|

Valve Train

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Movingparts

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form, so heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine, in which hea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

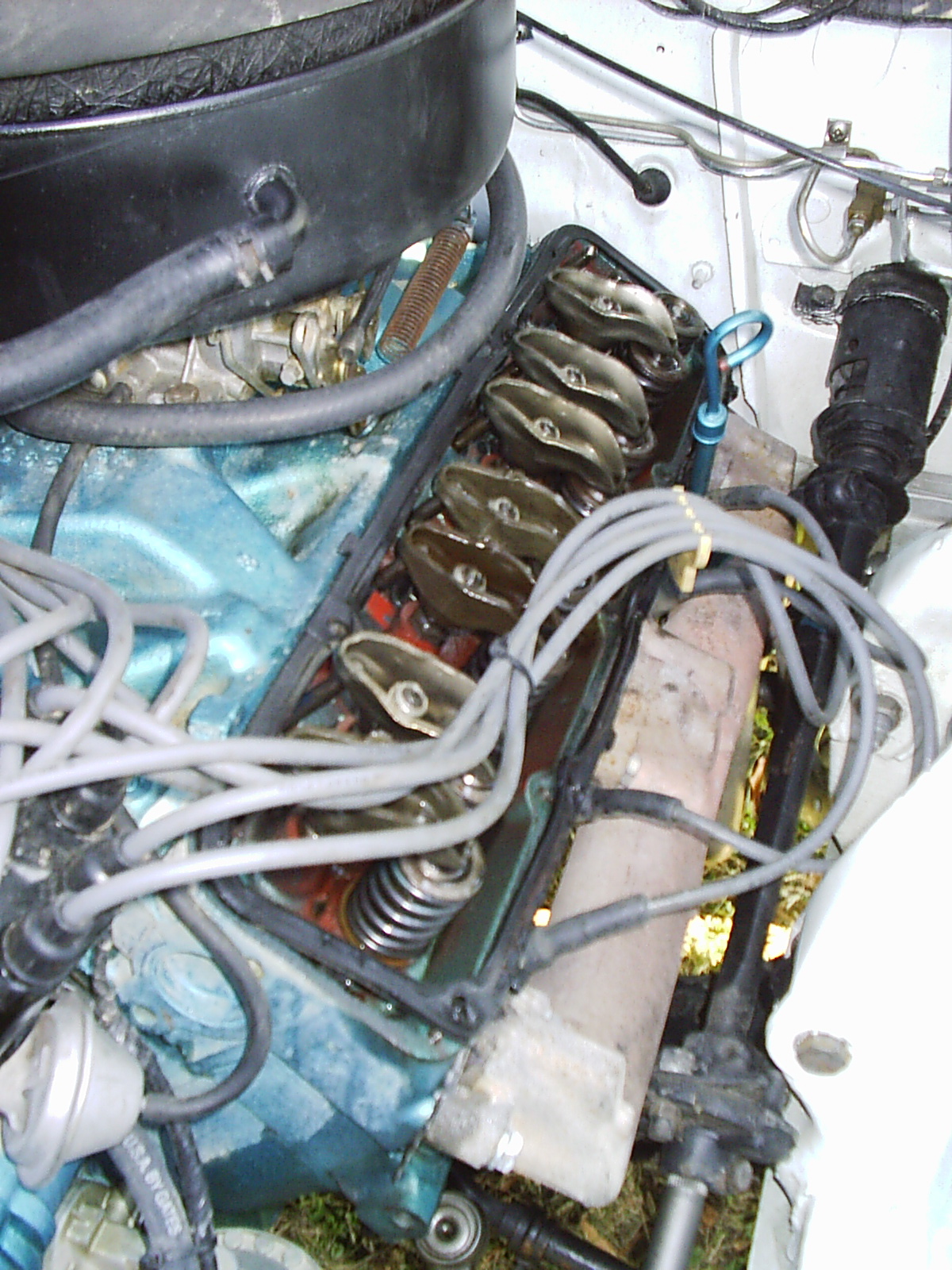

Rocker Arm

In the context of an internal combustion engine, a rocker arm is a valvetrain component that typically transfers the motion of a pushrod to the corresponding intake/exhaust valve. Rocker arms in automobiles are typically made from stamped steel, or aluminum in higher-revving applications. Some rocker arms (called ''roller rockers'') include a bearing at the contact point, to reduce wear and friction at the contact point. Overview In the typical use-case of an overhead valve (pushrod) engine, the camshaft at the bottom of the engine pushes the pushrod upwards. The top of the pushrod presses upwards on one side of the rocker arm (located at the top of the engine), which causes the rocker arm to rotate. This rotation causes the other end of the rocker arm to press downwards on the top of the valve, which opens the valve by moving it downwards. A ''roller rocker'' is a rocker arm that uses needle bearings (or a single bearing ball in older engines) at the contact point between th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valvetrain

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camless Piston Engine

A camless or free-valve piston engine is an engine that has poppet valves operated by means of electromagnetic, hydraulic, or pneumatic actuators instead of conventional cams. Actuators can be used to both open and close valves, or to open valves closed by springs or other means. Camshafts normally have one lobe per valve, with a fixed valve duration and lift. Although many modern engines use camshaft phasing, adjusting the lift and valve duration in a working engine is more difficult. Some manufacturers use systems with more than one cam lobe, but this is still a compromise as only a few profiles can be in operation at once. This is not the case with the camless engine, where lift and valve timing can be adjusted freely from valve to valve and from cycle to cycle. It also allows multiple lift events per cycle and, indeed, no events per cycle—switching off the cylinder entirely. Camless development Camless valve trains have long been investigated by several companies, including ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam-in-block

A cam-in-block engine is where the camshaft is located in the engine block. Types of cam-in-block engines are: * F-Head Engine * Flathead engine A flathead engine, also known as a sidevalve engine''American Rodder'', 6/94, pp.45 & 93. or valve-in-block engine is an internal combustion engine with its poppet valves contained within the engine block, instead of in the cylinder head, as ... * Overhead valve engine (the only type where the valves are above the combustion chamber) * T-head engine {{set index ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Float

Valve float is an adverse condition which can occur at high engine speeds when the poppet valves in an internal combustion engine valvetrain do not properly follow the closure phase of the cam lobe profile. This reduces engine efficiency and performance. There is also a significant risk of severe engine damage due to valve spring damage, and/or pistons contacting the valves, and/or catastrophic lifter and cam lobe failure, especially with roller lifters. Similar conditions 'Valve lift' is intentional, using a controlled valve float to increase lift and duration of the valve open cycle. In some motorsports there are rules that limit camshaft lift, provoking this type of exploitation. Properly optimizing the system avoids undue stresses to the camshaft lobes and tappets. 'Valve bounce' is a related condition where the valve does not stay seated because of the combined effects of the valve's inertia and resonance of metallic valve springs that reduce the closing force and allow t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Valve

A rotary valve (also called rotary-motion valve) is a type of valve in which the rotation of a passage or passages in a transverse plug regulates the flow of liquid or gas through the attached pipes. The common stopcock is the simplest form of rotary valve. Rotary valves have been applied in numerous applications, including: * Changing the pitch of brass instruments. * Controlling the steam and exhaust ports of steam engines, most notably in the Corliss steam engine. * Periodically reversing the flow of air and fuel across the open hearth furnace. * Loading sample on chromatography columns. * Certain types of two-stroke and four-stroke engines. * Most hydraulic automotive power steering control valves. Use in brass instruments In the context of brass instruments, rotary valves are found on horns, trumpets, trombones, flugelhorns, and tubas. The cornet derived from the posthorn, by applying rotary valves to it in the 1820s in France. An alternative to a rotary valve trumpet w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Slide Valve

The slide valve is a rectilinear valve used to control the admission of steam into and emission of exhaust from the cylinder of a steam engine. Use In the 19th century, most steam locomotives used slide valves to control the flow of steam into and out of the cylinders. In the 20th century, slide valves were gradually superseded by piston valves, particularly in engines using superheated steam. There were two reasons for this: * With piston valves, the steam passages can be made shorter. This reduces resistance to the flow of steam and improves efficiency. * It is difficult to lubricate slide valves adequately in the presence of superheated steam. Murdoch's D slide valve The D slide valve, or more specifically Long D slide valve, is a form of slide valve, invented by William Murdoch and patented in 1799. It is named after the hollow central D-sectioned piston. This valve worked by "connecting the upper and lower valves so as to be worked by one rod or spindle, and in mak ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sleeve Valve

The sleeve valve is a type of valve mechanism for piston engines, distinct from the usual poppet valve. Sleeve valve engines saw use in a number of pre-World War II luxury cars and in the United States in the Willys-Knight car and light truck. They subsequently fell from use due to advances in poppet-valve technology, including sodium cooling, and the Knight system double sleeve engine's tendency to burn a lot of lubricating oil or to seize due to lack of it. The Scottish Argyll company used its own, much simpler and more efficient, single sleeve system (Burt-McCollum) in its cars, a system which, after extensive development, saw substantial use in British aircraft engines of the 1940s, such as the Napier Sabre, Bristol Hercules, Centaurus, and the promising but never mass-produced Rolls-Royce Crecy, only to be supplanted by the jet engines. Description A sleeve valve takes the form of one or more machined sleeves. It fits between the piston and the cylinder wall in the cylind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poppet Valves

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45° bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. The poppet valve was invented in 1833 by American E.A.G. Young of the Newcastle and Frenchtown Railroad. Young had patented his idea, but the Patent Office fire of 1836 destroyed all records of it. Etymology The word ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cam Lobe

Calmodulin (CaM) (an abbreviation for calcium-modulated protein) is a multifunctional intermediate calcium-binding messenger protein expressed in all eukaryotic cells. It is an intracellular target of the secondary messenger Ca2+, and the binding of Ca2+ is required for the activation of calmodulin. Once bound to Ca2+, calmodulin acts as part of a calcium signal transduction pathway by modifying its interactions with various target proteins such as kinases or phosphatases. Structure Calmodulin is a small, highly conserved protein that is 148 amino acids long (16.7 kDa). The protein has two approximately symmetrical globular domains (the N- and C- domains) each containing a pair of EF hand motifs separated by a flexible linker region for a total of four Ca2+ binding sites, two in each globular domain. In the Ca2+-free state, the helices that form the four EF-hands are collapsed in a compact orientation, and the central linker is disordered; in the Ca2+-saturated state, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tappet

A tappet is most commonly a component in an internal combustion engine which converts the rotating motion of the camshaft into linear motion of the valves, either directly or indirectly. An earlier use of the term was for part of the valve gear in beam engines beginning in 1715. The term is also used for components in pneumatic cylinders and weaving loom. __TOC__ Beam engines The first recorded use of the term tappet is as part of the valve gear in the 1715 Newcomen engine, an early form of steam engine. Early versions of the Newcomen engines from 1712 had manually operated valves, but by 1715 this repetitive task had been automated through the use of tappets. The beam of the engine had a vertical 'plug rod' hung from it, alongside the cylinder. Adjustable blocks or 'tappets' were attached to this rod and as the beam moved up and down, the tappets pressed against long levers or 'horns' attached to the engine's valves, working the cycle of steam and injection water valves ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)