|

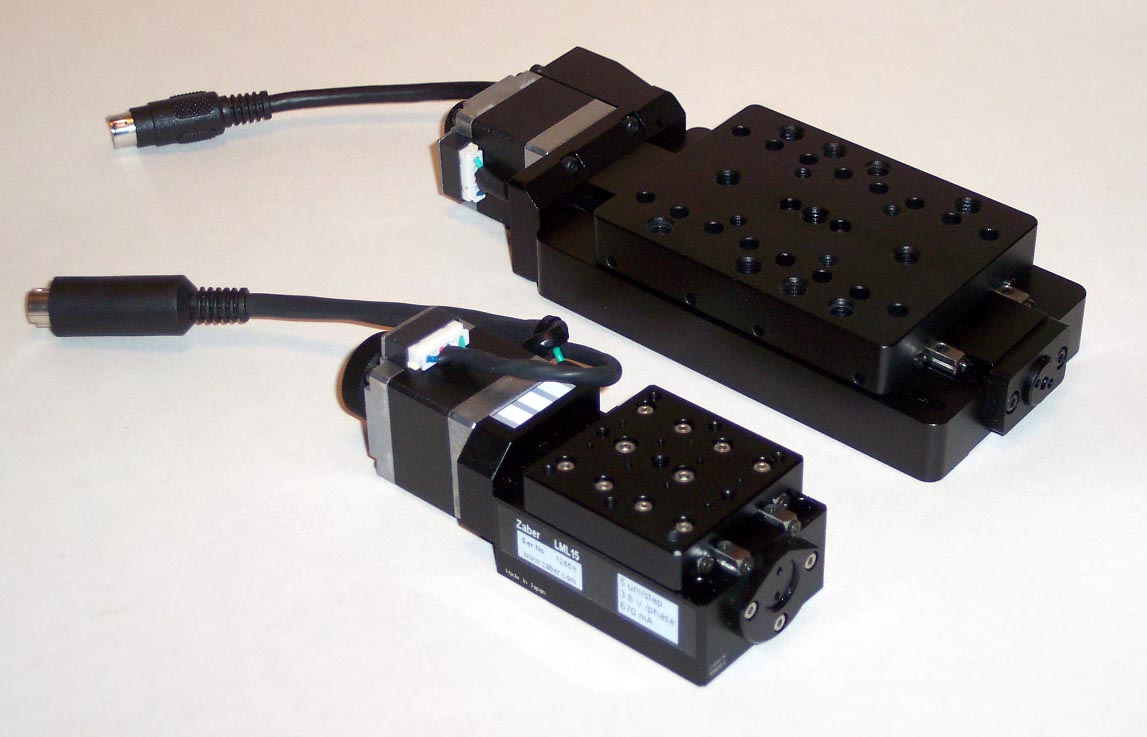

Translation Stage

A linear stage or translation stage is a component of a precise motion system used to restrict an object to a single axis of motion. The term linear slide is often used interchangeably with "linear stage", though technically "linear slide" refers to a linear motion bearing, which is only a component of a linear stage. All linear stages consist of a platform and a base, joined by some form of guide or linear bearing in such a way that the platform is restricted to linear motion with respect to the base. In common usage, the term linear stage may or may not also include the mechanism by which the position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along any of three axes. Thus the object is said to have six degrees of freedom (3 rotational and 3 translational). A linear stage exhibits only one degree of freedom (translation along one axis). In other words, linear stages opera ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Zaber Motorized Linear Stage

The Zaber () is a minor tributary of the River Neckar in Baden-Württemberg, Germany. It is some 22 km in length and joins the Neckar from the west at Lauffen am Neckar. It has given its name to the Zabergäu, the area between the Heuchelberg and Stromberg hills. Name The first mention is from the year 793 as ''Zabernahgouwe'' (Zabernachgau). Traditionally it is assumed that the name is derived from the Latin word ''Taberna'' ("restaurant", "street station"). It is assumed that the Roman settlement in today's Meimsheim bore this name (similar to the Alsatian place Zabern) and that with time the place name was transferred to the surroundings or to the river.Albrecht Greule: ''Deutsches Gewässernamenbuch. Etymology of the names of waters and the corresponding names of areas, settlements and fields.'' De Gruyter, Berlin 2014, This theory is supported by the fact that there was a traffic junction in Roman Meimsheim and that the place was possibly of administrative importanc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motion System

{{refimprove, date=September 2007 Motion system in engineering and systems, is a component of a test and measurement system that provides motion to a load or loads in a one or many directions. Generally a motion system is made up of a set (or stack) of linear and rotational stages. A linear stage moves in a straight line, while a rotation stage moves in a partial or full circle. A stage can either be manually controlled with a knob control, or automated with a motion controller. A motion system generally is computer controlled and can perform fast, reliable, repeatable, and accurate positioning of loads. Most systems will support motion in X and Y directions, which is referred to as an XY stack. Often either a Z axis (up/down motion) or R axis (rotational motion) is placed on top of the XY stack. For automated stages, a scale can be attached to the internals of the stage and an encoder used to measure the position on the scale and report this to the controller, thereby determin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Motion Bearing

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings. Motorized linear slides such as machine slides, X-Y tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. X-Y tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis. Rolling-element bearing A rolling-element bearing is generally composed of a sleeve-like outer ring and several rows of balls retained by cages. The cages were originally machined from soli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Actuator

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer Peripheral, peripherals such as disk drives and printers, in Valve, valves and Damper (flow), dampers, and in many other places where linear motion is required. Hydraulics, Hydraulic or Pneumatics, pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor. Types Mechanical actuators Machine, Mechanical linear actuators typically operate by conversion of rotary motion into linear motion. Conversion is commonly made via a few simple types of mechanism: * Screw (simple machine), Screw: leadscrew, screw jack, ball screw and roller screw actuators all operate on the principle of the simple machine known as the screw. By rotating the actuator's nut, the screw shaft moves in a line. * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optics

Optics is the branch of physics that studies the behaviour and properties of light, including its interactions with matter and the construction of instruments that use or detect it. Optics usually describes the behaviour of visible, ultraviolet, and infrared light. Because light is an electromagnetic wave, other forms of electromagnetic radiation such as X-rays, microwaves, and radio waves exhibit similar properties. Most optical phenomena can be accounted for by using the classical electromagnetic description of light. Complete electromagnetic descriptions of light are, however, often difficult to apply in practice. Practical optics is usually done using simplified models. The most common of these, geometric optics, treats light as a collection of rays that travel in straight lines and bend when they pass through or reflect from surfaces. Physical optics is a more comprehensive model of light, which includes wave effects such as diffraction and interference that cannot be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micrometer (device)

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers (opposing ends joined by a frame). The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil. Micrometers are also used in telescopes or microscopes to measure the apparent diameter of celestial bodies or microscopic objects. The micrometer used with a telescope was invented about 1638 by William Gascoigne, an English astronomer. History The word ''micrometer'' is a neoclassical coinage ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stepper Motor

A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller), as long as the motor is correctly sized to the application in respect to torque and speed. Switched reluctance motors are very large stepping motors with a reduced pole count, and generally are closed-loop commutated. Mechanism Brushed DC motors rotate continuously when DC voltage is applied to their terminals. The stepper motor is known for its property of converting a train of input pulses (typically square waves) into a precisely defined increment in the shaft’s rotational position. Each pulse rotates the shaft through a fixed angle. Stepper motors effectively have multiple "toothed" electromagnets arranged as a stator around a central rotor, a gear-shaped piece of iron. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Stage

A rotary stage is a component of a motion system used to restrict an object to a single axis of rotation. The terms rotary table or rotation stage are often used interchangeably with rotary stage. All rotary stages consist of a platform and a base, joined by some form of guide in such a way that the platform is restricted to rotation about a single axis with respect to the base. In common usage, the term rotary stage may or may not also include the mechanism by which the angular position of the platform is controlled relative to the base. Principle of operation In three-dimensional space, an object may either rotate about, or translate along, any of three axes. Thus, the object is said to have six degrees of freedom (3 rotational and 3 translational). A rotary stage exhibits only one degree of freedom (rotation about one axis). In other words, rotary stages operate by physically restricting 3 axes of translation and 2 axes of rotation. Bearing types Rotary stages consist of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Positioning Goniometer

A positioning goniometer or goniometric stage is a device used to rotate an object precisely (within a small angular range) about a fixed axis in space. Its appearance is similar to that of a linear stage. However, rather than moving linearly with respect to its base, the stage platform rotates partially about a fixed axis above the mounting surface of the platform. The distance of the center of rotation from the platform mounting surface is often chosen so that two different goniometer models may be stacked in an X-Y configuration and both stages will rotate about the same point. Positioning goniometers typically use a worm drive with a partial worm wheel fixed to the underside of the stage platform meshing with a worm in the base. The worm may be rotated manually or by a motor as in automated positioning systems. See also *Goniometer *Indexing head An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Performance Positioning Systems

A high performance positioning system (HPPS) is a type of positioning system consisting of a piece of electromechanics equipment (e.g. an assembly of linear stages and rotary stages) that is capable of moving an object in a three-dimensional space within a work envelope. Positioning could be done point to point or along a desired path of motion. Position is typically defined in six degrees of freedom, including linear, in an x,y,z cartesian coordinate system, and angular orientation of yaw, pitch, roll. HPPS are used in many manufacturing processes to move an object (tool or part) smoothly and accurately in six degrees of freedom, along a desired path, at a desired orientation, with high acceleration, high deceleration, high velocity and low settling time. It is designed to quickly stop its motion and accurately place the moving object at its desired final position and orientation with minimal jittering. HPPS requires a structural characteristics of low moving mass and high stiffnes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Device Fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuit (IC) chips such as modern computer processors, microcontrollers, and memory chips such as NAND flash and DRAM that are present in everyday electrical and electronics, electronic devices. It is a multiple-step sequence of Photolithography, photolithographic and chemical processing steps (such as surface passivation, thermal oxidation, planar process, planar diffusion and p–n junction isolation, junction isolation) during which electronic circuits are gradually created on a wafer (electronics), wafer made of pure semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. The entire manufacturing process takes time, from start to packaged chips ready for shipment, at least six to eight weeks (tape-out only, not including the circuit design) and is performed in highly specialized semiconduct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epitaxial Wafer

An epitaxial wafer (also called epi wafer, epi-wafer, or epiwafer) is a wafer of semiconducting material made by epitaxial growth (epitaxy) for use in photonics, microelectronics, spintronics, or photovoltaics. The epi layer may be the same material as the substrate, typically monocrystaline silicon, or it may be a more exotic material with specific desirable qualities. Silicon epi wafers were first developed around 1966, and achieved commercial acceptance by the early 1980s. Methods for growing the epitaxial layer on monocrystalline silicon or other wafers include: various types of chemical vapor deposition (CVD) classified as Atmospheric pressure CVD (APCVD) or metal organic chemical vapor deposition (MOCVD), as well as molecular beam epitaxy (MBE). Two "kerfless" methods (without abrasive sawing) for separating the epitaxial layer from the substrate are called "implant-cleave" and "stress liftoff". A method applicable when the epi-layer and substrate are the same material empl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |