|

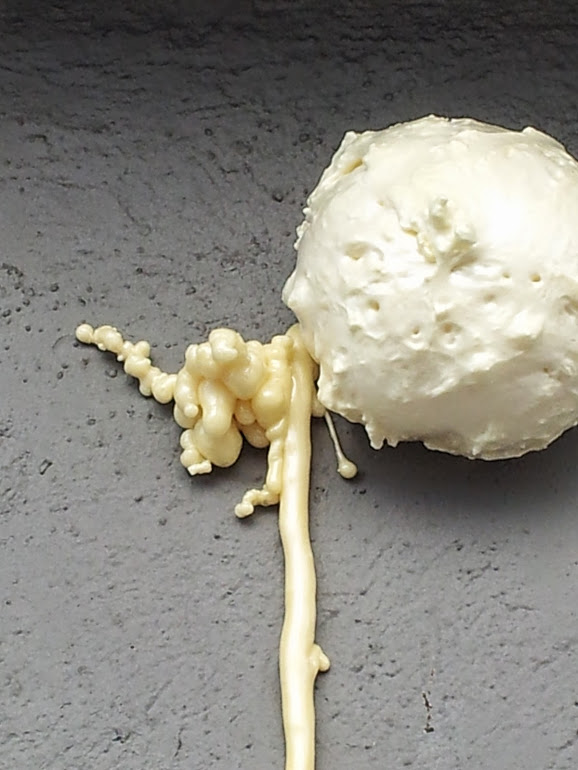

Urea-formaldehyde

Urea-formaldehyde (UF), also known as urea-methanal, so named for its common synthesis pathway and overall structure, is a nontransparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesives, plywood, particle board, medium-density fibreboard (MDF), and molded objects. UF and relate amino resins are a class of thermosetting resins of which urea-formaldehyde resins make up 80% produced worldwide. Examples of amino resins use include in automobile tires to improve the bonding of rubber to in paper for improving tear strength, in molding electrical devices, jar caps, etc. History UF was first synthesized in 1884 by Dr Hölzer, who was working with Bernhard Tollens, neither of whom realized that the urea and formaldehyde were polymerizing. In the following years a large number of authors worked on the structure of these resins. In 1896, Carl Goldschmidt investigated the reaction further. He also obtained an amorphous, almos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Urea-formaldehyde Insulation

Urea-formaldehyde (UF), also known as urea-methanal, so named for its common synthesis pathway and overall structure, is a nontransparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesives, plywood, particle board, medium-density fibreboard (MDF), and molded objects. UF and relate amino resins are a class of thermosetting resins of which urea-formaldehyde resins make up 80% produced worldwide. Examples of amino resins use include in automobile tires to improve the bonding of rubber to in paper for improving tear strength, in molding electrical devices, jar caps, etc. History UF was first synthesized in 1884 by Dr Hölzer, who was working with Bernhard Tollens, neither of whom realized that the urea and formaldehyde were polymerizing. In the following years a large number of authors worked on the structure of these resins. In 1896, Carl Goldschmidt investigated the reaction further. He also obtained an amorphous, almos ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Controlled-release Fertilizer

224px, Methylene diurea (MDU) is component of the most popular controlled-release fertilizers. A controlled-release fertiliser (CRF) is a granulated fertiliser that releases nutrients gradually into the soil (i.e., with a controlled release period). Controlled-release fertilizer is also known as controlled-availability fertilizer, delayed-release fertilizer, metered-release fertilizer, or slow-acting fertilizer. Usually CRF refers to nitrogen-based fertilizers. Slow- and controlled-release involve only 0.15% (562,000 tons) of the fertilizer market (1995). History Controlled-nitrogen-release technologies based on polymers derived from combining urea and formaldehyde were first produced in 1936 and commercialized in 1955. The early product had 60 percent of the total nitrogen cold-water-insoluble, and the unreacted (quick-release) less than 15%. Methylene ureas, e.g. methylene diurea, were commercialized in the 1960s and 1970s, having 25% and 60% of the nitrogen as cold-water-insolu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formaldehyde

Formaldehyde ( , ) (systematic name methanal) is a naturally occurring organic compound with the formula and structure . The pure compound is a pungent, colourless gas that polymerises spontaneously into paraformaldehyde (refer to section Forms below), hence it is stored as an aqueous solution (formalin), which is also used to store animal specimens. It is the simplest of the aldehydes (). The common name of this substance comes from its similarity and relation to formic acid. Formaldehyde is an important precursor to many other materials and chemical compounds. In 1996, the installed capacity for the production of formaldehyde was estimated at 8.7 million tons per year. It is mainly used in the production of industrial resins, e.g., for particle board and coatings. Forms Formaldehyde is more complicated than many simple carbon compounds in that it adopts several diverse forms. These compounds can often be used interchangeably and can be interconverted. *Molecular formald ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medium-density Fibreboard

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming it into panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres but can be used as a building material similar in application to plywood. It is stronger and denser than particle board. The name derives from the distinction in densities of fibreboard. Large-scale production of MDF began in the 1980s, in both North America and Europe. Physical properties Over time, the term "MDF" has become a generic name for any dry-process fibre board. MDF is typically made up of 82% wood fibre, 9% urea-formaldehyde resin glue, 8% water, and 1% paraffin wax. The density is typically between . The range of density and classification as light-, standard-, or high-density board is a misnomer and confusing. The density of the b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrinkle-resistant Fabric

Wrinkle-resistant or permanent press or durable press is a finishing method for textiles that avoids creases and wrinkles and provides a better appearance for the articles. Most cellulosic fabrics and blends of cellulosic rich fabrics tend to crease or wrinkle. A durable press finish makes them dimensionally stable and crease free. The finishing includes chemical finishing as well as mechanical finishing. Wrinkle-resistant finishes were developed in the early 20th century, as a way to deal with fabrics derived from cotton, rayon, and linen, which were found to wrinkle easily and retain the wrinkles. These treatments have a lasting effect on the fabric. Synthetics like polyester, nylon, acrylic and olefin, have a natural resistance to wrinkles and a greater stability since they do not absorb water as efficiently. These fabrics are textiles that have been treated to resist external stress and hold their shape. Clothing made from this fabric does not need to be ironed and may ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Urea

Urea, also known as carbamide, is an organic compound with chemical formula . This amide has two amino groups (–) joined by a carbonyl functional group (–C(=O)–). It is thus the simplest amide of carbamic acid. Urea serves an important role in the metabolism of nitrogen-containing compounds by animals and is the main nitrogen-containing substance in the urine of mammals. It is a colorless, odorless solid, highly soluble in water, and practically non-toxic ( is 15 g/kg for rats). Dissolved in water, it is neither acidic nor alkaline. The body uses it in many processes, most notably nitrogen excretion. The liver forms it by combining two ammonia molecules () with a carbon dioxide () molecule in the urea cycle. Urea is widely used in fertilizers as a source of nitrogen (N) and is an important raw material for the chemical industry. In 1828 Friedrich Wöhler discovered that urea can be produced from inorganic starting materials, which was an important conceptual milestone ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plywood

Plywood is a material manufactured from thin layers or "plies" of wood veneer that are glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. It is an engineered wood from the family of manufactured boards which include medium-density fibreboard (MDF), oriented strand board (OSB) and particle board (chipboard). All plywoods bind resin and wood fibre sheets (cellulose cells are long, strong and thin) to form a composite material. This alternation of the grain is called ''cross-graining'' and has several important benefits: it reduces the tendency of wood to split when nailed at the edges; it reduces expansion and shrinkage, providing improved dimensional stability; and it makes the strength of the panel consistent across all directions. There is usually an odd number of plies, so that the sheet is balanced—this reduces warping. Because plywood is bonded with grains running against one another and with an odd number of composite part ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Particle Board

Particle board, also known as chipboard or low-density fiberboard, is an engineered wood product manufactured from wood chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board (OSB) (also known as flakeboard, or waferboard), a different type of fiberboard that uses machined wood flakes and offers more strength. Characteristics Particle board is cheaper, denser and more uniform than conventional wood and plywood and is substituted for them when cost is more important than strength and appearance. Particleboard can be made more appealing by painting or the use of wood veneers on visible surfaces. Though it is denser than conventional wood, it is the lightest and weakest type of fiberboard, except for insulation board. Medium-density fibreboard and hardboard, also called high-density fiberboard, are stronger and denser than particleboard. Different grades of particleboard have different densi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bis(hydroxymethyl)urea

Bis(hydroxymethyl)urea is an organic compound with the formula OC(NHCH2OH)2. This white water-soluble solid is an intermediate in the formation of urea-formaldehyde resin Urea-formaldehyde (UF), also known as urea-methanal, so named for its common synthesis pathway and overall structure, is a nontransparent thermosetting resin or polymer. It is produced from urea and formaldehyde. These resins are used in adhesive ...s. It forms upon treatment of urea with an excess of formaldehyde.{{ Ullmann , author = C. Nitschke , author2 = G. Scherr , title = Urea Derivatives , year = 2012, doi = 10.1002/14356007.o27_o04 References Ureas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

R-value (insulation)

In the context of construction, the R-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The ''R-value'' is the building industry term for thermal resistance "per unit area." It is sometimes denoted RSI-value if the SI units are used. An R-value can be given for a material (e.g. for polyethylene foam), or for an assembly of materials (e.g. a wall or a window). In the case of materials, it is often expressed in terms of R-value per metre. R-values are additive for layers of materials, and the higher the R-value the better the performance. The U-factor or U-value is the overall heat transfer coefficient and can be found by taking the inverse of the R-value. It is a property ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spray Foams (insulation)

Spray foam is a chemical product created by two materials, isocyanate and polyol resin, which react when mixed with each other and expand up to 30-60 times its liquid volume after it is sprayed in place. This expansion makes it useful as a specialty packing material which forms to the shape of the product being packaged and produces a high thermal insulating value with virtually no air infiltration. History Otto Bayer (1902–1982) is credited with the invention of polyurethane in 1937. He succeeded in synthesizing polyurethane foam by exploring his basic idea that mixing small volumes of chemical substances could create dry foam materials. Polyurethane was further developed for different applications, ranging from shoe soles and cushions to industrial uses. In the 1940s rigid foam was applied to airplanes, and in 1979 polyurethane began being used as building insulation. Properties Thermal resistance R-value is the term given to thermal resistance to heat flow. The higher th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

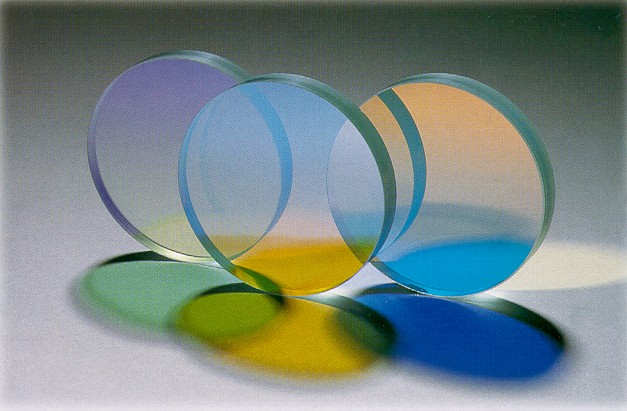

Transparency (optics)

In the field of optics, transparency (also called pellucidity or diaphaneity) is the physical property of allowing light to pass through the material without appreciable scattering of light. On a macroscopic scale (one in which the dimensions are much larger than the wavelengths of the photons in question), the photons can be said to follow Snell's law. Translucency (also called translucence or translucidity) allows light to pass through, but does not necessarily (again, on the macroscopic scale) follow Snell's law; the photons can be scattered at either of the two interfaces, or internally, where there is a change in index of refraction. In other words, a translucent material is made up of components with different indices of refraction. A transparent material is made up of components with a uniform index of refraction. Transparent materials appear clear, with the overall appearance of one color, or any combination leading up to a brilliant spectrum of every color. The opposite ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |