|

Formability

Formability is the ability of a given metal workpiece to undergo plastic deformation without being damaged. The plastic deformation capacity of metallic materials, however, is limited to a certain extent, at which point, the material could experience tearing or fracture (breakage). Processes affected by the formability of a material include: rolling, extrusion, forging, rollforming, stamping, and hydroforming. Fracture strain A general parameter that indicates the formability and ductility of a material is the fracture strain which is determined by a uniaxial tensile test (see also fracture toughness). The strain identified by this test is defined by elongation with respect to a reference length. For example, a length of is used for the standardized uniaxial test of flat specimens, pursuant to EN 10002. It is important to note that deformation is homogeneous up to uniform elongation. Strain subsequently localizes until fracture occurs. Fracture strain is not an engineering ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically ductile (can be drawn into wires) and malleable (they can be hammered into thin sheets). These properties are the result of the '' metallic bond'' between the atoms or molecules of the metal. A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polythiazyl, polymeric sulfur nitride. In physics, a metal is generally regarded as any substance capable of conducting electricity at a temperature of absolute zero. Many elements and compounds that are not normally classified as metals become metallic under high pressures. For example, the nonmetal iodine gradually becomes a metal at a pressure of between 40 and 170 thousand times atmospheric pressure. Equally, some materials re ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

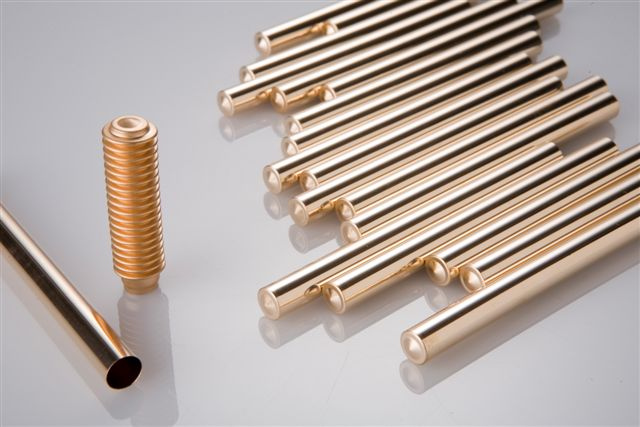

Deep Drawing

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses ( hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius. Deep drawing presses, especially in the Aerospace and Medical industries, require unparalleled accuracy and precision. Sheet hydroforming presses do complex draw work. Bed size, tonnage, stroke, speed, and more ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IDDRG

International Deep Drawing Research Group (IDDRG) Background The International Deep Drawing Research GroupIDDRG focuses on sheet metal research in industry and academia. It was started 1957 as an organization of national groups.Col, A.: “How started IDDRG?” in ‘Tools and Technologies for the Processing of Ultra High Strength Steels´, IDDRG2010 Conference Proceedings, Kolleck, R. (ed.), Verlag der Technischen Universität Graz, 2010, . The original focus was on the fabrication of cups hence the name Deep Drawing Research Group. At the initial meeting the purpose was enlarged to do cooperative research on tests, materials, and processes. Such work included for example, methods for determining the strain hardening exponent n, the anisotropy-values ( lankford coefficient), as well as other tests for sheet metal formability and, later, forming limit diagrams.Marciniak, Z.; Duncan, J.L.; Hu S.J.: “The Mechanics of Sheet Metal Forming”, 2nd edition, Butterworth-Heinemann, 20 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal Forming Analysis

For sheet metal forming analysis within the metal forming process, a successful technique requires a non-contact optical 3D deformation measuring system. The system analyzes, calculates and documents deformations of sheet metal parts, for example. It provides the 3D coordinates of the component's surface as well as the distribution of major and minor strain on the surface and the material thickness reduction. In the Forming Limit Diagram, the measured deformations are compared to the material characteristics. The system supports optimization processes in sheet metal forming by means of; * Fast detection of critical deformation areas * Solving complex forming problems * Verification of numerical simulations * Verification of FE models * Creation of Forming Limit Curves, FLC * Comparison of measured deformations to the material characteristics by means of a Forming Limit Diagram. The optical forming analysis with Forming analysis system provides for precise and fast measurement of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

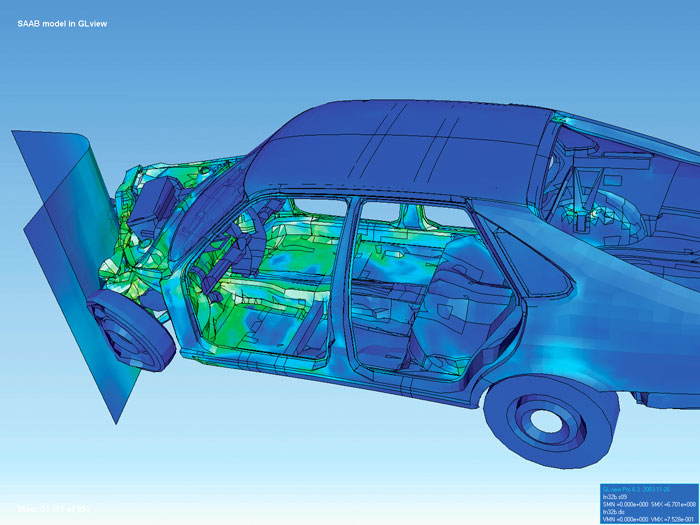

Sheet Metal Forming Simulation

Today the metal forming industry is making increasing use of simulation to evaluate the performing of dies, processes and blanks prior to building try-out tooling. Finite element analysis (FEA) is the most common method of simulating sheet metal forming operations to determine whether a proposed design will produce parts free of defects such as fracture or wrinkling. Sheet metal forming challenges Sheet metal forming, which is often referred to as stamping, is a process in which a piece of sheet metal, referred to as the blank, is formed by stretching between a punch and a die. The most painful and most frequent defects are wrinkles, thinning, springback and splits or cracks. Few methods are being used around the industry to cope with the main defects, based on the experience of the technicians. However, the correct process is the most vital, since it involves the correct geometry followed by number of steps to reach at final geometry. Which demands for specific experience or highe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finite-element Method

The finite element method (FEM) is a popular method for numerically solving differential equations arising in engineering and mathematical modeling. Typical problem areas of interest include the traditional fields of structural analysis, heat transfer, fluid flow, mass transport, and electromagnetic potential. The FEM is a general numerical method for solving partial differential equations in two or three space variables (i.e., some boundary value problems). To solve a problem, the FEM subdivides a large system into smaller, simpler parts that are called finite elements. This is achieved by a particular space discretization in the space dimensions, which is implemented by the construction of a mesh of the object: the numerical domain for the solution, which has a finite number of points. The finite element method formulation of a boundary value problem finally results in a system of algebraic equations. The method approximates the unknown function over the domain. The simple ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nucleation

In thermodynamics, nucleation is the first step in the formation of either a new thermodynamic phase or structure via self-assembly or self-organization within a substance or mixture. Nucleation is typically defined to be the process that determines how long an observer has to wait before the new phase or self-organized structure appears. For example, if a volume of water is cooled (at atmospheric pressure) below 0°C, it will tend to freeze into ice, but volumes of water cooled only a few degrees below 0°C often stay completely free of ice for long periods (supercooling). At these conditions, nucleation of ice is either slow or does not occur at all. However, at lower temperatures nucleation is fast, and ice crystals appear after little or no delay. Nucleation is a common mechanism which generates first-order phase transitions, and it is the start of the process of forming a new thermodynamic phase. In contrast, new phases at continuous phase transitions start to form im ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ductile

Ductility is a mechanical property commonly described as a material's amenability to drawing (e.g. into wire). In materials science, ductility is defined by the degree to which a material can sustain plastic deformation under tensile stress before failure. Ductility is an important consideration in engineering and manufacturing. It defines a material's suitability for certain manufacturing operations (such as cold working) and its capacity to absorb mechanical overload.. Some metals that are generally described as ductile include gold and copper. However, not all metals experience ductile failure as some can be characterized with brittle failure like cast iron. Polymers generally can be viewed as ductile materials as they typically allow for plastic deformation. Malleability, a similar mechanical property, is characterized by a material's ability to deform plastically without failure under compressive stress. Historically, materials were considered malleable if they were ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forming Limit Diagram

A forming limit diagram, also known as a forming limit curve, is used in sheet metal forming for predicting forming behavior of sheet metal. The diagram attempts to provide a graphical description of material failure tests, such as a punched dome test. In order to determine whether a given region has failed, a mechanical test is performed. The mechanical test is performed by placing a circular mark on the work piece prior to deformation, and then measuring the post-deformation ellipse that is generated from the action on this circle. By repeating the mechanical test to generate a range of stress states, the formability limit diagram can be generated as a line at which failure is onset (see also formability). Description The semi-axes of the ellipse formed in this circle allow for the measurement of relative strain in two primary directions, known as the major and minor directions, which correspond to the major and minor semi-axes of the ellipse. Under the assumption of path i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lankford Coefficient

The Lankford coefficient (also called Lankford value, R-value, or plastic strain ratio) is a measure of the plastic anisotropy of a rolled sheet metal. This scalar quantity is used extensively as an indicator of the formability of recrystallized low-carbon steel sheets.Ken-ichiro Mori, ''Simulation of Materials Processing: Theory, Methods and Applications'', (), p. 436 Definition If x and y are the coordinate directions in the plane of rolling and z is the thickness direction, then the R-value is given by : R = \cfrac where \epsilon^p_ is the in-plane plastic strain, transverse to the loading direction, and \epsilon^p_ is the plastic strain through-the-thickness. ISO 10113:202/ref> More recent studies have shown that the R-value of a material can depend strongly on the strain even at small strains . In practice, the R value is usually measured at 20% elongation in a tensile test. For sheet metals, the R values are usually determined for three different directi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Anisotropy

Anisotropy () is the property of a material which allows it to change or assume different properties in different directions, as opposed to isotropy. It can be defined as a difference, when measured along different axes, in a material's physical or mechanical properties ( absorbance, refractive index, conductivity, tensile strength, etc.). An example of anisotropy is light coming through a polarizer. Another is wood, which is easier to split along its grain than across it. Fields of interest Computer graphics In the field of computer graphics, an anisotropic surface changes in appearance as it rotates about its geometric normal, as is the case with velvet. Anisotropic filtering (AF) is a method of enhancing the image quality of textures on surfaces that are far away and steeply angled with respect to the point of view. Older techniques, such as bilinear and trilinear filtering, do not take into account the angle a surface is viewed from, which can result in alias ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |