|

Incoloy

Incoloy refers to a range of superalloys now produced by the Special Metals Corporation (SMC) group of companies and created with a trademark by the Inco company in 1952. Originally Inco protected these alloys by patent. In 2000, the SMC published a 61-page document entitled "High-Performance Alloys for Resistance to Aqueous Corrosion" highlighting Incoloy, as well as Monel and Inconel products, and their use in fluid environments such as sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, nitric acid, other acids as well as freshwater environments. Incoloy products are mostly chromium-based and mostly nickel-based, and designed for corrosion resistance as well as strength at high temperatures. Incoloy alloys belong to the category of super austenitic stainless steels. One advantage is that Incoloy alloys do not have to be heat treated after welding to restore the corrosion resistance. There are specific alloys for resistance to particular chemical attacks. For ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Special Metals Corporation

Special Metals Corporation (SMC) is an American supplier of special refractory alloys and is headquartered in New Hartford, New York, United States. The company has operations in Huntington, West Virginia; Dunkirk, New York; Burnaugh, Kentucky; Elkhart, Indiana and Hereford, England. SMC's trademarks include Inconel, Incoloy, Monel, Nimonic, and Udimet. History "In 1952, a predecessor of Special Metals pioneered the melting technology that led to the practical development of the superalloys that are the critical materials used in the 'hot' section of modern jet engines." At year end of 1996, SMC had "45 million pounds of vacuum induction melting capacity", 590 employees, was incorporated in Delaware and was managed by Don Muzyka. SMC acquired Inco Alloys International from Inco in 1998 at the same time as it sold US$125 million of preferred stock to Titanium Metals Corporation. In 2006, Special Metals was acquired by Precision Castparts Corporation of Portland, Oregon, US ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation. The crystal structure is typically face-centered cubic (FCC) austenitic. Examples of such alloys are Hastelloy, Inconel, Waspaloy, Rene alloys, Incoloy, MP98T, TMS alloys, and CMSX single crystal alloys. Superalloy development has relied heavily on both chemical and process innovations. Superalloys develop high temperature strength through solid solution strengthening and precipitation strengthening from secondary phase precipitates such as gamma prime and carbides. Oxidation or corrosion resistance is provided by elements such as aluminium and chromium. Superalloys are often cast as a single crystal—while grain boundaries may provide strength at low temperatures, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inconel

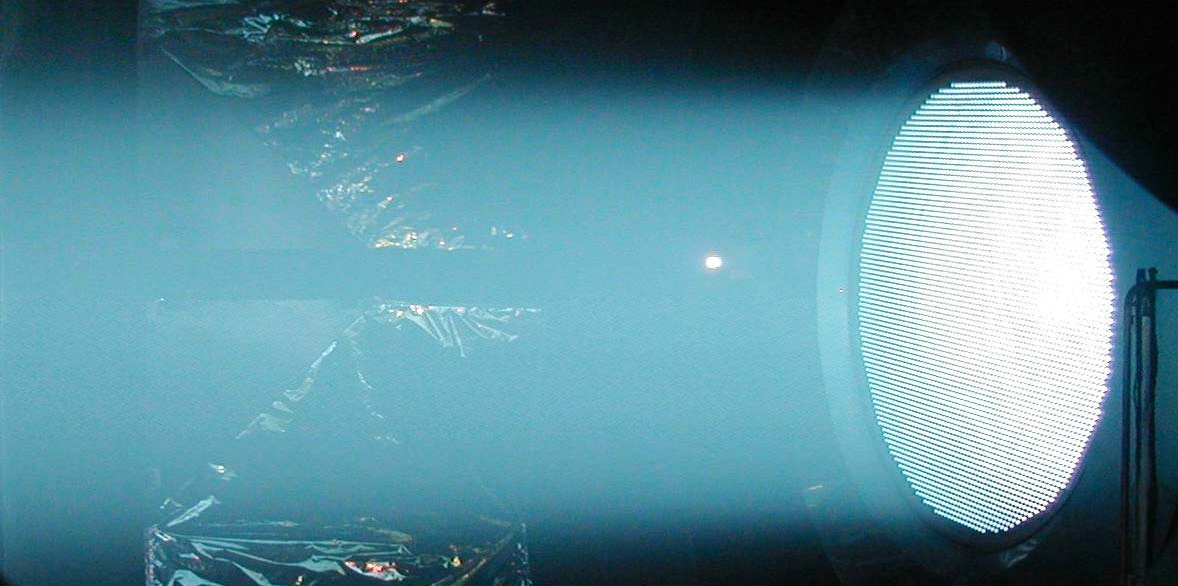

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys. Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.INCONEL alloy 718 Special Metals Corporation Inconel alloys are typical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow to react with air under standard conditions because a passivation layer of nickel oxide forms on the surface that prevents further corrosion. Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks, and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere. Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's outer and inner cores. Use of nickel (as natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classified as an e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chromium

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6. It is a steely-grey, lustrous, hard, and brittle transition metal. Chromium metal is valued for its high corrosion resistance and hardness. A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic chromium to form stainless steel. Stainless steel and chrome plating (electroplating with chromium) together comprise 85% of the commercial use. Chromium is also greatly valued as a metal that is able to be highly polished while resisting tarnishing. Polished chromium reflects almost 70% of the visible spectrum, and almost 90% of infrared light. The name of the element is derived from the Greek word χρῶμα, ''chrōma'', meaning color, because many chromium compounds are intensely colored. Industrial production of chromium proceeds from chromite ore (mostly FeCr2O4) to produce ferro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper. Stronger than pure nickel, Monel alloys are resistant to corrosion by many aggressive agents, including rapidly flowing seawater. They can be fabricated readily by hot- and cold-working, machining, and welding. Monel was created in 1905 by Robert Crooks Stanley, who at the time worked at the International Nickel Company (Inco). Monel alloy 400 is a binary alloy of the same proportions of nickel and copper as is found naturally in the meteoritic nickel ore from the Sudbury (Ontario) mines and is therefore considered a puritan alloy. Monel was named after company president Ambrose Monell, and patented in 1906. One L was dropped, because family names were not allowed as trademarks at that time. The trademark was registered in May 1921, and the name is now a trademark of Special Metals C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Austenitic

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures. The austenite allotrope is named after Sir William Chandler Roberts-Austen (1843–1902); it exists at room temperature in some stainless steels due to the presence of nickel stabilizing the austenite at lower temperatures. Allotrope of iron From alpha iron undergoes a phase transition from body-centered cubic (BCC) to the face-centered cubic (FCC) configuration of gamma iron, also called austenite. This is similarly soft and ductile but can dissolve considerably more carbon (as much as 2.03% by mass at ). This gamma form of iron is present in the most commonly used type of stainless steel for making hospital and food-service equipment. Material Austenitizati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Home, North Carolina. The Kokomo facility specializes in flat products, the Arcadia facility in tubular products, and the Mountain Home facility in wire products. In fiscal year 2018, the company's revenues were derived from the aerospace (52.1%), chemical processing (18.2%), industrial gas turbine (12.0%) and other (12.3%) industries. The company's alloys are primarily marketed under the Hastelloy and the Haynes brands. They are based on nickel, but also include cobalt, chromium, molybdenum, tungsten, iron, silicon, manganese, carbon, aluminum, and/or titanium. History The company was founded by Elwood Haynes in 1912 in Kokomo, Indiana, as Haynes Stellite Works. Haynes had recently received a patent for a metal he created, which he named Stel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction Welding

Friction welding (FRW) is a solid-state welding process that generates heat through mechanical friction between workpieces in relative motion to one another, with the addition of a lateral force called "upset" to plastically displace and fuse the materials. Because no melting occurs, friction welding is not a fusion welding process, but a solid-state welding technique more like forge welding. Friction welding is used with metals and thermoplastics in a wide variety of aviation and automotive applications. ISO norm of friction welding is EN ISO 15620:2019 there is information about basic terms and definitions and table of weldability of metals and alloys. History Some applications and patents connected with friction welding were dated back to the turn of the 20th century and rotary friction welding is the oldest of this methods. W. Richter patented the method of linear friction welding (LFW) process in 1924 in England and 1929 in Germany, however, the description of the process ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jupiter Icy Moons Orbiter

The ''Jupiter Icy Moons Orbiter'' (JIMO) was a proposed NASA spacecraft designed to explore the icy moons of Jupiter. The main target was Europa, where an ocean of liquid water may harbor alien life. Ganymede and Callisto, which are now thought to have liquid, salty oceans beneath their icy surfaces, were also targets of interest for the probe. The JIMO spacecraft JIMO was to have a large number of revolutionary features. Throughout its main voyage to the Jupiter moons, it was to be propelled by an ion propulsion system via either the High Power Electric Propulsion or NEXIS engine, and powered by a small fission reactor. A Brayton power conversion system would convert reactor heat into electricity. Providing a thousand times the electrical output of conventional solar- or radioisotope thermoelectric generator (RTG)-based power systems, the reactor was expected to open up opportunities like flying a full scale ice-penetrating radar system and providing a strong, high-ba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mechanical Alloying

Mechanical alloying (MA) is a solid-state and powder processing technique involving repeated cold welding, fracturing, and re-welding of blended powder particles in a high-energy ball mill to produce a homogeneous material. Originally developed to produce oxide-dispersion strengthened (ODS) nickel- and iron-base superalloys for applications in the aerospace industry, MA has now been shown to be capable of synthesizing a variety of equilibrium and non-equilibrium alloy phases starting from blended elemental or pre-alloyed powders.''Suryanarayana C. Mechanical alloying and milling'', Progress in Materials Science 46 (2001) 1-184 The non-equilibrium phases synthesized include supersaturated solid solutions, metastable crystalline and quasicrystalline phases, nanostructures, and amorphous alloys. Metal mixes Mechanical alloying is akin to metal powder processing, where metals may be mixed to produce superalloys. Mechanical alloying occurs in three steps. First, the alloy materials ar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. Design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure tests ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |