|

Shingling (metallurgy)

{{about, the industrial steel manufacturing process, the text mining technique, w-shingling Shingling was a stage in the production of bar iron or steel, in the finery and puddling processes. As with many ironmaking terms, this is derived from the French - ''cinglage''. The product of the finery was a bloom or loop (from old Frankish ''luppa'' or '' lopp'', meaning a shapeless mass); that of the puddling furnace was a puddled ball. In each case, this needed to be consolidated by hammering it into a more regular shape. This was done manually with heavy hammers; later by a waterwheel or steam powered hammers, leading to modern power hammers. The result was an oblong-shaped iron product similar in appearance to shingles used on roofs. In the finery, this was part of the work of the finer; during puddling, it was done by a special workman called the shingler. The iron (or steel) then had to be further shaped (drawn out) under the hammer or rolled in a rolling mill In met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag Inclusion (mineral), inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to structural failure, failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welding, forge welded, but is more difficult to welding, weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is Carbon steel#Mild or low-carbon steel, mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finery Forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800. History A finery forge was used to refine wrought iron at least by the 3rd century BC in ancient China, based on the earliest archaeological specimens of cast and pig iron fined into wrought iron and steel found at the early Han Dynasty (202 BC – 220 AD) site at Tieshengguo.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 186-187. Pigott speculates that the finery forge existed in the previous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

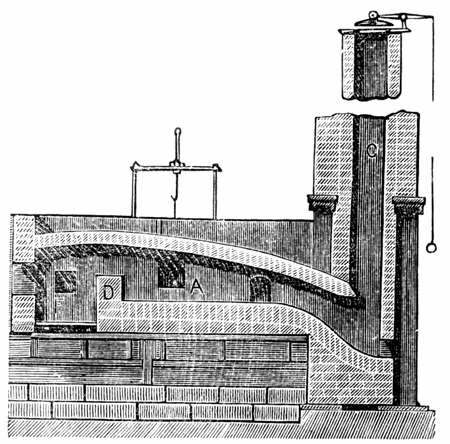

Puddling Furnace

Puddling is the process of converting pig iron to bar (wrought) iron in a coal fired reverberatory furnace. It was developed in England during the 1780s. The molten pig iron was stirred in a reverberatory furnace, in an oxidizing environment, resulting in wrought iron. It was one of the most important processes of making the first appreciable volumes of valuable and useful bar iron (malleable wrought iron) without the use of charcoal. Eventually, the furnace would be used to make small quantities of specialty steels. Though it was not the first process to produce bar iron without charcoal, puddling was by far the most successful, and replaced the earlier potting and stamping processes, as well as the much older charcoal finery and bloomery processes. This enabled a great expansion of iron production to take place in Great Britain, and shortly afterwards, in North America. That expansion constitutes the beginnings of the Industrial Revolution so far as the iron industry is co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Bloom

A bloomery is a type of metallurgical furnace once used widely for smelting iron from its oxides. The bloomery was the earliest form of smelter capable of smelting iron. Bloomeries produce a porous mass of iron and slag called a ''bloom''. The mix of slag and iron in the bloom, termed ''sponge iron'', is usually consolidated and further forged into wrought iron. Blast furnaces, which produce pig iron, have largely superseded bloomeries. Process A bloomery consists of a pit or chimney with heat-resistant walls made of earth, clay, or stone. Near the bottom, one or more pipes (made of clay or metal) enter through the side walls. These pipes, called ''tuyeres'', allow air to enter the furnace, either by natural draught or forced with bellows or a trompe. An opening at the bottom of the bloomery may be used to remove the bloom, or the bloomery can be tipped over and the bloom removed from the top. The first step taken before the bloomery can be used is the preparation of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Old Frankish

Frankish ( reconstructed endonym: *), also known as Old Franconian or Old Frankish, was the West Germanic language spoken by the Franks from the 5th to 9th century. After the Salian Franks settled in Roman Gaul, its speakers in Picardy and Île-de-France were outnumbered by the local populace who spoke Proto-Romance dialects. However, a number of modern French words and place names, including the eventual country's name of "France", have a Frankish (i.e. Germanic) origin. France itself is still known by terms literally meaning the "Frankish Realm" in languages such as German (), Yiddish ( ), Dutch (), the derived Afrikaans (), and Danish () as well as Swedish and Norwegian (). Between the 5th and 9th centuries, Frankish spoken in Northwestern France, present-day Belgium and the Netherlands is subsequently referred to as Old Dutch, whereas the Frankish varieties spoken in the Rhineland were heavily influenced by Elbe Germanic dialects and the Second Germanic consonant sh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waterwheel

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or buckets arranged on the outside rim forming the driving car. Water wheels were still in commercial use well into the 20th century but they are no longer in common use. Uses included milling flour in gristmills, grinding wood into pulp for papermaking, hammering wrought iron, machining, ore crushing and pounding fibre for use in the manufacture of cloth. Some water wheels are fed by water from a mill pond, which is formed when a flowing stream is dammed. A channel for the water flowing to or from a water wheel is called a mill race. The race bringing water from the mill pond to the water wheel is a headrace; the one carrying water after it has left the wheel is commonly referred to as a tailrace. Waterwheels were used for various purposes from ag ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Hammer

Power hammers are mechanical forging hammers that use an electrical power source or steam to raise the hammer preparatory to striking, and accelerate it onto the work being hammered. They are also called open die power forging hammers. They have been used by blacksmiths, bladesmiths, metalworkers, and manufacturers since the late 1880s, having replaced trip hammers. Design and operation A typical power hammer consists of a frame, an anvil, and a reciprocating ram holding a hammer head or die. The workpiece is placed on the lower anvil or die and the head or upper die strikes the workpiece. The power hammer is a direct descendant of the trip hammer, differing in that the power hammer stores potential energy in an arrangement of mechanical linkages and springs, in compressed air, or steam, and by the fact that it accelerates the ram on the downward stroke. This provides more force than simply allowing the weight to fall. Predecessors like trip hammers, steam drop hammers, b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rolling Mill

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes... Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (I-beams, angle stock, channel stock), bar stock, and rails. Most steel mills ha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |