|

Micro-electromechanical Systems

Microelectromechanical systems (MEMS), also written as micro-electro-mechanical systems (or microelectronic and microelectromechanical systems) and the related micromechatronics and microsystems constitute the technology of microscopic devices, particularly those with moving parts. They merge at the nanoscale into nanoelectromechanical systems (NEMS) and nanotechnology. MEMS are also referred to as micromachines in Japan and microsystem technology (MST) in Europe. MEMS are made up of components between 1 and 100 micrometers in size (i.e., 0.001 to 0.1 mm), and MEMS devices generally range in size from 20 micrometres to a millimetre (i.e., 0.02 to 1.0 mm), although components arranged in arrays (e.g., digital micromirror devices) can be more than 1000 mm2. They usually consist of a central unit that processes data (an integrated circuit chip such as microprocessor) and several components that interact with the surroundings (such as microsensors). Because of the la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molecular Electronics

Molecular electronics is the study and application of molecular building blocks for the fabrication of electronic components. It is an interdisciplinary area that spans physics, chemistry, and materials science. The unifying feature is use of molecular building blocks to fabricate electronic components. Due to the prospect of size reduction in electronics offered by molecular-level control of properties, molecular electronics has generated much excitement. It provides a potential means to extend Moore's Law beyond the foreseen limits of small-scale conventional silicon integrated circuits. Molecular scale electronics Molecular scale electronics, also called single-molecule electronics, is a branch of nanotechnology that uses single molecules, or nanoscale collections of single molecules, as electronic components. Because single molecules constitute the smallest stable structures possible, this miniaturization is the ultimate goal for shrinking electrical circuits. Convention ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Harvey C

Harvey, Harveys or Harvey's may refer to: Arts, entertainment, and media * ''Harvey'' (play), a 1944 play by Mary Chase about a man befriended by an invisible anthropomorphic rabbit * Harvey Awards ("Harveys"), one of the most important awards in American comic industry, founded in 1988 * "Harvey", a song by Her's off the album ''Invitation to Her's'', 2018 Films * ''Harvey'' (1950 film), a 1950 film adapted from Mary Chase's play, starring James Stewart * ''Harvey'' (1996 film), a 1996 American made-for-television film * ''Harvey'' (Hallmark), a 1972 adaptation of Mary Chase's play for the ''Hallmark Hall of Fame'' Characters * Harvey (''Farscape''), a character in the TV show ''Farscape'' * Harvey, a crane engine in ''Thomas & Friends'' * Harvey Beaks, in the Nickelodeon animated series ''Harvey Beaks'' * Harvey Birdman, title character from the teen-adult animated series ''Harvey Birdman, Attorney at Law'' * Harvey Dent, fictional District Attorney and supervillain (a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Discharge Machining

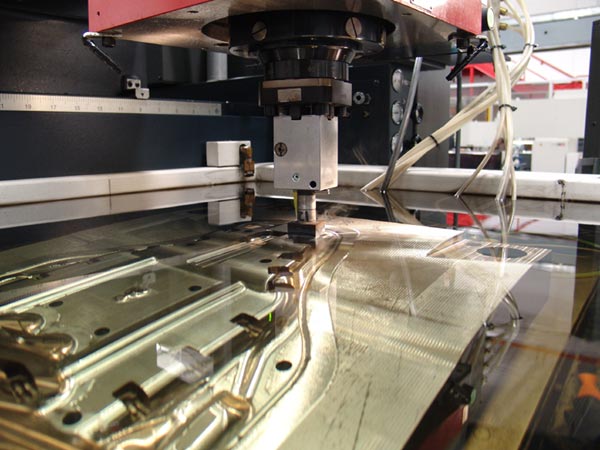

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing dielectric break down of the liquid, and produces an electric arc. As a result, material is removed from the electrodes. Once the current stops (or is stopped, depending on the type of generator), new liquid di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reactive-ion Etching

Reactive-ion etching (RIE) is an etching technology used in microfabrication. RIE is a type of dry etching which has different characteristics than wet etching. RIE uses chemically reactive plasma to remove material deposited on wafers. The plasma is generated under low pressure (vacuum) by an electromagnetic field. High-energy ions from the plasma attack the wafer surface and react with it. Equipment A typical (parallel plate) RIE system consists of a cylindrical vacuum chamber, with a wafer platter situated in the bottom portion of the chamber. The wafer platter is electrically isolated from the rest of the chamber. Gas enters through small inlets in the top of the chamber, and exits to the vacuum pump system through the bottom. The types and amount of gas used vary depending upon the etch process; for instance, sulfur hexafluoride is commonly used for etching silicon. Gas pressure is typically maintained in a range between a few millitorr and a few hundred millitorr by adj ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Etching

Dry etching refers to the removal of material, typically a masked pattern of semiconductor material, by exposing the material to a bombardment of ions (usually a plasma of reactive gases such as fluorocarbons, oxygen, chlorine, boron trichloride; sometimes with addition of nitrogen, argon, helium and other gases) that dislodge portions of the material from the exposed surface. A common type of dry etching is reactive-ion etching. Unlike with many (but not all, see isotropic etching) of the wet chemical etchants used in wet etching, the dry etching process typically etches directionally or anisotropically. Applications Dry etching is used in conjunction with photolithographic techniques to attack certain areas of a semiconductor surface in order to form recesses in material. Applications include contact holes (which are contacts to the underlying semiconductor substrate), via holes (which are holes that are formed to provide an interconnect path between conductive layers in th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tetramethylammonium Hydroxide

Tetramethylammonium hydroxide (TMAH or TMAOH) is a quaternary ammonium salt with molecular formula N(CH3)4+ OH−. It is commonly encountered in form of concentrated solutions in water or methanol. TMAH in solid state and its aqueous solutions are all colorless, but may be yellowish if impure. Although TMAH has virtually no odor when pure, samples often have a strong fishy smell due to presence of trimethylamine which is a common impurity. TMAH has several diverse industrial and research applications. Chemical properties Structure TMAH is most commonly encountered as an aqueous solution, in concentrations from ~2–25%, and less frequently as solutions in methanol. These solutions are identified by CAS numbe75-59-2 Several hydrates such as N(CH3)4OH·xH2O. have been crystallized. These salts contain well separated Me4N+ cations and hydroxide anions ( Me is an abbreviation of methyl group). The hydroxide groups are linked by hydrogen bonds to the water of crystallization ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Potassium Hydroxide

Potassium hydroxide is an inorganic compound with the formula K OH, and is commonly called caustic potash. Along with sodium hydroxide (NaOH), KOH is a prototypical strong base. It has many industrial and niche applications, most of which exploit its caustic nature and its reactivity toward acids. An estimated 700,000 to 800,000 tonnes were produced in 2005. KOH is noteworthy as the precursor to most soft and liquid soaps, as well as numerous potassium-containing chemicals. It is a white solid that is dangerously corrosive. Properties and structure KOH exhibits high thermal stability. Because of this high stability and relatively low melting point, it is often melt-cast as pellets or rods, forms that have low surface area and convenient handling properties. These pellets become tacky in air because KOH is hygroscopic. Most commercial samples are ca. 90% pure, the remainder being water and carbonates. Its dissolution in water is strongly exothermic. Concentrated aqueous solut ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etching (microfabrication)

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete. For many etch steps, part of the wafer is protected from the etchant by a "masking" material which resists etching. In some cases, the masking material is a photoresist which has been patterned using photolithography. Other situations require a more durable mask, such as silicon nitride. Orientation-Dependent Etching * KOH pellets dissolved in water (self-heating) * Etch Rate > >> ** KOH has a slower etching orientation for the planes ** You cannot use this KOH photoresist as a etching mask, because the oxide attacks too slowly, so this resist will not survive * Photoresist can be used a etching mask, and the best photoresist for etching is nitride * For example, the etch rate of Si in KOH Depends on Crystallographic Plane * At low temperatur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scientific American

''Scientific American'', informally abbreviated ''SciAm'' or sometimes ''SA'', is an American popular science magazine. Many famous scientists, including Albert Einstein and Nikola Tesla, have contributed articles to it. In print since 1845, it is the oldest continuously published magazine in the United States. ''Scientific American'' is owned by Springer Nature, which in turn is a subsidiary of Holtzbrinck Publishing Group. History ''Scientific American'' was founded by inventor and publisher Rufus Porter (painter), Rufus Porter in 1845 as a four-page weekly newspaper. The first issue of the large format newspaper was released August 28, 1845. Throughout its early years, much emphasis was placed on reports of what was going on at the United States Patent and Trademark Office, U.S. Patent Office. It also reported on a broad range of inventions including perpetual motion machines, an 1860 device for buoying vessels by Abraham Lincoln, and the universal joint which now can be found ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronics

The field of electronics is a branch of physics and electrical engineering that deals with the emission, behaviour and effects of electrons using electronic devices. Electronics uses active devices to control electron flow by amplification and rectification, which distinguishes it from classical electrical engineering, which only uses passive effects such as resistance, capacitance and inductance to control electric current flow. Electronics has hugely influenced the development of modern society. The central driving force behind the entire electronics industry is the semiconductor industry sector, which has annual sales of over $481 billion as of 2018. The largest industry sector is e-commerce, which generated over $29 trillion in 2017. History and development Electronics has hugely influenced the development of modern society. The identification of the electron in 1897, along with the subsequent invention of the vacuum tube which could amplify and rectify small ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Device Fabrication

Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuit (IC) chips such as modern computer processors, microcontrollers, and memory chips such as NAND flash and DRAM that are present in everyday electrical and electronics, electronic devices. It is a multiple-step sequence of Photolithography, photolithographic and chemical processing steps (such as surface passivation, thermal oxidation, planar process, planar diffusion and p–n junction isolation, junction isolation) during which electronic circuits are gradually created on a wafer (electronics), wafer made of pure semiconducting material. Silicon is almost always used, but various compound semiconductors are used for specialized applications. The entire manufacturing process takes time, from start to packaged chips ready for shipment, at least six to eight weeks (tape-out only, not including the circuit design) and is performed in highly specialized semiconduct ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)