|

Drill Bits

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spindle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drillbits

Drill bits are cutting tools used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck (engineering), chuck. Drills come in standardized drill bit sizes. A comprehensive drill and tap size chart, drill bit and tap size chart lists Metric system, metric and Imperial system, imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: *The spiral (or rate of twist) in the drill bit controls the rate of swarf, chip removal. A fast spiral (high twist rate or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

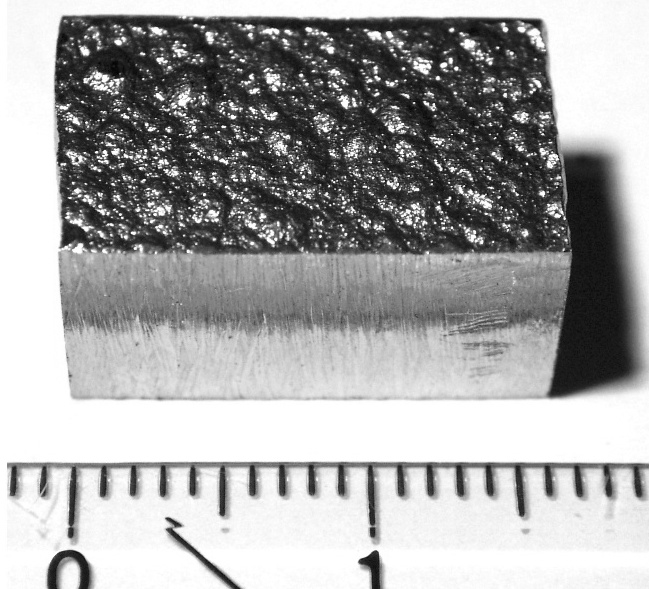

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity (optics), opacity, and lustre (mineralogy), luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in Atomic ratio, atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cobalt

Cobalt is a chemical element with the symbol Co and atomic number 27. As with nickel, cobalt is found in the Earth's crust only in a chemically combined form, save for small deposits found in alloys of natural meteoric iron. The free element, produced by reductive smelting, is a hard, lustrous, silver-gray metal. Cobalt-based blue pigments ( cobalt blue) have been used since ancient times for jewelry and paints, and to impart a distinctive blue tint to glass, but the color was for a long time thought to be due to the known metal bismuth. Miners had long used the name ''kobold ore'' (German for ''goblin ore'') for some of the blue-pigment-producing minerals; they were so named because they were poor in known metals, and gave poisonous arsenic-containing fumes when smelted. In 1735, such ores were found to be reducible to a new metal (the first discovered since ancient times), and this was ultimately named for the ''kobold''. Today, some cobalt is produced specifically from one of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool Steel

Tool steel is any of various carbon steels and alloy steels that are particularly well-suited to be made into tools and tooling, including cutting tools, dies, hand tools, knives, and others. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures. As a result, tool steels are suited for use in the shaping of other materials, as for example in cutting, machining, stamping, or forging. With a carbon content between 0.5% and 1.5%, tool steels are manufactured under carefully controlled conditions to produce the required quality. The presence of carbides in their matrix plays the dominant role in the qualities of tool steel. The four major alloying elements that form carbides in tool steel are: tungsten, chromium, vanadium and molybdenum. The rate of dissolution of the different carbides into the austenite form of the iron determines the high-temperature performance of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-speed Steel

High-speed steel (HSS or HS) is a subset of tool steels, commonly used as cutting tool material. It is often used in power-saw blades and drill bits. It is superior to the older high-carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name ''high-speed steel''. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above Rockwell hardness 60) and abrasion resistance (generally linked to tungsten and vanadium content often used in HSS) compared with common carbon and tool steels. History In 1868 English metallurgist Robert Forester Mushet developed Mushet steel, considered the forerunner of modern high-speed steels. It consisted of 2% carbon, 2.5% manganese, and 7% tungsten. The major advantage of this steel was that it hardened when air cooled from a temperature a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tempering (metallurgy)

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures. Introduction Tempering is a heat treatment technique applied to ferrous alloys, such as steel or cast iron, to achieve greater toughness by decreasing the hardness of the alloy. The reduction in hardness is usually accompanied by an increase in ductility, thereby decreasing the brittleness of the metal. Tempering is usually performed after quench ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treatment

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals called "gr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Softwood

file:Pinus sylvestris wood ray section 1 beentree.jpg, Scots Pine, a typical and well-known softwood Softwood is wood from gymnosperm trees such as conifers. The term is opposed to hardwood, which is the wood from angiosperm trees. The main differences between hardwoods and softwoods is that the structure of hardwoods lack resin canals, whereas softwoods lack pores (though not all softwoods have resin canals). Characteristics Softwood is wood from gymnosperm trees such as pines and spruces. Softwoods are not necessarily softer than hardwoods. In both groups there is an enormous variation in actual wood hardness, the range of density in hardwoods completely including that of softwoods. Some hardwoods (e.g. balsa) are softer than most softwoods, while the hardest hardwoods are much harder than any softwood. The woods of longleaf pine, Douglas fir, and Taxus, yew are much harder in the mechanical sense than several hardwoods. Softwoods are generally most used by the construction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardwood

Hardwood is wood from dicot trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood (which comes from angiosperm trees) contrasts with softwood (which is from gymnosperm trees). Characteristics Hardwoods are produced by angiosperm trees that reproduce by flowers, and have broad leaves. Many species are deciduous. Those of temperate regions lose their leaves every autumn as temperatures fall and are dormant in the winter, but those of tropical regions may shed their leaves in response to seasonal or sporadic periods of drought. Hardwood from deciduous species, such as oak, normally shows annual growth rings, but these may be absent in some tropical hardwoods. Hardwoods have a more complex structure than softwoods and are often much slower growing as a result. The dominant feature separating "hardwoods" from softwoods is the presence o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11% chromium. Because of its high tensile strength and low cost, steel is used in buildings, infrastructure, tools, ships, trains, cars, machines, electrical appliances, weapons, and rockets. Iron is the base metal of steel. Depending on the temperature, it can take two crystalline forms (allotropic forms): body-centred cubic and face-centred cubic. The interaction of the allotropes of iron with the alloying elements, primarily carbon, gives steel and cast iron their range of unique properties. In pure iron, the crystal structure has relatively little resistance to the iron atoms slipping past one another, and so pure iron is quite ductile, or soft and easily formed. In steel, small amounts of carbon, other ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |