|

Iron-making

Ferrous metallurgy is the metallurgy of iron and its alloys. The earliest surviving prehistory, prehistoric iron artifacts, from the 4th millennium BC in Egypt, were made from meteorite, meteoritic Iron–nickel alloy, iron-nickel. It is not known when or where the smelting of iron from ores began, but by the end of the 2nd millennium BC iron was being produced from iron ores in the region from Greece to India,Riederer, Josef; Wartke, Ralf-B.: "Iron", Cancik, Hubert; Schneider, Helmuth (eds.): Brill's New Pauly, Brill 2009Early Antiquity By I.M. Drakonoff. 1991. University of Chicago Press. . p. 372 and Sub-Saharan Africa. The use of wrought iron (worked iron) was known by the 1st millennium BC, and its spread defined the Iron Age. During the medieval period, smiths in Europe found a way of producing wrought iron from cast iron (in this context known as pig iron) using finery forges. All these processes required charcoal as fuel. By the 4th century BC southern India had started ex ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

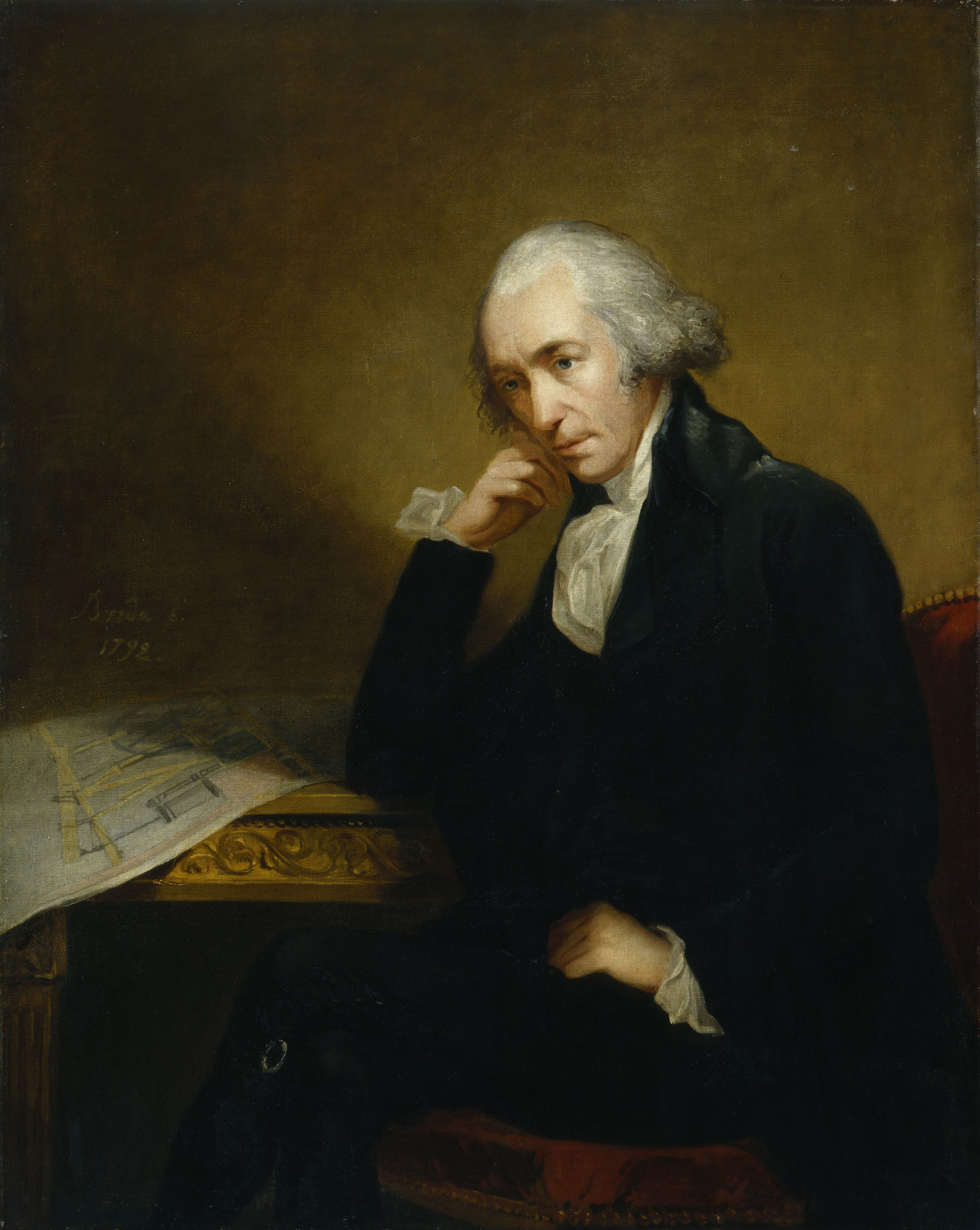

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

Smelting is a process of applying heat to ore, to extract a base metal. It is a form of extractive metallurgy. It is used to extract many metals from their ores, including silver, iron, copper, and other base metals. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal base behind. The reducing agent is commonly a fossil fuel source of carbon, such as coke—or, in earlier times, charcoal. The oxygen in the ore binds to carbon at high temperatures due to the lower potential energy of the bonds in carbon dioxide (). Smelting most prominently takes place in a blast furnace to produce pig iron, which is converted into steel. The carbon source acts as a chemical reactant to remove oxygen from the ore, yielding the purified metal element as a product. The carbon source is oxidized in two stages. First, the carbon (C) combusts with oxygen (O2) in the air to produce carbon monoxide (CO). Second, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finery Forge

A finery forge is a forge used to produce wrought iron from pig iron by decarburization in a process called "fining" which involved liquifying cast iron in a fining hearth and removing carbon from the molten cast iron through oxidation. Finery forges were used as early as the 3rd century BC in China. The finery forge process was replaced by the puddling process and the roller mill, both developed by Henry Cort in 1783–4, but not becoming widespread until after 1800. History A finery forge was used to refine wrought iron at least by the 3rd century BC in ancient China, based on the earliest archaeological specimens of cast and pig iron fined into wrought iron and steel found at the early Han Dynasty (202 BC – 220 AD) site at Tieshengguo.Pigott, Vincent C. (1999). ''The Archaeometallurgy of the Asian Old World''. Philadelphia: University of Pennsylvania Museum of Archaeology and Anthropology. , p. 186-187. Pigott speculates that the finery forge existed in the previous ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Age

The Iron Age is the final epoch of the three-age division of the prehistory and protohistory of humanity. It was preceded by the Stone Age (Paleolithic, Mesolithic, Neolithic) and the Bronze Age (Chalcolithic). The concept has been mostly applied to Iron Age Europe and the Ancient Near East, but also, by analogy, to other parts of the Old World. The duration of the Iron Age varies depending on the region under consideration. It is defined by archaeological convention. The "Iron Age" begins locally when the production of iron or steel has advanced to the point where iron tools and weapons replace their bronze equivalents in common use. In the Ancient Near East, this transition took place in the wake of the Bronze Age collapse, in the 12th century BC. The technology soon spread throughout the Mediterranean Basin region and to South Asia (Iron Age in India) between the 12th and 11th century BC. Its further spread to Central Asia, Eastern Europe, and Central Europe is somewhat dela ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coke (fuel)

Coke is a grey, hard, and porous coal-based fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of air—a destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern. The unqualified term "coke" usually refers to the product derived from low-ash and low-sulphur bituminous coal by a process called coking. A similar product called petroleum coke, or pet coke, is obtained from crude oil in oil refineries. Coke may also be formed naturally by geologic processes.B. Kwiecińska and H. I. Petersen (2004): "Graphite, semi-graphite, natural coke, and natural char classification — ICCP system". ''International Journal of Coal Geology'', volume 57, issue 2, pages 99-116. History China Historical sources dating to the 4th century describe the production of coke in ancient China. The Chinese first used coke for heating and c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (, 72.4% Fe), hematite (, 69.9% Fe), goethite (, 62.9% Fe), limonite (, 55% Fe) or siderite (, 48.2% Fe). Ores containing very high quantities of hematite or magnetite (greater than about 60% iron) are known as "natural ore" or "direct shipping ore", meaning they can be fed directly into iron-making blast furnaces. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. In 2011 the ''Financial Times'' quoted Christopher LaFemina, mining analyst at Barclays Capital, saying that iron ore is "more integral to the global economy than any other commodity, except perhaps oil". Sources Metallic iron is virtually unknown on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Bessemer

Sir Henry Bessemer (19 January 1813 – 15 March 1898) was an English inventor, whose steel-making process would become the most important technique for making steel in the nineteenth century for almost one hundred years from 1856 to 1950. He also played a significant role in establishing the town of Sheffield, nicknamed ‘Steel City’, as a major industrial centre. Bessemer had been trying to reduce the cost of steel-making for military ordnance, and developed his system for blowing air through molten pig iron to remove the impurities. This made steel easier, quicker and cheaper to manufacture, and revolutionised structural engineering. One of the most significant inventors of the Second Industrial Revolution, Bessemer also made over 100 other inventions in the fields of iron, steel and glass. Unlike many inventors, he managed to bring his own projects to fruition and profited financially from their success. He was knighted for his contribution to science in 1879, and in th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bessemer Process

The Bessemer process was the first inexpensive industrial process for the mass production of steel from molten pig iron before the development of the open hearth furnace. The key principle is removal of impurities from the iron by oxidation with air being blown through the molten iron. The oxidation also raises the temperature of the iron mass and keeps it molten. Related decarburizing with air processes had been used outside Europe for hundreds of years, but not on an industrial scale. One such process (similar to puddling) was known in the 11th century in East Asia, where the scholar Shen Kuo of that era described its use in the Chinese iron and steel industry. In the 17th century, accounts by European travelers detailed its possible use by the Japanese. The modern process is named after its inventor, the Englishman Henry Bessemer, who took out a patent on the process in 1856. The process was said to be independently discovered in 1851 by the American inventor William Kelly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but has since also been applied to other sources of heat energy, such as nuclear energy (via nuclear fission and nuclear fusion). The heat energy released by reactions of fuels can be converted into mechanical energy via a heat engine. Other times, the heat itself is valued for warmth, cooking, or industrial processes, as well as the illumination that accompanies combustion. Fuels are also used in the cells of organisms in a process known as cellular respiration, where organic molecules are oxidized to release usable energy. Hydrocarbons and related organic molecules are by far the most common source of fuel used by humans, but other substances, including radioactive metals, are also utilized. Fuels are contrasted with other substances or de ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kiruna

(; se, Giron ; fi, Kiiruna ) is the northernmost Stad (Sweden), city in Sweden, situated in the province of Lapland, Sweden, Lapland. It had 17,002 inhabitants in 2016 and is the seat of Kiruna Municipality (population: 23,167 in 2016) in Norrbotten County. The city was originally built in the 1890s to serve the Kiruna Mine. The Esrange Space Center was established in Kiruna in the 1960s. Also in Kiruna are the Institute of Space Physics (Sweden), Institute of Space Physics and Luleå University of Technology's Department of Space Science. History Origins Archaeological findings have shown that the region around Kiruna has been inhabited for at least 6,000 years. Centuries before Kiruna was founded in 1900, the presence of iron ore at Kiirunavaara and Luossavaara had been known by the local Sami people, Sami population. In 1696, Samuel Mört, a bookkeeper of the Kengis works, wrote on rumours about the presence of iron in the two hills.Kummu 1997, p. 96. The ore became b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |