|

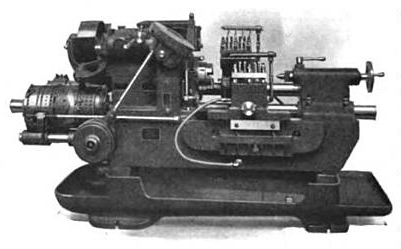

Turret Lathe

The turret lathe is a form of metalworking lathe that is used for repetitive production of duplicate parts, which by the nature of their cutting process are usually interchangeable. It evolved from earlier lathes with the addition of the ''turret'', which is an indexable toolholder that allows multiple cutting operations to be performed, each with a different cutting tool, in easy, rapid succession, with no need for the operator to perform set-up tasks in between (such as installing or uninstalling tools) or to control the toolpath. The latter is due to the toolpath's being controlled by the machine, either in jig-like fashion, via the mechanical limits placed on it by the turret's slide and stops, or via digitally-directed servomechanisms for computer numerical control lathes. The name derives from the way early turrets took the general form of a flattened cylindrical block mounted to the lathe's cross-slide, capable of rotating about the vertical axis and with toolholders pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sharps Rifle Manufacturing Company

Sharps Rifle Manufacturing Company was the manufacturer of the Sharps Rifle. The company was organized by Samuel Robbins and Richard S. Lawrence as a holding company in Hartford, Connecticut, on October 9, 1851 with $100,000 in capital. Despite Sharps departing from the company bearing his name, Sharps Rifle Manufacturing Company produced over 100,000 rifles, but it dissolved in 1881 with the widespread use of repeating rifles. History Christian Sharps (1810–1874), patented his rifle in 1848. The first contract for 5,000 rifles was in 1850 and manufacturing started in 1851. The Model 1851 "box-lock" was developed by Christian Sharps, Rollin White, and Richard Lawrence at Robbins & Lawrence of Windsor, Vermont. The second contract for 15,000 rifles was so large that no suitable land was available in Windsor, Vermont. The holding company advanced Robbins & Lawrence $40,000 to purchase of land in Hartford, Connecticut, and to erect a brick factory building. Christian Sharps ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be print ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer

A computer is a machine that can be programmed to Execution (computing), carry out sequences of arithmetic or logical operations (computation) automatically. Modern digital electronic computers can perform generic sets of operations known as Computer program, programs. These programs enable computers to perform a wide range of tasks. A computer system is a nominally complete computer that includes the Computer hardware, hardware, operating system (main software), and peripheral equipment needed and used for full operation. This term may also refer to a group of computers that are linked and function together, such as a computer network or computer cluster. A broad range of Programmable logic controller, industrial and Consumer electronics, consumer products use computers as control systems. Simple special-purpose devices like microwave ovens and remote controls are included, as are factory devices like industrial robots and computer-aided design, as well as general-purpose devi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing military alliances: the Allies and the Axis powers. World War II was a total war that directly involved more than 100 million personnel from more than 30 countries. The major participants in the war threw their entire economic, industrial, and scientific capabilities behind the war effort, blurring the distinction between civilian and military resources. Aircraft played a major role in the conflict, enabling the strategic bombing of population centres and deploying the only two nuclear weapons ever used in war. World War II was by far the deadliest conflict in human history; it resulted in 70 to 85 million fatalities, mostly among civilians. Tens of millions died due to genocides (including the Holocaust), starvation, massa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

World War I

World War I (28 July 1914 11 November 1918), often abbreviated as WWI, was one of the deadliest global conflicts in history. Belligerents included much of Europe, the Russian Empire, the United States, and the Ottoman Empire, with fighting occurring throughout Europe, the Middle East, Africa, the Pacific, and parts of Asia. An estimated 9 million soldiers were killed in combat, plus another 23 million wounded, while 5 million civilians died as a result of military action, hunger, and disease. Millions more died in genocides within the Ottoman Empire and in the 1918 influenza pandemic, which was exacerbated by the movement of combatants during the war. Prior to 1914, the European great powers were divided between the Triple Entente (comprising France, Russia, and Britain) and the Triple Alliance (containing Germany, Austria-Hungary, and Italy). Tensions in the Balkans came to a head on 28 June 1914, following the assassination of Archduke Franz Ferdi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screw Machine (automatic Lathe)

In metalworking and woodworking, an automatic lathe is a lathe with an automatically controlled cutting process. Automatic lathes were first developed in the 1870s and were mechanically controlled. From the advent of NC and CNC in the 1950s, the term automatic lathe has generally been used for only mechanically controlled lathes, although some manufacturers (e.g., DMG Mori and Tsugami) market Swiss-type CNC lathes as 'automatic'. CNC has not yet entirely displaced mechanically automated lathes, as although no longer in production, many mechanically automated lathes remain in service. General nomenclature The term "automatic lathe" is still often used in manufacturing in its earlier sense, referring to automated lathes of non- CNC types. The first automatic lathes were mechanically automated and controlled by cams or tracers and pantographs. Thus, before electronic automation via numerical control, the "automatic" in the term "automatic machine tool" always referred implicit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cuckoo Clock

A cuckoo clock is, typically, a pendulum clock that strikes the hours with a sound like a common cuckoo call and has an automated cuckoo bird that moves with each note. Some move their wings and open and close their beaks while leaning forwards, whereas others have only the bird's body leaning forward. The mechanism to produce the cuckoo call has been in use since the middle of the 18th century and has remained almost without variation. It is unknown who invented the cuckoo clock and where the first one was made. It is thought that much of its development and evolution was made in the Black Forest area in southwestern Germany (in the modern state of Baden-Württemberg), the region where the cuckoo clock was popularized and from where it was exported to the rest of the world, becoming world-famous from the mid-1850s on. Today, the cuckoo clock is one of the favourite souvenirs of travellers in Germany, Switzerland and Austria. It has become a cultural icon of Germany. Characteri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chuck (engineering)

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws (sometimes called dogs) are typically arranged in a radially symmetrical pattern like the points of a star. Jawed chucks may require a wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a chuck may use magnetism, vacuum, or collets, which are flexible collars or sleeves that fit closely around the tool or workpiece ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)