|

Dip Pen Nanolithography

Dip pen nanolithography (DPN) is a scanning probe lithography technique where an atomic force microscope (AFM) tip is used to create patterns directly on a range of substances with a variety of inks. A common example of this technique is exemplified by the use of alkane thiolates to imprint onto a gold surface. This technique allows surface patterning on scales of under 100 nanometers. DPN is the nanotechnology analog of the dip pen (also called the quill pen), where the tip of an atomic force microscope cantilever acts as a "pen," which is coated with a chemical compound or mixture acting as an "ink," and put in contact with a substrate, the "paper." DPN enables direct deposition of nanoscale materials onto a substrate in a flexible manner. Recent advances have demonstrated massively parallel patterning using two-dimensional arrays of 55,000 tips. Applications of this technology currently range through chemistry, materials science, and the life sciences, and inclu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microcontact Printing

Microcontact printing (or μCP) is a form of soft lithography that uses the relief patterns on a master polydimethylsiloxane (PDMS) stamp or Urethane rubber micro stamp to form patterns of self-assembled monolayers (SAMs) of ink on the surface of a substrate through conformal contact as in the case of nanotransfer printing (nTP). Its applications are wide-ranging including microelectronics, surface chemistry and cell biology. History Both lithography and stamp printing have been around for centuries. However, the combination of the two gave rise to the method of microcontact printing. The method was first introduced by George M. Whitesides and Amit Kumar at Harvard University. Since its inception many methods of soft lithography have been explored. Procedure Preparing the master Creation of the master, or template, is done using traditional photolithography techniques. The master is typically created on silicon, but can be done on any solid patterned surface. Photoresist i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Soft Lithography

In technology, soft lithography is a family of techniques for fabricating or replicating structures using "elastomeric stamps, molds, and conformable photomasks". It is called "soft" because it uses elastomeric materials, most notably PDMS. Soft lithography is generally used to construct features measured on the micrometer to nanometer scale. According to Rogers and Nuzzo (2005), development of soft lithography expanded rapidly from 1995 to 2005. Soft lithography tools are now commercially available. Types * PDMS stamp * Microcontact printing * Multilayer soft lithography Advantages Soft lithography has some unique advantages over other forms of lithography (such as photolithography and electron beam lithography). They include the following: *Lower cost than traditional photolithography in mass production *Well-suited for applications in biotechnology *Well-suited for applications in plastic electronics *Well-suited for applications involving large or nonplanar (nonflat) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sarfus

Sarfus is an optical quantitative imaging technique based on the association of: *an upright or inverted optical microscope in crossed polarization configuration and *specific supporting plates – called surfs – on which the sample to observe is deposited. Sarfus visualization is based on the perfect control of the reflection properties of polarized light on a surface, which leads to an increase in the axial sensitivity of optical microscope by a factor of around 100 without reducing its lateral resolution. Thus this new technique increases the sensitivity of standard optical microscope to a point that it becomes possible to directly visualize thin films (down to 0.3 micrometer) and isolated nano-objects in real-time, be it in air or in water. Principles A recent study on polarized light coherence leads to the development of new supports – the surfs – having contrast amplification properties for standard optical microscopy in cross polarizers mode. Made of optical layers ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polydimethylsiloxane

Polydimethylsiloxane (PDMS), also known as dimethylpolysiloxane or dimethicone, belongs to a group of polymeric organosilicon compounds that are commonly referred to as silicones. PDMS is the most widely used silicon-based organic polymer, as its versatility and properties lead to many applications. It is particularly known for its unusual rheological (or flow) properties. PDMS is optically clear and, in general, inert, non-toxic, and non-flammable. It is one of several types of silicone oil (polymerized siloxane). Its applications range from contact lenses and medical devices to elastomers; it is also present in shampoos (as it makes hair shiny and slippery), food (antifoaming agent), caulk, lubricants and heat-resistant tiles. Structure The chemical formula of PDMS is , where ''n'' is the number of repeating monomer units.Mark, J. E.; Allcock, H. R.; West, R. “Inorganic Polymers” Prentice Hall, Englewood, NJ: 1992. . Industrial synthesis can begin from dimethyldichloro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radius Of Gyration

''Radius of gyration'' or gyradius of a body about the axis of rotation is defined as the radial distance to a point which would have a moment of inertia the same as the body's actual distribution of mass, if the total mass of the body were concentrated there. Mathematically the radius of gyration is the root mean square distance of the object's parts from either its center of mass or a given axis, depending on the relevant application. It is actually the perpendicular distance from point mass to the axis of rotation. One can represent a trajectory of a moving point as a body. Then radius of gyration can be used to characterize the typical distance travelled by this point. Suppose a body consists of n particles each of mass m. Let r_1, r_2, r_3, \dots , r_n be their perpendicular distances from the axis of rotation. Then, the moment of inertia I of the body about the axis of rotation is :I = m_1 r_1^2 + m_2 r_2^2 + \cdots + m_n r_n^2 : If all the masses are the same (m), then ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

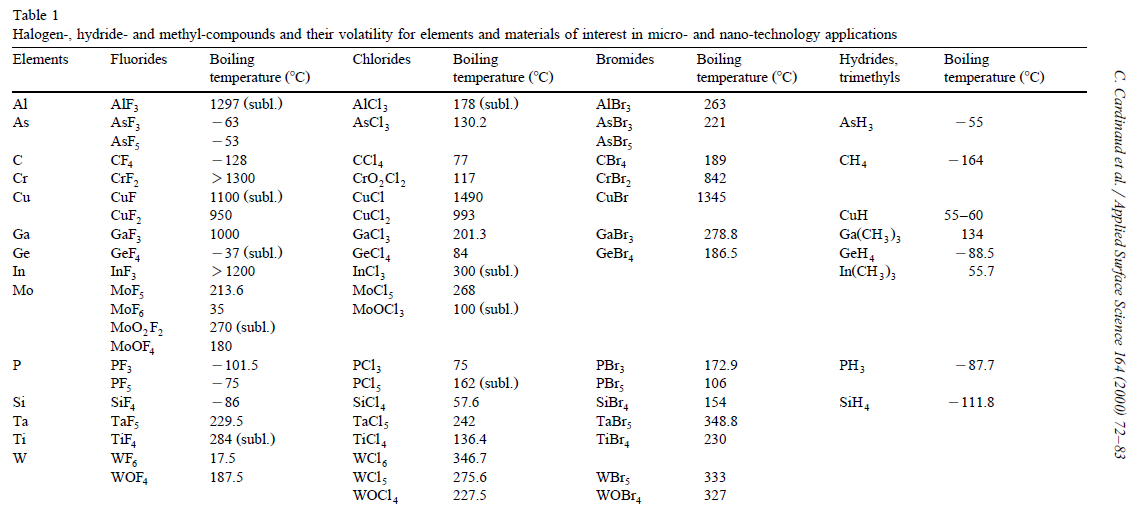

Plasma Etching

Plasma etching is a form of plasma processing used to fabricate integrated circuits. It involves a high-speed stream of glow discharge (plasma) of an appropriate gas mixture being shot (in pulses) at a sample. The plasma source, known as etch species, can be either charged (ions) or neutral (atoms and radicals). During the process, the plasma generates volatile etch products at room temperature from the chemical reactions between the elements of the material etched and the reactive species generated by the plasma. Eventually the atoms of the shot element embed themselves at or just below the surface of the target, thus modifying the physical properties of the target. Mechanisms Plasma generation A plasma is a high energetic condition in which a lot of processes can occur. These processes happen because of electrons and atoms. To form the plasma electrons have to be accelerated to gain energy. Highly energetic electrons transfer the energy to atoms by collisions. Three different pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Poly(methyl Methacrylate)

Poly(methyl methacrylate) (PMMA) belongs to a group of materials called engineering plastics. It is a transparent thermoplastic. PMMA is also known as acrylic, acrylic glass, as well as by the trade names and brands Crylux, Plexiglas, Acrylite, Astariglas, Lucite, Perclax, and Perspex, among several others ( see below). This plastic is often used in sheet form as a lightweight or shatter-resistant alternative to glass. It can also be used as a casting resin, in inks and coatings, and for many other purposes. Although not a type of familiar silica-based glass, the substance, like many thermoplastics, is often technically classified as a type of glass, in that it is a non-crystalline vitreous substance—hence its occasional historic designation as ''acrylic glass''. Chemically, it is the synthetic polymer of methyl methacrylate. It was developed in 1928 in several different laboratories by many chemists, such as William Chalmers, Otto Röhm, and Walter Bauer, and first brought ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoparticles

A nanoparticle or ultrafine particle is usually defined as a particle of matter that is between 1 and 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At the lowest range, metal particles smaller than 1 nm are usually called atom clusters instead. Nanoparticles are usually distinguished from microparticles (1-1000 µm), "fine particles" (sized between 100 and 2500 nm), and "coarse particles" (ranging from 2500 to 10,000 nm), because their smaller size drives very different physical or chemical properties, like colloidal properties and ultrafast optical effects or electric properties. Being more subject to the brownian motion, they usually do not sediment, like colloidal particles that conversely are usually understood to range from 1 to 1000 nm. Being much smaller than the wavelengths of visible light (400-700 nm), nano ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maskless Lithography

Maskless lithography (MPL) is a photomask-less photolithography-like technology used to project or focal-spot write the image pattern onto a chemical resist-coated substrate (e.g. wafer) by means of UV radiation or electron beam. In microlithography, typically UV radiation casts an image of a time constant mask onto a photosensitive emulsion (or photoresist). Traditionally, mask aligners, steppers, scanners, and other kinds of non-optical techniques are used for high speed microfabrication of microstructures, but in case of MPL, some of these become redundant. Maskless lithography has two approaches to project a pattern: rasterized and vectorized. In the first one it utilizes generation of a time-variant intermittent image on an electronically modifiable (virtual) mask that is projected with known means (also known as Laser Direct Imaging and other synonyms). In the vectored approach, direct writing is achieved by radiation that is focused to a narrow beam that is scanned in vect ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Square Circ Metastruc

In Euclidean geometry, a square is a regular quadrilateral, which means that it has four equal sides and four equal angles (90- degree angles, π/2 radian angles, or right angles). It can also be defined as a rectangle with two equal-length adjacent sides. It is the only regular polygon whose internal angle, central angle, and external angle are all equal (90°), and whose diagonals are all equal in length. A square with vertices ''ABCD'' would be denoted . Characterizations A convex quadrilateral is a square if and only if it is any one of the following: * A rectangle with two adjacent equal sides * A rhombus with a right vertex angle * A rhombus with all angles equal * A parallelogram with one right vertex angle and two adjacent equal sides * A quadrilateral with four equal sides and four right angles * A quadrilateral where the diagonals are equal, and are the perpendicular bisectors of each other (i.e., a rhombus with equal diagonals) * A convex quadrilateral with succ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etching (microfabrication)

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete. For many etch steps, part of the wafer is protected from the etchant by a "masking" material which resists etching. In some cases, the masking material is a photoresist which has been patterned using photolithography. Other situations require a more durable mask, such as silicon nitride. Orientation-Dependent Etching * KOH pellets dissolved in water (self-heating) * Etch Rate > >> ** KOH has a slower etching orientation for the planes ** You cannot use this KOH photoresist as a etching mask, because the oxide attacks too slowly, so this resist will not survive * Photoresist can be used a etching mask, and the best photoresist for etching is nitride * For example, the etch rate of Si in KOH Depends on Crystallographic Plane * At low temperatur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |