|

Valve Timing

In a piston engine, the valve timing is the precise timing of the opening and closing of the valves. In an internal combustion engine those are usually poppet valves and in a steam engine they are usually slide valves or piston valves. Internal combustion engines Camshaft In four-stroke cycle engines and some two-stroke cycle engines, the valve timing is controlled by the camshaft. It can be varied by modifying the camshaft, or it can be varied during engine operation by variable valve timing. It is also affected by the adjustment of the valve mechanism, and particularly by the tappet clearance. However, this variation is normally unwanted. Valve overlap With traditional fixed valve timing, an engine will have a period of "valve overlap" at the end of the exhaust stroke, when both the intake and exhaust valves are open. The intake valve is opened before the exhaust gases have completely left the cylinder, and their considerable velocity assists in drawing in the fresh cha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wankel Engine

The Wankel engine (, ) is a type of internal combustion engine using an Eccentric (mechanism), eccentric rotary combustion engine, rotary design to convert pressure into rotating motion. It was invented by German engineer Felix Wankel, and designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor rotates inside an oval-like epitrochoidal housing, around a central output shaft. The rotor spins in a hula-hoop fashion around the central output shaft, spinning the shaft via toothed gearing. Due to its inherent poor thermodynamics, the Wankel engine has a significantly worse thermal efficiency and worse exhaust gas behaviour when compared against the Otto engine or the Diesel engine, which is why the Wankel engine has seen limited use since its introduction in the 1960s. However, its advantages of compact design, smoothness, lower weight and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

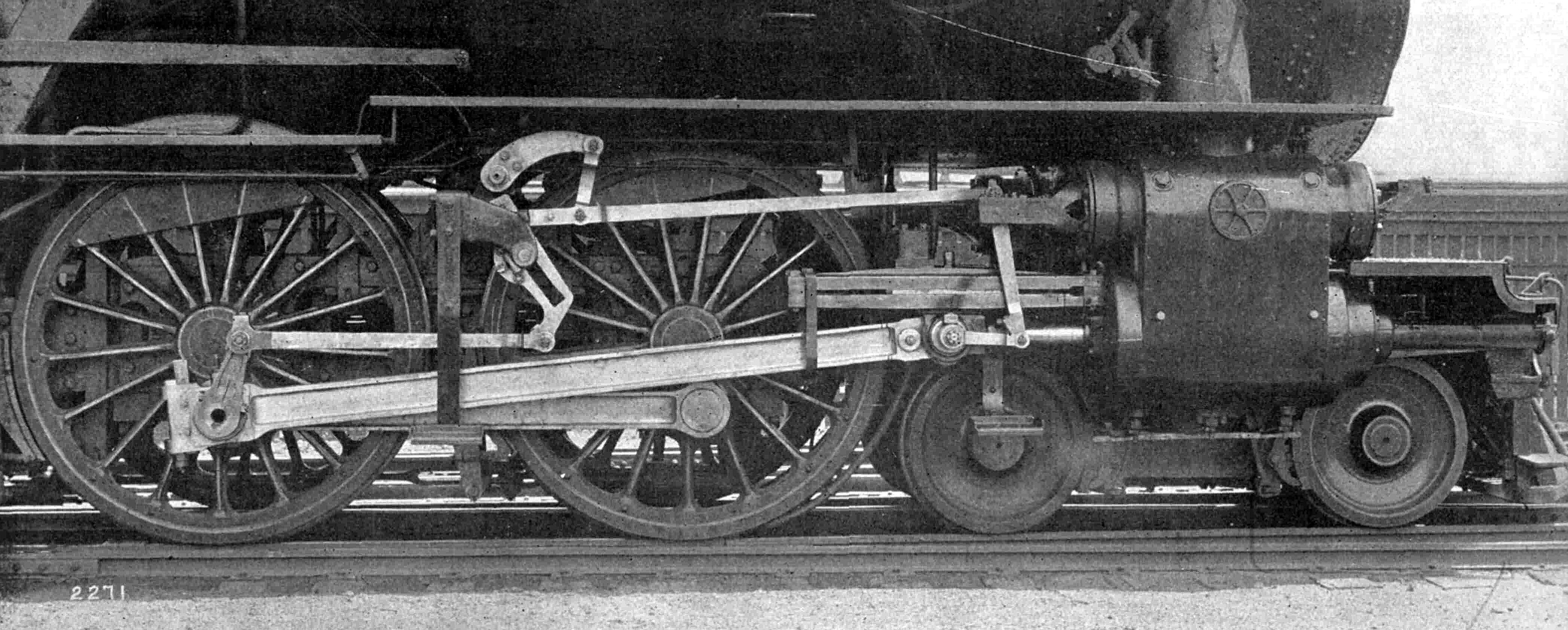

Valve Gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing gear. It is sometimes referred to as the "motion". Purpose In the simple case, this can be a relatively simple task as in the internal combustion engine in which the valves always open and close at the same points. This is not the ideal arrangement for a steam engine, though, because greatest power is achieved by keeping the inlet valve open throughout the power stroke (thus having full boiler pressure, minus transmission losses, against the piston throughout the stroke) while peak efficiency is achieved by only having the inlet valve open for a short time and then letting the steam expand in the cylinder (expansive working). The point at which steam stops being admitted to the cylinder is known as the '' cutoff'', and the optimal positio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head Porting

Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve their air flow. Cylinder heads, as manufactured, are usually suboptimal for racing applications due to being designed for maximum durability. Ports can be modified for maximum power, minimum fuel consumption, or a combination of the two, and the power delivery characteristics can be changed to suit a particular application. Dealing with air Daily human experience with air gives the impression that air is light and nearly non-existent as we move slowly through it. However, an engine running at high speed experiences a totally different substance. In that context, air can be thought of as thick, sticky, elastic, gooey and heavy (see viscosity), and head porting helps to alleviate this. Port modifications When a modification is decided upon through testing with an air flow bench, the original port wall material can be reshaped by hand with die grinde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Caprotti Valve Gear

The Caprotti valve gear is a type of steam engine valve gear invented in the early 1920s by Italian architect and engineer Arturo Caprotti. It uses camshafts and poppet valves rather than the piston valves used in other valve gear. While basing his design on automotive valves, Caprotti made several significant departures from this design to adapt the valves for steam. Having agreed a joint-venture with Worcester-based engineering company Heenan & Froude from 1938, Heenan & Froude fully acquired Caprotti post-World War II in 1947. Usage in Italy The Caprotti valve gear was first tested on a Ferrovie dello Stato Italiane Class 740 2-8-0 mixed-traffic locomotive in 1921; although more expensive and complicated than the standard piston valves, it substantially improved the locomotive's performance. Until the 1930s it was fitted on some 334 FS locomotives and on 77 narrow-gauge locomotives of other companies; of the former, some were new-builds, the others were rebuilds of non-su ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Valve

A "piston valve" is a device used to control the motion of a fluid along a tube or pipe by means of the linear motion of a piston within a chamber or cylinder. Examples of piston valves are: * The valves used in many brass instruments * The valves used in pneumatic cannons * The valves used in many stationary steam engines and steam locomotives Brass instruments Cylindrical piston valves called Périnet valves (after their inventor François Périnet) are used to change the length of tube in the playing of most brass instruments, particularly the trumpet-like members of the family (cornet, flugelhorn, saxhorn, etc.). Other brass instruments use rotary valves, notably the orchestral horns and many tuba models, but also a number of rotary-valved variants of those brass instruments which more commonly employ piston valves. The first piston-valved musical instruments were developed just after the start of the 19th century. The Stölzel valve (invented by Heinrich Stölzel in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Gear

The valve gear of a steam engine is the mechanism that operates the inlet and exhaust valves to admit steam into the cylinder and allow exhaust steam to escape, respectively, at the correct points in the cycle. It can also serve as a reversing gear. It is sometimes referred to as the "motion". Purpose In the simple case, this can be a relatively simple task as in the internal combustion engine in which the valves always open and close at the same points. This is not the ideal arrangement for a steam engine, though, because greatest power is achieved by keeping the inlet valve open throughout the power stroke (thus having full boiler pressure, minus transmission losses, against the piston throughout the stroke) while peak efficiency is achieved by only having the inlet valve open for a short time and then letting the steam expand in the cylinder (expansive working). The point at which steam stops being admitted to the cylinder is known as the '' cutoff'', and the optimal positio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

External Combustion Engine

An external combustion engine (EC engine) is a reciprocating heat engine where a working fluid, contained internally, is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine, produces motion and usable work. The fluid is then dumped (open cycle), or cooled, compressed and reused (closed cycle). In these types of engines, the combustion is primarily used as a heat source, and the engine can work equally well with other types of heat sources. Combustion "Combustion" refers to burning fuel with an oxidizer, to supply the heat. Engines of similar (or even identical) configuration and operation may use a supply of heat from other sources such as nuclear, solar, geothermal or exothermic reactions not involving combustion; they are not then strictly classed as external combustion engines, but as external thermal engines. Working fluid The working fluid can be of any composition ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Feeler Gauge

A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in engineering to measure the clearance between two parts. Description They consist of a number of small lengths of steel of different thicknesses with measurements marked on each piece. They are flexible enough that, even if they are all on the same hinge, several can be stacked together to gauge intermediate values. It is common to have two sets: one for imperial units (typically measured in thousandths of an inch), and one for metric (typically measured in hundredths of a millimetre) measurements (with intervals of thousandths of an inch and hundredths of a millimetre being roughly in the same order of magnitude). The same device with wires of specific diameter instead of flat blades is used to set the gap in spark plugs to the correct size; this is done by increasing or decreasing the gap until the gauge of the correct size just fits inside the gap. The lengths of steel are sometimes called ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are now lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wilksch WAM Series

The Wilksch WAM series is a family of aero-engines for light and general aviation aircraft. WAM series engines are produced by Wilksch Airmotive in Gloucestershire, England. The engine outputs range between and , and are suitable for both tractor and pusher configurations. Initially intended for homebuilt aircraft, the WAM engines may become certified for use on factory-built aircraft. Wilksch engines are compression ignition engines which burn diesel fuel or jet fuel. Aero-diesels are more efficient than the avgas engines more commonly found in general aviation aircraft. Kerosene jet fuel is ideal for jet turbines, but it lacks the lubricity of diesel fuel. Accordingly, diesel aero-engines that use jet fuel must have sufficient lubrication to compensate. Design and development The WAM unit is a direct-drive two-stroke inverted inline triple with wet-sump, liquid cooling, supercharger, turbocharger and intercooler. Compression boost at startup comes via a supercha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is une ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |