|

Washdown

Washdown (also wash down) is the process of cleaning or washing a surface for appearance, sanitation, or removal of contamination. It may involve pressure washing. Sometimes wash down involves rinsing with fresh water; other times it involves use of detergents and other chemicals. Food processing and packaging machinery Regulations for processing sensitive products such as food and pharmaceuticals require periodic thorough washing and sanitizing. Some equipment can be moved to a central washing facility. Other machinery must be cleaned in place using portable specialized washing equipment. High-pressure cleaning is used with water and cleaning chemicals. A washdown is usually a manual operation and is designed to kill bacteria and other microorganisms. Automatic cleaning of industrial equipment is often carried out by clean-in-place (CIP) and/or steam-in-place (SIP) operations. CIP( CIP) systems often make use of Programmable logic controllers and SCADA software. Decks ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Washing

Pressure washing or power washing is the use of high-pressure water spray to remove loose paint, mold, grime, dust, mud, and dirt from surfaces and objects such as buildings, vehicles and concrete surfaces. The volume of a mechanical pressure washer is expressed in gallons or liters per minute, often designed into the pump and not variable. The pressure, expressed in pounds per square inch, pascals, or bar, is designed into the pump but can be varied by adjusting the unloader valve. Machines that produce pressures from 750 to 30,000 psi (5 to 200 MPa) or more are available. The terms pressure washing and power washing are used interchangeably in many scenarios, and there is some debate as to whether they are actually different processes. A pressure washing surface cleaner is a tool consisting of two to four high-pressure jets on a rotating bar that swivels when water is flowing. This action creates a uniformed cleaning pattern that can clean flat surfaces at a rapid rate. H ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clean-in-place

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, equipment, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers. CIP employs turbulent flow through piping, and/or spray balls for large surfaces. In some cases, CIP can also be accomplished with fill, soak and agitate. Up to the 1950s, closed systems were disassembled and cleaned manually. The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics. The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radioactive Contamination

Radioactive contamination, also called radiological pollution, is the deposition of, or presence of radioactive substances on surfaces or within solids, liquids, or gases (including the human body), where their presence is unintended or undesirable (from the International Atomic Energy Agency (IAEA) definition). Such contamination presents a hazard because the radioactive decay of the contaminants, produces ionizing radiation (namely alpha, beta, gamma rays and free neutrons). The degree of hazard is determined by the concentration of the contaminants, the energy of the radiation being emitted, the type of radiation, and the proximity of the contamination to organs of the body. It is important to be clear that the contamination gives rise to the radiation hazard, and the terms "radiation" and "contamination" are not interchangeable. The sources of radioactive pollution can be classified into two groups: natural and man-made. Following an atmospheric nuclear weapon discharge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Good Manufacturing Practice

Current good manufacturing practices (cGMP) are those conforming to the guidelines recommended by relevant agencies. Those agencies control the authorization and licensing of the manufacture and sale of food and beverages, cosmetics, pharmaceutical products, dietary supplements, and medical devices. These guidelines provide minimum requirements that a manufacturer must meet to assure that their products are consistently high in quality, from batch to batch, for their intended use. The rules that govern each industry may differ significantly; however, the main purpose of GMP is always to prevent harm from occurring to the end user. Additional tenets include ensuring the end product is free from contamination, that it is consistent in its manufacture, that its manufacture has been well documented, that personnel are well trained, and that the product has been checked for quality more than just at the end phase. GMP is typically ensured through the effective use of a quality managemen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleaning The Hull Sea Scout Fred

Cleaning is the process of removing unwanted substances, such as dirt, infectious agents, and other impurities, from an object or environment. Cleaning is often performed for aesthetic, hygienic, functional, environmental, or safety purposes. Cleaning occurs in many different contexts, and uses many different methods. Several occupations are devoted to cleaning. Contexts Cleaning occurs in various commercial, domestic, personal, and environmental contexts, which differ in scale and requirements. * Commercial cleaning, in business or other commercial settings ** Terminal cleaning, in healthcare settings * Environmental remediation, the removal of pollution or contaminants from the natural environment * Housekeeping, including spring cleaning * Hygiene, including personal grooming Methods Cleaning is broadly achieved through mechanical action and/or solvent action; many methods rely on both processes. * Washing, usually done with water and often some kind of soap or detergent * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

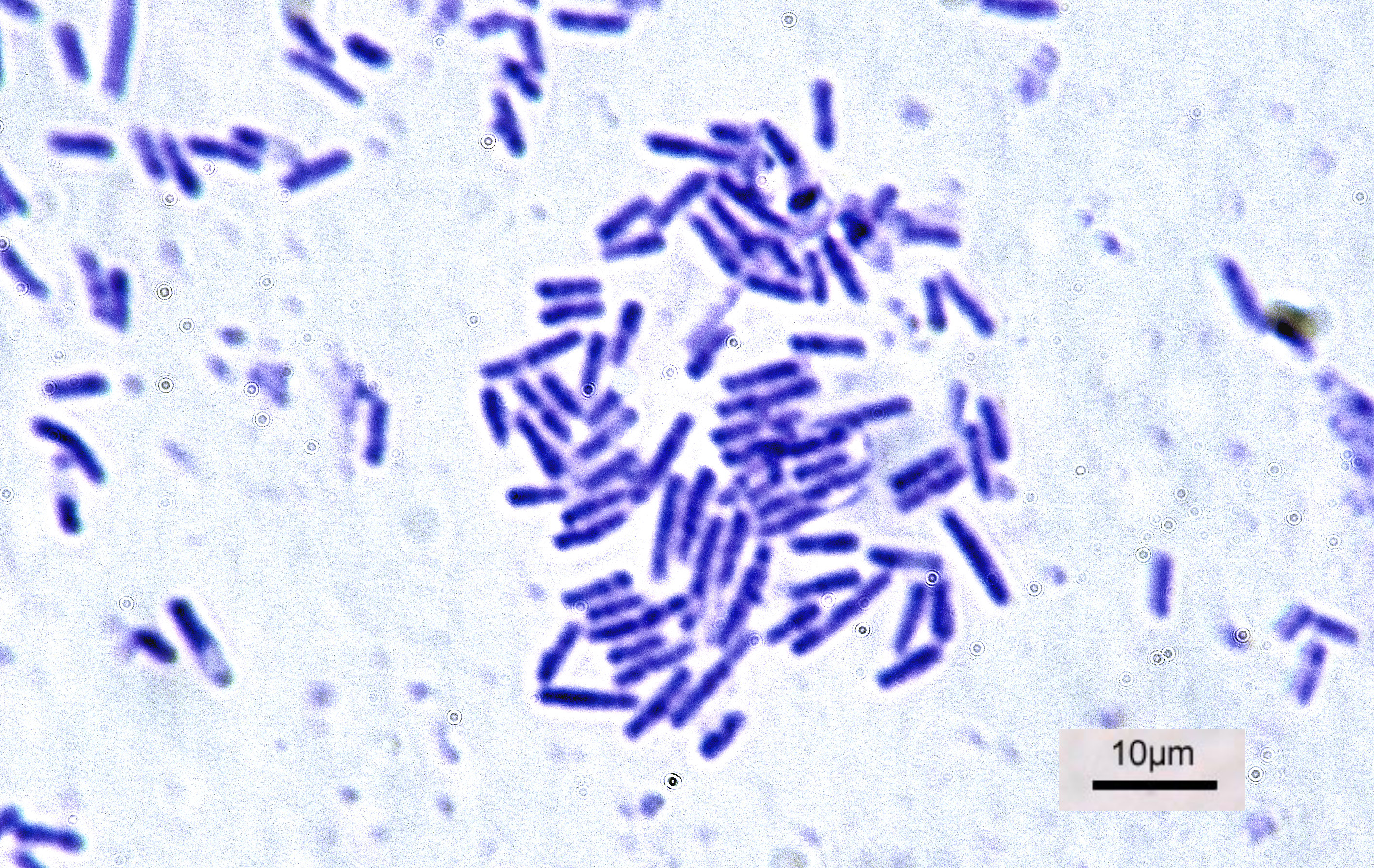

Bacteria

Bacteria (; singular: bacterium) are ubiquitous, mostly free-living organisms often consisting of one biological cell. They constitute a large domain of prokaryotic microorganisms. Typically a few micrometres in length, bacteria were among the first life forms to appear on Earth, and are present in most of its habitats. Bacteria inhabit soil, water, acidic hot springs, radioactive waste, and the deep biosphere of Earth's crust. Bacteria are vital in many stages of the nutrient cycle by recycling nutrients such as the fixation of nitrogen from the atmosphere. The nutrient cycle includes the decomposition of dead bodies; bacteria are responsible for the putrefaction stage in this process. In the biological communities surrounding hydrothermal vents and cold seeps, extremophile bacteria provide the nutrients needed to sustain life by converting dissolved compounds, such as hydrogen sulphide and methane, to energy. Bacteria also live in symbiotic and parasitic relationsh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microorganism

A microorganism, or microbe,, ''mikros'', "small") and ''organism'' from the el, ὀργανισμός, ''organismós'', "organism"). It is usually written as a single word but is sometimes hyphenated (''micro-organism''), especially in older texts. The informal synonym ''microbe'' () comes from μικρός, mikrós, "small" and βίος, bíos, "life". is an organism of microscopic size, which may exist in its single-celled form or as a colony of cells. The possible existence of unseen microbial life was suspected from ancient times, such as in Jain scriptures from sixth century BC India. The scientific study of microorganisms began with their observation under the microscope in the 1670s by Anton van Leeuwenhoek. In the 1850s, Louis Pasteur found that microorganisms caused food spoilage, debunking the theory of spontaneous generation. In the 1880s, Robert Koch discovered that microorganisms caused the diseases tuberculosis, cholera, diphtheria, and anthrax. Because mi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Technology

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler, and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity. Industrial technology programs typically include instruction in optimization theory, human factors, organizational behavior, industrial processes, industrial planning procedures, computer applications, and report and presentation preparation. Planning and designing manufacturing processes and equipment is the main aspect of being an industrial technologist. An industrial technologist is often responsible for implementing certain designs and processes. Accreditation and certification The USA-based Association of Technology, Management, and Applied Engineering (ATMAE), accredits selected collegiate programs in Industrial Technology in the USA. An instructor or graduate of an Industrial Techn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Programmable Logic Controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity that requires high reliability, ease of programming, and process fault diagnosis. Dick Morley is considered as the father of PLC as he had invented the first PLC, the Modicon 084, for General Motors in 1968. PLCs can range from small modular devices with tens of inputs and outputs (I/O), in a housing integral with the processor, to large rack-mounted modular devices with thousands of I/O, and which are often networked to other PLC and SCADA systems. They can be designed for many arrangements of digital and analog I/O, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in battery-backed-up or non-volatile memory. PLCs were first devel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and other devices, such as programmable logic controllers, which interface with process plant or machinery. Explanation The operator interfaces which enable monitoring and the issuing of process commands, like controller set point changes, are handled through the SCADA computer system. The subordinated operations, e.g. the real-time control logic or controller calculations, are performed by networked modules connected to the field sensors and actuators. The SCADA concept was developed to be a universal means of remote-access to a variety of local control modules, which could be from different manufacturers and allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

USS Worcester (CL-144) Testing Her Anti-nuclear Radiation Washdown System On 7 July 1954 (NH 97335)

USS ''Worcester'' has been the name of three ships in the United States Navy. * a bark-rigged screw steam sloop-of-war that was launched in 1866. * USS ''Worcester'' (PG-170) was renamed before it was laid down as a in 1943. * was the lead ship The lead ship, name ship, or class leader is the first of a series or class of ships all constructed according to the same general design. The term is applicable to naval ships and large civilian vessels. Large ships are very complex and may ... of the s. {{DEFAULTSORT:Worcester, Uss United States Navy ship names ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hazard Analysis And Critical Control Points

Hazard analysis and critical control points, or HACCP (), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. In this manner, HACCP attempts to avoid hazards rather than attempting to inspect finished products for the effects of those hazards. The HACCP system can be used at all stages of a food chain, from food production and preparation processes including packaging, distribution, etc. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for juice and meat as an effective approach to food safety and protecting public health. Meat HACCP systems are regulated by the USDA, while seafood and juice are regulated by the FDA. All other food companies in the United States that are required to register with the FDA under the Public Health ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |