|

Spline (mechanical)

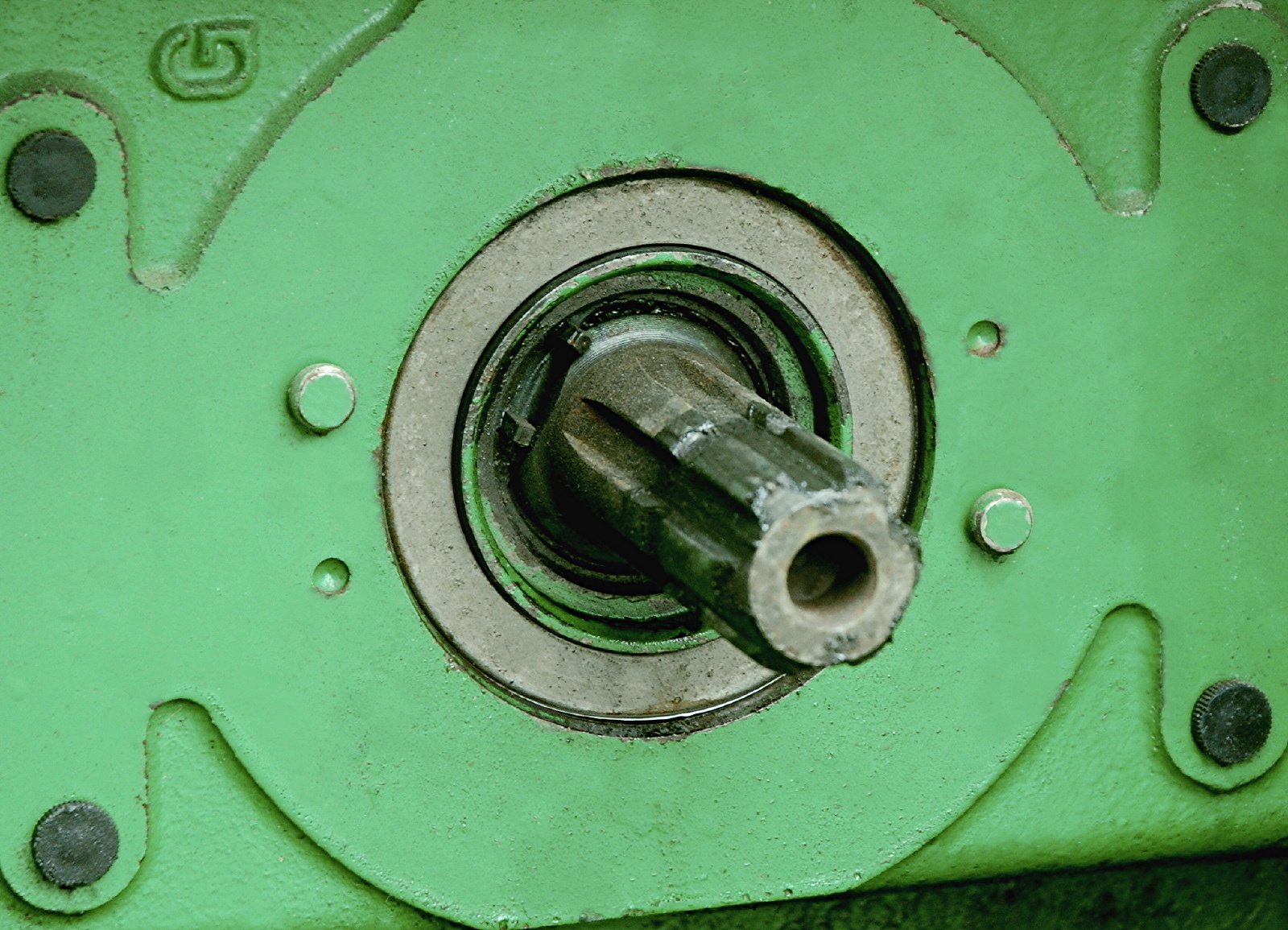

Splines are ridges or teeth on a drive shaft that matches with grooves in a mating piece and transfer torque to it, maintaining the angular correspondence between them. For instance, a gear mounted on a shaft might use a male spline on the shaft that matches the female spline on the gear. The splines on the pictured drive shaft match with the female splines in the center of the clutch plate, while the smooth tip of the axle is supported in the pilot bearing in the flywheel. An alternative to splines is a keyway and key, though splines provide a longer fatigue life, and can carry significantly greater torques for the size. Types There are several types of splines: ;Parallel key spline: where the sides of the equally spaced grooves are parallel in both directions, radial and axial. ;Involute spline: where the sides of the equally spaced grooves are involute, as with an involute gear, but not as tall. The curves increase strength by decreasing stress concentrations. ;Crowned spl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drive Shaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power (physics), power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. As torque carriers, drive shafts are subject to torsion (mechanics), torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a Rotating spline, splined joint or prismatic joint. History The term ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Take-off

A power take-off or power takeoff (PTO) is one of several methods for taking power from a power source, such as a running engine, and transmitting it to an application such as an attached implement or separate machine. Most commonly, it is a splined drive shaft installed on a tractor or truck allowing implements with mating fittings to be powered directly by the engine. Semi-permanently mounted power take-offs can also be found on industrial and marine engines. These applications typically use a drive shaft and bolted joint to transmit power to a secondary implement or accessory. In the case of a marine application, such shafts may be used to power fire pumps. In aircraft applications, such an accessory drive may be used in conjunction with a constant speed drive. Jet aircraft have four types of PTO units: internal gearbox, external gearbox, radial drive shaft, and bleed air, which are used to power engine accessories. In some cases, aircraft power take-off systems also provid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling Machine

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying direction on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs). The integra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Shaping

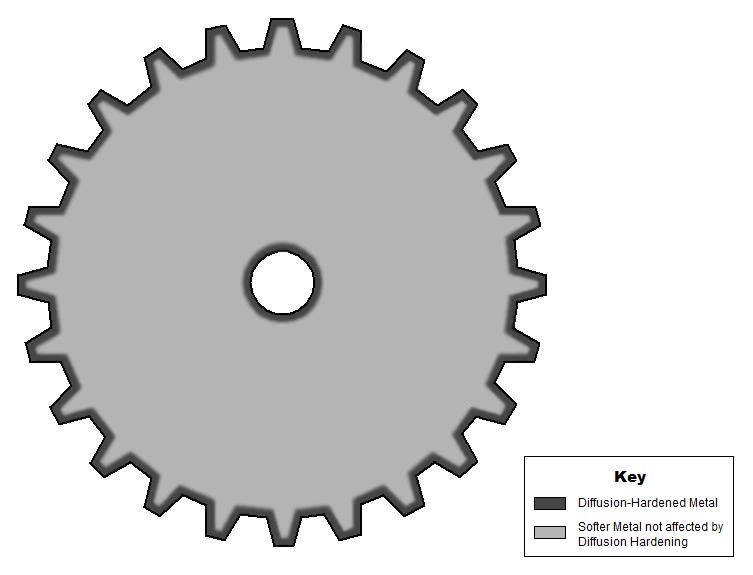

Gear shaping is a machining process for creating teeth on a gear using a cutter. Gear shaping is a convenient and versatile method of gear cutting. It involves continuous, same-plane rotational cutting of gear. Process theory The types of cutters used for gear shaping can be grouped into four categories: disk, hub, shank, and helical cutters. The cutters are essentially gears that are used to form the teeth. This method of gear cutting is based on the principle that any two gears will mesh if they are of the same pitch, proper helix angle, and proper tooth depth and thickness. Process characteristics By using a gear-shaped corresponding cutter that is rotated (in relation to a blank gear) produces the gear teeth. The cutters that are rotated are timed with the workpiece. This process produces internal gears, external gears, and integral gear- pinion arrangements. Process schematic The process of gear shaping uses a toothed disk cutter which reciprocates in axial rotations. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gear Shaper

A gear shaper is a machine tool for cutting the teeth of internal or external gears, it is a specialised application of the more general shaper machine. The name shaper relates to the fact that the cutter engages the part on the forward stroke and pulls away from the part on the return stroke, just like the clapper box on a planer shaper.Woodbury, Robert S. ''Studies in the history of machine'' ''tools''. Cambridge, Mass. :M.I.T. Press, 1972 The cutting tool is also gear shaped having the same pitch as the gear to be cut. However number of cutting teeth must be less than that of the gear to be cut for internal gears. For external gears the number of teeth on the cutter is limited only by the size of the shaping machine. For larger gears the blank is sometimes gashed to the rough shape to make shaping easier. The principal motions involved in rotary gear shaper cutting are of the following : # ''Cutting Motion'': The downward linear motion of the cutter spindle together with the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Broaching (metalworking)

Broaching is a machining process that uses a toothed tool, called a broach, to remove material. There are two main types of broaching: ''linear'' and ''rotary''. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to ''broach''. In rotary broaching, the broach is rotated and pressed into the workpiece to cut an axisymmetric shape. A rotary broach is used in a lathe or screw machine. In both processes the cut is performed in one pass of the broach, which makes it very efficient. Broaching is used when precision machining is required, especially for odd shapes. Commonly machined surfaces include circular and non-circular holes, splines, keyways, and flat surfaces. Typical workpieces include small to medium-sized castings, forgings, screw machine parts, and stampings. Even though broaches can be expensive, broach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tire Balance

Tire balance, also called tire unbalance or tire imbalance, describes the distribution of mass within an automobile tire or the entire wheel (including the rim) on which it is mounted. When the wheel rotates, asymmetries in its mass distribution may cause it to apply periodic forces and torques to the axle, which can cause ride disturbances, usually as vertical and lateral vibrations, and this may also cause the steering wheel to oscillate. The frequency and magnitude of this ride disturbance usually increases with speed, and vehicle suspensions may become excited when the rotating frequency of the wheel equals the resonant frequency of the suspension. Tire balance is measured in factories and repair shops by two methods: with static balancers and with dynamic balancers. Tires with large unbalances are downgraded or rejected. When tires are fitted to wheels at the point of sale, they are measured again on a balancing machine, and correction weights are applied to counteract the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propeller

A propeller (colloquially often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are specially shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft (ship), propeller shaft with an approximately horizontal axis. History Early developments The principle employed in using a screw propeller is derived from sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aircraft Engine

An aircraft engine, often referred to as an aero engine, is the power component of an aircraft propulsion system. Most aircraft engines are either piston engines or gas turbines, although a few have been rocket powered and in recent years many small UAVs have used electric motors. Manufacturing industry In commercial aviation the major Western manufacturers of turbofan engines are Pratt & Whitney (a subsidiary of Raytheon Technologies), General Electric, Rolls-Royce, and CFM International (a joint venture of Safran Aircraft Engines and General Electric). Russian manufacturers include the United Engine Corporation, Aviadvigatel and Klimov. Aeroengine Corporation of China was formed in 2016 with the merger of several smaller companies. The largest manufacturer of turboprop engines for general aviation is Pratt & Whitney. General Electric announced in 2015 entrance into the market. Development history * 1848: John Stringfellow made a steam engine for a 10-foot wingspan mod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bicycle Brake Systems

A bicycle brake reduces the speed of a bicycle or prevents it from moving. The three main types are: rim brakes, disc brakes, and drum brakes. Most bicycle brake systems consist of three main components: a mechanism for the rider to apply the brakes, such as brake levers or pedals; a mechanism for transmitting that signal, such as Bowden cables, hydraulic hoses, rods, or the bicycle chain; and the brake mechanism itself, a caliper or drum, to press two or more surfaces together in order to convert, via friction, kinetic energy of the bike and rider into thermal energy to be dissipated. History Karl Drais included a pivoting brake shoe that could be pressed against the rear iron tyre of his 1817 . This was continued on the earliest bicycles with pedals, such as the boneshaker, which were fitted with a spoon brake to press onto the rear wheel. The brake was operated by a lever or by a cord connecting to the handlebars. The rider could also slow down by resisting the pedals ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Freehub

A freehub is a type of bicycle hub that incorporates a ratcheting mechanism. A set of sprockets (called a "cassette") is mounted onto a splined shaft of the freehub to engage the chain. The ratcheting mechanism is a part of the hub, in contrast to a freewheel, an older technology, which contains both the sprockets and a ratcheting mechanism in a single unit separate from the hub. In many high-end and midrange bicycles, freehubs have replaced freewheel systems. A freewheel mechanism allows a rider to stop pedalling whilst the cycle is still in forward motion. On a cycle without a freewheel mechanism, the rider has to keep pedalling whenever the cycle is moving. Comparison to freewheels The freehub concept answers several drawbacks encountered with the freewheel design: * Freewheels are threaded onto an axle hub, using conventional right-hand threads. As the bicycle rider pedals, the freewheel is continuously kept tight, as chain torque is in the right-hand direction. This be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cassette (bicycle Part)

On a bicycle, the cassette or cluster is the set of multiple sprockets that attaches to the hub on the rear wheel. A cogset works with a rear derailleur to provide multiple gear ratios to the rider. Cassettes come in two varieties, freewheels or cassettes, of which cassettes are a newer development. Although cassettes and freewheels perform the same function and look almost the same when installed, they have important mechanical differences and are not interchangeable. Freewheels A freewheel (also known as a block) consists of either a single sprocket or a set of sprockets mounted on a body which contains an internal ratcheting mechanism and mounts on a threaded hub. Threaded rear hubs were available in different thread patterns depending on the country of manufacture, French and British threads being the most common. British C.E.I. (Cycle Engineers Institute) thread was adopted as the international standard and is now known as B.S.C. (British Standard Cycle). It is a standar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |