|

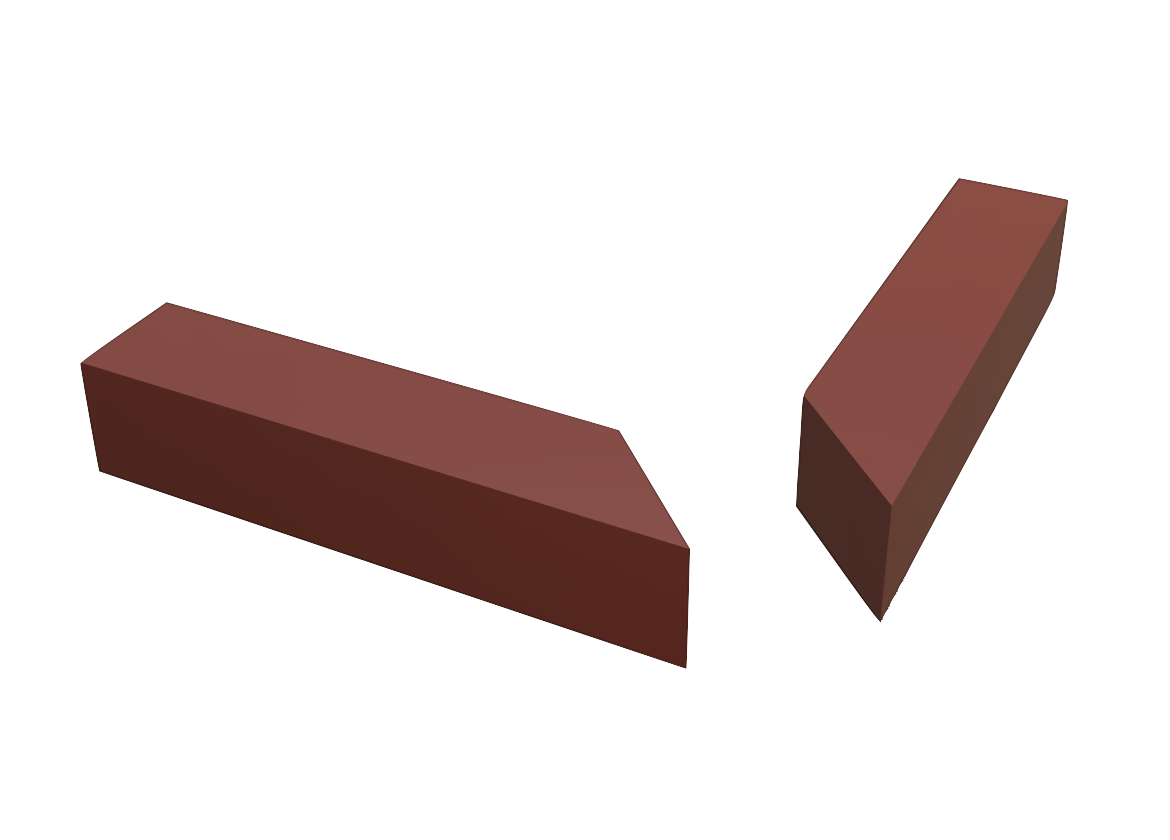

Mitre Joint

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint. For woodworking, a disadvantage of a mitre joint is its weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber). There are two common variations of a splined mitre joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges. Common applications include picture frames, pipes, and molding. Non-perpendicular joints For mitre joints occurring at angles other than 90°, for materials of the s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

90º Mitre

9 (nine) is the natural number following and preceding . Evolution of the Arabic digit In the beginning, various Indians wrote a digit 9 similar in shape to the modern closing question mark without the bottom dot. The Kshatrapa, Andhra and Gupta started curving the bottom vertical line coming up with a -look-alike. The Nagari continued the bottom stroke to make a circle and enclose the 3-look-alike, in much the same way that the sign @ encircles a lowercase ''a''. As time went on, the enclosing circle became bigger and its line continued beyond the circle downwards, as the 3-look-alike became smaller. Soon, all that was left of the 3-look-alike was a squiggle. The Arabs simply connected that squiggle to the downward stroke at the middle and subsequent European change was purely cosmetic. While the shape of the glyph for the digit 9 has an ascender in most modern typefaces, in typefaces with text figures the character usually has a descender, as, for example, in . The mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joinery

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes (such as laminate), to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements (such as dowels or plain mortise and tenon fittings). The characteristics of wooden joints - strength, flexibility, toughness, appearance, etc. - derive from the properties of the materials involved and the purpose of the joint. Therefore, different joinery techniques are used to meet differing requirements. For example, the joinery used to construct a house can be different from that used to make cabinetry or furniture, although some concepts overlap. While a form of carpentry elsewhere, in British English usage it is distinguished from it, which is considered to be a form of structural timber work. History Many traditional wood joinery techniques use the distinctive material properties of wood, of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Adamson (publisher)

John Adamson (born 1949) is a British publisher, translator and writer. He specialises in illustrated books in the fine and decorative arts. Biography John Adamson was born in Devon, the younger son of George Worsley Adamson, illustrator and cartoonist and Mary Marguerita Renée (''née'' Diamond). After studying at the University of Edinburgh and the University of Geneva, he joined Cambridge University Press in 1974. He held various functions within the marketing department of the Press: first as European sales representative (1975); then publicity manager (1977); becoming export sales director in 1980. During the period of his directorship, Cambridge University Press won for the first time the Queen's Award for Export Achievement. While at Cambridge University Press he helped mount two exhibitions of humorous art in his spare time. For the first of these, "L’Humour Actuel franco-britannique. 200 dessins" ranco-British Humour Today: 200 drawings hosted by the Galerie M.L. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Notching

Notching is a metal-cutting process used on sheet-metal or thin bar-stock, sometimes on angle sections or tube. A shearing or punching process is used in a press, so as to cut vertically down and perpendicular to the surface, working from the edge of a work-piece. Sometimes the goal is merely the notch itself, but usually this is a precursor to some other process: such as bending a corner in sheet or joining two tubes at a tee joint, notching one to fit closely to the other. Notching is a low-cost process, particularly for its low tooling costs with a small range of standard punches. The capital cost of the punch press can be expensive though, so small fabrication shops often out-source their notching work to a press shop or notching specialist. Notching of large or heavy sections, particularly for large tube fabrication or HVAC, is increasingly carried out by plasma-cutting rather than punch tools. The first punch & die type tool for notching tube & pipe was invented in Chicago ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Miter Square

A miter square or mitre square is a hand tool used in woodworking and metalworking for marking and checking angles other than 90°. Most miter squares are for marking and checking 45° angles and its supplementary angle In Euclidean geometry, an angle is the figure formed by two rays, called the '' sides'' of the angle, sharing a common endpoint, called the ''vertex'' of the angle. Angles formed by two rays lie in the plane that contains the rays. Angles are ..., 135°. ''A miter'' is a bevelled edge – usually 45° – used, for example, for making miter joints for woodworking. '' Squares'' are tools designed for marking and checking specific fixed angles, usually 90° or 45°, though most squares are exclusively for working with 90° angles. Description As with 90° squares, there are many different types of miter square. Miter squares are usually made from two fixed parts, a ''stock'' and a ''blade'' (sometimes called a ''tongue''). The blade on a modern factory-mad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Miter Saw

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence. Powered miter saws also cut bevels into a work piece by adjusting the vertical tilt axis of upper portion of the machine while the table lays flat horizontally. A miter saw for which the axis can be tilted in a single direction is known as a single compound miter saw. If the axis can tilt both left and right, it is known as a double bevel compound miter saw. Some are equipped with a sliding rail system or have a pivot arm to cut wider work pieces when laid flat on the table of the saw and flush against the fence. This is known as a sliding compound miter saw. Miter saws are primarily ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitre Clamp

Mitre clamps are designed to hold mitre joints together. The earliest mitre clamps are a simple spring in a C-shape with sharpened points that are sprung onto the outside corner of the mitre joint. The right angled plates are higher than the screws and the red holder. The screws go under the frame (work-piece) to be held, and the red bit clamps down on the lower-edge of the frame. Recent designs are more complicated; a rigid body holds one fixed and one moveable jaw activated by a cam. Examples of the newer clamps are Jim Chestnut's "Clam Clamp" and the Maestro Mitre Clamp. Woodworking clamps Woodworking hand tools {{Tool-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Miter Box

A mitre box or miter box (American English) is a wood working appliance used to guide a hand saw for making precise cuts, usually 45° mitre cuts. Traditional mitre boxes are simple in construction and made of wood, while adjustable mitre boxes are made of metal and can be adjusted for cutting any angle from 45° to 90°. In many workshops and jobsites mitre boxes have been superseded by the powered mitre saw, however advocates for mitre boxes argue that they are more accurate, safer, quieter, cheaper, and take up less space than a powered mitre saw. Description Basic mitre box The most common and simplest form of a mitre box is a U-shaped block made from wood, plastic or aluminium, which is open at the top and the ends. The box is made wide enough to accommodate the width of the workpieces to be cut. Slots are cut in the walls of the box at the precise angle at which the cut is to be made. These slots provide the guide for the saw to follow. Most commonly, the slots in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mason's Mitre

A mason's mitre is a type of mitre joint, traditionally used in stonework or masonry but commonly seen in kitchen countertops. In a mason's mitre, the two elements being joined meet as for a butt joint but a small section of one member is removed creating a socket to receive the end of the other. A small mitre is made at the inside edges of the socket and on the end of the intersecting member so that edge treatments are carried through the joint appropriately. The mason's mitre allows the appearance of a mitre joint to be created with much less waste than occurs with a common mitre joint, in which triangular sections must be removed from the ends of both joint members. The terms "back mitre" and "mason's mitre" (or "miter") are often used interchangeably, but are different types of joints, and used for different purposes. Both joints are traditionally used in stone or woodwork. Neither joint requires that one part be coped (or fit) over the other. In the back mitre, the joints f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mitre Joint Pipe

The mitre (Commonwealth English) (; Greek: μίτρα, "headband" or "turban") or miter (American English; see spelling differences), is a type of headgear now known as the traditional, ceremonial headdress of bishops and certain abbots in traditional Christianity. Mitres are worn in the Catholic Church, Eastern Orthodox Church, Oriental Orthodox Churches, the Anglican Communion, some Lutheran churches, for important ceremonies, by the Metropolitan of the Malankara Mar Thoma Syrian Church, and also, in the Catholic Church, all cardinals, whether or not bishops, and some Eastern Orthodox archpriests. Etymology μίτρα, ''mítra'' ( Ionic μίτρη, ''mítrē'') is Greek, and means a piece of armour, usually a metal guard worn around the waist and under a cuirass, as mentioned in Homer's Iliad. In later poems, it was used to refer to a headband used by women for their hair; and a sort of formal Babylonian headdress, as mentioned by Herodotus (''Histories'' 1.195 and 7.90). ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |