|

Spark Erosion

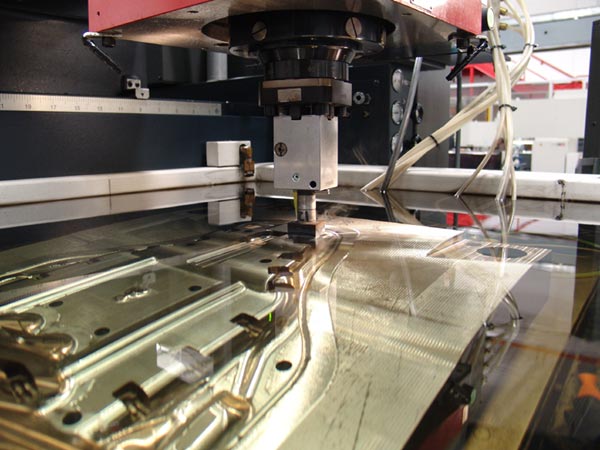

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing dielectric break down of the liquid, and produces an electric arc. As a result, material is removed from the electrodes. Once the current stops (or is stopped, depending on the type of generator), new liquid di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling

Drilling is a cutting process where a drill bit is spun to cut a hole of circular cross-section in solid materials. The drill bit is usually a rotary cutting tool, often multi-point. The bit is pressed against the work-piece and rotated at rates from hundreds to thousands of revolutions per minute. This forces the cutting edge against the work-piece, cutting off chips (swarf) from the hole as it is drilled. In rock drilling, the hole is usually not made through a circular cutting motion, though the bit is usually rotated. Instead, the hole is usually made by hammering a drill bit into the hole with quickly repeated short movements. The hammering action can be performed from outside the hole ( top-hammer drill) or within the hole (down-the-hole drill, DTH). Drills used for horizontal drilling are called drifter drills. In rare cases, specially-shaped bits are used to cut holes of non-circular cross-section; a square cross-section is possible. Process Drilled holes are char ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as Cutting tool (machining), cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and abrasive saw, cut-off saws * Stationary power tools such as bench grinders and abrasive saw, cut-off saws * Stationary hydropower, hydro- or human power, hand-powered grindstone (tool), sharpening stones Milling practice is a large and diverse area of manufacturing and Tool and die maker, toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very Hardness, hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other typ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) is used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. History In 1965, the first production laser cutting machine was used to drilling, drill holes in diamond Die (manufacturing), dies. This machine was made by the Western Electric Engineering Research Center. In 1967, the British pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |