|

Superhard Material

A superhard material is a material with a hardness value exceeding 40 gigapascals (GPa) when measured by the Vickers hardness test. They are virtually incompressible solids with high electron density and high bond covalency. As a result of their unique properties, these materials are of great interest in many industrial areas including, but not limited to, abrasives, polishing and cutting tools, disc brakes, and wear-resistant and protective coatings. Diamond is the hardest known material to date, with a Vickers hardness in the range of 70–150 GPa. Diamond demonstrates both high thermal conductivity and electrically insulating properties, and much attention has been put into finding practical applications of this material. However, diamond has several limitations for mass industrial application, including its high cost and oxidation at temperatures above 800 °C. In addition, diamond dissolves in iron and forms iron carbides at high temperatures and therefore is inefficien ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vickers Hardness Test

The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter can be used for all materials irrespective of hardness. The basic principle, as with all common measures of hardness, is to observe a material's ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid Number (HV) or Diamond Pyramid Hardness (DPH). The hardness number can be converted into units of pascals, but should not be confused with pressure, which uses the same units. The hardness number is determined by the load over the surface area of the indentation and not t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Beta Carbon Nitride

Beta (, ; uppercase , lowercase , or cursive ; grc, βῆτα, bē̂ta or ell, βήτα, víta) is the second letter of the Greek alphabet. In the system of Greek numerals, it has a value of 2. In Modern Greek, it represents the voiced labiodental fricative while in borrowed words is instead commonly transcribed as μπ. Letters that arose from beta include the Roman letter and the Cyrillic letters and . Name Like the names of most other Greek letters, the name of beta was adopted from the acrophonic name of the corresponding letter in Phoenician, which was the common Semitic word ''*bait'' ('house'). In Greek, the name was ''bêta'', pronounced in Ancient Greek. It is spelled βήτα in modern monotonic orthography and pronounced . History The letter beta was derived from the Phoenician letter beth . Uses Algebraic numerals In the system of Greek numerals, beta has a value of 2. Such use is denoted by a number mark: Β′. Computing Finance Beta is used i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rockwell Scale

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different loads or indenters. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale. When testing metals, indentation hardness correlates linearly with tensile strength. History The differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book ''Die Kegelprobe'' (crudely, "the cone test"). The differential-depth method subtracted out the errors associated with the mechanical imperfections of the system, such as backlash and surface imperfections. The Brinell hardness test, invented in Sweden, was developed earlier – in 1900 – but it was slow, not use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brinell Scale

The Brinell scale characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science. History Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests. Test details The typical test uses a diameter steel ball as an indenter with a force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as: :\operatorname=\frac where: :BHN = Brinell Hardne ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

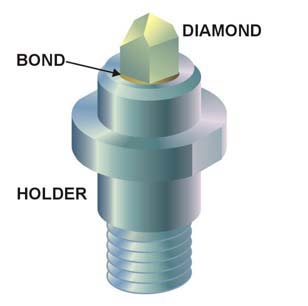

Nanoindenter

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called ''depth sensing indentation'' or ''instrumented indentation'', gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties. Types There are many types of nanoindenters in current use differing mainly on their tip geometry. Among the numerous available geometries are three and four sided pyramids, wedges, cones, cylinders, filaments, and spheres. Several geometries have become a well established common standard due to their extended use and well known properties; such as Berkovich, cube corner, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mohs Scale Of Mineral Hardness

The Mohs scale of mineral hardness () is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of various minerals through the ability of harder material to scratch softer material. The scale was introduced in 1812 by the German geologist and mineralogist Friedrich Mohs, in his book ''"Versuch einer Elementar-Methode zur naturhistorischen Bestimmung und Erkennung der Fossilien"''; it is one of several definitions of hardness in materials science, some of which are more quantitative. The method of comparing hardness by observing which minerals can scratch others is of great antiquity, having been mentioned by Theophrastus in his treatise ''On Stones'', , followed by Pliny the Elder in his ''Naturalis Historia'', . The Mohs scale is useful for identification of minerals in the field, but is not an accurate predictor of how well materials endure in an industrial setting – ''toughness''. Minerals The Mohs scale of mineral hardness is based on the ability ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HPHT

Lab-grown diamond (LGD; also called laboratory-grown, laboratory-created, man-made, artisan-created, artificial, synthetic, or cultured diamond) is diamond that is produced in a controlled technological process (in contrast to naturally formed diamond, which is created through geological processes and obtained by mining). Unlike diamond simulants (imitations of diamond made of superficially-similar non-diamond materials), synthetic diamonds are composed of the same material as naturally formed diamonds – pure carbon crystallized in an isotropic 3D form – and share identical chemical and physical properties. Numerous claims of diamond synthesis were reported between 1879 and 1928; most of these attempts were carefully analyzed but none was confirmed. In the 1940s, systematic research of diamond creation began in the United States, Sweden and the Soviet Union, which culminated in the first reproducible synthesis in 1953. Further research activity yielded the discoveries of H ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasticity (physics)

In physics and materials science, plasticity, also known as plastic deformation, is the ability of a solid material to undergo permanent Deformation (engineering), deformation, a non-reversible change of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the material itself. In engineering, the transition from Elasticity (physics), elastic behavior to plastic behavior is known as Yield (engineering), yielding. Plastic deformation is observed in most materials, particularly metals, soils, Rock (geology), rocks, concrete, and foams. However, the physical mechanisms that cause plastic deformation can vary widely. At a crystalline scale, plasticity in metals is usually a consequence of dislocations. Such defects are relatively rare in most crystalline materials, but are numerous in some and part of their crystal structure; in such cases, plastic crystallinity can res ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain: :G \ \stackrel\ \frac = \frac = \frac where :\tau_ = F/A \, = shear stress :F is the force which acts :A is the area on which the force acts :\gamma_ = shear strain. In engineering :=\Delta x/l = \tan \theta , elsewhere := \theta :\Delta x is the transverse displacement :l is the initial length of the area. The derived SI unit of shear modulus is the pascal (Pa), although it is usually expressed in gigapascals (GPa) or in thousand pounds per square inch (ksi). Its dimensional form is M1L−1T−2, replacing ''force'' by ''mass'' times ''acceleration''. Explanation The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in the generalized Hooke's law: * Young's modulus ''E'' describes the mat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Case Hardened Steel-vickers Hardness Test

Case or CASE may refer to: Containers * Case (goods), a package of related merchandise * Cartridge case or casing, a firearm cartridge component * Bookcase, a piece of furniture used to store books * Briefcase or attaché case, a narrow box to carry paperwork * Computer case, the enclosure for a PC's main components * Keep case, DVD or CD packaging * Pencil case * Phone case, protective or vanity accessory for mobile phones ** Battery case * Road case or flight case, for fragile equipment in transit * Shipping container or packing case * Suitcase, a large luggage box * Type case, a compartmentalized wooden box for letterpress typesetting Places * Case, Laclede County, Missouri * Case, Warren County, Missouri * Case River, a Kabika tributary in Ontario, Canada * Case Township, Michigan * Case del Conte, Italy People * Case (name), people with the surname (or given name) * Case (singer), American R&B singer-songwriter and producer (Case Woodard) Arts, entertainment, and medi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoindenter Holder

A nanoindenter is the main component for indentation hardness tests used in nanoindentation. Since the mid-1970s nanoindentation has become the primary method for measuring and testing very small volumes of mechanical properties. Nanoindentation, also called ''depth sensing indentation'' or ''instrumented indentation'', gained popularity with the development of machines that could record small load and displacement with high accuracy and precision. The load displacement data can be used to determine modulus of elasticity, hardness, yield strength, fracture toughness, scratch hardness and wear properties. Types There are many types of nanoindenters in current use differing mainly on their tip geometry. Among the numerous available geometries are three and four sided pyramids, wedges, cones, cylinders, filaments, and spheres. Several geometries have become a well established common standard due to their extended use and well known properties; such as Berkovich, cube corner, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |