|

Production Control

Within supply chain management and manufacturing, production control is the activity of monitoring and controlling any particular production or operation. Production control is often run from a specific control room or operations room. With inventory control and quality control, production control is one of the key functions of operations management. Overview Production control is the activity of monitoring and controlling a large physical facility or physically dispersed service. It is a "set of actions and decision taken during production to regulate output and obtain reasonable assurance that the specification will be met."S. N. Ghosh (ed.) ''Cement and Concrete Science & Technology.'' 1991. p. 419 The American Production and Inventory Control Society, nowadays APICS, defined production control in 1959 as: :''Production control is the task of predicting, planning and scheduling work, taking into account manpower, materials availability and other capacity restrictions, and cost ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Supply Chain Management

In commerce, supply chain management (SCM) is the management of the flow of goods and services including all processes that transform raw materials into final products between businesses and locations. This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain. Supply-chain management has been defined as the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". SCM practice draws heavily on industrial engineering, systems engineering, operations management, logis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spaceflight

Spaceflight (or space flight) is an application of astronautics to fly spacecraft into or through outer space, either with or without humans on board. Most spaceflight is uncrewed and conducted mainly with spacecraft such as satellites in orbit around Earth, but also includes space probes for flights beyond Earth orbit. Such spaceflight operates either by telerobotic or autonomous control. The more complex human spaceflight has been pursued soon after the first orbital satellites and has reached the Moon and permanent human presence in space around Earth, particularly with the use of space stations. Human spaceflight programs include the Soyuz, Shenzhou, the past Apollo Moon landing and the Space Shuttle programs, with currently the International Space Station as the main destination of human spaceflight missions while China's Tiangong Space Station is under construction. Spaceflight is used for placing in Earth's orbit communications satellites, reconnaissance satellites ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Harold Koontz

Harold D. (Howdy) Koontz (May 19, 1909 - February 11, 1984) was an American organizational theorist, professor of business management at the University of California, Los Angeles and a consultant for many of America's largest business organizations. Koontz co-authored the book ''Principles of Management'' with Cyril J. O'Donnell; the book has sold around two million copies and has been translated into 15 languages. Biography Koontz was born in 1909 in Findlay, Ohio, to Joseph Darius and Harriett (Dillinger) Koontz. He obtained his A.B. from Oberlin College, his MBA from Northwestern University in 1931, and his PhD from Yale University in 1935.''Who's who in the world, 1978-1979,'' 1978. p. 531 Koontz had started his academic career as instructor in business administration at Duke University in the year 1933–34. The next year, 1934–35, he was instructor in accounting and transparency at the University of Toledo. After his graduation in 1935 he was assistant professor in econ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

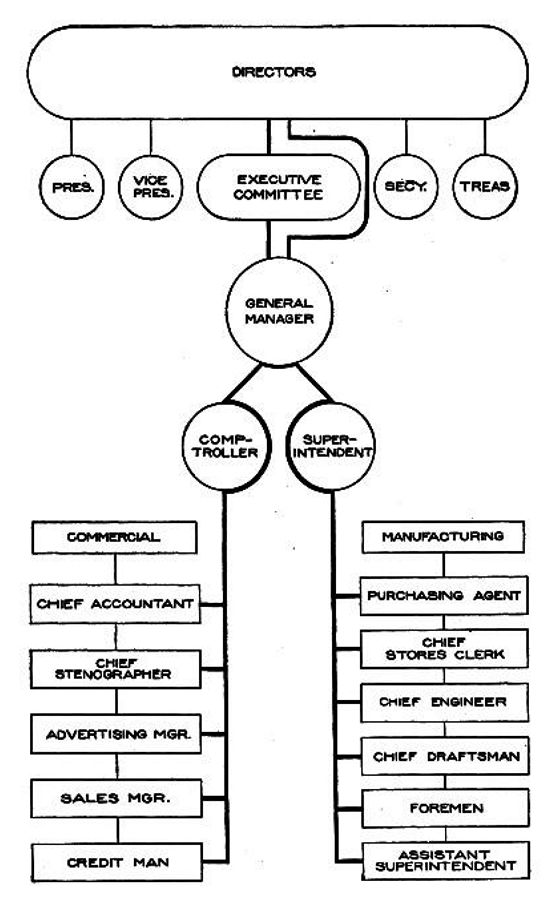

Charles Edward Knoeppel

Charles Edward (C. E.) Knoeppel (15 April 1881 – 29 November 1936)Knoeppel, Charles Edward (1881–1936) in: Morgen Witzel, ed. The Encyclopedia of the History of American Management'' 2005, p. 303 was an American organizational theorist and consultant, who was among the foremost writers on management techniques early 20th century. Yehouda A. Shenhav (2002). ''Manufacturing Rationality: The Engineering Foundations of the Managerial Revolution''. Oxford University Press. p. 221 Biography Knoeppel was born in Milwaukee, Wisconsin as son of John C. Knoeppel, a practical molder and foundryman, who had received some patents in 1878, 1881, and later on in 1909. The family moved to Buffalo, New York, where he attended school. Financially unable to continue college, he started to work. Knoeppel was journalist for a short while, before he started working his way up in an ironworks from laborer to draughtsman and designer to manager in 1904 at the age of 23. The next years he started ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Time Book

A time book is a mostly outdated accounting record, that registered the hours worked by employees in a certain organization in a certain period. These records usually contain names of employees, type of work, hours worked, and sometimes wages paid. In the 19th and early 20th century time books were separate held records. In those days time books were held by company clerks or foremen or specialized timekeepers. These time books were used by the bookkeeper to determine the wages to be paid. The data was used in financial accounting to determine the weekly, monthly and annual labour costs, and in cost accounting to determine the cost price. Late 19th century additional time cards came in use to register labour hours. Nowadays the time book can be a part of an integrated payroll system, or cost accounting system. Those systems can contain registers that describe the labour time spend to produce products, but those registers are not regularly called time books, but timesheets. Hist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Project Production Management

Project production management (PPM) is the application of operations managementA Guide to the Project Management Body of Knowledge, Fifth Edition, Project Management Institute Sec 1.5.1.1, p13 http://www.pmi.org/pmbok-guide-standards/foundational/pmbok to the delivery of capital projects. The PPM framework is based on a project as a production system view, in which a project transforms inputs (raw materials, information, labor, plant & machinery) into outputs (goods and services). The knowledge that forms the basis of PPM originated in the discipline of industrial engineering during the Industrial Revolution. During this time, industrial engineering matured and then found application in many areas such as military planning and logistics for both the First and Second World Wars and manufacturing systems. As a coherent body of knowledge began to form, industrial engineering evolved into various scientific disciplines including operations research, operations management and queue ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Production Engineering

Manufacturing engineering or production engineering is a branch of professional engineering that shares many common concepts and ideas with other fields of engineering such as mechanical, chemical, electrical, and industrial engineering. Manufacturing engineering requires the ability to plan the practices of manufacturing; to research and to develop tools, processes, machines and equipment; and to integrate the facilities and systems for producing quality products with the optimum expenditure of capital. The manufacturing or production engineer's primary focus is to turn raw material into an updated or new product in the most effective, efficient & economic way possible. An example would be a company uses computer integrated technology in order for them to produce their product so that it is faster and uses less human labor. Overview Manufacturing Engineering is based on core industrial engineering and mechanical engineering skills, adding important elements from mechatronics, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Materials Management

Materials management is a core supply chain function and includes supply chain planning and supply chain execution capabilities. Specifically, materials management is the capability firms use to plan total material requirements. The material requirements are communicated to procurement and other functions for sourcing. Materials management is also responsible for determining the amount of material to be deployed at each stocking location across the supply chain, establishing material replenishment plans, determining inventory levels to hold for each type of inventory (raw material, WIP, finished goods), and communicating information regarding material needs throughout the extended supply chain. Typical roles in Materials Management include: Materials Manager, Inventory Control Manager, Inventory Analyst, Material Planner, Expediter and emerging hybrid roles like "buyer planner". The primary business objective of Materials Management is assured supply of material, optimum invent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Process Management

Manufacturing process management (MPM) is a collection of technologies and methods used to define how products are to be manufactured. MPM differs from ERP/MRP which is used to plan the ordering of materials and other resources, set manufacturing schedules, and compile cost data. A cornerstone of MPM is the central repository for the integration of all these tools and activities aids in the exploration of alternative production line scenarios; making assembly lines more efficient with the aim of reduced lead time to product launch, shorter product times and reduced work in progress (WIP) inventories as well as allowing rapid response to product or product changes. * Production process planning ** Manufacturing concept planning ** Factory layout planning and analysis *** work flow simulation. *** walk-path assembly planning *** plant design optimization ** Mixed model line balancing. ** Workloads on multiple stations. ** Process simulation tools e.g. die press lines, manufacturin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Engineering

Industrial engineering is an engineering profession that is concerned with the optimization of complex process (engineering), processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations. Industrial engineers use specialized knowledge and skills in the mathematical, physical and social sciences, together with the principles and methods of engineering analysis and design, to specify, predict, and evaluate the results obtained from systems and processes.Salvendy, Gabriel. Handbook of Industrial Engineering. John Wiley & Sons, Inc; 3rd edition p. 5 There are several industrial engineering principles followed in the manufacturing industry to ensure the effective flow of the systems, processes and operations. This includes Lean Manufacturing, Six Sigma, Information Systems, Process Capability and Define, Measure, Analyze, Improve a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality (philosophy)

A quality is an attribute or a property characteristic of an object in philosophy.Cargile, J. (1995). qualities. in Honderich, T. (Ed.) (2005). ''The Oxford Companion to Philosophy'' (2nd ed.). Oxford In contemporary philosophy the idea of qualities, and especially how to distinguish certain kinds of qualities from one another, remains controversial. Background Aristotle analyzed qualities in his logical work, the Categories. To him, qualities are hylomorphically–formal attributes, such as "white" or "grammatical". Categories of ''state'', such as "shod" and "armed" are also non– essential qualities ''( katà symbebekós)''. line 70. Aristotle observed: "one and the selfsame substance, while retaining its identity, is yet capable of admitting contrary qualities. The same individual person is at one time white, at another black, at one time warm, at another cold, at one time good, at another bad. This capacity is found nowhere else... it is the peculiar mark of substance that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |