3D Textiles on:

[Wikipedia]

[Google]

[Amazon]

3D textiles are three-dimensional structures made with different manufacturing methods such as

3D textiles are three-dimensional structures made with different manufacturing methods such as

'' Vapor Laser Talon boots'' has 3D-printed footplates. ''Futurecraft STRUNG'' is another 3D printed variant belongs to Adidas.

Other applications of 3D textiles are:

Other applications of 3D textiles are:

3D textiles are three-dimensional structures made with different manufacturing methods such as

3D textiles are three-dimensional structures made with different manufacturing methods such as weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal th ...

, knitting

Knitting is a method by which yarn is manipulated to create a textile, or fabric. It is used to create many types of garments. Knitting may be done by hand or by machine.

Knitting creates stitches: loops of yarn in a row, either flat or i ...

, braiding, or nonwoven

Nonwoven fabric is a fabric-like material made from staple fibre (short) and long fibres (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabri ...

, or made with alternative technologies. 3D textiles are produced with three planar geometry, opposed to 2D textiles that are made on two planes.The weave in 2D textiles is perpendicular. The yarn is fed along two axis: length (x-axis) and width (y-axis), while 3D textiles also have a perpendicular weave, but they have an extra yarn with an angular feeding (z-axis) which creates thickness. 3D weaves are orthogonal

In mathematics, orthogonality is the generalization of the geometric notion of ''perpendicularity''.

By extension, orthogonality is also used to refer to the separation of specific features of a system. The term also has specialized meanings in ...

weave structures, multilayer structures, and angle interlocks. 3D textiles have more manufacturing opportunities, various properties, and a broader scope of applications. These textiles have a wide range of applications, but they are most commonly used where performance

A performance is an act of staging or presenting a play, concert, or other form of entertainment. It is also defined as the action or process of carrying out or accomplishing an action, task, or function.

Management science

In the work place ...

is the primary criterion, such as technical textiles. Composite materials, manufacturing is one of the significant areas of using 3D textiles.

3D structures have two kinds of structural formations, i.e., hollow and solid.

Types

3D fabrics can be formed with 3D weaving, 3D knitting, 3D braiding, non-woven methods and with many newer technologies, such as 3D printing, etc.3D weaving

There are several types of 3D woven fabrics that are commercially available; they can be classified according to their weaving technique. # 3D woven interlock fabrics, are 3D woven fabrics produced on a traditional 2Dweaving loom

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal th ...

, using proper weave design and techniques, it could either have the weaver/z-yarn going through all the thickness of the fabric or from layer to layer.

# 3D orthogonal

In mathematics, orthogonality is the generalization of the geometric notion of ''perpendicularity''.

By extension, orthogonality is also used to refer to the separation of specific features of a system. The term also has specialized meanings in ...

woven fabrics, are 3D woven fabrics produced on a special 3D weaving loom. The process to form such fabric was patented by Mohamed and Zhang. The architecture of the 3D orthogonal woven fabric consists of three different sets of yarns; warp yarns (y-yarn), weft yarns (x-yarn), and (z-yarn). The Z - yarn is placed in the through-thickness direction of the preform. In 3D orthogonal woven fabrics there is no interlacing between the warp and weft yarns and they are straight and perpendicular to each other. On the other hand, z-yarns combine the warp and the weft layers by interlacing (moving up and down) along the y-direction over the weft yarn. Interlacing occurs on the top and the bottom surface of the fabric.

Advantages

* 3D woven fabrics are very useful in applications where the composite structure is subjected to out-of-plane loading, thanks to the extra strength provided by the z-yarn in the through thickness dimension. Thus, it can better resist delamination, which is the separation of layers due to out-of-plane forces.F. C. Campbell, Manufacturing Processes For Advanced Composites, Oxford, UK: Elsevier, 2004. * 3D woven fabrics have a highformability Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experienc ...

, which means they can easily take the shape of the mold in case of complex composite designs.

* 3D woven fabrics have a highly porous structure, which decreases resin

In polymer chemistry and materials science, resin is a solid or highly viscous substance of plant or synthetic origin that is typically convertible into polymers. Resins are usually mixtures of organic compounds. This article focuses on natu ...

infusion time.

* 3D orthogonal woven fabrics have less or no yarn crimp (the difference in length of yarn, before and after weaving); therefore, mechanical properties of fibers are almost fully used in warp and weft directions. Thus, it could benefit from the maximum load carrying capacity of high performance fibers in these directions.

* The shape of 3D woven fabrics can be tapered in all three directions during the weaving process, producing near net shape fabrics such as I-beam

An I-beam, also known as H-beam (for universal column, UC), w-beam (for "wide flange"), universal beam (UB), rolled steel joist (RSJ), or double-T (especially in Polish language, Polish, Bulgarian language, Bulgarian, Spanish language, Spanish ...

s and stiffeners. This means that these preforms could be placed directly in the mold without any additional labor work.P. Schwartz, "Structure and Mechanics of Textile Fibre Assemblies", Woodhead publishing Ltd. 2008.

* There is no need for layering to create a part, because the single fabric has a considerable thickness that provides the full three-dimensional reinforcement.

* The 3D woven fabric can be molded into different shapes and can be used in biological applications to create replacement tissues

3D knitting

3D knitting is a method of forming an article of clothing directly from the yarns. Typical examples are socks and one piece tights. 3D knitted fabrics are also used for the production of certain reinforcement structures.3D braiding

Nonwoven

Non-woven 3D fabrics are made of short fibers (natural and cut filaments of synthetic yarn). They are comparatively less successful.3D composites

3D printing

3D printing has entered the world of clothing, with fashion designers experimenting with 3D-printed bikinis, shoes, and dresses.Bikini

"N-12" is a nylon bikini that was 3D printed byShapeways

Shapeways, Inc. is a global, 3D printing marketplace and service, publicly traded company. Users design and upload 3D printable files, and Shapeways prints the objects for them or others. Users can have objects printed in over 55 materials and f ...

.

Footwear and accessories

Nike is using 3D printing to prototype and manufacture the 2012 Vapor Laser Talon football shoe for players of American football, and New Balance is 3D manufacturing custom-fit shoes for athletes.Dresses

Though very expensive, the 3D printer also printed a dress.Dita Von Teese

Heather Renée Sweet (born September 28, 1972), known professionally as Dita Von Teese, is an American vedette, burlesque dancer, model, and businesswoman. She is credited with re-popularizing burlesque performance, earning the moniker "Queen ...

wore a 3D printed gown with a fibonacci sequence that was designed by Michael Schmidt and the architect, Francis Bitonti.

Auxetic textiles

Auxetic materials are materials which expand when stretched. They have the ability to be thicker when stretched. Fibers, yarns, and fabrics with auxetic properties are known as auxetic textiles. There are certain types of needle-punched nonwovens.3D printers

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer co ...

are also helpful in making auxetic

Auxetics are structures or materials that have a negative Poisson's ratio. When stretched, they become thicker perpendicular to the applied force. This occurs due to their particular internal structure and the way this deforms when the sample i ...

materials for textile

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the ...

s. These fabrics have advanced properties that are useful in making various composite materials and high-performance applications.

Use

Auxetic textiles are used in protective clothing, upholstery, sports, filtration, body armor,bulletproof vest

A bulletproof vest, also known as a ballistic vest or a bullet-resistant vest, is an item of body armor that helps absorb the impact and reduce or stop penetration to the torso from firearm-fired projectiles and fragmentation from explosions. T ...

s (because of shock absorbing properties), etc.

Applications

Other applications of 3D textiles are:

Other applications of 3D textiles are:

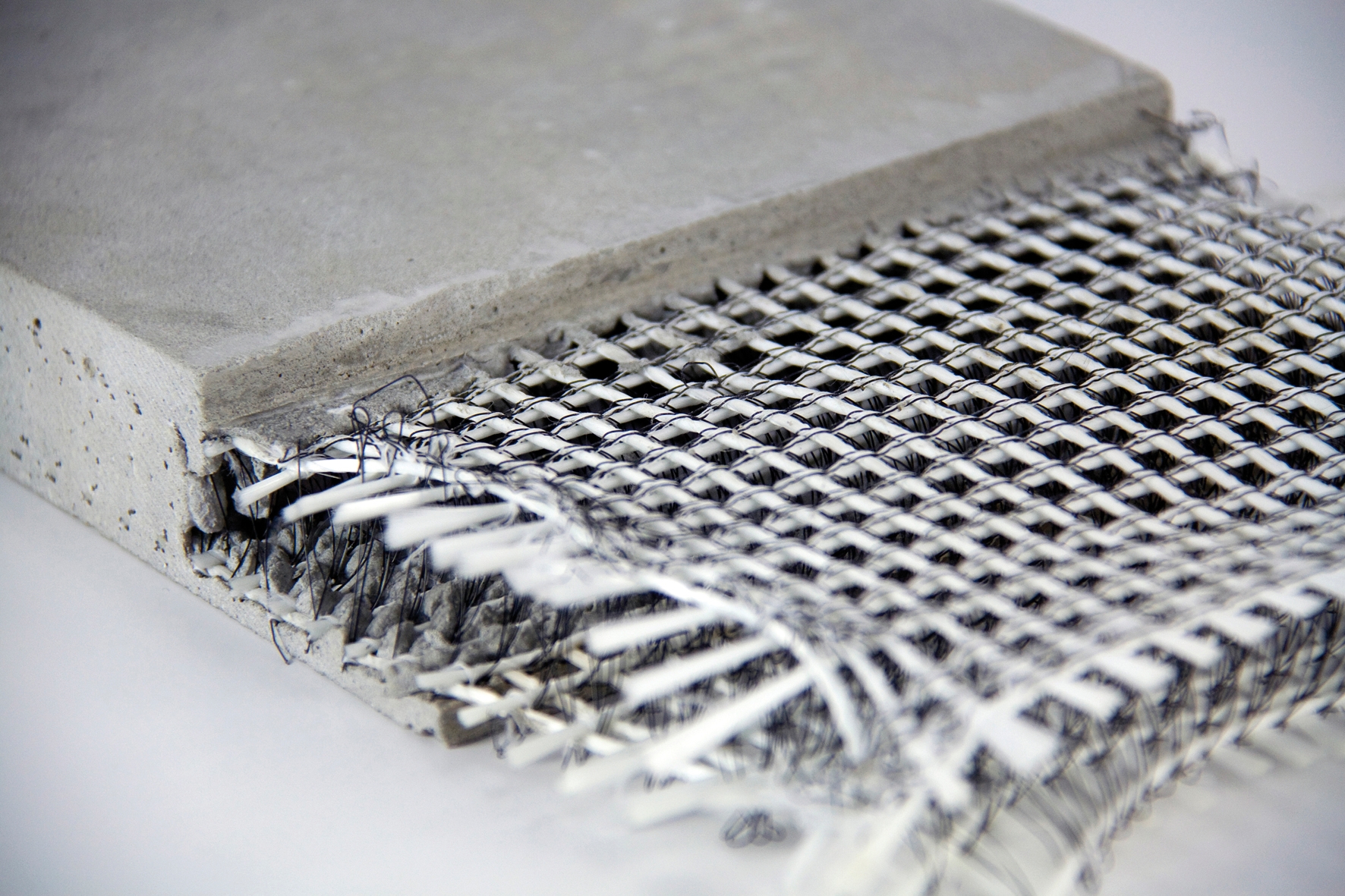

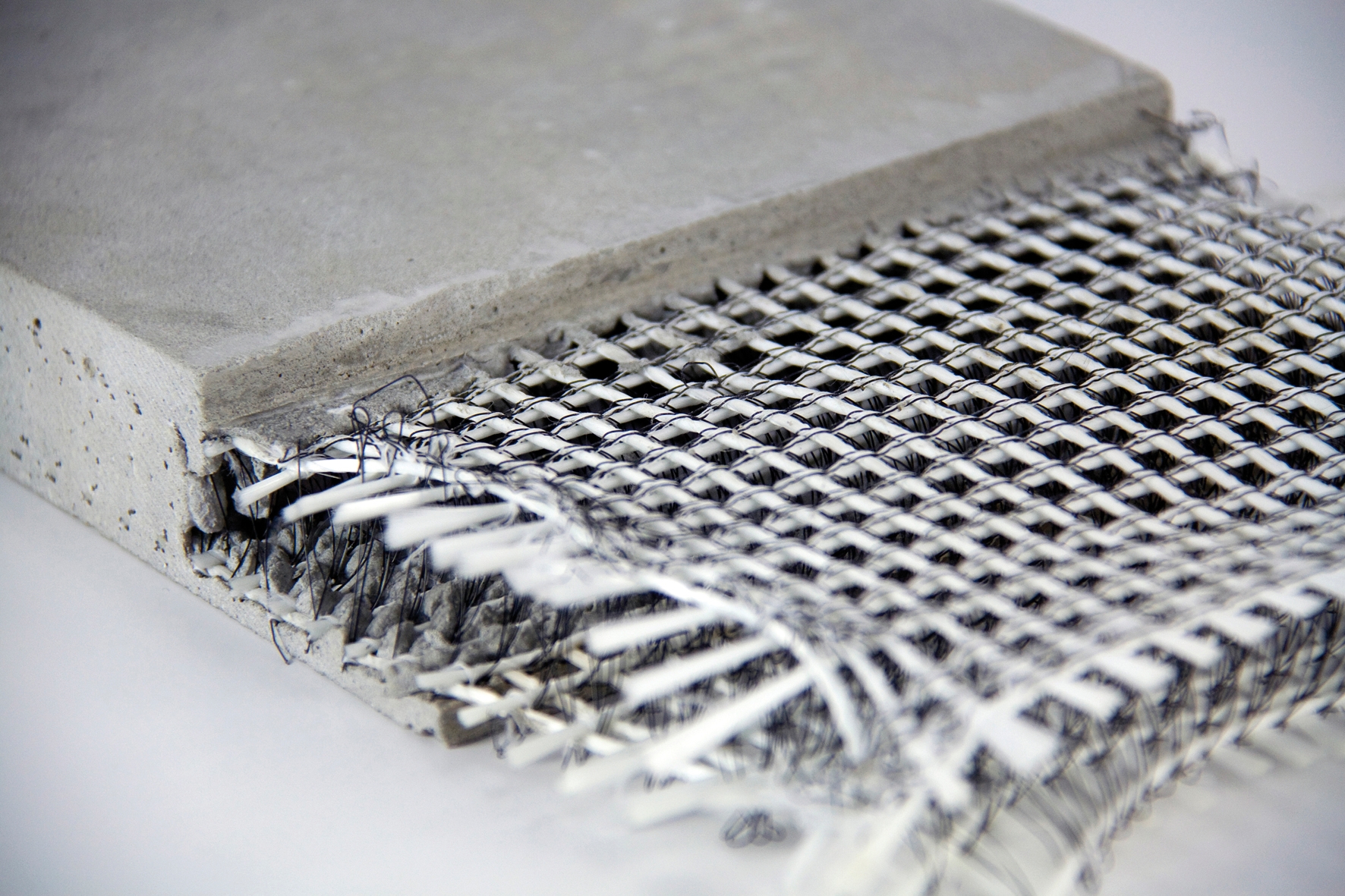

Composite materials

3D textiles are primarily used in manufacturing textile structural composites that are usable in military and construction.Medical textiles

3D textiles in medical textiles contribute to the following sectors:Wound care

In treating a wound over time by creating a favorable environment for healing, using both direct and indirect approaches, as well as preventing skin disintegration. Examples include 3D spacer fabrics.Vascular grafting

Tissue engineering

Implants

Medical textiles use tubular fabrics with carefully chosen materials that are biocompatible, nonallergic, and nontoxic. For example, Dyneema, PTFE, Polyester, and Teflon are used for implants. The material type varies depending on the implant area; for example, PTFE is preferred for stent implants due to its nonstick properties, while polyolefin is used for mesh implants. *Aerospace and automobile industry * Shoes * Filteration * Construction industryReferences

{{Reflist Textiles