|

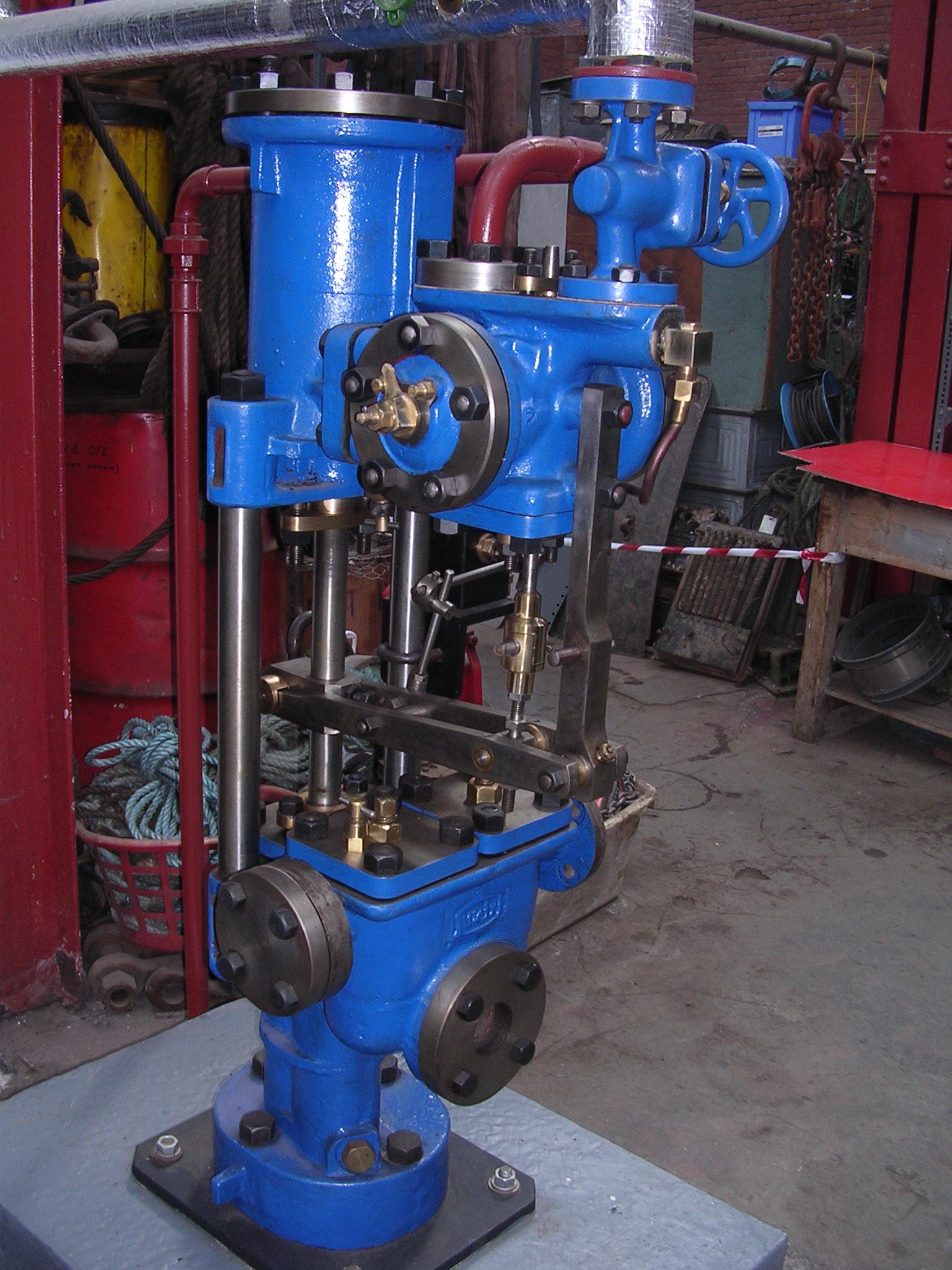

Feed Pump

A boiler feedwater pump is a specific type of pump used to pump feedwater into a steam boiler. The water may be freshly supplied or returning condensate produced as a result of the condensation of the steam produced by the boiler. These pumps are normally high pressure units that take suction from a condensate return system and can be of the centrifugal pump type or positive displacement type. Construction and operation Feedwater pumps range in size up to many kilowatts and the electric motor is usually separated from the pump body by some form of mechanical coupling. Large industrial condensate pumps may also serve as the feedwater pump. In either case, to force the water into the boiler, the pump must generate sufficient pressure to overcome the steam pressure developed by the boiler. This is usually accomplished through the use of a centrifugal pump. Another common form of feedwater pump runs constantly and is provided with a minimum flow device to stop overpressuring the pu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: ''direct lift'', ''displacement'', and ''gravity'' pumps. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis. When a casing contains only one revolving impeller, it is called a single-stage pump. Whe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Locomotive

A steam locomotive is a locomotive that provides the force to move itself and other vehicles by means of the expansion of steam. It is fuelled by burning combustible material (usually coal, oil or, rarely, wood) to heat water in the locomotive's boiler to the point where it becomes gaseous and its volume increases 1,700 times. Functionally, it is a steam engine on wheels. In most locomotives, the steam is admitted alternately to each end of its cylinders, in which pistons are mechanically connected to the locomotive's main wheels. Fuel and water supplies are usually carried with the locomotive, either on the locomotive itself or in a tender coupled to it. Variations in this general design include electrically-powered boilers, turbines in place of pistons, and using steam generated externally. Steam locomotives were first developed in the United Kingdom during the early 19th century and used for railway transport until the middle of the 20th century. Richard Trevithick ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pumps

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they use to move the fluid: ''direct lift'', ''displacement'', and ''gravity'' pumps. Mechanical pumps serve in a wide range of applications such as pumping water from wells, aquarium filtering, pond filtering and aeration, in the car industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and as artificial replacements for body parts, in particular the artificial heart and penile prosthesis. When a casing contains only one revolving impeller, it is called a single-stage pump. When ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluid Dynamics

In physics and engineering, fluid dynamics is a subdiscipline of fluid mechanics that describes the flow of fluids— liquids and gases. It has several subdisciplines, including ''aerodynamics'' (the study of air and other gases in motion) and hydrodynamics (the study of liquids in motion). Fluid dynamics has a wide range of applications, including calculating forces and moments on aircraft, determining the mass flow rate of petroleum through pipelines, predicting weather patterns, understanding nebulae in interstellar space and modelling fission weapon detonation. Fluid dynamics offers a systematic structure—which underlies these practical disciplines—that embraces empirical and semi-empirical laws derived from flow measurement and used to solve practical problems. The solution to a fluid dynamics problem typically involves the calculation of various properties of the fluid, such as flow velocity, pressure, density, and temperature, as functions of space and time. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle. History of feedwater treatment During the early development of boilers, water treatment was not so much of an issue, as temperatures and pressures were so low that high amounts of scale and rust would not form to such a significant extent, especially if the boiler was “ blown down”. It was general practice to install zinc plates and/or alkaline chemicals to reduce corrosion within the boiler. Many tests had been performed to determine the cause (and possible protection) from corrosi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Venturi Effect

The Venturi effect is the reduction in fluid pressure that results when a fluid flows through a constricted section (or choke) of a pipe. The Venturi effect is named after its discoverer, the 18th century Italian physicist, Giovanni Battista Venturi. Background In inviscid fluid dynamics, an incompressible fluid's velocity must ''increase'' as it passes through a constriction in accord with the principle of mass continuity, while its static pressure must ''decrease'' in accord with the principle of conservation of mechanical energy (Bernoulli's principle). Thus, any gain in kinetic energy a fluid may attain by its increased velocity through a constriction is balanced by a drop in pressure. By measuring pressure, the flow rate can be determined, as in various flow measurement devices such as Venturi meters, Venturi nozzles and orifice plates. Referring to the adjacent diagram, using Bernoulli's equation in the special case of steady, incompressible, inviscid flows (such as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

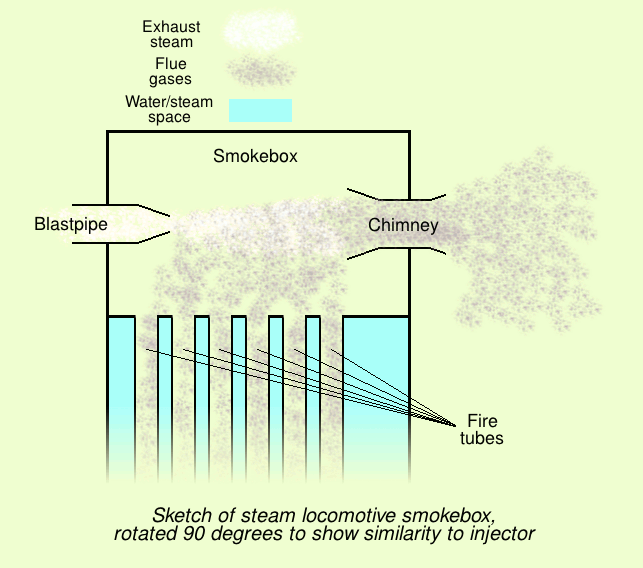

Injector

An injector is a system of ducting and nozzles used to direct the flow of a high-pressure fluid in such a way that a lower pressure fluid is entrained in the jet and carried through a duct to a region of higher pressure. It is a fluid-dynamic pump with no moving parts except a valve to control inlet flow. A steam injector is a typical application of the principle used to deliver cold water to a boiler against its own pressure, using its own live or exhaust steam, replacing any mechanical pump. When first developed, its operation was intriguing because it seemed paradoxical, almost like perpetual motion, but it was later explained using thermodynamics. Other types of injector may use other pressurised motive fluids such as air. Depending on the application, an injector can also take the form of an ''eductor-jet pump'', a ''water eductor'' or an ''aspirator''. An '' ejector'' operates on similar principles to create a vacuum feed connection for braking systems etc. History The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Power Plant

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid. Many power stations contain one or more generators, a rotating machine that converts mechanical power into three-phase electric power. The relative motion between a magnetic field and a conductor creates an electric current. The energy source harnessed to turn the generator varies widely. Most power stations in the world burn fossil fuels such as coal, oil, and natural gas to generate electricity. Low-carbon power sources include nuclear power, and an increasing use of renewables such as solar, wind, geothermal, and hydroelectric. History In early 1871 Belgian inventor Zénobe Gramme invented a generator powerful enough to produce power on a commercial scale for industry. In 1878, a hydroelectric power station was designed and built by Wil ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

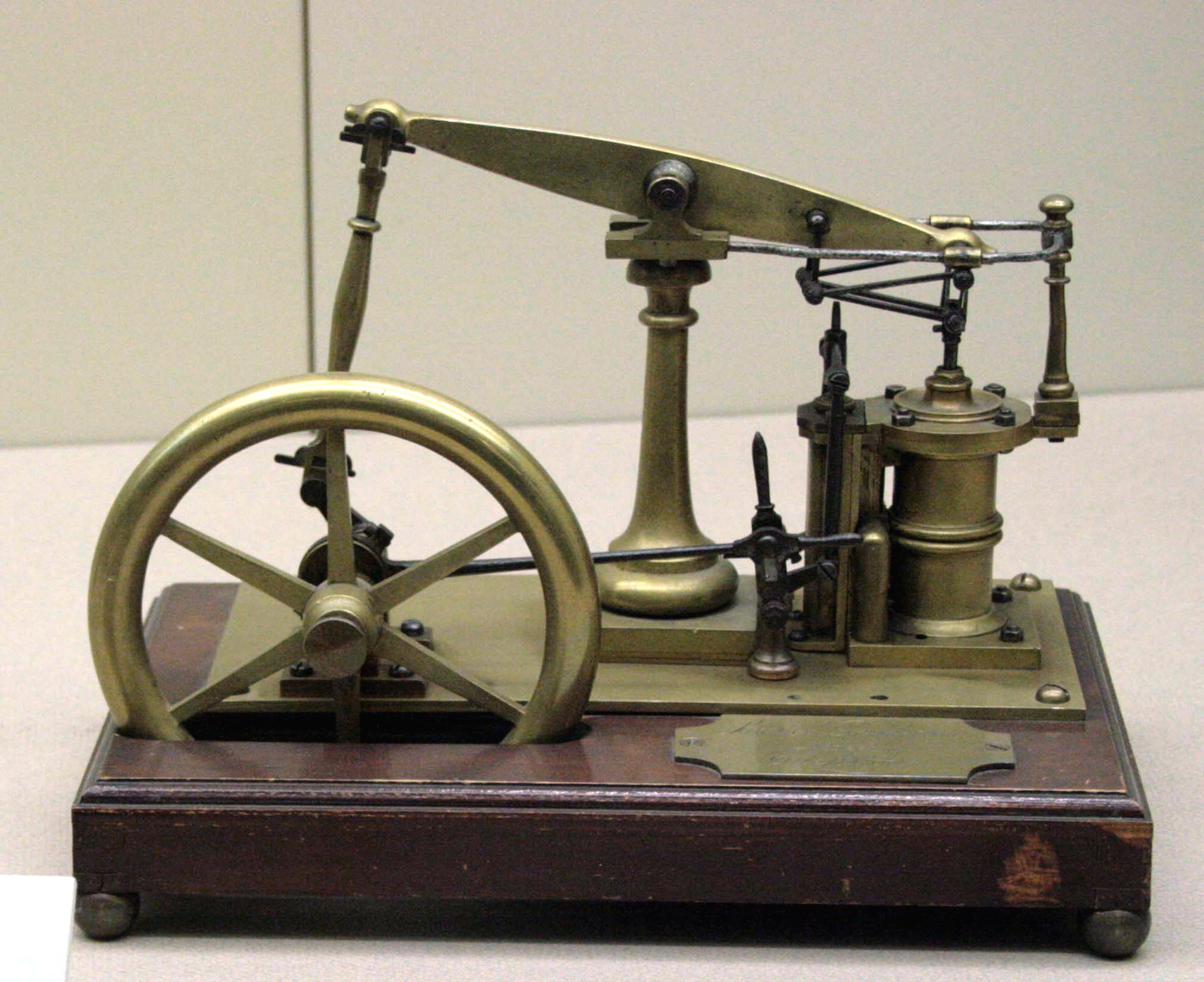

Steam Engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine. Although steam-driven devices were known as early as the aeolipile in the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weir Boiler Feed Water Pump

A weir or low head dam is a barrier across the width of a river that alters the flow characteristics of water and usually results in a change in the height of the river level. Weirs are also used to control the flow of water for outlets of lakes, ponds, and reservoirs. There are many weir designs, but commonly water flows freely over the top of the weir crest before cascading down to a lower level. Etymology There is no single definition as to what constitutes a weir and one English dictionary simply defines a weir as a small dam, likely originating from Middle English ''were'', Old English ''wer'', derivative of root of ''werian,'' meaning "to defend, dam". Function Commonly, weirs are used to prevent flooding, measure water discharge, and help render rivers more navigable by boat. In some locations, the terms dam and weir are synonymous, but normally there is a clear distinction made between the structures. Usually, a dam is designed specifically to impound water behind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Feedwater

Boiler feedwater is an essential part of boiler operations. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used it is then dumped to the main condenser. From the condenser it is then pumped to the deaerated feed tank. From this tank it then goes back to the steam drum to complete its cycle. The feed water is never open to the atmosphere. This cycle is known as a closed system or Rankine cycle. History of feedwater treatment During the early development of boilers, water treatment was not so much of an issue, as temperatures and pressures were so low that high amounts of scale and rust would not form to such a significant extent, especially if the boiler was “ blown down”. It was general practice to install zinc plates and/or alkaline chemicals to reduce corrosion within the boiler. Many tests had been performed to determine the cause (and possible protection) from corrosi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Technical University Of Graz

Graz University of Technology (german: link=no, Technische Universität Graz, short ''TU Graz'') is one of five universities in Styria, Austria. It was founded in 1811 by Archduke John of Austria and is the oldest science and technology research and educational institute in Austria. It currently comprises seven faculties and is a public university. It offers 19 bachelors and 35 masters study programmes (of which 18 are in English) across all technology and natural science disciplines. Doctoral training is organised in 14 English-speaking doctoral schools. The university has more than 13,000 students, and approximately 2,000 students graduate every year. Science study programmes are offered in the framework of NAWI Graz together with the University of Graz. The university has a staff of 3,912. Research areas are combined in five fields of expertise. ''TU Graz'', the ''University of Leoben'' and '' TU Wien'' form the network ''Austrian Universities of Technology (TU Austria)'' w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |