle. Once back in the water cycle, the effluent creates an acceptable impact on ...

plants. The majority of those refineries installed the API separators using the original design based on the specific gravity difference between oil and water. However, many refineries now use plastic parallel plate packing to enhance the gravity separation. Today regulations often require API separators with fixed or floating covers for volatile organic compound

Volatile organic compounds (VOCs) are organic compounds that have a high vapor pressure at room temperature. They are common and exist in a variety of settings and products, not limited to Indoor mold, house mold, Upholstery, upholstered furnitur ...

(VOC) control. Also, most API separators must be above ground for spill detection.

Other oil–water separation applications

There are other applications requiring oil-water separation. For example: *Oily water separator

An oily water separator (OWS) (marine) is a piece of equipment specific to the shipping or marine industry. It is used to separate oil and water mixtures into their separate components. This page refers exclusively to oily water separators aboard ...

s (OWS) for separating oil from the bilge water

The bilge of a ship or boat is the part of the Hull (watercraft), hull that would rest on the ground if the vessel were unsupported by water. The "turn of the bilge" is the transition from the bottom of a hull to the sides of a hull.

Internal ...

accumulated in ships as required by the international MARPOL Convention.

* Oil and water separators are commonly used in electrical substation

A substation is a part of an electrical generation, transmission, and distribution system. Substations transform voltage from high to low, or the reverse, or perform any of several other important functions. Between the generating station an ...

s. The transformer

In electrical engineering, a transformer is a passive component that transfers electrical energy from one electrical circuit to another circuit, or multiple Electrical network, circuits. A varying current in any coil of the transformer produces ...

s found in substations use a large amount of oil for cooling purposes. Moats are constructed surrounding unenclosed substations to catch any leaked oil, but these will also catch rainwater. Oil and water separators therefore provide a quicker and easier cleanup of an oil leak.

See also

*Pollution

Pollution is the introduction of contaminants into the natural environment that cause harm. Pollution can take the form of any substance (solid, liquid, or gas) or energy (such as radioactivity, heat, sound, or light). Pollutants, the component ...

* Wastewater

Wastewater (or waste water) is water generated after the use of freshwater, raw water, drinking water or saline water in a variety of deliberate applications or processes. Another definition of wastewater is "Used water from any combination of do ...

* Industrial wastewater treatment

Industrial wastewater treatment describes the processes used for Wastewater treatment, treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reus ...

* Industrial water treatment

Industrial may refer to:

Industry

* Industrial archaeology, the study of the history of the industry

* Industrial engineering, engineering dealing with the optimization of complex industrial processes or systems

* Industrial city, a city domina ...

* Centrifugal water–oil separator

* Induced gas flotation

* Wescorp Energy

References

External links

Photographs, drawings and design discussion of gravimetric API Separators

Oil/Water Separators

Diagrams and description of separators using plastic parallel plate packing.

Oil-in-water Separation

Good discussion and explanation of

wastewater treatment

Wastewater treatment is a process which removes and eliminates contaminants from wastewater. It thus converts it into an effluent that can be returned to the water cycle. Once back in the water cycle, the effluent creates an acceptable impact on ...

processes.

Monroe Environmental API Separators

Manufacturer, drawings, photographs, diagrams, case studies, and descriptions.

Oil Water Separators

Features, Case Studies, Technology, Photos

AFL Industries

Manufacturer. OWS descriptions and drawings {{DEFAULTSORT:API oil-water separator Oil refineries Liquid-liquid separation Waste treatment technology Chemical equipment

oil–water separator

An oil water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. There are many different types of oil-water separator. Each has different oil separation capability and are used in differ ...

Industrial water treatment