|

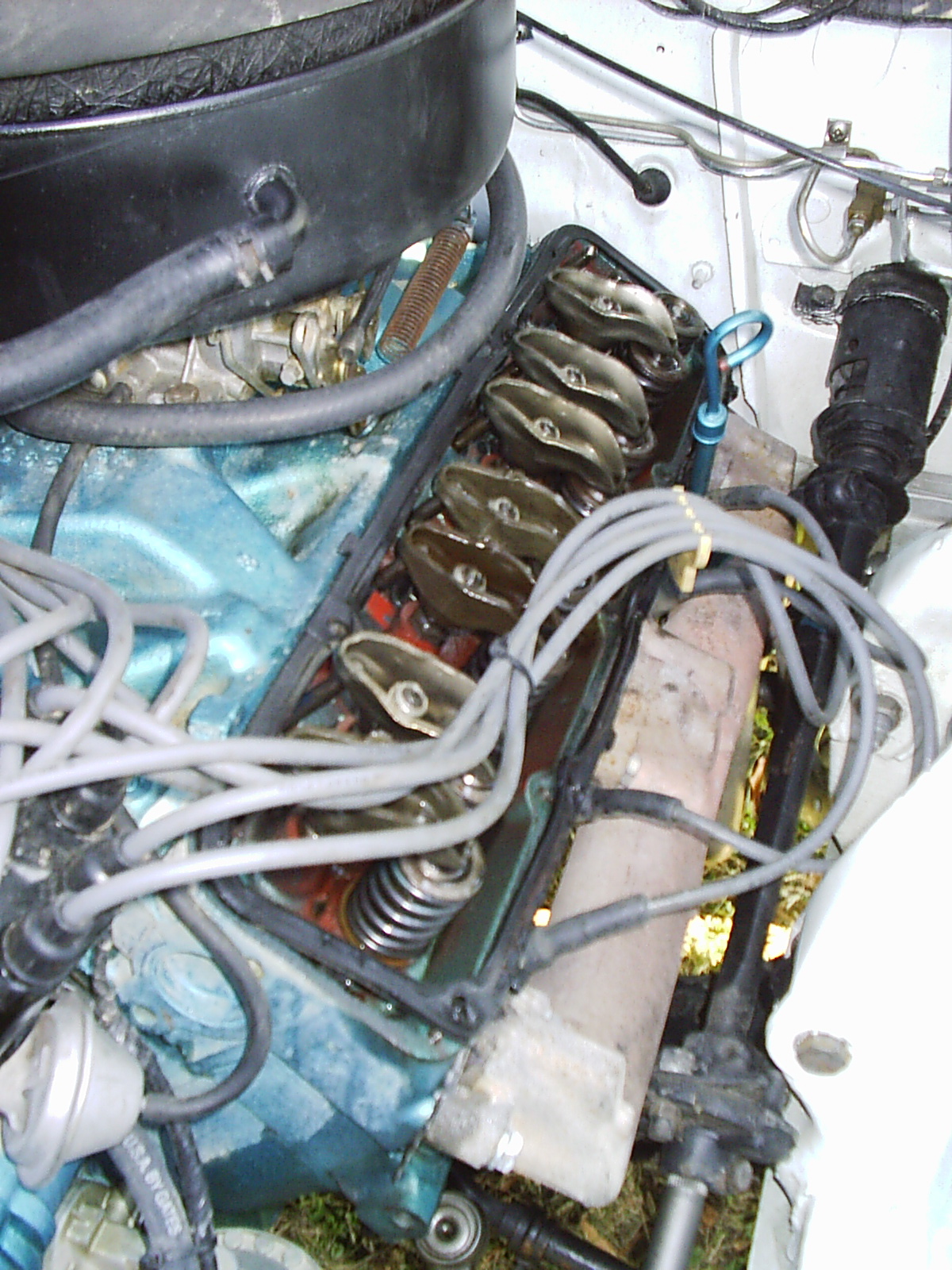

Valve Guide

In most types of reciprocating engines, a valve guide is provided for each poppet valve in the cylinder head. Along with the valve spring, it serves to positively locate the valve so that it may make proper contact with the valve seat. A valve guide is a cylindrical piece of metal, pressed or integrally cast into the cylinder head, with the valve reciprocating inside it. Guides also serve to conduct heat from the combustion process out from the exhaust valve and into the cylinder head where it may be taken up by the cooling system. Bronze is commonly used, as is steel; a balance between stiffness and wear on the valve is essential to achieve a useful service life. The clearance between the inner diameter of the valve guide and the outer diameter of the poppet valve stem is critical for the proper performance of an engine. If there is too little clearance, the valve may stick as oil contaminants and thermal expansion become factors. If there is too much clearance, the valve may not ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reamer

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press. Construction A typical reamer consists of a set of parallel straight or helical cutting edges along the length of a cylindrical body. Each cutting edge is ground at a slight angle and with a slight undercut below the cutting edge. Reamers must combine both hardness in the cutting edges, for long life, and toughness, so that the tool does not fail under the normal forces of use. They should only be used to remove small amounts of material. This ensures a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poppet Valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine. It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usually a disk shape on the end of a shaft known as a valve stem. The working end of this plug, the valve face, is typically ground at a 45° bevel to seal against a corresponding valve seat ground into the rim of the chamber being sealed. The shaft travels through a valve guide to maintain its alignment. A pressure differential on either side of the valve can assist or impair its performance. In exhaust applications higher pressure against the valve helps to seal it, and in intake applications lower pressure helps open it. The poppet valve was invented in 1833 by American E.A.G. Young of the New Castle and Frenchtown Turnpike and Railroad Company, Newcastle and Frenchtown Railroad. Young had patented his idea, but the 1836 U.S. Patent Offic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are now lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Seat

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed. The valve seat is a critical component of an engine in that if it is improperly positioned, oriented, or formed during manufacture, valve leakage will occur which will adversely affect the engine compression ratio and therefore the engine efficiency, performance (engine power and engine torque), exhaust emissions, and engine life. Valve seats are often formed by first press-fitting an approximately cylindrical piece of a hardened metal alloy, such as Stellite, into a cast depression in a cylinder head above each eventual valve stem position, and then machining a conical-section surface into the valve seat that will mate with a corresponding conical section of the corresponding valve. Generally two conical-section surfaces, one with a wider cone angle and one with a narrowe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bronze

Bronze is an alloy consisting primarily of copper, commonly with about 12–12.5% tin and often with the addition of other metals (including aluminium, manganese, nickel, or zinc) and sometimes non-metals, such as phosphorus, or metalloids such as arsenic or silicon. These additions produce a range of alloys that may be harder than copper alone, or have other useful properties, such as ultimate tensile strength, strength, ductility, or machinability. The three-age system, archaeological period in which bronze was the hardest metal in widespread use is known as the Bronze Age. The beginning of the Bronze Age in western Eurasia and India is conventionally dated to the mid-4th millennium BCE (~3500 BCE), and to the early 2nd millennium BCE in China; elsewhere it gradually spread across regions. The Bronze Age was followed by the Iron Age starting from about 1300 BCE and reaching most of Eurasia by about 500 BCE, although bronze continued to be much more widely used than it is in mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Remanufacturing

Remanufacturing is "the rebuilding of a product to specifications of the original manufactured product using a combination of reused, repaired and new parts". It requires the repair or replacement of worn out or obsolete components and modules. Parts subject to degradation affecting the performance or the expected life of the whole are replaced. Remanufacturing is a form of a product recovery process that differs from other recovery processes in its completeness: a remanufactured machine should match the same customer expectation as new machines. In 1995, the United States Environmental Protection Agency (EPA) implemented the Comprehensive Procurement Guideline (CPG) program to promote waste reduction and resource conservation through the use of materials recovered from solid waste, and to ensure that the materials collected in recycling programs will be used again in the manufacture of new products. The EPA is required to designate products that are or can be made with recovered ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valve Train

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing stones Honing uses a special tool, called a ''honing stone'' or a ''hone'', to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit). Smaller grain sizes produce a smoother surface on t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inlet Manifold

In automotive engineering, an inlet manifold or intake manifold (in American English) is the part of an engine that supplies the fuel/air mixture to the cylinders. The word '' manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' epeatedly and refers to the multiplying of one (pipe) into many.manifold, (adv.) "in the proportion of many to one, by many times". AD1526 ''Oxford English Dictionary'', In contrast, an exhaust manifold collects the exhaust gases from multiple cylinders into a smaller number of pipes – often down to one pipe. The primary function of the intake manifold is to ''evenly'' distribute the combustion mixture (or just air in a direct injection engine) to each intake port in the cylinder head(s). Even distribution is important to optimize the efficiency and performance of the engine. It may also serve as a mount for the carburetor, throttle body, fuel injectors and other components of the engi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Manifold

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word ''manifold'' comes from the Old English word ''manigfeald'' (from the Anglo-Saxon ''manig'' anyand ''feald'' old and refers to the folding together of multiple inputs and outputs (in contrast, an inlet or intake manifold ''supplies'' air ''to'' the cylinders). Exhaust manifolds are generally simple cast iron or stainless steel units which collect engine exhaust gas from multiple cylinders and deliver it to the exhaust pipe. For many engines, there are aftermarket tubular exhaust manifolds known as headers in American English, as extractor manifolds in British and Australian English,''The Design and Tuning of Competition Engines'', Philip H. Smith, pp. 137–138 and simply as "tubular manifolds" in British English. These consist of individual exhaust headpipes for each cylinder, which then usually converge into one tube called a collector. Headers that do n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)