|

In-circuit Test

In-circuit testing (ICT) is an example of white box testing where an electrical probe tests a populated printed circuit board (PCB), checking for shorts, opens, resistance, capacitance, and other basic quantities which will show whether the assembly was correctly fabricated. It may be performed with a "bed of nails" test fixture and specialist test equipment, or with a fixtureless in-circuit test setup. Fixtures for in-circuit testing A common form of in-circuit testing uses a bed-of-nails tester. This is a fixture that uses an array of spring-loaded pins known as "pogo pins". When a printed circuit board is aligned with and pressed down onto the bed-of-nails tester, the pins make electrical contact with locations on the circuit board, allowing them to be used as test points for in-circuit testing. Bed-of-nails testers have the advantage that many tests may be performed at a time, but have the disadvantage of placing substantial strain on the PCB. An alternative is the use of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

White Box Testing

White-box testing (also known as clear box testing, glass box testing, transparent box testing, and structural testing) is a method of software testing that tests internal structures or workings of an application, as opposed to its functionality (i.e. black-box testing). In white-box testing, an internal perspective of the system is used to design test cases. The tester chooses inputs to exercise paths through the code and determine the expected outputs. This is analogous to testing nodes in a circuit, e.g. in-circuit testing (ICT). White-box testing can be applied at the unit, integration and system levels of the software testing process. Although traditional testers tended to think of white-box testing as being done at the unit level, it is used for integration and system testing more frequently today. It can test paths within a unit, paths between units during integration, and between subsystems during a system–level test. Though this method of test design can uncover many ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

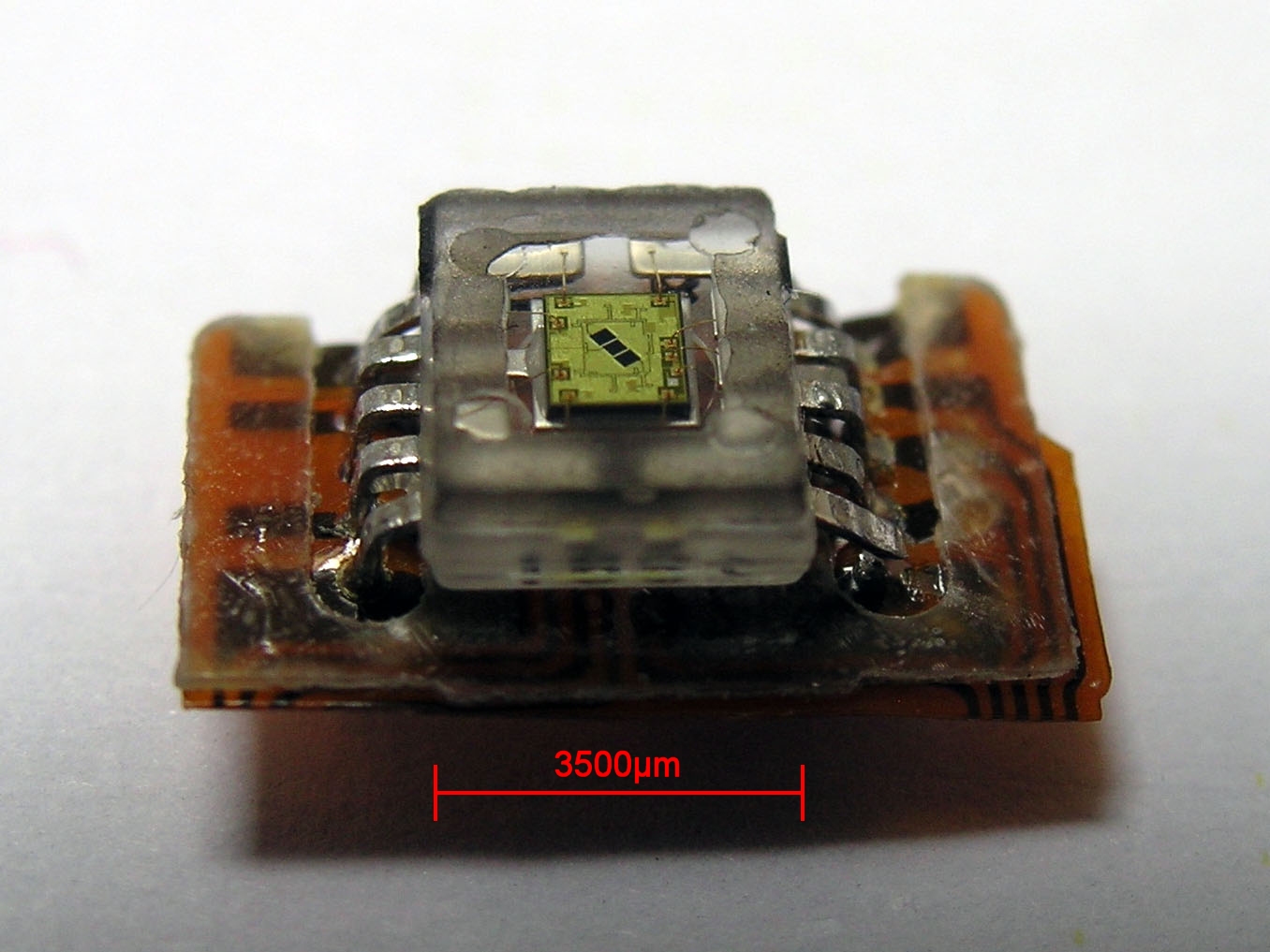

Bead Probe Technology

A bead is a small, decorative object that is formed in a variety of shapes and sizes of a material such as stone, bone, shell, glass, plastic, wood, or pearl and with a small hole for threading or stringing. Beads range in size from under to over in diameter. Beads represent some of the earliest forms of jewellery, with a pair of beads made from ''Nassarius'' sea snail shells dating to approximately 100,000 years ago thought to be the earliest known example. Beadwork is the art or craft of making things with beads. Beads can be woven together with specialized thread, strung onto thread or soft, flexible wire, or adhered to a surface (e.g. fabric, clay). Types of beads Beads can be divided into several types of overlapping categories based on different criteria such as the materials from which they are made, the process used in their manufacturing, the place or period of origin, the patterns on their surface, or their general shape. In some cases, such as millefiori and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board Manufacturing

Printing is a process for mass reproducing text and images using a master form or template. The earliest non-paper products involving printing include cylinder seals and objects such as the Cyrus Cylinder and the Cylinders of Nabonidus. The earliest known form of printing as applied to paper was woodblock printing, which appeared in China before 220 AD for cloth printing. However, it would not be applied to paper until the seventh century.Shelagh Vainker in Anne Farrer (ed), "Caves of the Thousand Buddhas", 1990, British Museum publications, Later developments in printing technology include the movable type invented by Bi Sheng around 1040 AD and the printing press invented by Johannes Gutenberg in the 15th century. The technology of printing played a key role in the development of the Renaissance and the Scientific Revolution and laid the material basis for the modern knowledge-based economy and the spread of learning to the masses. History Woodblock printing Woodblock pri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Acceptance Testing

In engineering and its various subdisciplines, acceptance testing is a test conducted to determine if the requirements of a specification or contract are met. It may involve chemical tests, physical tests, or performance tests. In systems engineering, it may involve black-box testing performed on a system (for example: a piece of software, lots of manufactured mechanical parts, or batches of chemical products) prior to its delivery. In software testing, the ISTQB defines ''acceptance testing'' as: Acceptance testing is also known as user acceptance testing (UAT), end-user testing, operational acceptance testing (OAT), acceptance test-driven development (ATDD) or field (acceptance) testing. Acceptance criteria are the criteria that a system or component must satisfy in order to be accepted by a user, customer, or other authorized entity. Overview Testing is a set of activities conducted to facilitate discovery and/or evaluation of properties of one or more items under ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated Optical Inspection

Automated optical inspection (AOI) is an automated visual inspection of printed circuit board (PCB) (or LCD, transistor) manufacture where a camera autonomously scans the device under test for both catastrophic failure (e.g. missing component) and quality defects (e.g. fillet size or shape or component skew). It is commonly used in the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-reflow as well as other stages. Historically, the primary place for AOI systems has been after solder reflow or "post-production." Mainly because, post-reflow AOI systems can inspect for most types of defects (component placement, solder shorts, missing solder, etc.) at one place in the line with one single system. In this way the faulty boards are reworked and the other boards are sent to the next process stage. SMT inspection AOIs for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boundary Scan

Boundary scan is a method for testing interconnects (wire lines) on printed circuit boards or sub-blocks inside an integrated circuit. Boundary scan is also widely used as a debugging method to watch integrated circuit pin states, measure voltage, or analyze sub-blocks inside an integrated circuit. The Joint Test Action Group (JTAG) developed a specification for boundary scan testing that was standardized in 1990 as the IEEE Std. 1149.1-1990. In 1994, a supplement that contains a description of the Boundary Scan Description Language (BSDL) was added which describes the boundary-scan logic content of IEEE Std 1149.1 compliant devices. Since then, this standard has been adopted by electronic device companies all over the world. Boundary scan is now mostly synonymous with JTAG.IEEE Std 1149.1 (JTAG) Testability Primer< ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joint Test Action Group

JTAG (named after the Joint Test Action Group which codified it) is an industry standard for verifying designs and testing printed circuit boards after manufacture. JTAG implements standards for on-chip instrumentation in electronic design automation (EDA) as a complementary tool to digital simulation. It specifies the use of a dedicated debug port implementing a serial communications interface for low-overhead access without requiring direct external access to the system address and data buses. The interface connects to an on-chip Test Access Port (TAP) that implements a stateful protocol to access a set of test registers that present chip logic levels and device capabilities of various parts. The Joint Test Action Group formed in 1985 to develop a method of verifying designs and testing printed circuit boards after manufacture. In 1990 the Institute of Electrical and Electronics Engineers codified the results of the effort in IEEE Standard 1149.1-1990, entitled ''Standard Tes ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automated X-ray Inspection

Automated inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses as its source, instead of visible light, to automatically inspect features, which are typically hidden from view. Automated X-ray inspection is used in a wide range of industries and applications, predominantly with two major goals: # Process optimization, i.e. the results of the inspection are used to optimize following processing steps, # Anomaly detection, i.e. the result of the inspection serve as a criterion to reject a part (for scrap or re-work). Whilst AOI is mainly associated with electronics manufacturing (due to widespread use in PCB manufacturing), AXI has a much wider range of applications. It ranges from the quality check of alloy wheels to the detection of bone fragments in processed meat. Wherever large numbers of very similar items are produced according to a defined standard, automatic inspection using advanced image processing and pattern reco ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

PCB Electrical Test

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features (similar to wires on a flat surface) etched from one or more sheet layers of copper laminated onto and/or between sheet layers of a non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds vias: plated-through holes that allow interconnections between layers. Printed circuit boards are used in nearly all electronic products. Alternatives to PCBs include wire wrap a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Test

Design for testing or design for testability (DFT) consists of IC design techniques that add testability features to a hardware product design. The added features make it easier to develop and apply manufacturing tests to the designed hardware. The purpose of manufacturing tests is to validate that the product hardware contains no manufacturing defects that could adversely affect the product's correct functioning. Tests are applied at several steps in the hardware manufacturing flow and, for certain products, may also be used for hardware maintenance in the customer's environment. The tests are generally driven by test programs that execute using automatic test equipment (ATE) or, in the case of system maintenance, inside the assembled system itself. In addition to finding and indicating the presence of defects (i.e., the test fails), tests may be able to log diagnostic information about the nature of the encountered test fails. The diagnostic information can be used to locate th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Photodetector

Photodetectors, also called photosensors, are sensors of light or other electromagnetic radiation. There is a wide variety of photodetectors which may be classified by mechanism of detection, such as photoelectric or photochemical effects, or by various performance metrics, such as spectral response. Semiconductor-based photodetectors typically photo detector have a p–n junction that converts light photons into current. The absorbed photons make electron–hole pairs in the depletion region. Photodiodes and photo transistors are a few examples of photo detectors. Solar cells convert some of the light energy absorbed into electrical energy. Types Photodetectors may be classified by their mechanism for detection: * Photoemission or photoelectric effect: Photons cause electrons to transition from the conduction band of a material to free electrons in a vacuum or gas. * Thermal: Photons cause electrons to transition to mid-gap states then decay back to lower bands, inducing ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |