|

Tumble Flap

A tumble flap is a flap housed in the intake area of many modern automotive gasoline engines to produce a swirl at right-angles to the cylinder axis. This swirling motion improves the air-fuel mixture and enhances power and torque, while at the same time lowering fuel consumption and decreasing emissions. The flaps can be actuated with pneumatic or electric power. Furthermore, the position of the flap can be controlled continuously with a feedback controller or just kept either fully closed or open. Use of a tumble flap improves the lean burn ability of a spark-ignition engine. Operation The set point of the tumble flap is adjusted by an electrical or vacuum-activated servo mechanism which is under the control of the engine management system. Tumble flaps are open or closed depending on engine operating states (related to engine speed and load), engine temperatures, combustion modes (characterized by air-fuel ratio), catalytic converter heating or cold start active or inactiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasoline Engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ''E10'' and ''E85''). Most petrol engines use spark ignition, unlike diesel engines which typically use compression ignition. Another key difference to diesel engines is that petrol engines typically have a lower compression ratio. Design Thermodynamic cycle Most petrol engines use either the four-stroke Otto cycle or the two-stroke cycle. Petrol engines have also been produced using the Miller cycle and Atkinson cycle. Layout Most petrol-powered piston engines are straight engines or V engines. However, flat engines, W engines and other layouts are sometimes used. Wankel engines are classified by the number of rotors used. Compression ratio Cooling Petrol engines are either air-cooled or water-cooled. Ignition Petrol en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark-ignition Engine

A spark-ignition engine (SI engine) is an internal combustion engine, generally a petrol engine, where the combustion process of the air-fuel mixture is ignited by a spark from a spark plug. This is in contrast to compression-ignition engines, typically diesel engines, where the heat generated from compression together with the injection of fuel is enough to initiate the combustion process, without needing any external spark. Fuels Spark-ignition engines are commonly referred to as "gasoline engines" in North America, and "petrol engines" in Britain and the rest of the world. Spark-ignition engines can (and increasingly are) run on fuels other than petrol/gasoline, such as autogas ( LPG), methanol, ethanol, bioethanol, compressed natural gas (CNG), hydrogen, and (in drag racing) nitromethane. Working cycle The working cycle of both spark-ignition and compression-ignition engines may be either two-stroke or four-stroke. A four-stroke spark-ignition engine is an Otto cycle engine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Setpoint (control System)

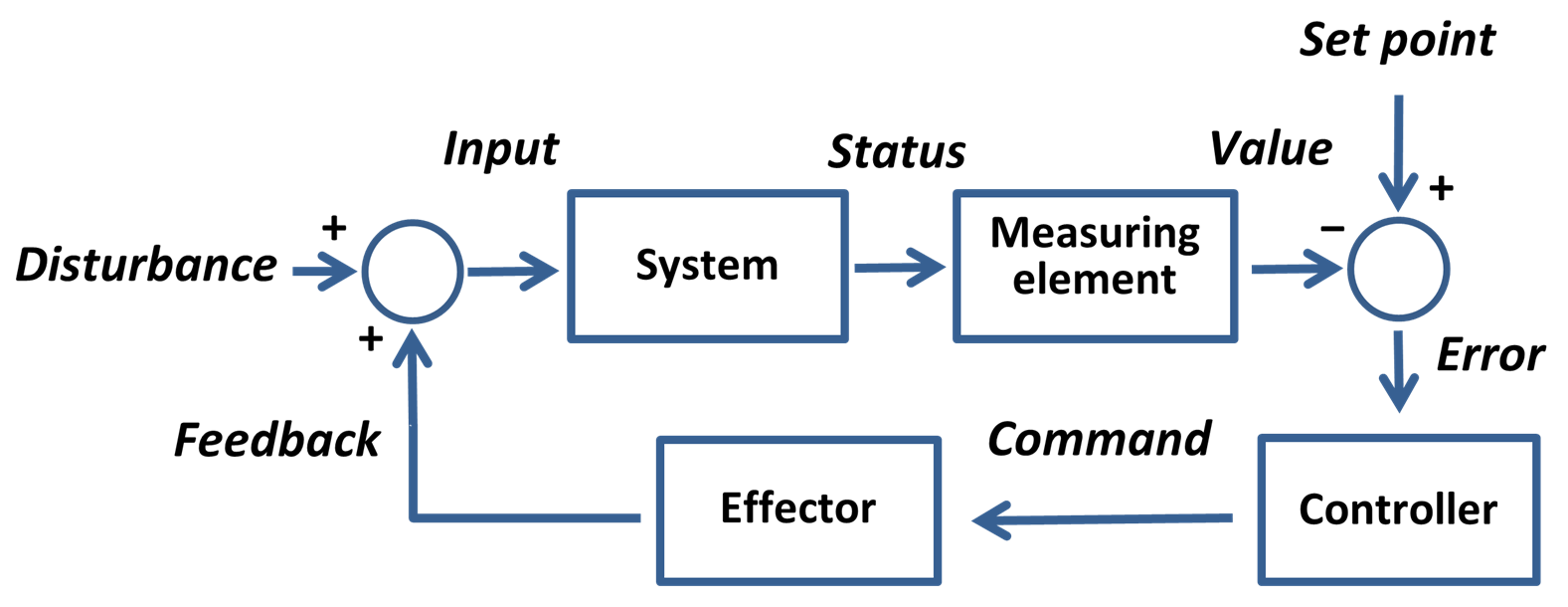

In cybernetics and control theory, a setpoint (SP; also set point) is the desired or target value for an essential variable, or process value (PV) of a control system. Departure of such a variable from its setpoint is one basis for error-controlled regulation using negative feedback for automatic control. Examples Cruise control The SP-PV error can be used to return a system to its norm. An everyday example is the cruise control on a road vehicle; where external influences such as gradients cause speed changes (PV), and the driver also alters the desired set speed (SP). The automatic control algorithm restores the actual speed to the desired speed in the optimum way, without delay or overshoot, by altering the power output of the vehicle's engine. In this way the SP-PV error is used to control the PV so that it equals the SP. A widespread use of SP-PV error control is the PID controller. Industrial applications Special consideration must be given for engineering application ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Servomechanism

In control engineering a servomechanism, usually shortened to servo, is an automatic device that uses error-sensing negative feedback to correct the action of a mechanism. On displacement-controlled applications, it usually includes a built-in encoder or other position feedback mechanism to ensure the output is achieving the desired effect. The term correctly applies only to systems where the feedback or error-correction signals help control mechanical position, speed, attitude or any other measurable variables. For example, an automotive power window control is not a servomechanism, as there is no automatic feedback that controls position—the operator does this by observation. By contrast a car's cruise control uses closed-loop feedback, which classifies it as a servomechanism. Applications Position control A common type of servo provides ''position control''. Commonly, servos are electric, hydraulic, or pneumatic. They operate on the principle of negative feedback, wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Management System

An engine control unit (ECU), also commonly called an engine control module (ECM), is a type of electronic control unit that controls a series of actuators on an internal combustion engine to ensure optimal engine performance. It does this by reading values from a multitude of sensors within the engine bay, interpreting the data using multidimensional performance maps (called lookup tables), and adjusting the engine actuators. Before ECUs, air–fuel mixture, ignition timing, and idle speed were mechanically set and dynamically controlled by mechanical and pneumatic means. If the ECU has control over the fuel lines, then it is referred to as an electronic engine management system (EEMS). The fuel injection system has the major role of controlling the engine's fuel supply. The whole mechanism of the EEMS is controlled by a stack of sensors and actuators. Workings Control of air–fuel ratio Most modern engines use some type of fuel injection to deliver fuel to the cylinders. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Start (automotive)

A cold start is an attempt to start a vehicle's engine when it is cold, relative to its normal operating temperature, often due to normal cold weather. A cold start situation is commonplace, as weather conditions in most climates will naturally be at a lower temperature than the typical operating temperature of an engine. Causes of cold starts Cold starts are more difficult than starting a vehicle that has been run recently (typically between 90 minutes and 2 hours). More effort is needed to turn over a cold engine for multiple reasons: * The engine compression is higher as the lack of heat makes ignition more difficult * Low temperatures cause engine oil to become more viscous, making it more difficult to circulate the oil. * Air becomes more dense the cooler it is. This affects the air-fuel ratio, which in turn affects the flammability of the mixture. Solutions to cold starting The problem of cold starting has been greatly reduced since the introduction of engine starte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gasoline Direct Injection

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a mixture formation system for internal combustion engines that run on gasoline (petrol), where fuel is injected into the combustion chamber. This is distinct from manifold fuel injection systems, which inject fuel into the intake manifold. The use of GDI can help increase engine efficiency and specific power output as well as reduce exhaust emissions. The first GDI engine to reach production was introduced in 1925 for a low-compression truck engine. Several German cars used a Bosch mechanical GDI system in the 1950s, however usage of the technology remained rare until an electronic GDI system was introduced in 1996 by Mitsubishi for mass-produced cars. GDI has seen rapid adoption by the automotive industry in recent years, increasing in the United States from 2.3% of production for model year 2008 vehicles to approximately 50% for model year 2016. Operating principle Charge modes The 'charg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stratified Charge

A stratified charge engine describes a certain type of internal combustion engine, usually spark ignition (SI) engine that can be used in trucks, automobiles, portable and stationary equipment. The term "stratified charge" refers to the working fluids and fuel vapors entering the cylinder. Usually the fuel is injected into the cylinder or enters as a fuel rich vapor where a spark or other means are used to initiate ignition where the fuel rich zone interacts with the air to promote complete combustion. A stratified charge can allow for slightly higher compression ratios without " knock," and leaner air/fuel ratio than in conventional internal combustion engines. Conventionally, a four-stroke (petrol or gasoline) Otto cycle engine is fueled by drawing a mixture of air and fuel into the combustion chamber during the intake stroke. This produces a homogeneous charge: a homogeneous mixture of air and fuel, which is ignited by a spark plug at a predetermined moment near the top of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spark Plug

A spark plug (sometimes, in British English, a sparking plug, and, colloquially, a plug) is a device for delivering electric current from an ignition system to the combustion chamber of a spark-ignition engine to ignite the compressed fuel/air mixture by an electric spark, while containing combustion pressure within the engine. A spark plug has a metal threaded shell, electrically isolated from a central electrode by a ceramic insulator. The central electrode, which may contain a resistor, is connected by a heavily insulated wire to the output terminal of an ignition coil or magneto. The spark plug's metal shell is screwed into the engine's cylinder head and thus electrically grounded. The central electrode protrudes through the porcelain insulator into the combustion chamber, forming one or more spark gaps between the inner end of the central electrode and usually one or more protuberances or structures attached to the inner end of the threaded shell and designated the ''side ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenging (automotive)

Scavenging is the process of replacing the exhaust gas in a cylinder of an internal combustion engine with the fresh air/fuel mixture (or fresh air, in the case of direct-injection engines) for the next cycle. If scavenging is incomplete, the remaining exhaust gases can cause improper combustion for the next cycle, leading to reduced power output. Scavenging is equally important for both two-stroke and four-stroke engines. Most modern four-stroke engines use crossflow cylinder heads and valve timing overlap to scavenge the cylinders. Modern two-stroke engines use either Schnuerle scavenging (also known as "loop scavenging") or uniflow scavenging. The scavenge or scavenging port refers to that port through which clean air enters the cylinder, the exhaust port through which it leaves. Origins The first engines deliberately designed to encourage scavenging were gas engines built by Crossley Brothers Ltd in the United Kingdom in the early 1890s. These ''Crossley Otto Scavengin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |