|

Optical Fabrication

Optical manufacturing and testing spans an enormous range of manufacturing procedures and optical test configurations. The manufacture of a conventional spherical lens typically begins with the generation of the optic's rough shape by grinding a glass blank. This can be done, for example, with ring tools. Next, the lens surface is polished to its final form. Typically this is done by lapping—rotating and rubbing the rough lens surface against a tool with the desired surface shape, with a mixture of abrasives and fluid in between. Typically a carved pitch tool is used to polish the surface of a lens. The mixture of abrasive is called slurry and it is typically made from cerium or zirconium oxide in water with lubricants added to facilitate pitch tool movement without sticking to the lens. The particle size in the slurry is adjusted to get the desired shape and finish. During polishing, the lens may be tested to confirm that the desired shape is being produced, and to ensure ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optics

Optics is the branch of physics that studies the behaviour and properties of light, including its interactions with matter and the construction of instruments that use or detect it. Optics usually describes the behaviour of visible, ultraviolet, and infrared light. Because light is an electromagnetic wave, other forms of electromagnetic radiation such as X-rays, microwaves, and radio waves exhibit similar properties. Most optical phenomena can be accounted for by using the classical electromagnetic description of light. Complete electromagnetic descriptions of light are, however, often difficult to apply in practice. Practical optics is usually done using simplified models. The most common of these, geometric optics, treats light as a collection of rays that travel in straight lines and bend when they pass through or reflect from surfaces. Physical optics is a more comprehensive model of light, which includes wave effects such as diffraction and interference that cannot be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polishing

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant specular reflection (still limited by the index of refraction of the material according to the Fresnel equations). In some materials (such as metals, glasses, black or transparent stones), polishing is also able to reduce diffuse reflection to minimal values. When an unpolished surface is magnified thousands of times, it usually looks like a succession of mountains and valleys. By repeated abrasion, those "mountains" are worn down until they are flat or just small "hills." The process of polishing with abrasives starts with a coarse grain size and gradually proceeds to the finer ones to efficiently flatten the surface imperfections and to obtain optimal results. Mechanical properties The strength of polished products can be higher than their unpolished counterparts owing to the removal of stress concentrations present ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vapor Polishing

Vapor polishing is a method of polishing plastics to reduce the surface roughness or improve clarity. Typically, a component is exposed to a chemical vapor causing the surface to flow thereby improving the surface finish. This method of polishing is frequently used to return clear materials to an optical quality finish after machining. Vapor polishing works well in the internal features of components. Feature size changes of the plastic component generally do not occur. Post stress relieving is usually required as vapor polishing sets up surface stresses that can cause crazing. Plastics that respond well to vapor polishing are polycarbonate, acrylic, polysulfone, PEI, and ABS. The technique is also being used to improve the surface of objects created with 3D printing 3D printing or additive manufacturing is the Manufacturing, construction of a three-dimensional object from a computer-aided design, CAD model or a digital 3D modeling, 3D model. It can be done in a variety ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical Lens Design

Optical lens design is the process of designing a lens to meet a set of performance requirements and constraints, including cost and manufacturing limitations. Parameters include surface profile types (spherical, aspheric, holographic, diffractive, etc.), as well as radius of curvature, distance to the next surface, material type and optionally tilt and decenter. The process is computationally intensive, using ray tracing or other techniques to model how the lens affects light that passes through it. Design requirements Performance requirements can include: #Optical performance (image quality): This is quantified by various metrics, including encircled energy, modulation transfer function, Strehl ratio, ghost reflection control, and pupil performance (size, location and aberration control); the choice of the image quality metric is application specific. #Physical requirements such as weight, static volume, dynamic volume, center of gravity and overall configuration requirements. # ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interferometric Testing

Interferometry is a technique which uses the ''interference'' of superimposed waves to extract information. Interferometry typically uses electromagnetic waves and is an important investigative technique in the fields of astronomy, fiber optics, engineering metrology, optical metrology, oceanography, seismology, spectroscopy (and its applications to chemistry), quantum mechanics, nuclear and particle physics, plasma physics, remote sensing, biomolecular interactions, surface profiling, microfluidics, mechanical stress/strain measurement, velocimetry, optometry, and making holograms. Interferometers are devices that extract information from interference. They are widely used in science and industry for the measurement of microscopic displacements, refractive index changes and surface irregularities. In the case with most interferometers, light from a single source is split into two beams that travel in different optical paths, which are then combined again to produce interfere ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-generated Hologram

Computer-generated holography (CGH) is the method of digitally generating holographic interference patterns. A holographic image can be generated e.g. by digitally computing a holographic interference pattern and printing it onto a mask or film for subsequent illumination by suitable coherent light source. Alternatively, the holographic image can be brought to life by a holographic 3D display (a display which operates on the basis of interference of coherent light), bypassing the need of having to fabricate a "hardcopy" of the holographic interference pattern each time. Consequently, in recent times the term "computer-generated holography" is increasingly being used to denote the whole process chain of synthetically preparing holographic light wavefronts suitable for observation. Computer-generated holograms have the advantage that the objects which one wants to show do not have to possess any physical reality at all (completely synthetic hologram generation). On the other hand, if ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Null Corrector

A null corrector is an optical device used in the testing of large aspheric mirrors. A spherical mirror of any size can be tested relatively easily using standard optical components such as laser, mirrors, beamsplitters, and converging lenses. One method of doing this using a ''Shack cube'' is shown at the right, and many other setups are possible. An interferometer test such as this one generates a contour map of the deviation of the surface from a perfect sphere, with the contours in units of half the wavelength used. This is called a ''null test'' because when the mirror is perfect, the result is null (no contours at all). If the result is not null, then the mirror is not perfect, and the pattern shows where the optician should polish the mirror to improve it. However, the mirrors used in modern telescopes are not spherical – they are rotations of parabolas or hyperbolas, since these more complex shapes reduce optical aberrations and give a larger field of view. (See, f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Caustic Test

Caustic most commonly refers to: * Causticity, a property of various corrosive substances ** Sodium hydroxide, sometimes called ''caustic soda'' ** Potassium hydroxide, sometimes called ''caustic potash'' ** Calcium oxide, sometimes called ''caustic lime'' Caustic may also refer to: * Caustic (band), an American industrial/powernoise band * Caustic (mathematics), the envelope of rays reflected or refracted by a manifold * Caustic (optics), optic phenomenon due to light rays reflecting/refracting through curved surfaces/objects * Caustic Graphics, a graphics technology developer, part of Imagination Technologies * Caustic Window, an alias of Aphex Twin (electronic musician Richard D. James) * A playable character in the battle royale game ''Apex Legends ''Apex Legends'' is a free-to-play Battle royale game, battle royale-hero shooter game developed by Respawn Entertainment and published by Electronic Arts. It was released for PlayStation 4, Windows, and Xbox One in February 20 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ronchi Test

In optical testing a Ronchi test is a method of determining the surface shape (figure) of a mirror used in telescopes and other optical devices. Description In 1923 Italian physicist Vasco Ronchi published a description of the eponymous Ronchi test, which is a variation of the Foucault knife-edge test and which uses simple equipment to test the quality of optics, especially concave mirrors.Masud Mansuripur (July 1997) "The Ronchi test," ''Optics & Photonics News'', vol. 8, pages 42-46. Available on-line at: http://www.mmresearch.com/articles/article1/index.htm . A "Ronchi tester" consists of: *A light source *A Diffuser (optics), diffuser *A Ronchi grating A Ronchi grating consists of alternate dark and clear stripes. One design is a small frame with several evenly spaced fine wires attached. Light is emitted through the Ronchi grating (or a single slit), reflected by the mirror being tested, then passes through the Ronchi grating again and is observed by the person doing th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foucault Knife-edge Test

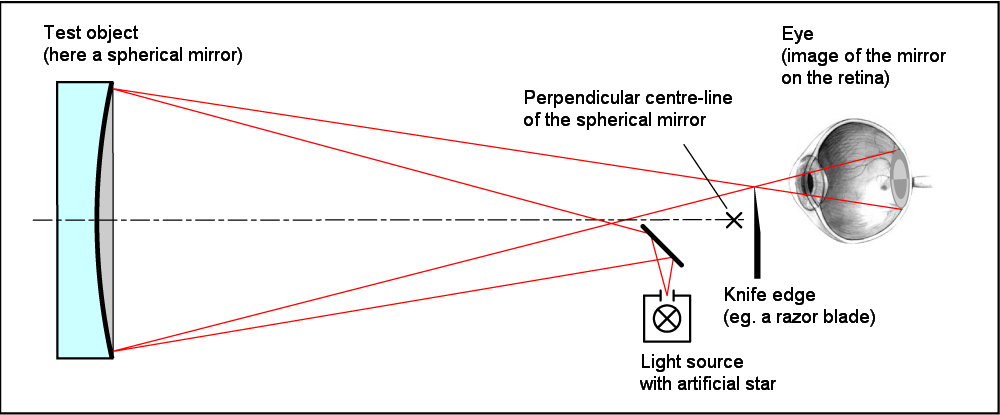

The Foucault knife-edge test is an optical test to accurately measure the shape of concave curved mirrors. It is commonly used by amateur telescope makers for figuring primary mirrors in reflecting telescopes. It uses a relatively simple, inexpensive apparatus compared to other testing techniques. Overview The Foucault knife-edge test was described in 1858 by French physicist Léon Foucault as a way to measure conic shapes of optical mirrors. It measures mirror surface dimensions by reflecting light into a knife edge at or near the mirror's centre of curvature. In doing so, it only needs a tester which in its most basic 19th century form consists of a light bulb, a piece of tinfoil with a pinhole in it, and a razor blade to create the knife edge. The testing device is adjustable along the X-axis (knife cut direction) across the Y-axis (optical axis), and is usually equipped with measurable adjustment to 0.001 inch (25 µm) or better along lines parallel to the optical axi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Profile Measurement

A profilometer is a measuring instrument used to measure a surface's profile, in order to quantify its roughness. Critical dimensions as step, curvature, flatness are computed from the surface topography. While the historical notion of a profilometer was a device similar to a phonograph that measures a surface as the surface is moved relative to the contact profilometer's stylus, this notion is changing with the emergence of numerous non-contact profilometry techniques. Non-scanning technologies are able to measure the surface topography within a single camera acquisition, XYZ scanning is no longer needed. As a consequence, dynamic changes of topography are measured in real-time. Contemporary profilometers are not only measuring static topography, but now also dynamic topography – such systems are described as time-resolved profilometers. Types Optical methodsJean M. Bennett, Lars Mattsson, Introduction to Surface Roughness and Scattering, Optical Society of America, Was ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precision Glass Moulding

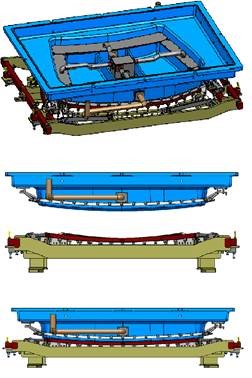

Precision glass moulding is a replicative process that allows the production of high precision optical components from glass without grinding and polishing. The process is also known as ultra-precision glass pressing. It is used to manufacture precision glass lenses for consumer products such as digital cameras, and high-end products like medical systems. The main advantage over mechanical lens production is that complex lens geometries such as aspheres can be produced cost-efficiently. Process The precision glass moulding process consists of six steps:Klocke, F. et al.: "Manufacturing of glass diffractive optics by use of molding process", ''American Society for Precision Engineering (Annual Meeting)'' 21, 2006, Monterey/Calif. #The glass blank is loaded into the lower side of the moulding tool. #Oxygen is removed from the working area by filling with nitrogen and/or evacuation of the process chamber. #The tool system is nearly closed (no contact of the upper mould) and the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |