|

Ink Jet Material Deposition

Ink jet material deposition is an emerging manufacturing technique in which ink jet technology is used to deposit materials on substrates. The technique aims to eliminate fixed costs of production and reduce the amount of materials used. Uses Anything that is produced using traditional printing techniques is a candidate for ink jet material deposition. In addition, the precision available with ink jet technology may be required for some industrial applications. Examples include: * Organic light-emitting diode display production. * Printed circuit boards are typically produced using screen printing, which is not cost-effective for prototyping or small production runs. Conductive ink can be used to create circuit traces. Advantages * Since the underlying technology is digital, startup costs of production are relatively low. Each copy produced may be different from the last. * Expensive materials may be used more efficiently; no material is wasted by placing it where it doesn't nee ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inkjet Printer

Inkjet printing is a type of computer printing that recreates a digital image by propelling droplets of ink onto paper and plastic substrates. Inkjet printers were the most commonly used type of printer in 2008, and range from small inexpensive consumer models to expensive professional machines. By 2019, laser printers outsold inkjet printers by nearly a 2:1 ratio, 9.6% vs 5.1% of all computer peripherals. The concept of inkjet printing originated in the 20th century, and the technology was first extensively developed in the early 1950s. While working at Canon in Japan, Ichiro Endo suggested the idea for a "Bubble jet" printer, while around the same time Jon Vaught at HP was developing a similar idea. In the late 1970s, inkjet printers that could reproduce digital images generated by computers were developed, mainly by Epson, Hewlett-Packard (HP) and Canon. In the worldwide consumer market, four manufacturers account for the majority of inkjet printer sales: Canon, HP, Epson ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Substrate (printing)

Substrate is used in a converting process such as printing or coating to generally describe the base material onto which, e.g. images, will be printed. Base materials may include: * plastic films or foils, * release liner * textiles, * plastic containers * any variety of paper (lightweight, heavyweight, coated, uncoated, paperboard, cardboard, etc.), or * parchment. Electronics Printing processes such as silk-screening and photolithography are used in electronics to produce printed circuit boards and integrated circuits. Some common substrates used are;Rogers & Plett, p. 162 * Glass-reinforced epoxy, eg FR-4 board * Ceramic-PTFE laminate, eg 6010 board * Alumina ceramic * Silicon * Gallium arsenide * Sapphire * Quartz Quartz is a hard, crystalline mineral composed of silica (silicon dioxide). The atoms are linked in a continuous framework of SiO4 silicon-oxygen tetrahedra, with each oxygen being shared between two tetrahedra, giving an overall chemical form ... Referen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Organic Light-emitting Diode

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode, is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications. There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in Electrical engineering, electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a Lamination, laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper Lamination, laminated onto and/or between sheet layers of a Insulator (electricity), non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds Via (electronics), vias: plated-through holes that allow interconnections between layers. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Screen-printing

Screen printing is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design. Traditionally, silk was used in the process. Currently, synthetic threads are commonly used in the screen printing process. The most popular mesh in general use is made of polyester. There are special-use mesh materials of nylon and stainless steel available to the screen-printer. There are also different types of mesh size which will determine the outcome and look of the fin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conductive Ink

Conductive ink is an ink that results in a printed object which conducts electricity. It is typically created by infusing graphite or other conductive materials into ink. There has been a growing interest in replacing metallic materials with nanomaterials due to the emergence of nanotechnology. Among other nanomaterials, graphene, and carbon nanotube-based conductive ink are gaining immense popularity due to their high electrical conductivity and high surface area. Recently, more attention has been paid on using eco-friendly conductive ink using water as a solvent as compared to organic solvents since they are harmful to the environment. However, the high surface tension of water prevents its applicability. Various natural and synthetic surfactants are now used to reduce the surface tension of water and ensure uniform nanomaterials dispersibility for smooth printing and wide application.{{cite journal , last1=Khan , first1=Junaid , last2=Mariatti , first2=M. , title=Effect of natur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inkjet Technology

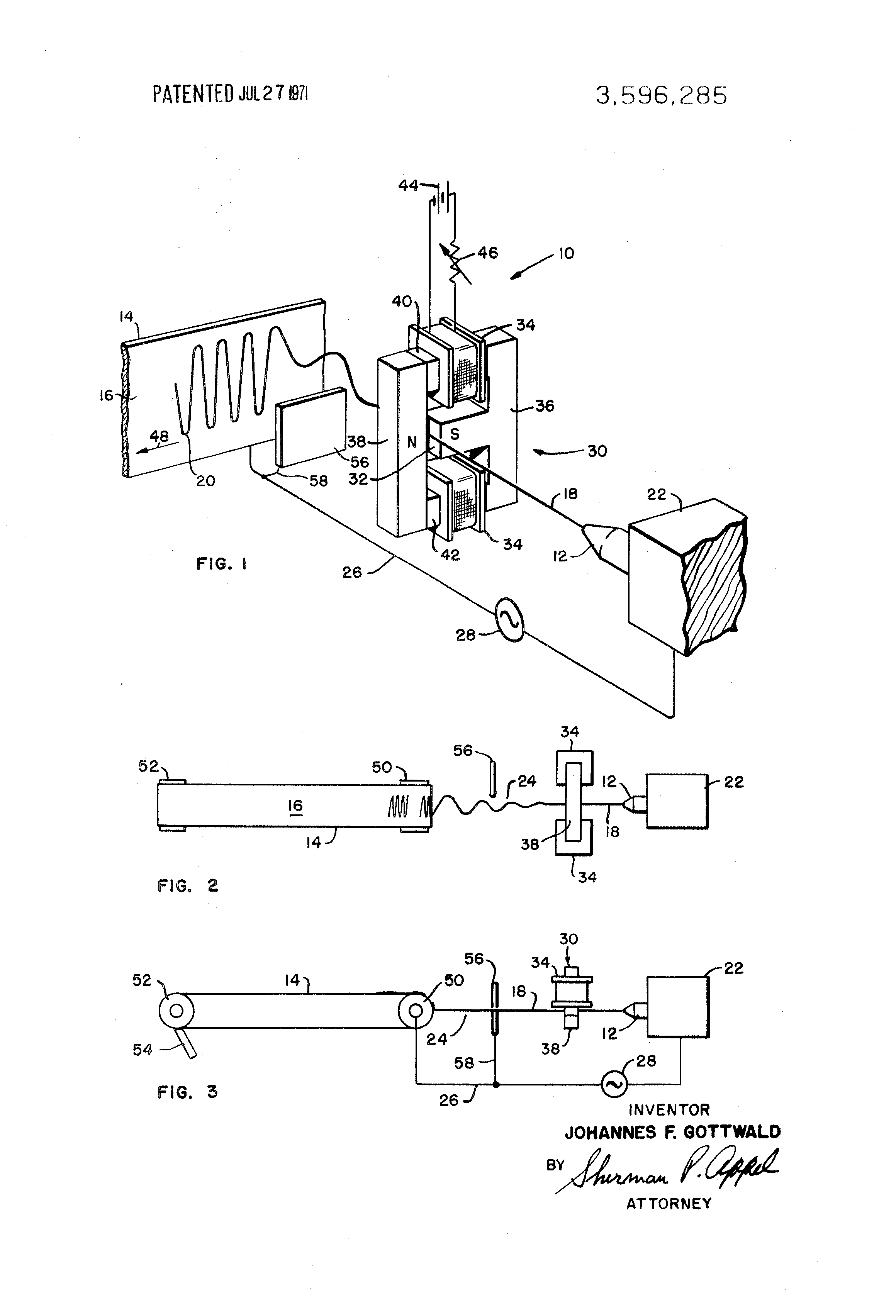

Inkjet technology originally was invented for depositing aqueous inks on paper in 'selective' positions based on the ink properties only. Inkjet nozzles and inks were designed together and the inkjet performance was based on a design. It was used as a data recorder in the early 1950s, later in the 1950s co-solvent-based inks in the publishing industry were seen for text and images, then solvent-based inks appeared in industrial marking on specialized surfaces and in the1990's phase change or hot-melt ink has become a popular with images and digital fabrication of electronic and mechanical devices, especially jewelry. Although the terms "jetting", "inkjet technology" and "inkjet printing", are commonly used interchangeably, inkjet printing usually refers to the publishing industry, used for printing graphical content, while industrial jetting usually refers to general purpose fabrication via material particle deposition. Many companies have worked with inkjet over the years. Many pat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |